Medium-anti-impact polystyrene resin and preparation method thereof

A technology of impact-resistant polystyrene and styrene-based, applied in the field of medium-impact polystyrene resin and its preparation, which can solve the problems of inability to maximize the toughening effect of rubber, reduce product fluidity, and increase labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] 1. Preparation method

[0081] A preparation method of medium-impact polystyrene resin, comprising the following steps:

[0082] (1) Preparation of the feed liquid: 2% of mineral oil, 3.2% of low-cis polybutadiene rubber with a solution viscosity of 150 cps, and 0.8% of a solution with a viscosity of 90 cps, based on the weight percentage of the feed liquid High cis polybutadiene rubber, 1% low cis polybutadiene rubber with a solution viscosity of 30 cps, dissolved in 93% styrene monomer, prepared as a rubber solution and sent to the first In the first-stage continuous stirred tank reactor (using the continuous stirred tank reactor as the pre-polymerization reactor);

[0083] (2) Continuous polymerization: Add 50 ppm of initiator (dibenzoyl peroxide) to carry out polymerization at 95°C to reach a conversion rate of 8%, and then send it to the second-stage continuous stirred tank reactor (second-stage pre-polymerization reaction device);

[0084] (3) Polymerize at a r...

Embodiment 2

[0088] 1, other conditions are identical with embodiment 1, difference is:

[0089] (1) Add 0.05% n-octadecyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate (antioxidant agent), while adding 1200 ppm of zinc stearate (internal lubricant) and 200 ppm of ethylene bisstearamide (external lubricant) to the final granule product in the first-stage plug flow reactor;

[0090] (2) Add 4% of superfine talc powder with an average particle size of 1 µm, 2% of styrene monomer and 3.5% of mineral oil to the first-stage plug flow reactor after mixing and dissolving in the powder treatment tank;

[0091] (3) Three-stage plug flow reactors are set up. The temperatures controlled by the plug flow reactors at each stage are 138°C, 165°C, and 180°C; the conversion rates are 43%, 63%, and 76%.

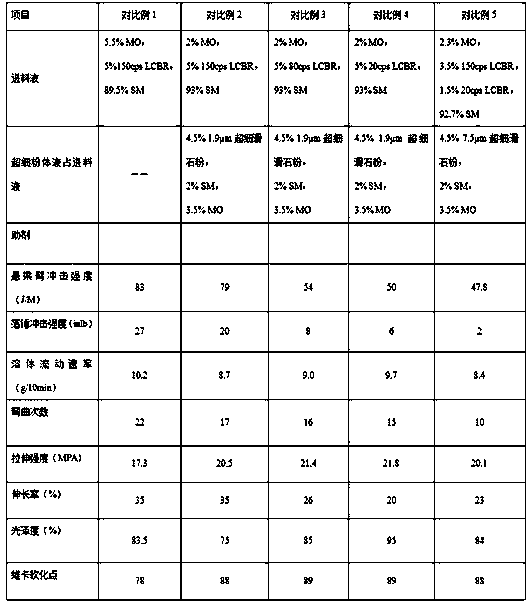

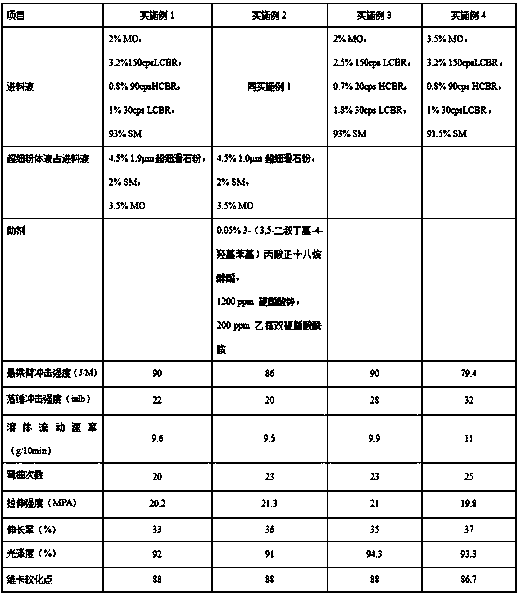

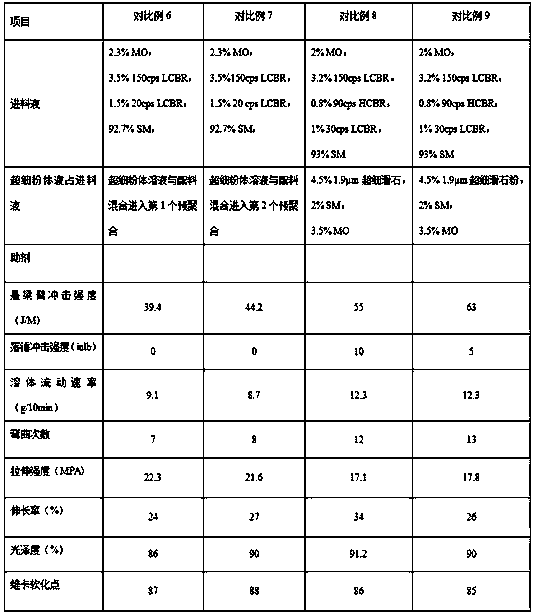

[0092] 2. Please refer to Table 1-3 for specific product characteristics and physical and chemical properties.

Embodiment 3

[0094] 1, other conditions are identical with embodiment 1, difference is:

[0095] (1) Mineral oil accounting for 2% by weight of the feed liquid, low-cis polybutadiene rubber (solution viscosity of 150 cps) accounting for 2.5% by weight of the feed liquid, and 0.7% by weight of the feed liquid High cis polybutadiene rubber (solution viscosity is 30 cps) and low cis polybutadiene rubber (solution viscosity is 30 cps) accounting for 1.8% by weight of the feed liquid are dissolved in 93% by weight of the feed liquid In the styrene monomer, the rubber solution is prepared as the feed liquid and sent to the first-stage continuous stirred tank reactor;

[0096] (2) Set up 4-stage plug flow reactors. The temperatures controlled by each stage of plug flow reactors are 139°C, 158°C, 167°C, and 180°C; the conversion rates are 41%, 53%, 62%, and 78%.

[0097] 2. Please refer to Table 1-3 for specific product characteristics and physical and chemical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com