Preparation method of ruminant trans-fatty acid

A technology for trans fatty acids and ruminants, which is used in fatty acid preparation/refining, fatty acid production, animal feed, etc., can solve the problems of high temperature and pressure, cannot reflect the whole picture of ruminant trans fatty acids, and maintain high temperature and high pressure, and achieves high temperature and pressure. The effect of low consumption, strong operability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

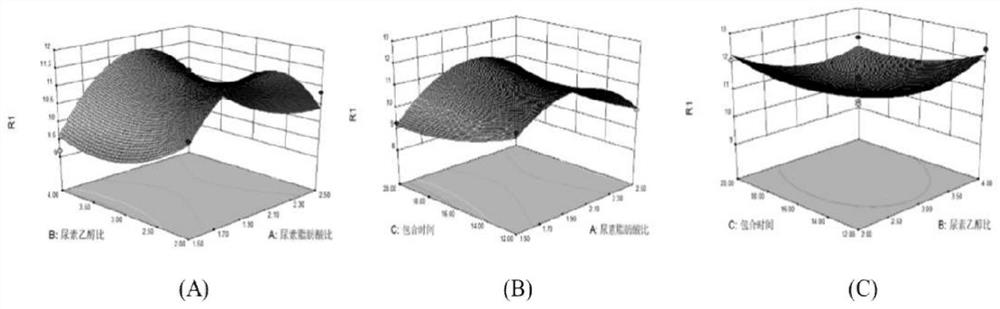

Image

Examples

Embodiment 1

[0020] Example 1 - Preparation of ruminant trans fatty acids

[0021] (1) Preparation of butter free fatty acid. In a constant temperature water bath at 90°C, put a certain amount of butter into a beaker, wait until the butter is completely melted into a liquid, add it into a 1mol / L NaOH ethanol solution, the ratio of solid to liquid is 1:6, stir magnetically for 2 hours, carry out saponification reaction, take out After the beaker is cooled to room temperature, the saponified product is obtained by vacuum filtration, and then 0.5mol / L sulfuric acid solution is added to the saponified product, stirred in a water bath at 50°C to dissolve it, and then separated into three layers , so that the pH of the upper layer oil is about 2-3, take the upper layer oil, wash with hot purified water until neutral, and obtain butter free fatty acid.

[0022] (2) Urea inclusion method to remove saturated fatty acids. Add urea to absolute ethanol in a certain proportion, and carry out rotary r...

Embodiment 2

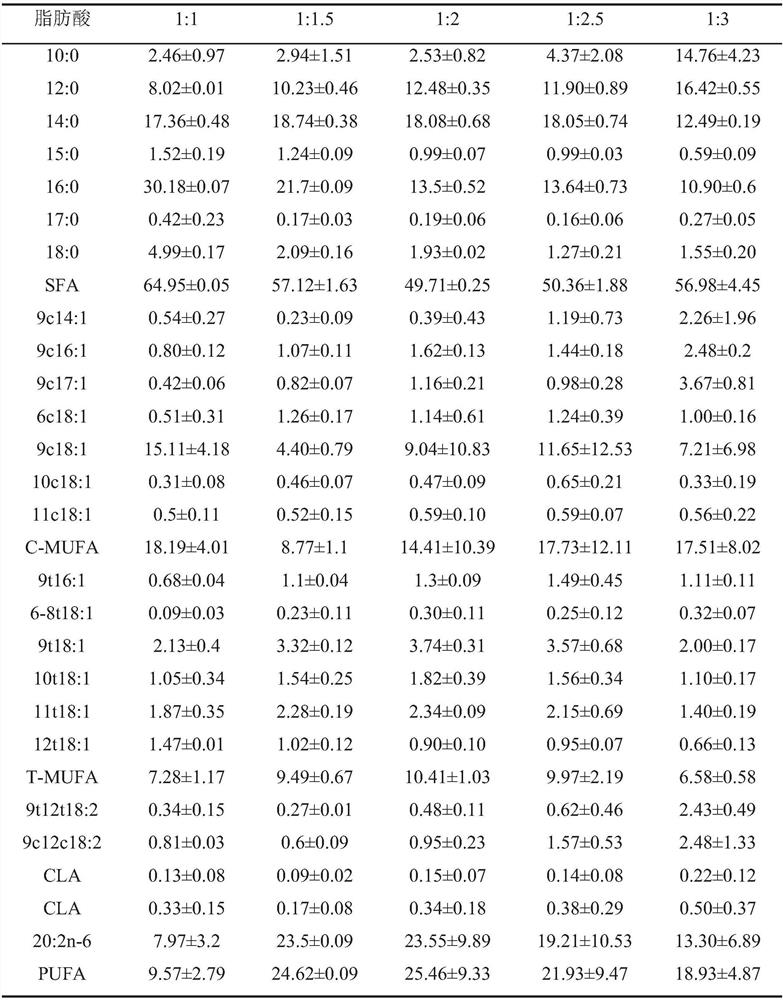

[0023] The single factor test of embodiment 2-urea and butter free fatty acid ratio

[0024] Weigh 10g of butter free fatty acid gained in step (1), step (2) is 1: 3 according to the ratio of urea and ethanol, inclusion time is 12h condition, butter free fatty acid and urea ratio are 1: 1, 1: 1.5, 1: 2. 1:2.5 and 1:3 were carried out to investigate the effect of the ratio of butter free fatty acid to urea on the content of ruminant trans fatty acid in the product. The results are shown in Table 1.

