Environment-friendly brick processing system

A processing system and technology of environmentally friendly bricks, applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve problems such as environmental pollution, high concentration of suspended particles, and occurrence of cavities or large particles, so as to protect the working environment, Improve the mixing effect and reduce the concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

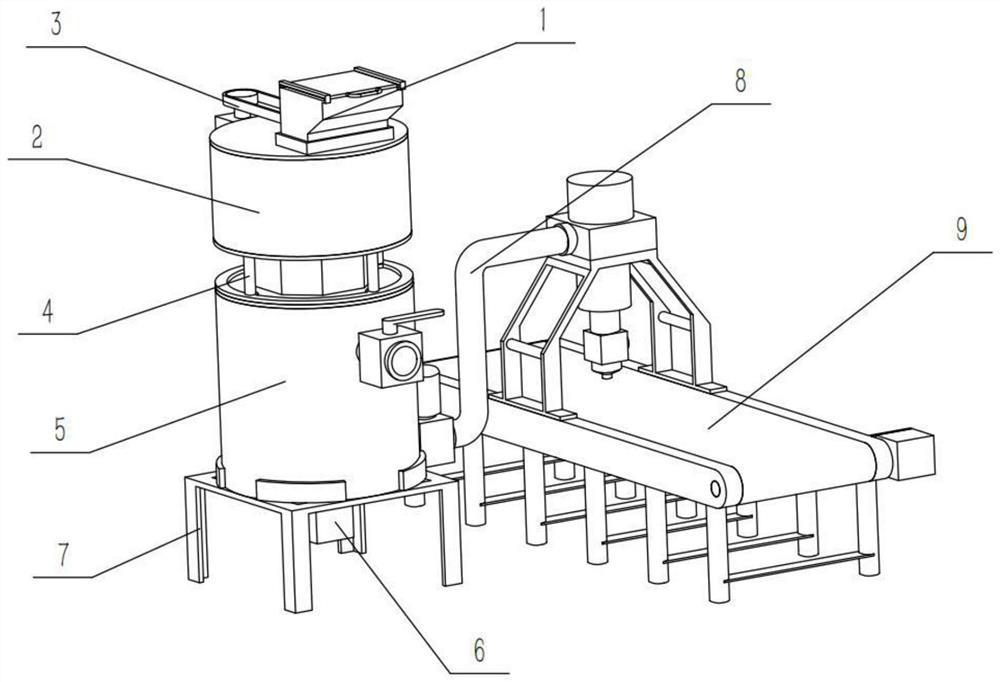

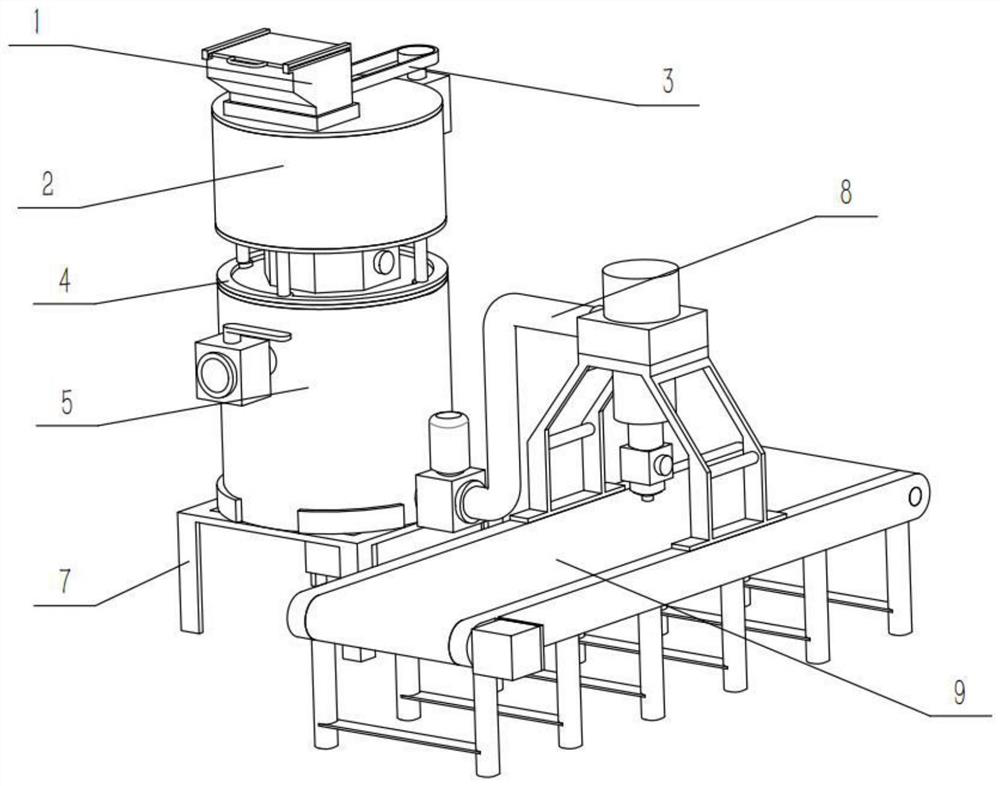

[0032] Combine below Figure 1-11 Description of this embodiment, an environmentally friendly brick processing system, including a connecting frame 4, a support frame 7 and a conveying mechanism 9, the environmentally friendly brick processing system also includes a feeding mechanism 1, a storage mechanism 2, a crushing mechanism 3, a mixing bucket 5, a stirring mechanism 6 and pumping mechanism 8, the feeding mechanism 1 is fixedly connected to the upper end of the storage mechanism 2, the crushing mechanism 3 is rotatably connected to the middle part of the upper end of the storage mechanism 2, and the mixing bucket 5 is fixedly connected to the storage mechanism 2, the connecting frame 4 is fixedly connected between the storage mechanism 2 and the mixing bucket 5, the mixing mechanism 6 is fixedly connected to the middle part of the lower end of the mixing bucket 5, and the support frame 7 is fixedly connected to the bottom of the mixing bucket 5 At the lower end, the pumpi...

specific Embodiment approach 2

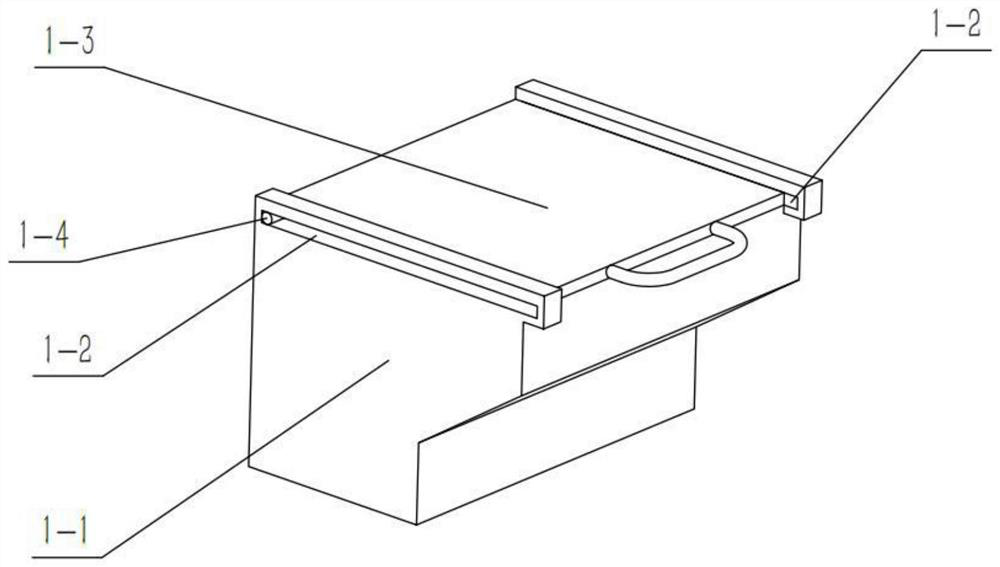

