Method for producing fat microcapsules through low temperature electrostatic spray drying

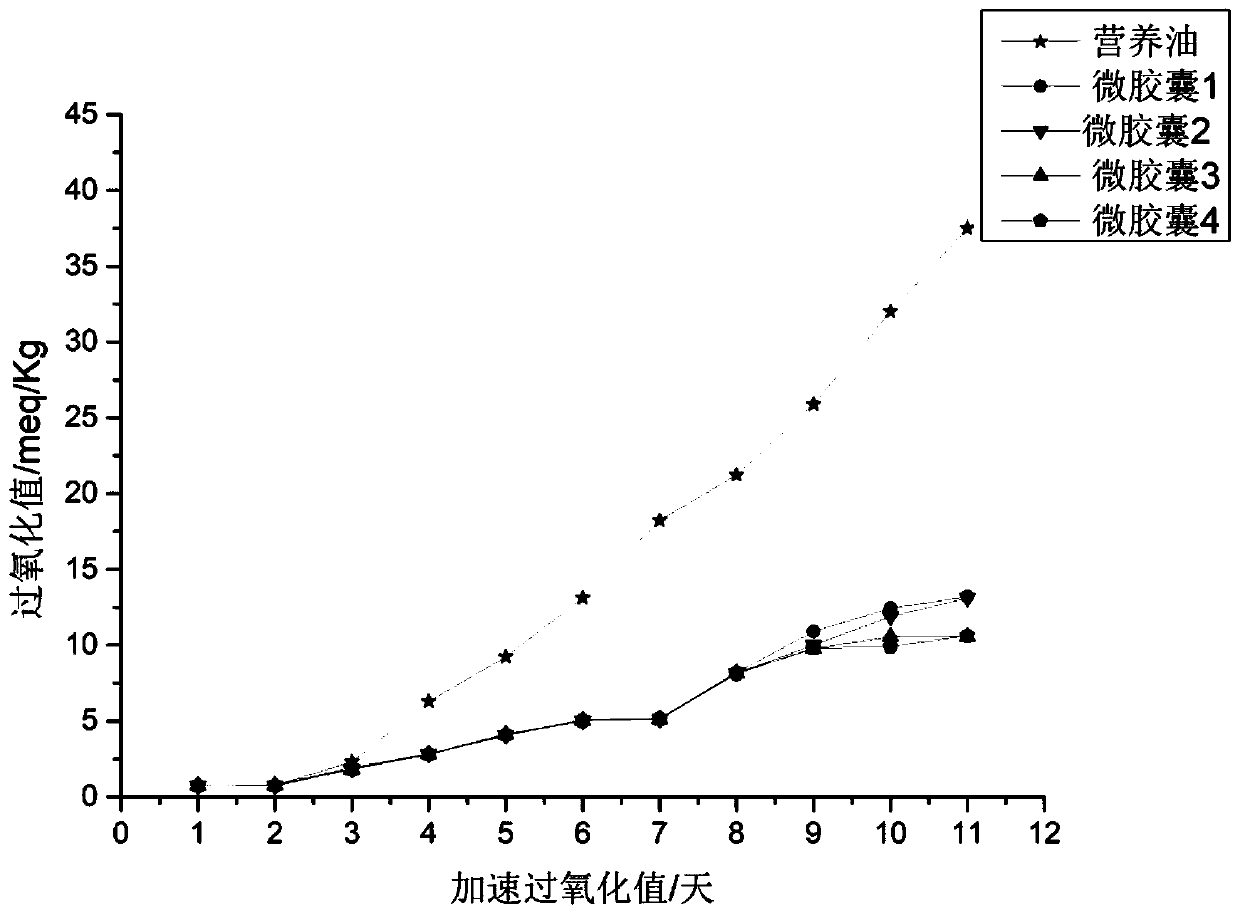

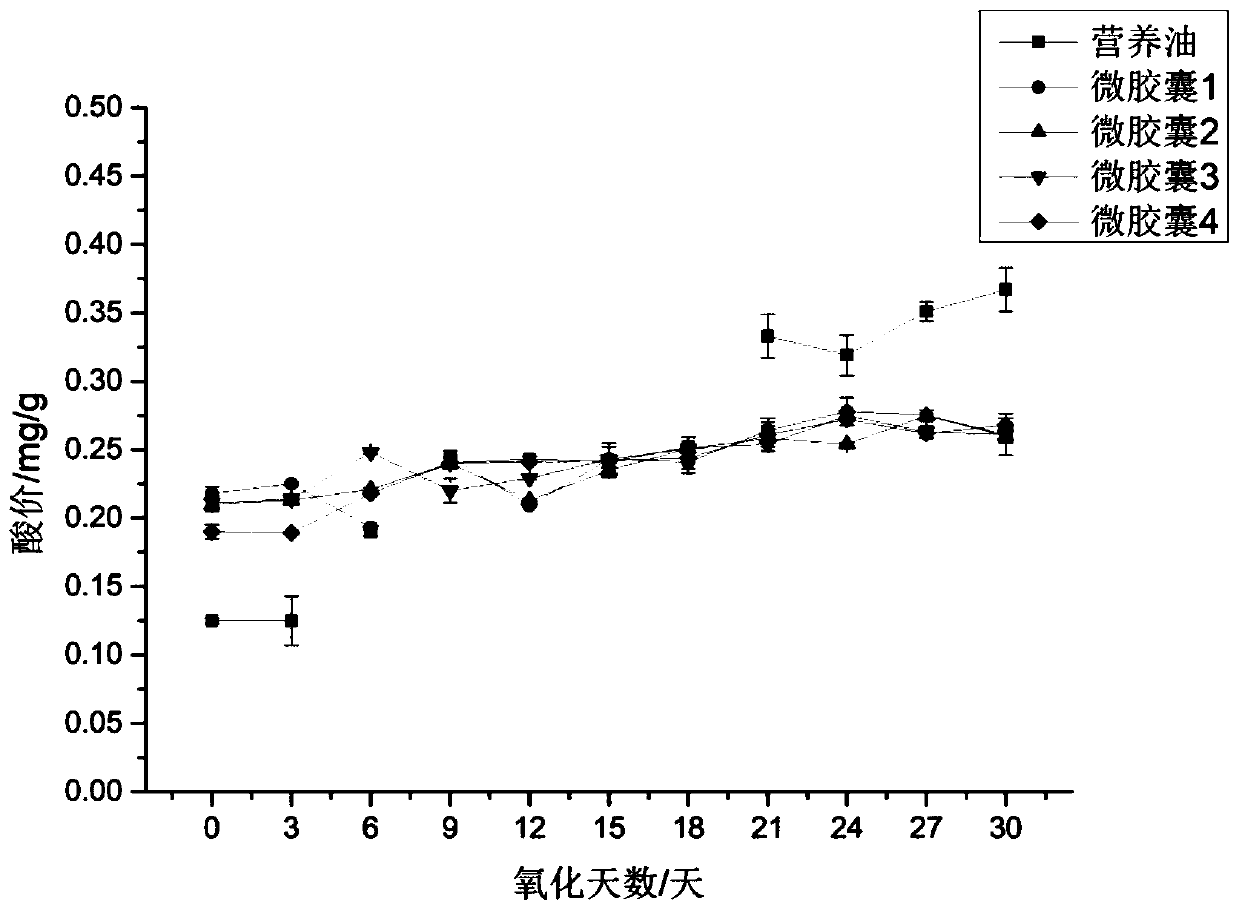

A technology of electrostatic spraying and microcapsules, which is applied in food forming, dairy products, food science, etc. It can solve the problems of unstable physical and chemical properties, cracks, and large particle size of microcapsule structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

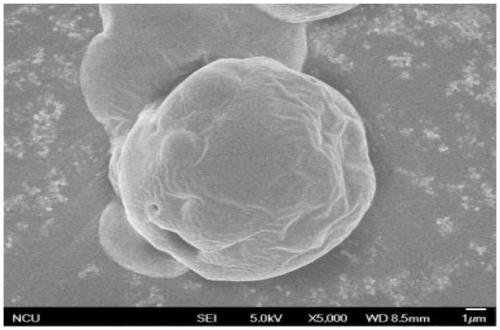

Image

Examples

Embodiment 1

[0109] A method for producing infant formula milk powder fat microcapsules by nitrogen-filled low-temperature electrostatic spray drying, comprising the following steps:

[0110] 1. Ingredients: at room temperature, weigh 48.75 grams of lactose, 13.54 grams of whey protein, 2.71 grams of skimmed milk powder, add 195 grams of water to initially dissolve and prepare a wall material solution with a solid content of 25%;

[0111] 2. Wall material dissolution: at room temperature, heat the wall material solution obtained in step 1 in a 65°C water bath for 20 minutes;

[0112] 3. Core material preparation: Weigh 35 grams of mixed oil, add compound emulsifier and emulsification auxiliary agent, and bathe in 60°C water for 10 to 15 minutes to dissolve the oil-soluble mixture evenly to obtain infant formula milk powder oil mixture; The emulsifier is composed of monoglyceride, fatty glyceride citrate, sodium caseinate, and sodium starch octenyl succinate, expressed in parts by weight, a...

Embodiment 2

[0118] A method for producing infant formula milk powder fat microcapsules by nitrogen-filled low-temperature electrostatic spray drying, comprising the following steps:

