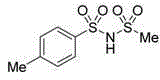

N-(methyl sulphonyl)-p-methylphenyl sulphonylamine and preparation method thereof

A technology of toluenesulfonamide and methylsulfonyl, which is applied in the field of N-(methylsulfonyl)-p-toluenesulfonamide and its preparation, can solve the problem of limited popularization and application, poor technical effect, lack of High-gloss powder coating curing agent catalysts and other issues to achieve a good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

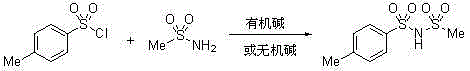

Method used

Image

Examples

Embodiment 1

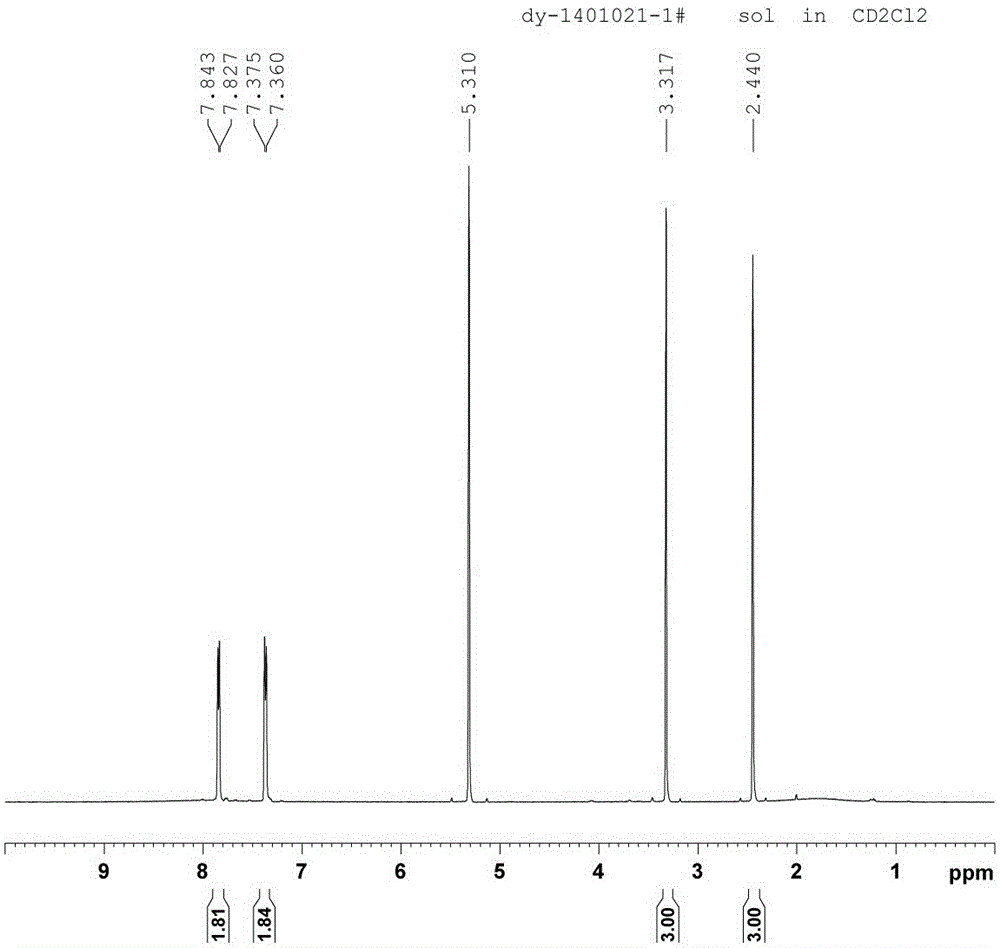

[0036] In the reactor equipped with mechanical stirring, reflux condenser, nitrogen feed device and sampling port, add 400 milliliters of tetrahydrofuran, react raw materials 41 grams of toluenesulfonyl chloride, 20 grams of methylsulfonamide and 1 gram of trimethyl trimethyl Add benzyl ammonium chloride, stir to dissolve, pass nitrogen protection, heat up to 67 ° C, reflux reaction, add 32 grams of anhydrous potassium carbonate in batches, keep the temperature for 10 hours, until the reaction raw materials disappear, evaporate the organic solvent under reduced pressure, A white to pale yellow solid was obtained.

[0037] Dissolve the above solid in 200 ml of demineralized water, stir until it is completely dissolved, add 40 ml of 36% concentrated hydrochloric acid dropwise, after the addition is completed, adjust the pH value to less than 1, cool down to 20°C, and stir for 2.5 hours, white crystals precipitate out. Filtration to obtain a white solid was dried under reduced pr...

Embodiment 2

[0039] In a reactor equipped with mechanical stirring, reflux condensing tube, nitrogen feeding device and sampling port, add 400 ml of 1,4-dioxane, 41 g of toluenesulfonyl chloride, 20 g of methylsulfonamide Add 1 gram of tetrabutylammonium chloride, stir to dissolve, pass nitrogen protection, heat up to 106 ° C, reflux reaction, add 25 grams of anhydrous sodium carbonate in batches, keep warm for 6 hours, until the reaction raw materials disappear, evaporate under reduced pressure The organic solvent was removed to obtain a white to light yellow solid.

[0040] Dissolve the above solid in 200 ml of demineralized water and stir to dissolve completely, add 40 ml of 36% concentrated hydrochloric acid dropwise, after the addition is completed, adjust the pH value to less than 1, cool down to 20°C, and stir for 3 hours, white crystals precipitate out. Filtration to obtain a white solid was dried under reduced pressure to obtain 45 g of product with a yield of 86.5%.

Embodiment 3

[0042] In the reactor equipped with mechanical stirring, reflux condenser, nitrogen feed device and sampling port, add 420 milliliters of toluene, react raw materials 41 grams of toluenesulfonyl chloride, 20 grams of methylsulfonamide and 1 gram of benzyl tri Ethylammonium chloride was added, stirred to dissolve, protected by nitrogen, heated to 115°C, reflux reaction, added 25 grams of anhydrous sodium carbonate in batches, kept for 5 hours, until the reaction raw materials disappeared, and the organic solvent was evaporated under reduced pressure. A white to pale yellow solid was obtained.

[0043] Dissolve the above solid in 200 ml of demineralized water, stir until it is completely dissolved, add 40 ml of 36% concentrated hydrochloric acid dropwise, after the addition is completed, adjust the pH value to less than 1, cool down to 20°C, stir for 2 hours, white crystals precipitate , filtered to obtain a white solid, dried under reduced pressure to obtain 40 grams of product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com