Porous membranes including pentablock copolymers and method of making same

A technology of block copolymers and porous membranes, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as scaling up, brittle nature limiting bending, and handling tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

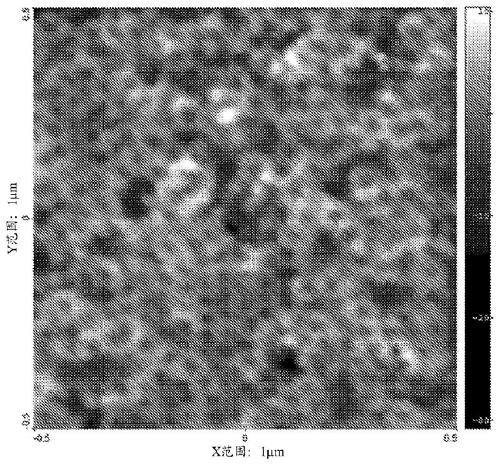

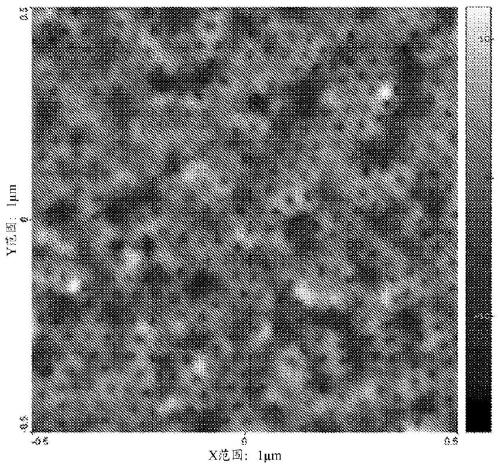

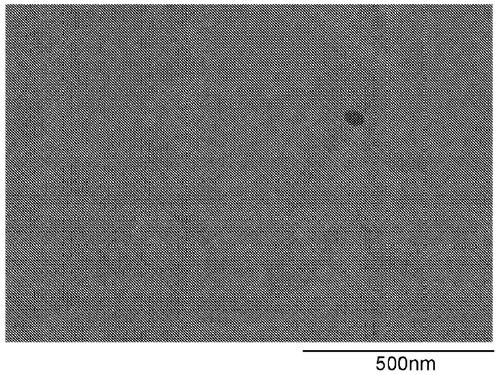

Image

Examples

preparation example Construction

[0069] A suitable method for preparing the pentablock involves the steps of a) anionic polymerization of a B block monomer (such as styrene) using a functional initiator, b) allowing a C block monomer (such as isoprene ene) polymerization, c) coupling the block polymer formed in steps a) and b) using a coupling agent, deprotecting, and further combining the polymer coupled in step c) with a ring-opening polymerizable monomer (such as ethylene oxide) polymerization.

[0070] In this method, the ends of the RO-BC-Li block copolymers are coupled using a coupling agent to generate RO-CBC-OR block copolymers such that substantially each polymer chain has An initiator residue at the end of a polymer chain. The coupling agent is present in the backbone of the CBC polymer chain in a minimal proportion. Suitable coupling agents include, in solution, dihalogenated compounds; diacid chlorides; diacid bromides; dichloro compounds; dibromosilanes and dichlorosilanes, and difunctional com...

Embodiment approach 1

[0093] Embodiment 1 is a porous membrane comprising an ABCBA block copolymer, and the membrane includes a plurality of pores. The A block is immiscible with each of the B and C blocks; the B block has a T of 90 degrees Celsius or higher g , and is present in an amount ranging from 30% to 80% by weight of the total block copolymer, inclusive; and the C block has a T of 25 degrees Celsius or less g , and is present in an amount ranging from 10% to 40% by weight of the total block copolymer, inclusive.

Embodiment approach 2

[0094] Embodiment 2 is the porous membrane of embodiment 1, wherein the pores comprise an average pore diameter at the surface of the membrane in the range of 1 nanometer (nm) to 500 nm, inclusive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com