Cutting device for partitioning environment-friendly green bricks

A technology for cutting devices and adobes, applied in unloading devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of cutting knife occupying space, affecting the quality of bricks, and secondary adhesion, so as to prevent secondary contact and improve The effect of cutting quality and guaranteeing molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

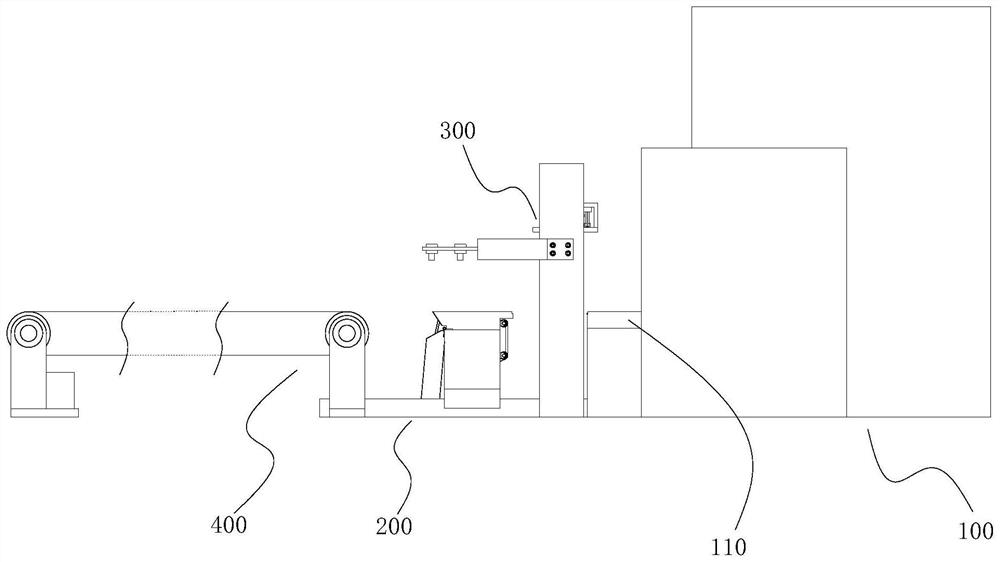

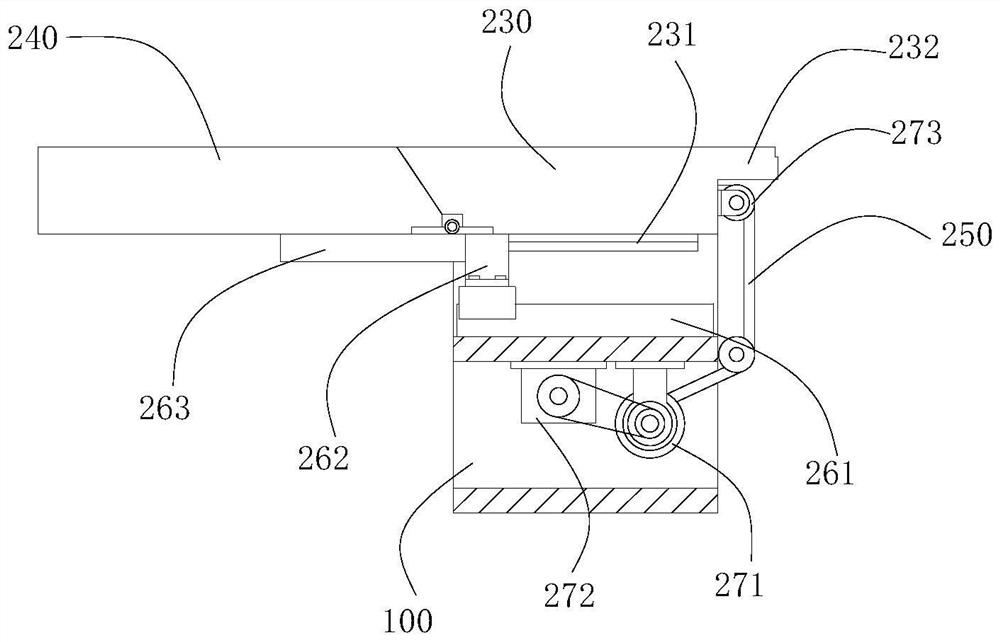

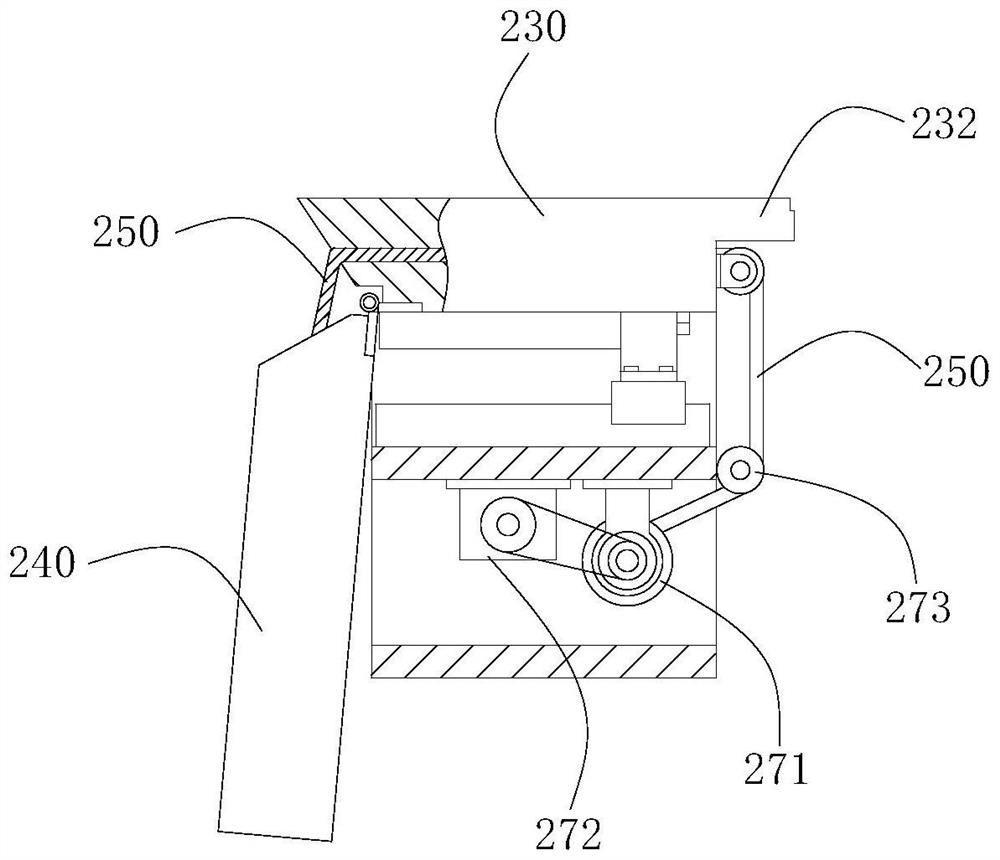

[0028] like Figure 1 to Figure 8 As shown in the figure, a specific embodiment of the present invention discloses a cutting device for environmental protection brick slicing, including a supporting and transferring structure 200 arranged outside the discharge port of the mud strip extruder 100, and the supporting and transferring structure 200 is close to the mud A cutting mechanism 300 is provided above one end of the strip extruder 100 , and a conveyor belt 400 is provided on the side of the supporting and transferring structure 200 away from the mud strip extruder 100 ; At this point, the mud strips sent by the mud strip extruder 100 can be sent to the supporting and transferring structure 200, the cutting mechanism 300 performs line cutting on the sent mud strips, and the supporting and transferring structure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com