A production system for medium-impact polystyrene resin

An impact polystyrene production system technology, applied in the field of resin synthesis, can solve the problems of inability to maximize rubber toughening effect, poor secondary blending effect, poor impact strength, etc., and achieve easy large-scale continuous production, Improvement of processing fluidity and effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

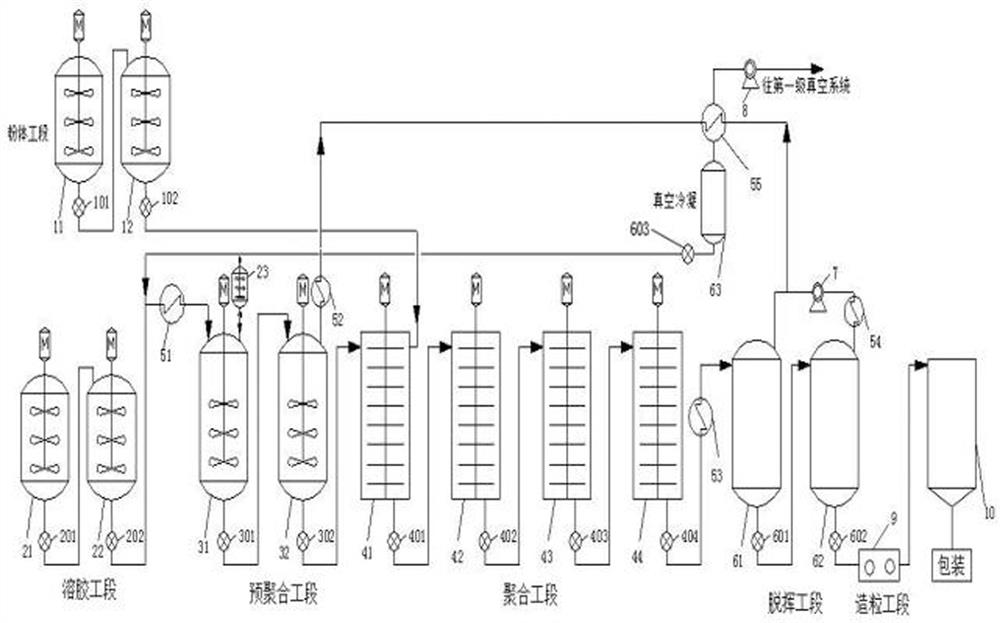

[0043] Embodiment 1 A kind of medium impact polystyrene resin production system

[0044] Such as figure 1 As shown, a medium-impact polystyrene resin production system includes a sol tank 21, a mixing feed tank 22, an ultrafine powder batching tank 11, an ultrafine powder feed tank 12, a prepolymerization preheater 51, First stage prepolymerization reactor 31, second stage prepolymerization reactor 32, first stage polymerization reactor 41, second stage polymerization reactor 42, third stage polymerization reactor 43, fourth stage polymerization reactor 44, Devolatilization preheater 53, first-stage devolatilizer 61, second-stage devolatilizer 62, circulating condenser 55, collection tank 63 and granulator 9; above-mentioned sol tank 21, mixed feed tank 22, superfine Powder batching tank 11, superfine powder feed tank 12, first stage prepolymerization reactor 31, second stage prepolymerization reactor 32, multistage polymerization reactor, first stage devolatilizer 61, second...

Embodiment 2

[0053] Embodiment 2 A kind of medium impact polystyrene resin production system

[0054] As a further improvement to Embodiment 1, the production system of this embodiment further includes a three-stage vacuum system.

[0055]This three-stage vacuum system comprises a first-stage vacuum pump, a second-stage vacuum pump 8, and a third-stage vacuum pump 7; the third-stage vacuum pump 7 is arranged on the delivery pipeline of the devolatilizer and the circulating condenser 55; the second-stage prepolymerization reactor The top outlet pipeline of 32 is connected in parallel with the top outlet pipeline of the first-stage devolatilizer 61 through the first reflux condenser 52, then is connected with the first-stage vacuum pump after being connected with the second-stage vacuum pump 8 by the circulation condenser 55; The outlet pipeline of the secondary devolatilizer 62 passes through the second reflux condenser 54 and the third stage vacuum pump 7 successively and is connected with...

Embodiment 3

[0058] Embodiment 3 A kind of medium impact polystyrene resin production system

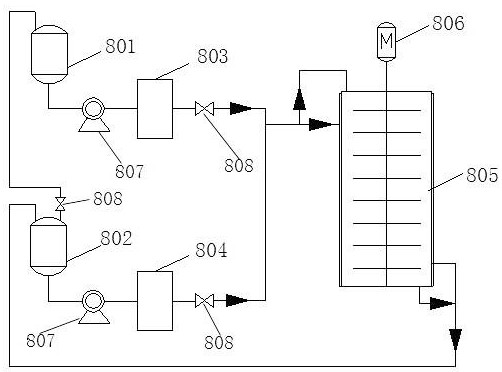

[0059] Such as figure 2 As shown, as a further improvement to Embodiment 1, the production system of this embodiment also includes a total heat transfer oil system.

[0060] The total heat transfer oil system includes a heat transfer oil circulation system and a heat transfer oil intelligent temperature control system. The heat transfer oil intelligent temperature control system connects the heat transfer oil pipeline with the inner coil and outer jacket of the reactor to form a heat transfer oil circulation system. Under normal circumstances, the temperature of the polymerization reactor is controlled through the heat transfer oil circulation of the inner coil and the outer jacket, and the reaction heat generated by the polymerization reaction is removed in time. Cool quickly.

[0061] The heat transfer oil intelligent temperature control system consists of a heat transfer oil storage tank 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com