Preparation method for organic and inorganic hollow fiber composite membrane

An inorganic hollow fiber and composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex production process, achieve simple process, improve high temperature resistance, and inhibit swelling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

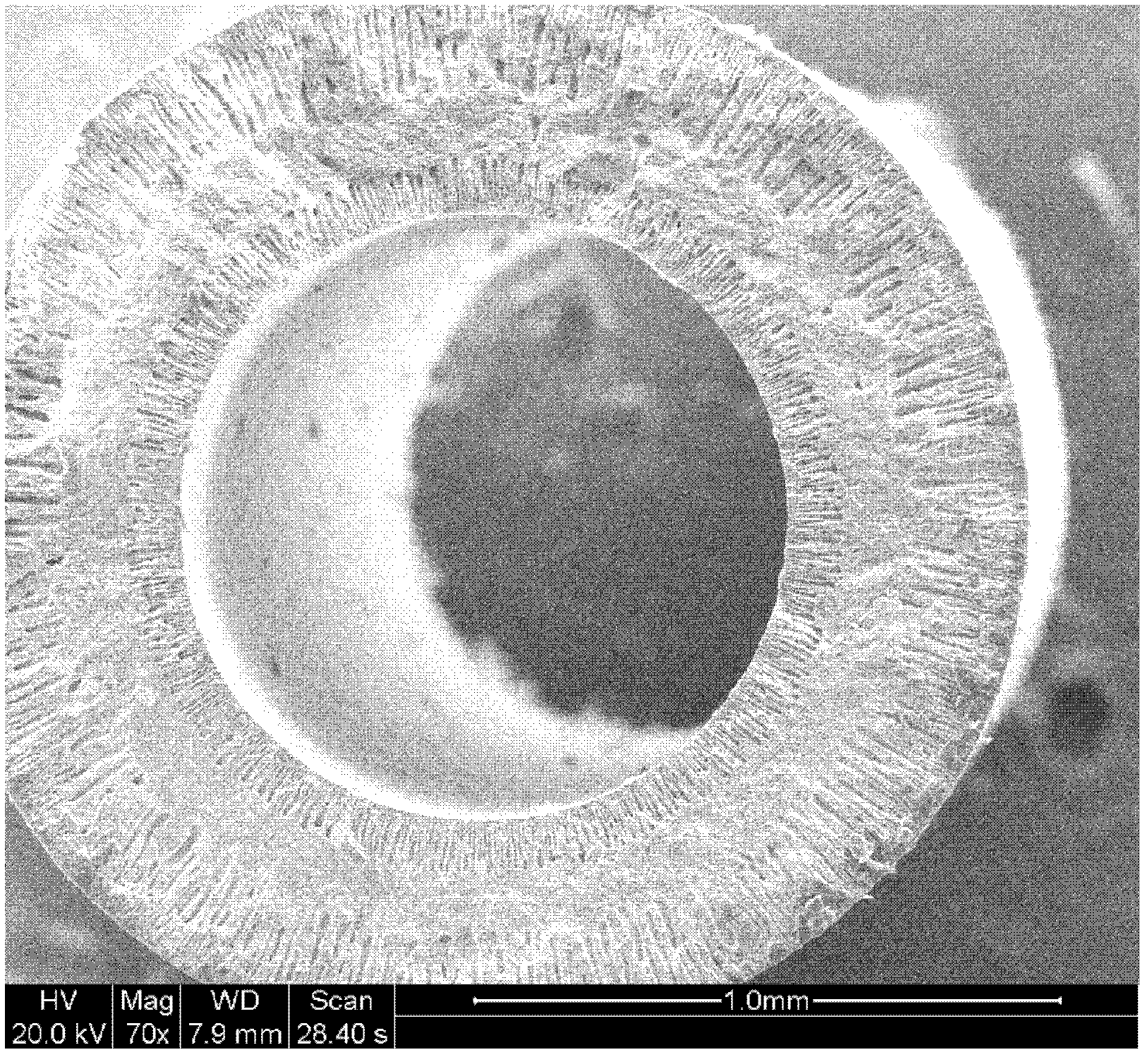

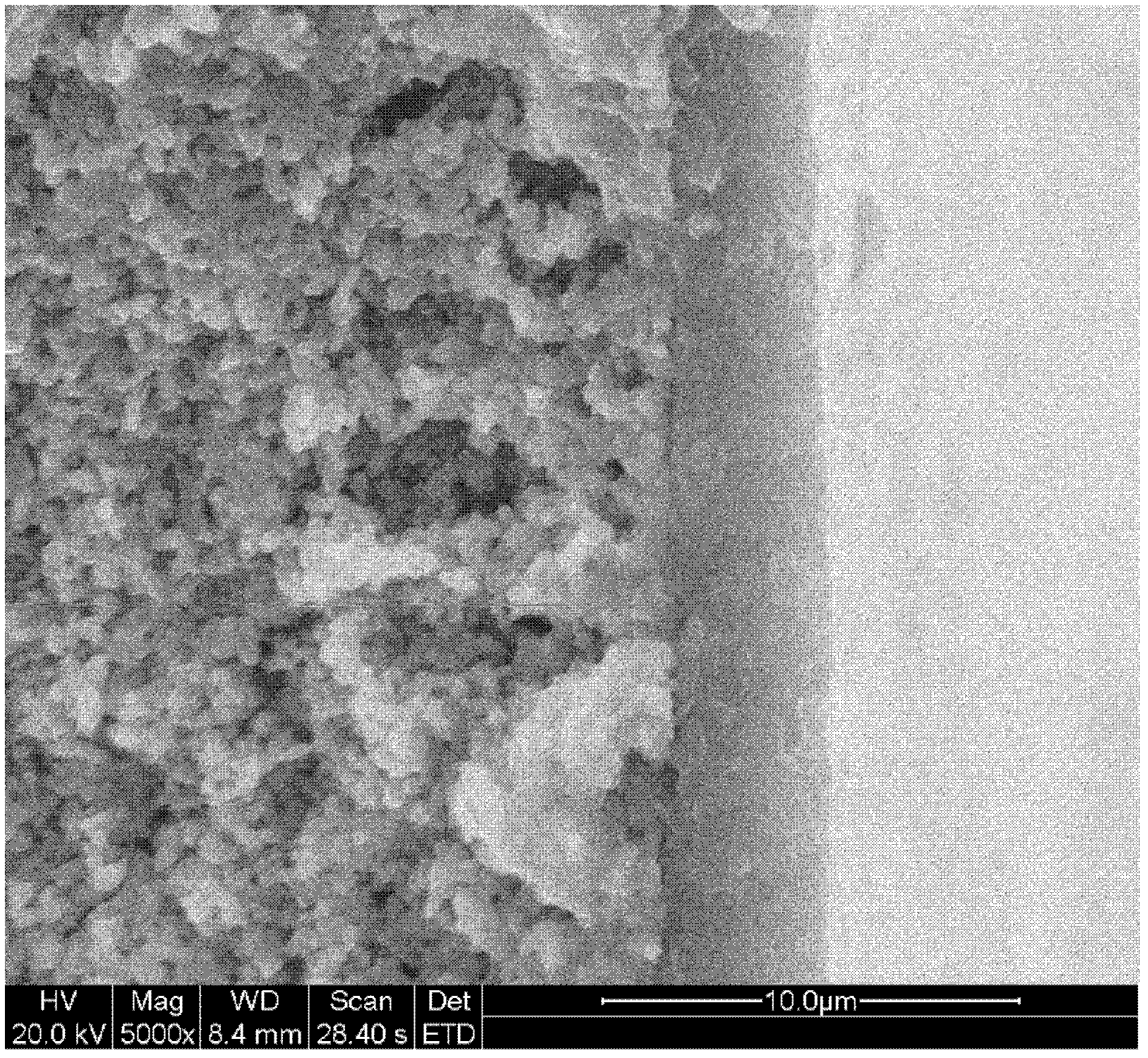

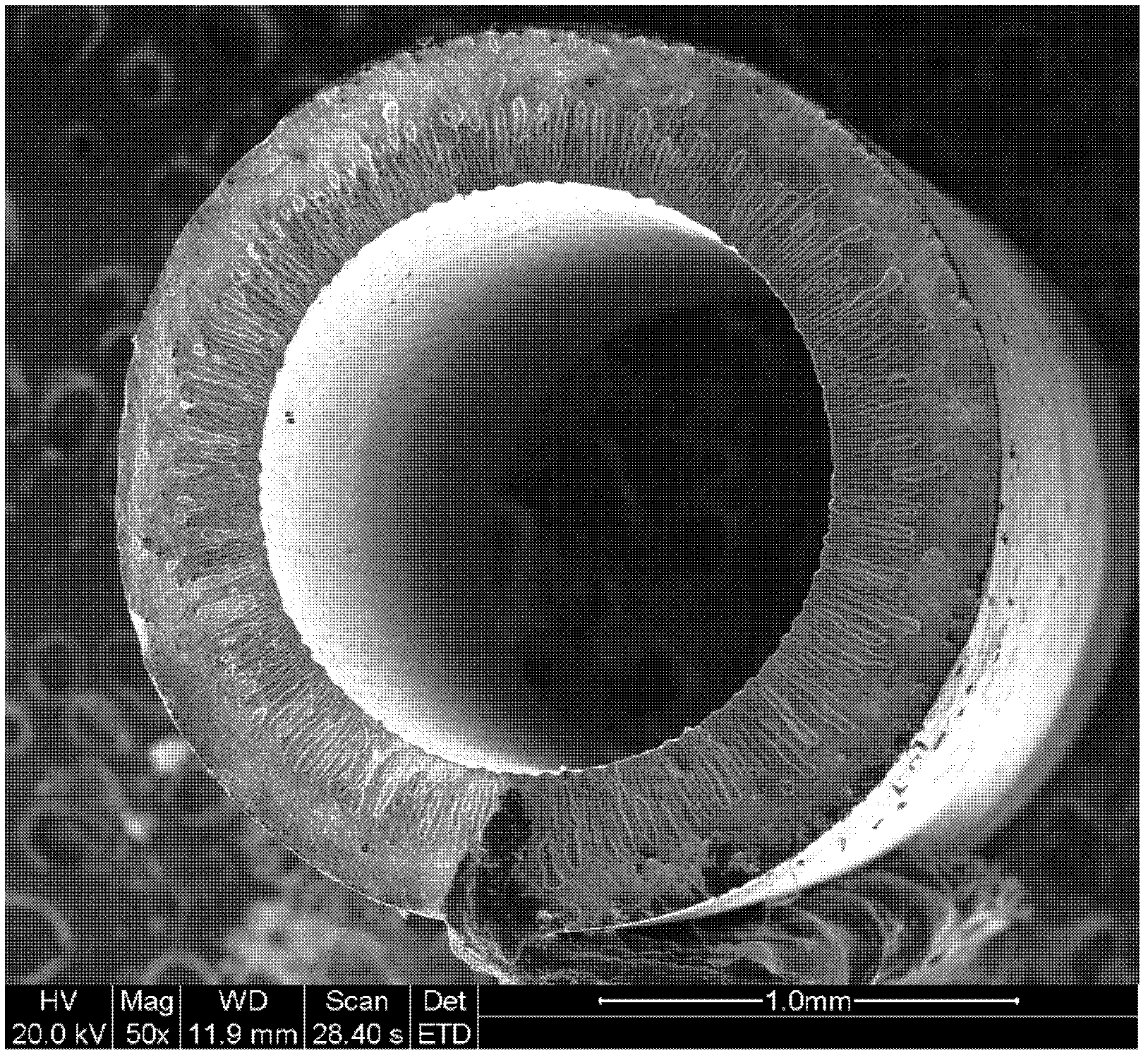

Image

Examples

example 1

[0029] (1) The Al doped YSZ with an average pore size of 200 nanometers 2 o 3 After cleaning the surface of the inorganic ceramic hollow fiber support body (Jin Wanqin et al., a method for preparing an alumina-based ceramic hollow fiber membrane, CN 101905121A), soak it in deionized water for 3 days;

[0030] (2) Take 7g of polyvinyl alcohol, add 93g of deionized water, heat to 90°C and stir evenly, remove the insoluble matter by suction filtration after cooling, and let stand; Take 2g of chitosan (deacetylation degree > 90%), add acetic acid content 0.5% (wt) acetic acid aqueous solution 98g, mixed and stirred to a clear and transparent state, suction filtered to remove impurities, and allowed to stand; 30g polyvinyl alcohol solution and 105g chitosan solution were mixed;

