Mould pressing device for preparing environment-friendly bricks

An environmentally friendly brick and molding technology, which is applied in the supply device, unloading device, forming indenter, etc., to achieve the effect of convenient operation and use, rational recycling of resources, and strengthening the effect of crushing and loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

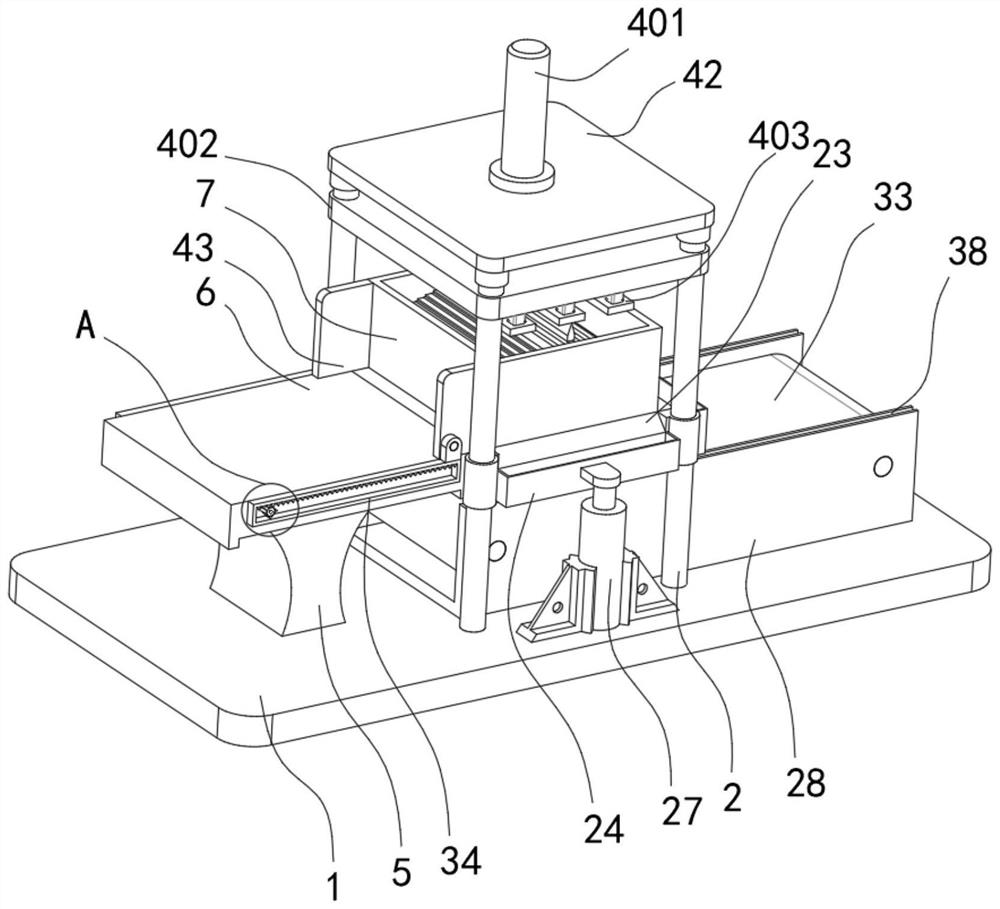

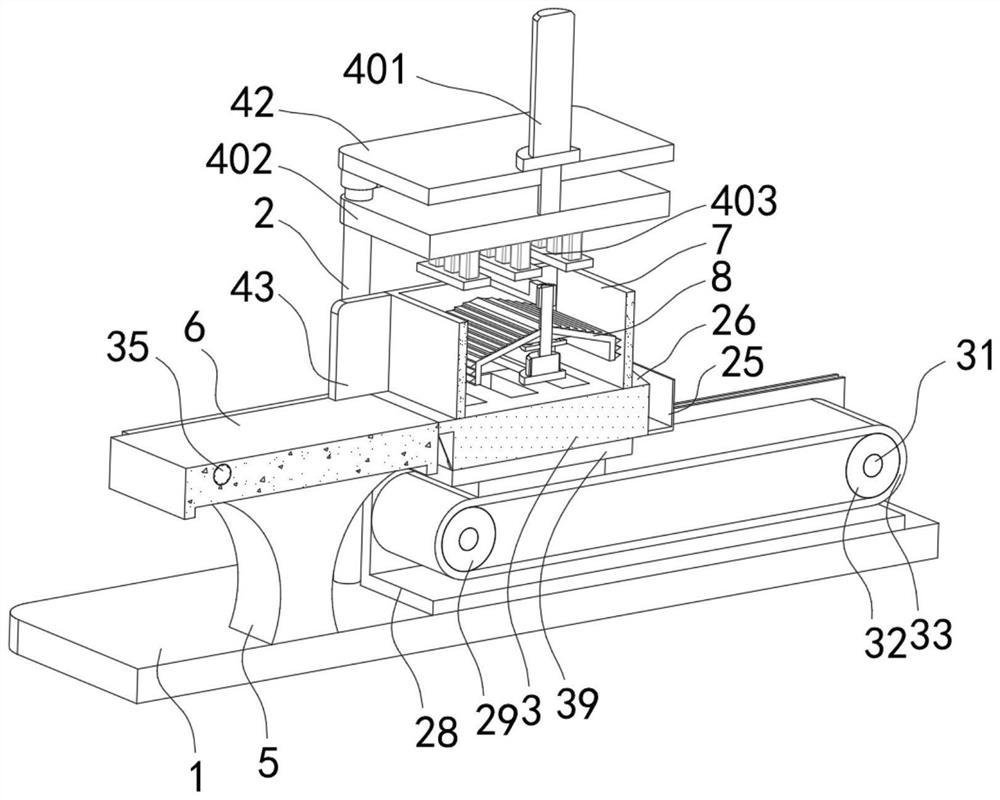

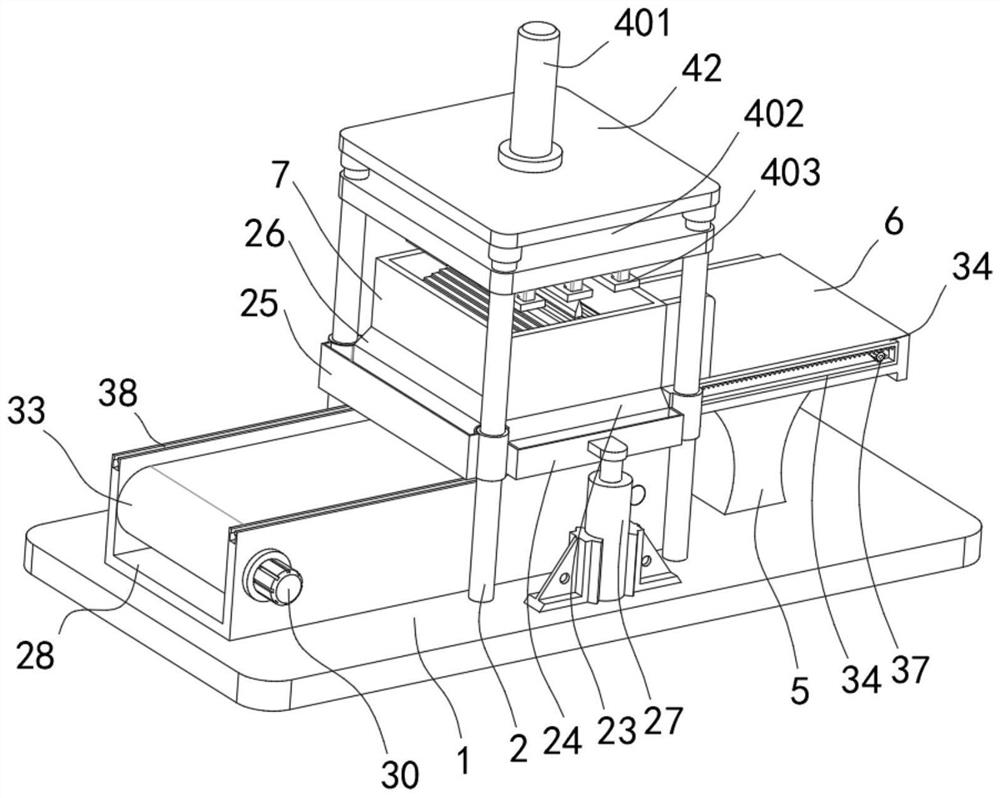

[0052] see Figure 1-15 , the present invention provides a technical solution: a molding device for the preparation of environmentally friendly bricks, including a base 1, fixed columns 2 are fixedly installed on the front and rear sides of the top of the base 1, and a top plate 42 is fixedly installed on the top of the fixed column 2, and the top plate 42 The middle part of the top is fixedly equipped with a pressing mechanism 4, and the number of fixed columns 2 is four, and the outer surfaces of the four fixed columns 2 are movably socketed with a formwork body 3, and the inside of the formwork body 3 is provided with a mold cavity body 40, and the base The top of 1 is fixedly installed with the fixed seat 5 that is positioned at the left side of template body 3, and the top of fixed seat 5 is fixedly installed with fixed table 6, and the top of template body 3 is movably connected with mixing box 7, and the front and back of mixing box 7 left side The side plate 43 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com