Rapid drying device for environment-friendly brick processing

A technology for fast drying and environmentally friendly bricks, which is applied in drying, dryer, drying gas arrangement, etc., can solve the problems of broken environmental bricks, low drying efficiency, poor drying effect, etc., to reduce fragmentation chance, improve drying efficiency, and increase the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

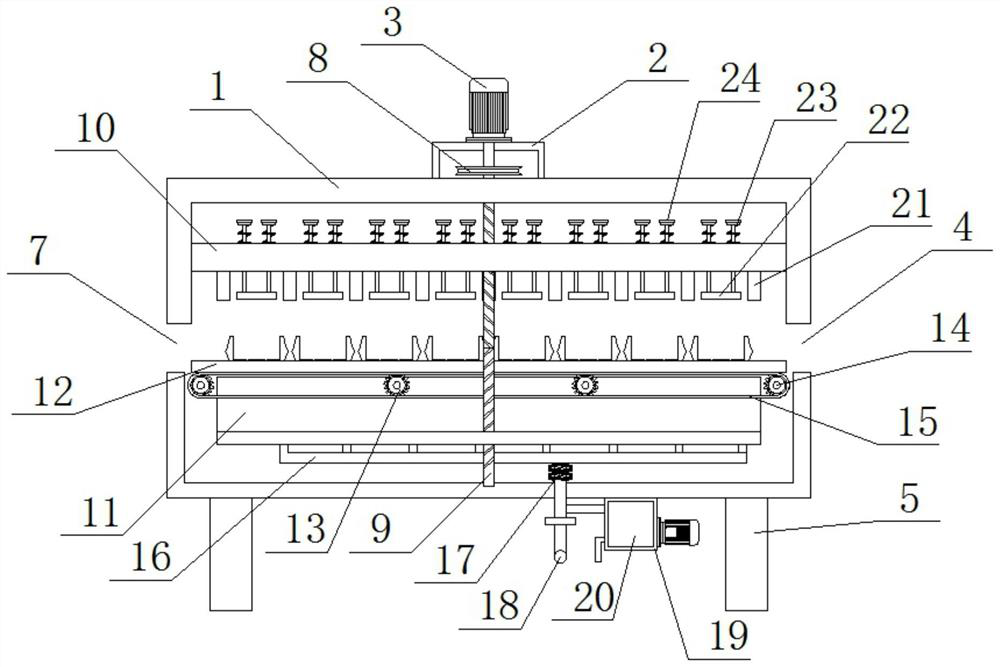

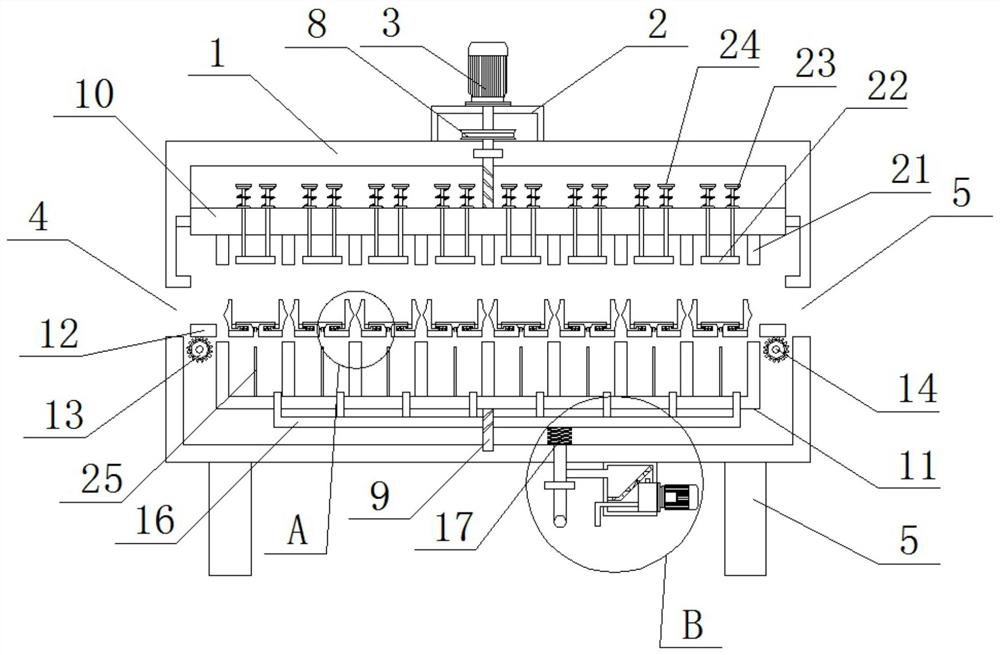

[0030] As a preferred embodiment of the present invention, the rotating rod 14 is movably installed on both sides of the inside of the box body 1, and the rotating rod 14 and the two-way screw rod 9 are arranged perpendicular to each other to avoid the impact on the lower adjustment plate 11. Elevation affects.

[0031] As a preferred embodiment of the present invention, the quantity of the chain 15 is 2, the quantity of the rotating rod 14 is 2, the quantity of the sprocket 13 is 8, and the chain 15 can be adjusted by the rotating rod 14. Transmission is carried out to facilitate the movement of the pallet 12.

[0032] As a preferred embodiment of the present invention, the upper adjusting plate 10 is arranged on the top of the inner side of the box body 1, the lower adjusting plate 11 is arranged on the bottom of the inner side of the box body 1, and the upper adjusting plate 10 and the lower adjusting plate 10 are arranged on the inner side of the box body 1. The movement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com