[0031] (3) 1.5g maleic anhydride is added in the 10g mixed solution, then drip into 0.15g of 98% (wt) concentrated sulfuric acid, leave standstill for defoaming after stirring;

[0032](4) Immerse the in...

example 2

[0036] (1) Al with an average pore diameter of 200 nanometers 2 o 3 After the surface of the inorganic ceramic hollow fiber support is cleaned, it is immersed in an aqueous ethanol solution with an ethanol content of 5% (wt) for 4 days;

[0037] (2) Take 7g of polyvinyl alcohol, add 93g of deionized water, heat to 90°C and stir evenly, remove insoluble matter by suction filtration after cooling, and let stand;

[0038] (3) 3g of glutaraldehyde was added in 10g of polymer solution, and then 2g of dilute hydrochloric acid with HCl content of 5% (wt) was added dropwise, stirred and allowed to stand for defoaming;

[0039] (4) Immerse the inorganic ceramic hollow fiber support body into the casting solution prepared in step (3), take it out after soaking for 30 seconds, and naturally solidify in the air for 12 hours;

[0040] (5) Immerse the inorganic ceramic hollow fiber support body in the casting solution prepared in step (3) for 30 seconds, and then cross-link and solidify a...

example 3

[0043] (1) After cleaning the surface of the mullite inorganic ceramic hollow fiber support body with an average pore diameter of 400 nanometers, soak it in an aqueous glycerin solution containing 10% (wt) of glycerol for 2 days;

[0044] (2) Take 7g of polyvinyl alcohol, add 93g of deionized water, heat to 90°C and stir evenly, remove the insoluble matter by suction filtration after cooling, and let stand; Take 2g of sodium alginate, add 98g of deionized water to make a uniform solution, pump After filtering to remove impurities, let stand; mix 50g polyvinyl alcohol solution and 50g sodium alginate solution;

[0045] (3) get 5g tartaric acid, add 10g polymer mixed solution, drop into 10gHCl content again and be the dilute hydrochloric acid of 2% (wt), leave standstill after stirring;

[0046] (4) Immerse the inorganic ceramic hollow fiber support body into the casting solution prepared in step (3), take it out after soaking for 40 seconds, and naturally cure it in the air for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com