Environment-friendly brick conveying device

A technology for transportation devices and environmentally friendly bricks, which is applied in the direction of construction, building structure, and building materials processing, etc. It can solve the problems of lack of brick body separation and conveying structure, affect construction and production efficiency, and consume physical strength of staff, so as to improve production. Efficiency, improvement of construction and production efficiency, and novel structural design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

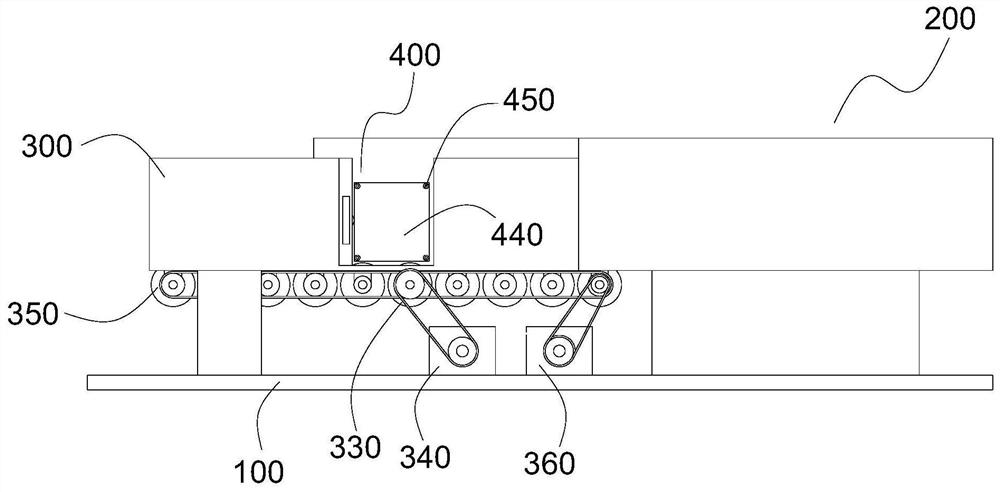

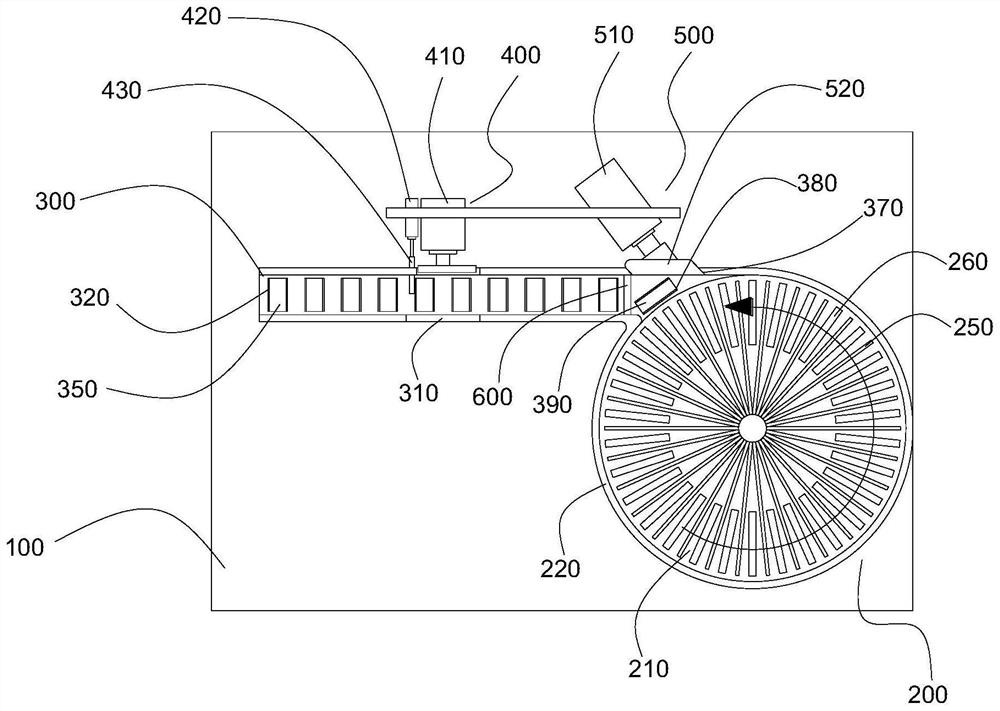

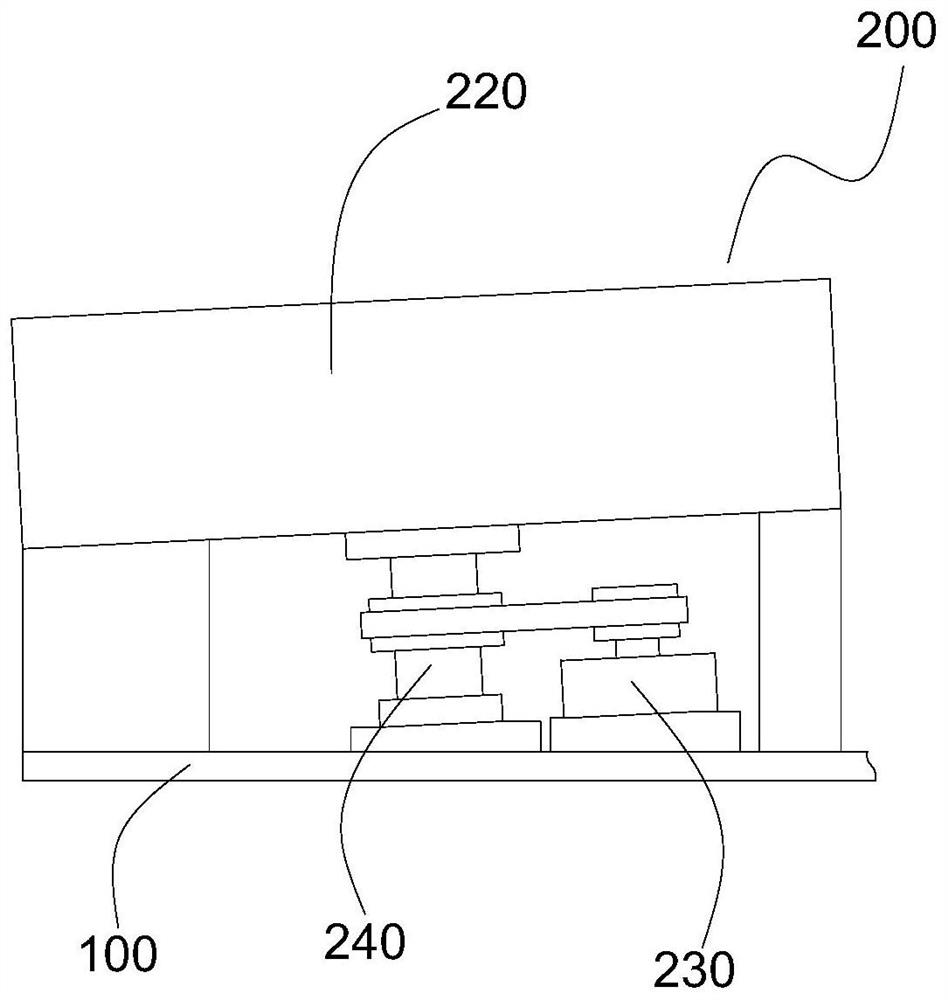

[0023] Such as figure 1 As shown, the environmental protection brick transportation device provided by the specific embodiment of the present invention includes a base plate 100, a feeding drum 200 and a feeding tank 300 fixed on the base plate 100; the feeding drum 200 includes a rotating disk 210, and the The rotating disk 210 is installed obliquely, and the outer cover of the rotating disk 210 is provided with a protective tube 220, the protective tube 220 is adapted to the shape of the rotating disk 210, and the protective tube 220 is fixed on the bottom plate 100 through a bracket. Above, the rotating disk 210 is driven by the first motor 230; the feeding chute 300 is fixed on the bottom plate 100 through a bracket, and the feeding chute 300 is on the higher side of the protection cylinder 220 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com