[0119] 1. Ingredients: at room temperature, weigh 48.75 grams of lactose, 13.63 grams of whey protein, 2.80 grams of skimmed milk powder, add 195 grams of water to initially dissolve and prepare a wall material solution with a solid content of 25%;

[0120] 2. Wall material dissolution: at room temperature, heat the wall material solution obtained in step 1 in a 67°C water bath for 20 minutes;

[0121] 3. Core material preparation: Weigh 35 grams of mixed oil, add compound emulsifier and emulsification auxiliary agent, and bathe in 60°C water for 10 to 15 minutes to dissolve the oil-soluble mixture evenly to obtain infant formula milk powder oil mixture; The emulsifier is composed of monoglyceride, fatty glyceride citrate, sodium caseinate, and sodium starch octenyl succinate, expressed in parts by weight, a...

Embodiment 3

[0127] A method for producing infant formula milk powder fat microcapsules by nitrogen-filled low-temperature electrostatic spray drying, comprising the following steps:

[0128] 1. Ingredients: at room temperature, weigh 43.75 grams of lactose, 16.04 grams of whey protein, 7.21 grams of skimmed milk powder, add 195 grams of water to initially dissolve and prepare a wall material solution with a solid content of 25%;

[0129] 2. Wall material dissolution: at room temperature, heat the wall material solution obtained in step 1 in a 62°C water bath for 20 minutes;

[0130] 3. Core material preparation: Weigh 35 grams of mixed oil, add compound emulsifier and emulsification auxiliary agent, and bathe in 60°C water for 14 minutes to dissolve the oil-soluble mixture evenly to obtain infant formula milk powder oil mixture; the compound emulsification The agent is composed of monoglyceride, fatty glyceride citrate, sodium caseinate, and sodium starch octenyl succinate, expressed in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com