Underwater oil droplet collection material and method for preparing same

An oil droplet and air technology, applied in the field of materials for collecting underwater oil droplets and its preparation, can solve the problems of easy clogging of membrane pores, high operating costs, and difficult cleaning, and achieve a simple preparation method, good function, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Soak a glass sheet with a clean surface and no oil stain in a mixed solution of 30% hydrogen peroxide and concentrated sulfuric acid (3:7 in volume ratio) for 2 hours, then wash it with water for 3 times, and dry it with nitrogen.

[0033] 2) Submerge the treated glass sheet into 10mL of toluene with a water content of 1ppm, add 1H, 1H, 2H, 2H-perfluorodecyltrichlorosilane dropwise to prepare a solution with a concentration of 0.5vt%, and keep it at room temperature After closed reaction for 1 h, the glass sheet was taken out, washed with toluene, ethanol, a mixed solution of ethanol and water (volume ratio 1:1) and water, respectively, and finally put into a drying oven with a temperature of 120 ° C for 10 min to obtain Material for collecting oil droplets underwater.

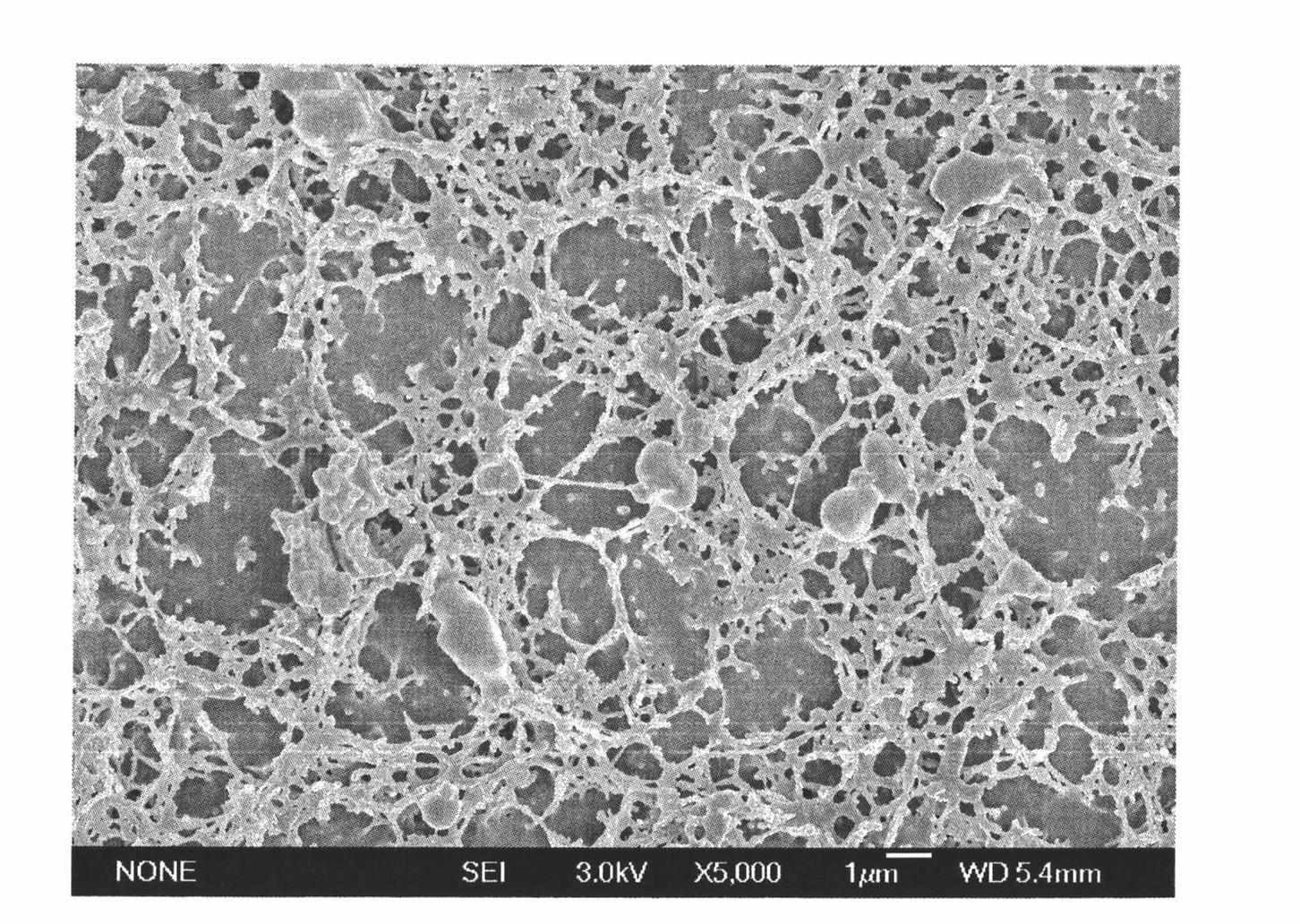

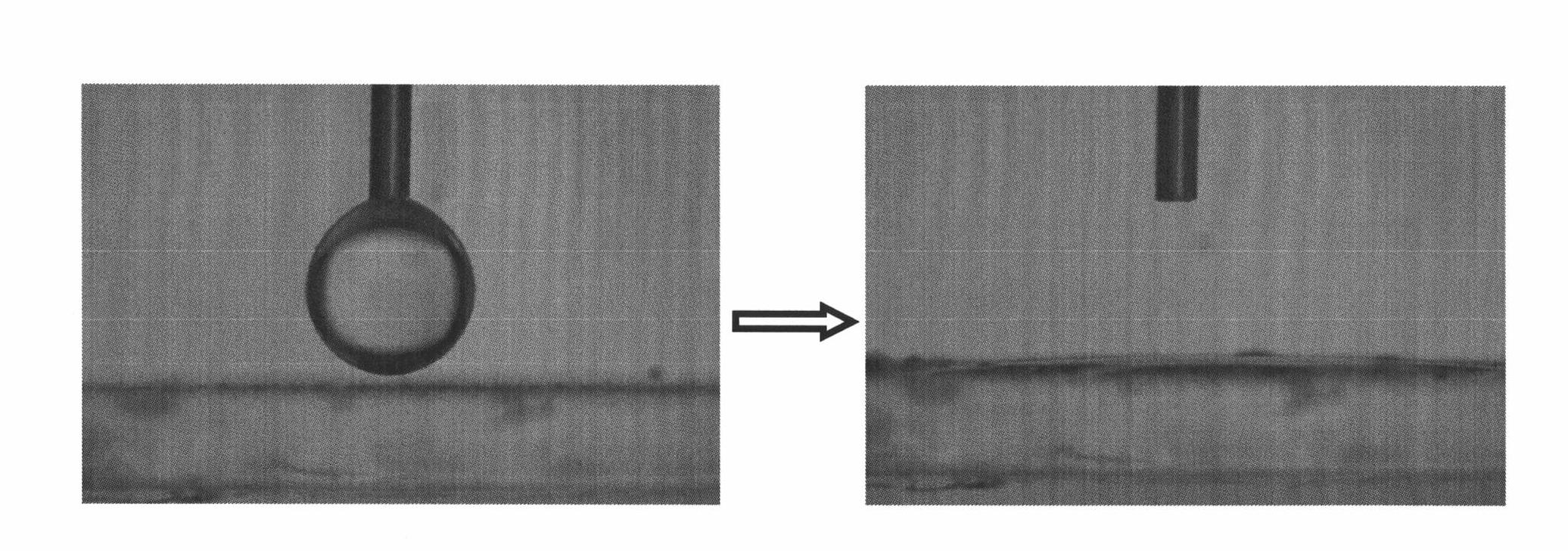

[0034] SEM photographs of the surface of the material collecting underwater oil droplets are shown in figure 1 Shown; the contact angle diagram of the underwater material surface before and after c...

Embodiment 2

[0037] 1) Soak a glass sheet with a clean surface and no oil stain in a mixed solution of 30% hydrogen peroxide and concentrated sulfuric acid (3:7 in volume ratio) for 2 hours, then wash it with water for 3 times, and dry it with nitrogen.

