Method for preparing sucralose microcapsules

A technology of sucralose and microcapsules, which is applied in food forming, food ingredients as emulsifiers, food science, etc., can solve the problem of affecting the distribution of sucralose microcapsules, large size of sucralose microcapsules, and spots on the surface of food and other problems, to achieve the effect of easy large-scale continuous production, excellent fluidity and complete sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Dissolve 100 kg of sucralose 100 mesh crystals in 230 kg of water, add 10 kg of sodium stearoyl lactylate, mix well, and stir at 1000 r / min to obtain emulsion A;

[0024] 2) After dissolving 30kg of modified starch in methanol solution at 70°C, add it dropwise to emulsion A, stir and emulsify at 100r / min to obtain emulsion B;

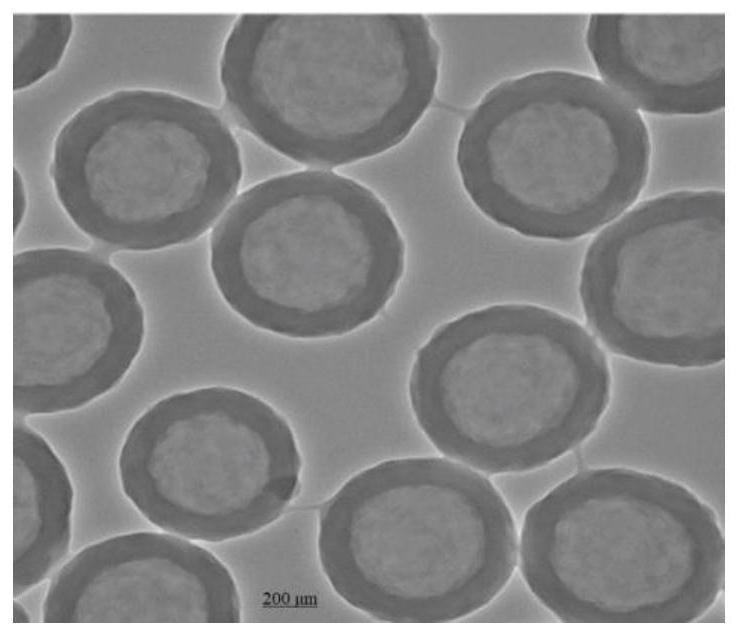

[0025] 3) Dry emulsion B at 80°C with a spray dryer and sieve to obtain 100um sucralose microcapsule powder, see figure 1 shown.

Embodiment 2

[0027] 1) Dissolve 100kg of sucralose 200 mesh crystals in 100kg of water, add 5kg of sucrose fatty ester, mix well, and stir at 8000r / min to obtain emulsion A;

[0028] 2) After dissolving 50kg of ethyl cellulose in ethanol solution at 50°C, add it dropwise to step 1), stir and emulsify at 500r / min to obtain emulsion B;

[0029] 3) The emulsion B was dried at 100° C. by a spray dryer and sieved to obtain 200 um sucralose microcapsule powder.

Embodiment 3

[0031] 1) Dissolve 100 kg of sucralose 100 mesh crystals in 67 kg of water, add 4 kg of sucrose fatty ester, mix well, and stir at 6000 r / min to obtain emulsion A;

[0032] 2) After dissolving 50kg of gelatin in methanol solution at 70°C, add it dropwise to emulsion A, stir and emulsify at 800r / min to obtain emulsion B;

[0033] 3) The emulsion B was dried at 90° C. by a spray dryer, and sieved to obtain 150 μm sucralose microcapsule powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com