Thermal-expansion strippable pressure-sensitive adhesive sheet and coater

A pressure-sensitive film and thermal expansion technology, which is applied to the device, coating, adhesive and other directions for coating liquid on the surface, which can solve the problems of unresolved, deformation of electronic components, weakened chip support, etc., to save production operation process, The manufacturing and use process is convenient, and the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

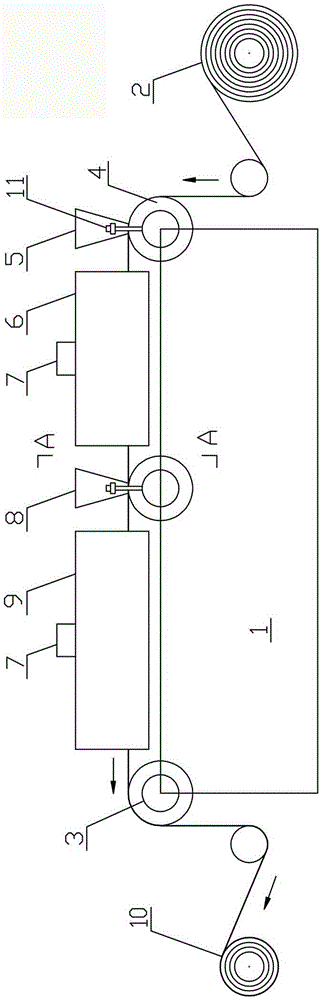

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

[0040] Facility Example 1:

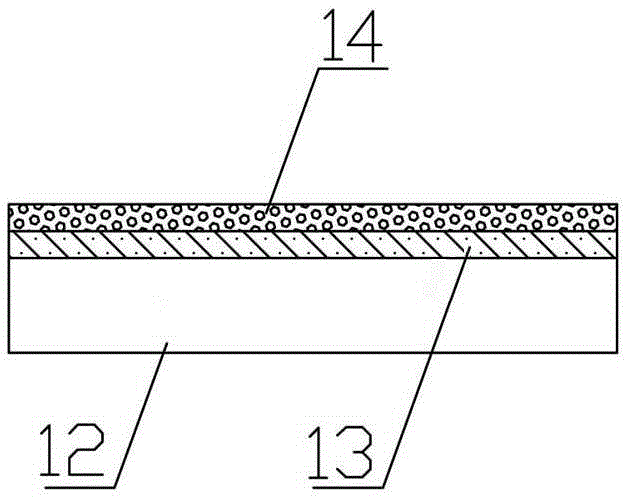

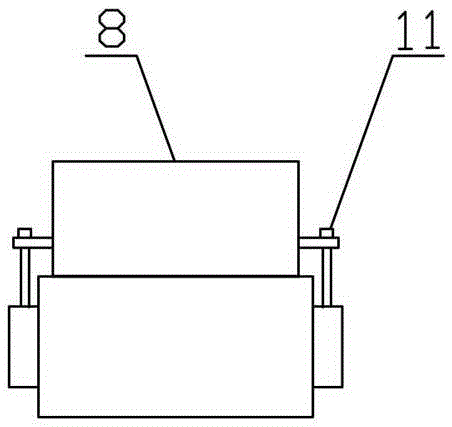

[0041] A heat-expandable peelable pressure-sensitive adhesive sheet, which includes coating an adhesive layer and a foam layer from bottom to top on a PET film substrate, and the adhesive layer consists of the following parts by weight: polyurethane resin 70, polyisocyanate crosslinking agent 12. Ethyl acetate 36, mixed and stirred to dissolve, and then coated on the PET film substrate, the drying temperature is 90 ° C, and the thickness of the adhesive layer after drying is 22 μm; the foaming layer is composed of the following parts by weight: polybutylmethacrylate ester or polymethyl methacrylate 68, organic superfine powder 280, dioctyl phthalate 12, ethyl acetate 320, and expanded microspheres 30, use a high-speed disperser to fully mix and disperse, and then coat on the On the adhesive layer, the drying temperature is 60° C., and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com