[0038] 2) Submerge the treated glass sheet into 10mL of xylene with a water content of 5ppm, add 1H, 1H, 2H, 2H-perfluorodecyltrichlorosilane dropwise to prepare a solution with a concentration of 5vt%, and keep it at room temperature After closed reaction for 1 hour, the glass sheet was taken out, rinsed with xylene, ethanol, a mixed solution of ethanol and water (volume ratio 1:1) and water, respectively, and finally put into a drying oven with a temperature of 120°C to dry for 10 minutes. Get the material for collecting oil droplets underwater.

[0039] The contact angle between the underwater material surface and the oil droplet is 0°. The material can collect oil 9~10ml / cm each time under water 2 , the function of collecting oil dr...

Embodiment 3

[0041] 1) Soak a glass sheet with a clean surface and no oil stain in a mixed solution of 30% hydrogen peroxide and concentrated sulfuric acid (3:7 in volume ratio) for 2 hours, then wash it with water for 3 times, and dry it with nitrogen.

[0042] 2) Submerge the treated glass sheet into 10 mL of isopropanol with a water content of 0 ppm, add 1H, 1H, 2H, 2H-perfluorodecyltrichlorosilane dropwise, and prepare a solution with a concentration of 0.0001vt%. , after airtight reaction at room temperature for 1 h, take out the glass sheet, wash it with isopropanol, ethanol, a mixed solution of ethanol and water (volume ratio: 1:1) and water, and finally put it into a drying oven with a temperature of 120 ° C. After drying for 10 minutes, a material collecting underwater oil droplets was obtained.

[0043] The contact angle between the underwater material surface and the oil droplet is 0°. The material can collect oil 0.1~1ml / cm each time under water 2 , the function of collecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com