[0035] Combine below Figure 1-11Describe this embodiment, this embodiment will further explain the first embodiment, the feeding mechanism 1 includes a feeding pipe 1-1, a slide rail 1-2, a baffle plate 1-3 and a sliding rod 1-4, the feeding pipe 1 The left and right sides of the upper end of -1 are provided with slide rails 1-2, the two slide bars 1-4 are provided with two, and the two slide bars 1-4 are respectively fixedly connected to the left and right sides of the rear end of the baffle plate 1-3, And the two sliding rods 1-4 are respectively slidably connected in the two sliding rails 1-2, and the feeding pipe 1-1 is fixedly connected to the upper end of the storage mechanism 2.

[0036] Pull the baffle 1-3, the two sliding rods 1-4 of the baffle 1-3 slide forward respectively along the two slide rails 1-2, then pull the baffle 1-3 to the front end, and the baffle 1 -3 natural downward turn.

[0037] Pour solid waste such as fly ash, cinder, coal gangue, tailings sla...

specific Embodiment approach 3

[0039] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the storage mechanism 2 includes a storage bucket 2-1, a tooth surface wall 2-2, a sealing cover 2-3, a rotating tube 2-4, and a stable frame 2-5 and a valve 2-6, the tooth surface wall 2-2 is fixedly connected to the inner wall of the storage barrel 2-1, the sealing cover 2-3 is fixedly connected to the upper end of the storage barrel 2-1, the The middle part of the sealing cover 2-3 is provided with a rotating tube 2-4, the valve 2-6 is fixedly connected to the middle part of the lower end of the storage barrel 2-1, and the stable frame 2-5 is fixedly connected to the upper end of the valve 2-6 , the crushing mechanism 3 is rotatably connected with the rotating tube 2-4 and the stabilizing frame 2-5 respectively, and the crushing mechanism 3 is fixedly connected to the outside of the storage barrel 2-1, and the connecting frame 4 is fixedly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com