Raw material screening device for environment-friendly brick preparation

A screening device and technology of environmental protection bricks, which are applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of low screening efficiency and feeding efficiency, and achieve the effect of accelerating feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

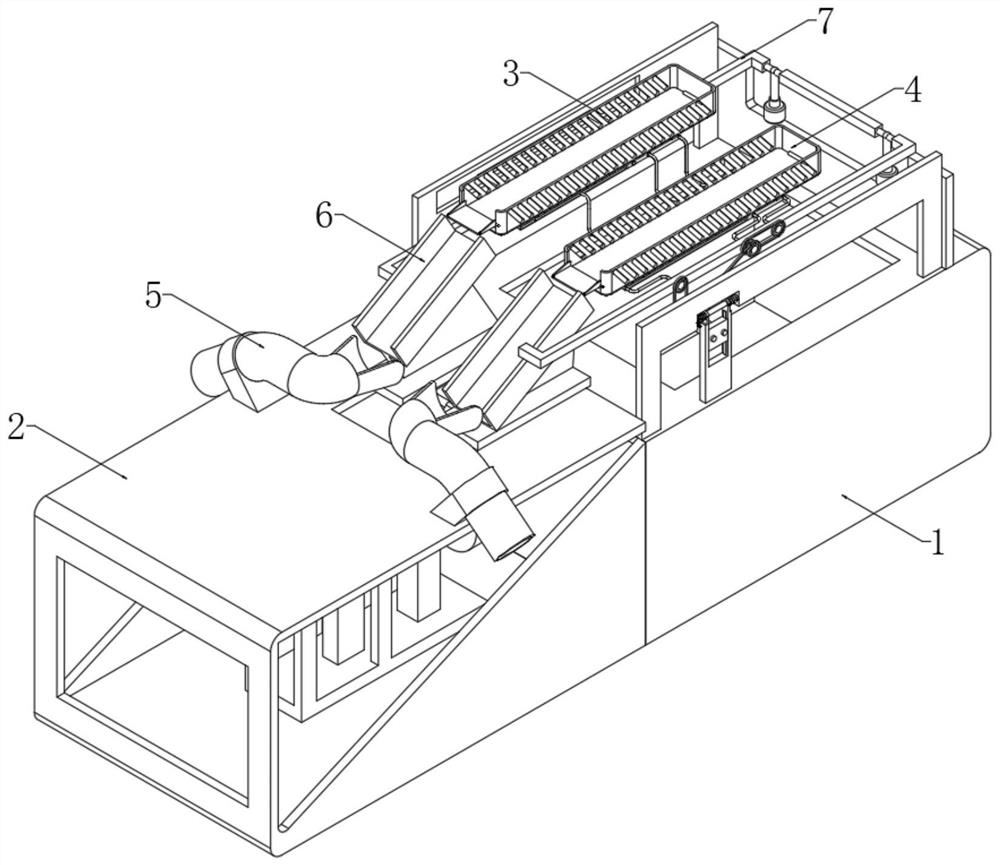

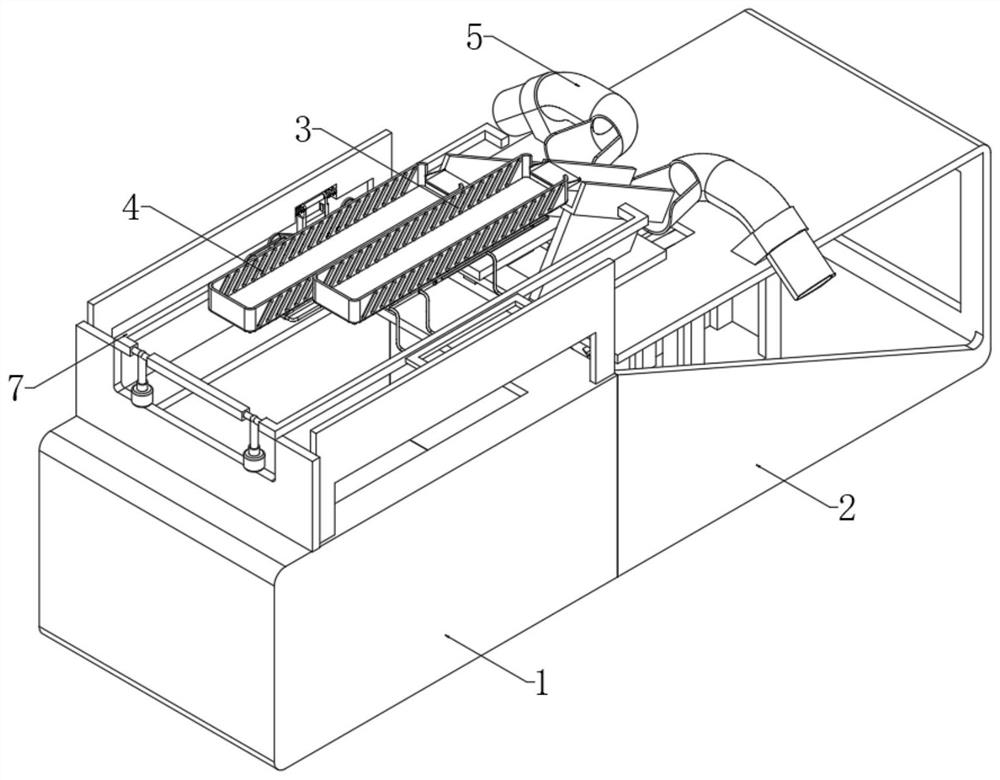

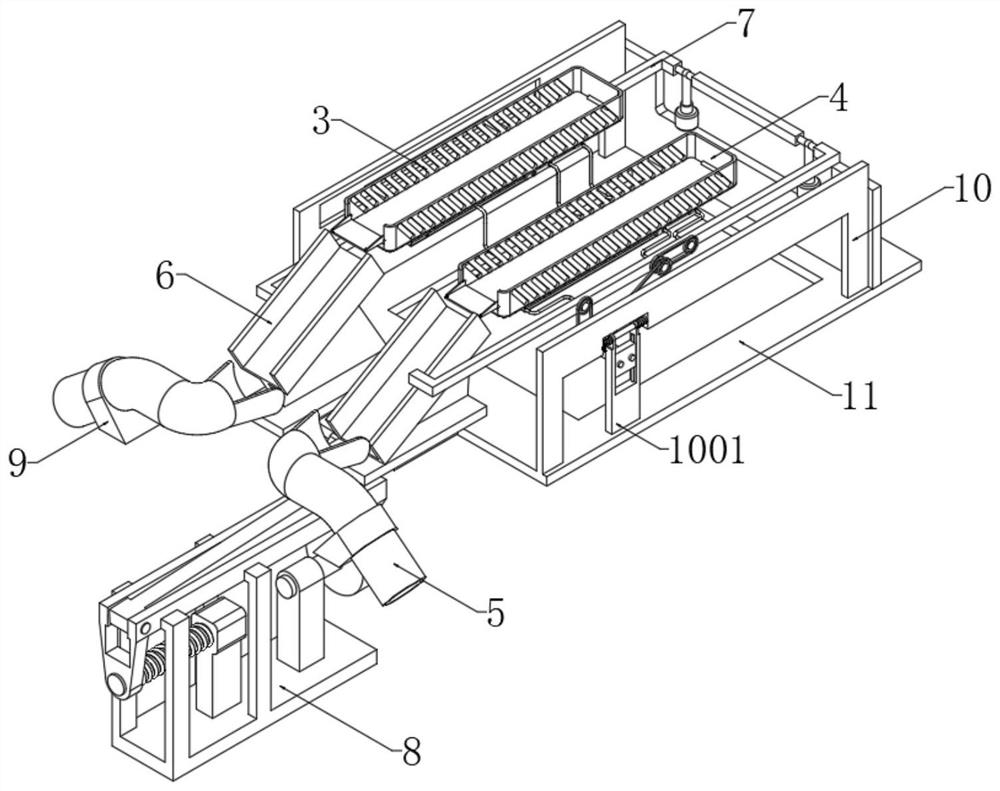

[0039] see Figure 1-6 , a raw material screening device for the preparation of environmentally friendly bricks, comprising an installation box 2, a collection box 1 is fixedly connected to the front side of the installation box 2, a sieve frame A3 and a sieve frame B4 are arranged above the collection box 1, and the sieve frame A3 and sieve material frame B4 are connected inside the collection box 1 through the transmission assembly B14, and a discharge port is provided under the collection box 1; an installation frame 7 is provided above the inside of the collection box 1, and a discharge opening is provided on the front side of the installation frame 7 Passage 6, the rear side of unloading passage 6 is fixedly connected with installation seat 601, and installation seat 601 is arranged on the upper side of installation box 2; The center of the pipe 5 is fixedly connected to the upper side of the installation box 2 through the connecting piece 9; the side of the sieve frame A...

Embodiment 2

[0045] Such as Figure 5-7 As shown, the differences based on Embodiment 1 are:

[0046] The transmission assembly B14 includes a driving wheel set 1402, the driving wheel set 1402 includes a driving wheel and a driven wheel, the driving wheel and the driven wheel are engaged and connected, and the driving wheel shaft is fixedly connected to the end of the output shaft of the driving motor; the driving motor is fixedly installed in the inner slider 1401 , the inner slider 1401 is slidably connected in the chute of the movable plate 1001;

[0047] Drive wheel set A1403 is connected to the rear side of the drive wheel shaft, drive wheel set B1404 is connected to the rear side of the driven wheel shaft center, drive wheel set C1405 is connected to the rear side of the wheel shaft on the upper side of the drive wheel set B1404; the wheel shaft on the upper side of the drive wheel set A1403 The rear side is fixedly connected with a transmission special-shaped rod A1406, and the re...

Embodiment 3

[0051] Such as Figure 8-13 As shown, based on embodiment 1-2, what is different is:

[0052] The lower side of the mounting base 601 is flexibly connected to the interior of the mounting box 2 through the transmission assembly A8, and one end of the upper side of the mounting box 2 is provided with a movable groove, and one side of the mounting base 601 is flexibly connected to the movable groove through a spring column. The transmission assembly A8 includes a fixed seat 801, The fixed seat 801 is fixedly connected to the inner bottom surface of the installation box 2; the upper side of the fixed seat 801 is slidingly connected with a fixed frame 802, and the inner side of the fixed frame 802 is provided with a jacking rotating rod 803, and one end of the jacking rotating rod 803 is connected to the fixed frame 802 through a rotating shaft. Inside;

[0053] The front end of the jacking rotating rod 803 is fixedly connected with a connecting rod 811, the center of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com