[0025] The influence (area %) of the ratio of free fatty acid of table 1 butter and urea on product trans monounsaturated fatty acid content

[0026]

[0027] Note: Fatty acid refers to the fatty acid composition and content of the prepared product, where SFA: saturated fatty acid; MUFA: monounsaturated fatty acid; PUFA: polyunsaturated fatty acid; C-MUFA: cis monounsaturated fatty acid; T-MUFA: trans monounsaturated fatty acid; CLA: conjugated linoleic acid.

Embodiment 3

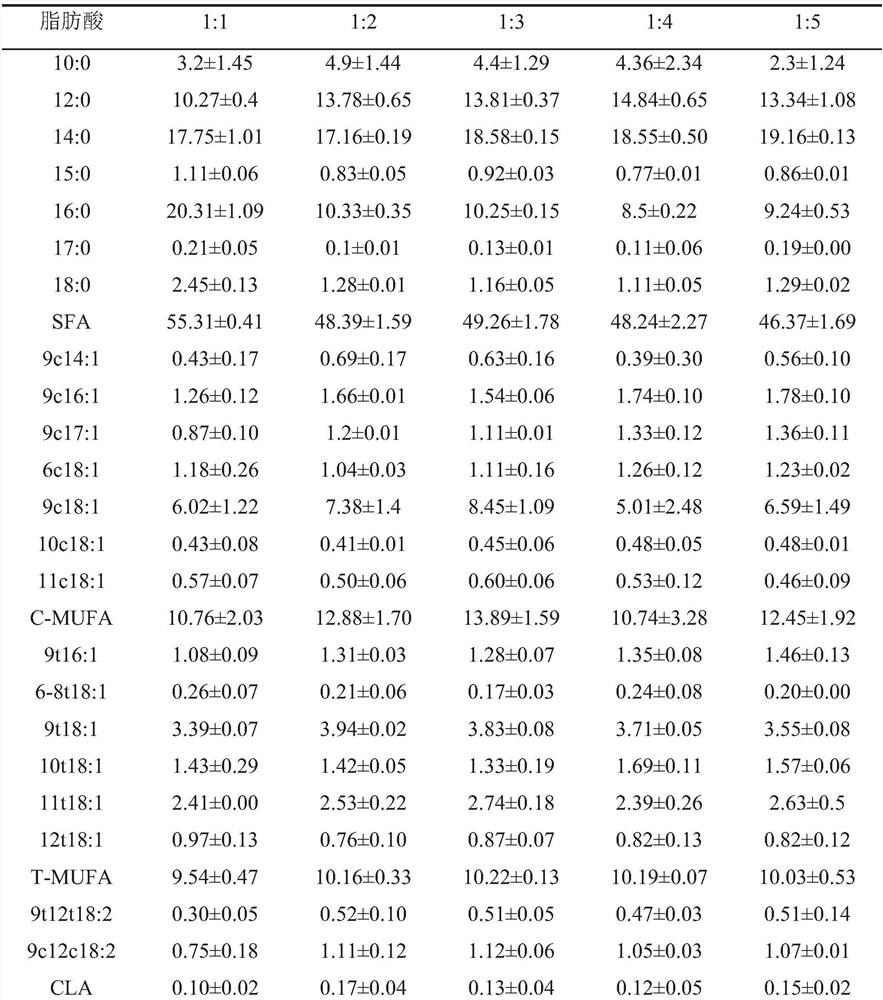

[0028] The single factor test of embodiment 3-ethanol and butter free fatty acid ratio

[0029] The ratio of butter free fatty acid to urea is 1:1, and the ratio of urea to ethanol is 1:1, 1:2, 1:3, 1:4, 1:5. The impact on the content of ruminant trans fatty acids in the product is shown in Table 2.

[0030] The influence (area %) of the ratio of free fatty acid in table 2 butter and ethanol on trans monounsaturated fatty acid content in the product

[0031]

[0032]

[0033] Note: fatty acid refers to the fatty acid composition and content of the prepared product, where SFA: saturated fatty acid MUFA: monounsaturated fatty acid PUFA: polyunsaturated fatty acid C-MUFA: cis monounsaturated fatty acid T-MUFA: trans monounsaturated fatty acid Fatty Acid CLA: Conjugated Linoleic Acid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com