A raw material preparation device for environmentally friendly bricks

A technology for preparing devices and environmentally friendly bricks, which is applied to clay preparation devices, clay mixing devices, chemical instruments and methods, etc., can solve the problems of difficult operation, numerous devices, slow preparation of environmentally friendly brick raw materials, etc. Ease of operation and the effect of improving the rate of raw material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

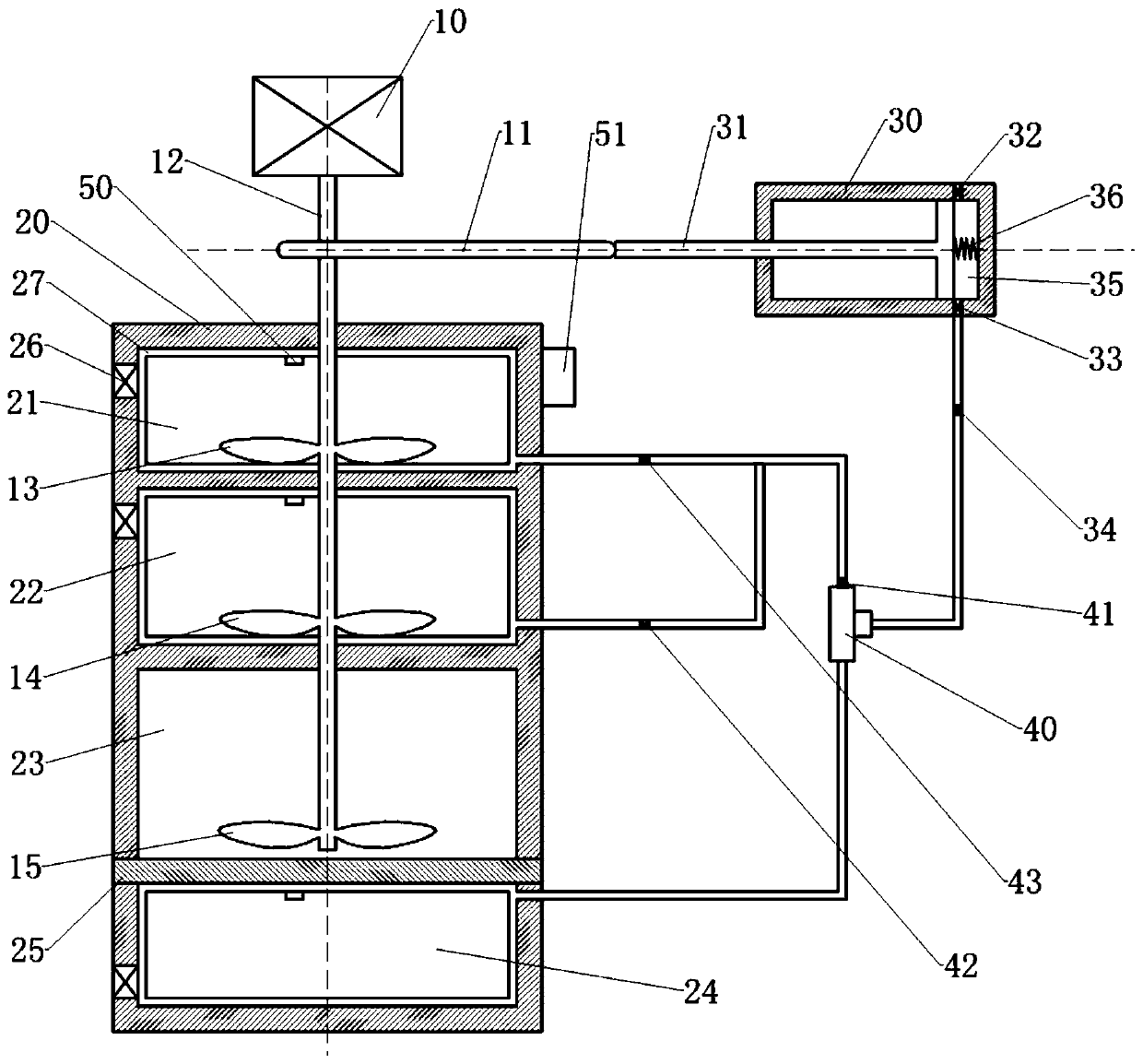

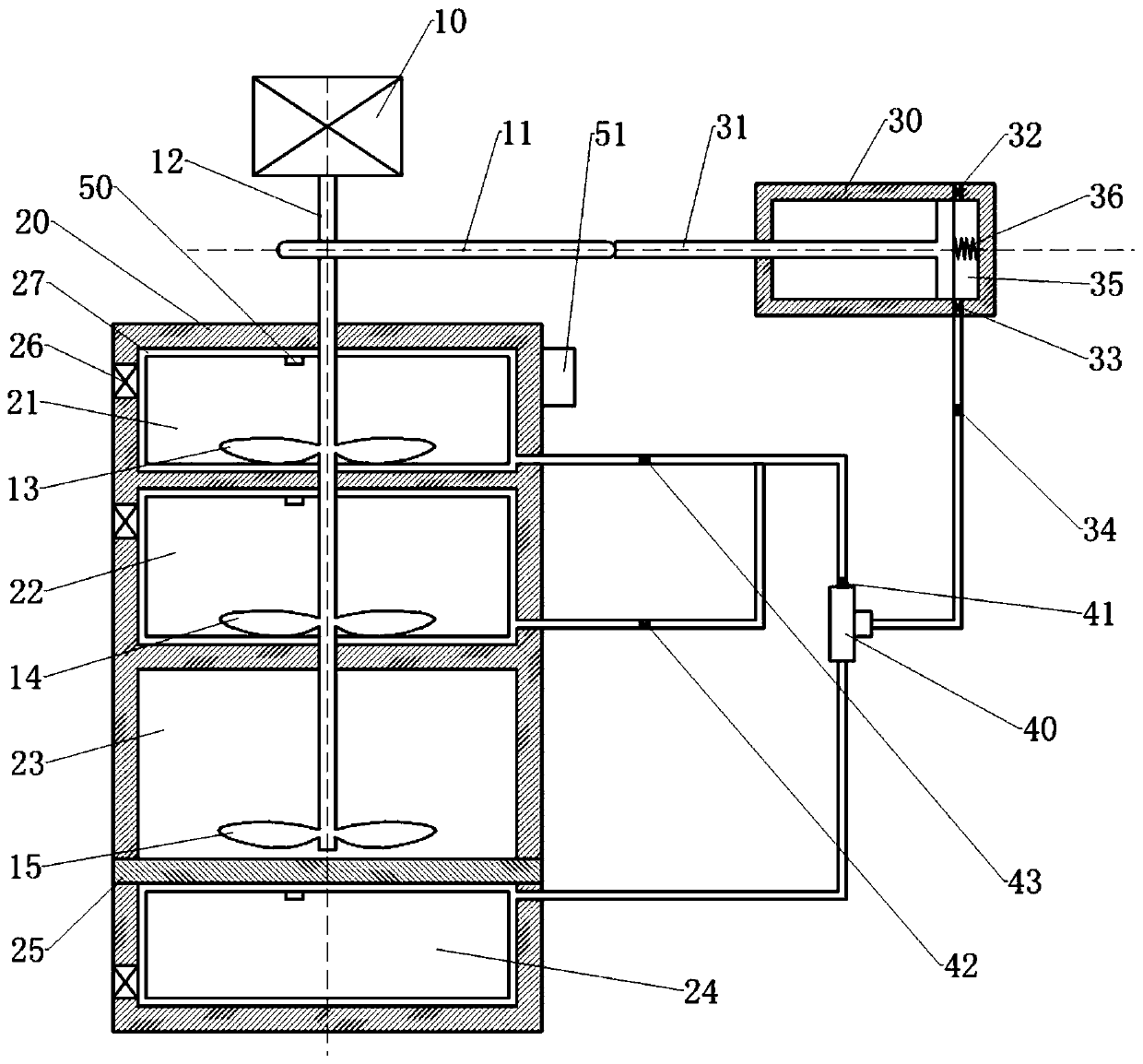

[0034] Embodiment 1 is basically as attached figure 1 Shown:

[0035] An environment-friendly brick raw material preparation device, including a driving device, a stirrer 20, a piston cylinder 30, and a vortex tube 40. The driving device includes a motor 10 and a stirring column 12 driven by the motor 10 to rotate rapidly. The stirring column 12 extends into the stirrer 20 Inside, the first stirring paddle 13, the second stirring paddle 14, and the third stirring paddle 15 are arranged on the stirring column 12 from top to bottom; the stirrer 20 is a cylindrical sealing device, and the stirrer 20 is sequentially arranged from top to bottom The first stirring chamber 21, the second stirring chamber 22, the third stirring chamber 23 and the static cooling chamber 24 are provided, the first stirring paddle 13, the second stirring paddle 14, the third stirring paddle 15 are respectively connected with the first stirring chamber 21 , the bottoms of the second stirring chamber 22 a...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is that there is a jacket 27 outside the first stirring chamber 21 , the second stirring chamber 22 , and the static cooling chamber 23 . The cold and hot air do not directly contact the raw materials, but transfer heat through the jacket 27. Compared with the direct contact between the cold and hot air and the materials, it is less likely to block the gas pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com