Preparation method of metal stable zirconia composite ceramics for dental restorations

A technology for stabilizing zirconia and composite ceramics, which is applied in dental preparations, dentistry, and dental prostheses. It can solve the problems of restoration performance, ceramic strength reduction, and complex process steps, so as to reduce operating steps, reduce sintering temperature, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

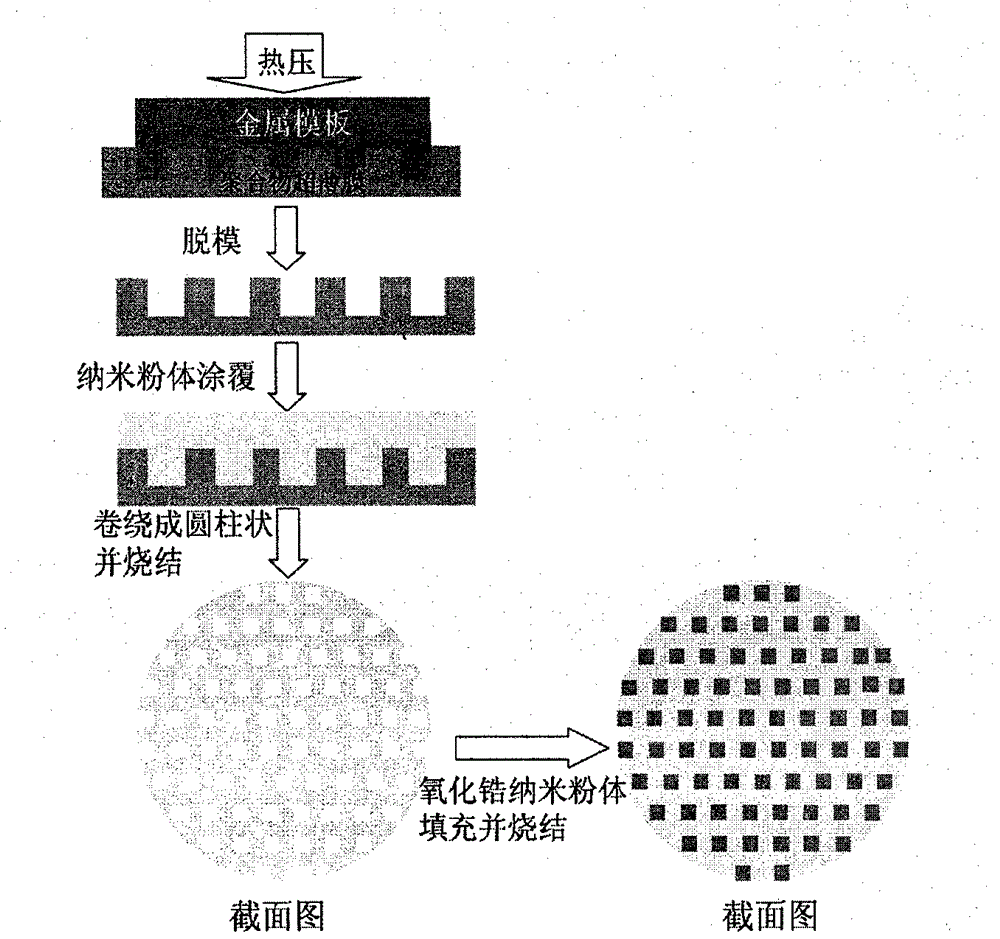

[0040] (1) Using micromachining technology to process micron-scale grooves on the surface of the aluminum block, the width of the grooves on the surface of the obtained aluminum template is 10 μm, the depth is 10 μm, and the spacing is 10 μm;

[0041] (2) PMMA is dissolved in N,N-dimethylformamide to form a solution with a mass concentration of 5%, and a film with a thickness of 20 μm is scraped on the glass surface. After curing, the template heated to 100 ° C is pressed on the On the ultra-thin PMMA film for 1 min, after removing the aluminum template, an ultra-thin PMMA film C with the surface structure opposite to that of the aluminum template is obtained;

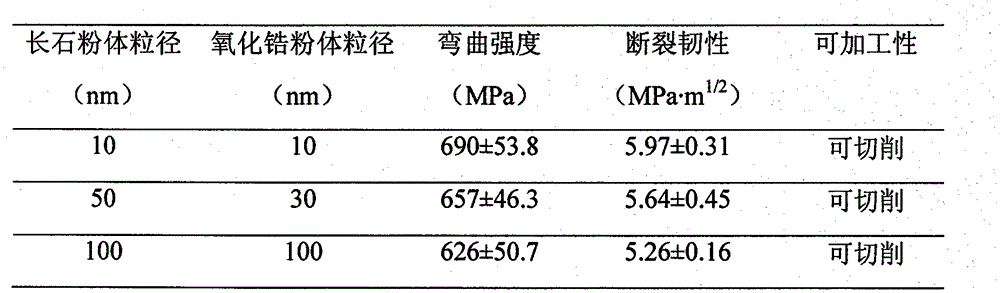

[0042] (3) 20g of feldspar nanopowder with a particle diameter of 100nm is evenly dispersed in 25g of water containing polyethylene glycol to obtain a slurry, and then this slurry is coated on the surface of C, and the coating thickness is 40 μm. After drying, C Rolled into a cylindrical shape and calcined at 1200°C fo...

Embodiment 2

[0046] (1) Metal formwork is metal aluminum formwork in embodiment 1;

[0047] (2) Dissolve polystyrene (PS) in acetone to form a solution with a mass concentration of 1%, scrape-coat the glass surface into a film with a thickness of 15 μm, and press a template heated to 100°C on the PS film after curing 1min, after removing the aluminum template, an ultra-thin PS film C with a surface structure opposite to that of the aluminum template was obtained;

[0048] (3) Evenly disperse 20 g of feldspar nanopowder with a particle size of 10 nm in 50 g of water containing Tween 60 to obtain a slurry, then coat the slurry on the surface of C with a coating thickness of 20 μm, and roll the roll after drying into a cylindrical shape and calcined at 800°C for 2 hours to obtain a columnar ceramic D with a through-hole structure; the amount of Tween 60 added is 10g;

[0049] (4) 80g of cerium-stabilized zirconia nanopowders with a particle diameter of 10nm (the content of cerium oxide is 10...

Embodiment 3

[0052] (1) metal formwork is with metal aluminum formwork in embodiment 1;

[0053] (2) Under the condition of 150°C, dissolve polyethylene (PE) in liquid paraffin to form a solution with a mass concentration of 10%, scrape it on the glass surface to form a film with a thickness of 30 μm, cool and solidify, and press the template heated to 150°C On the ultra-thin PE film for 1min, after removing the aluminum template, an ultra-thin PE film C with a surface structure opposite to that of the aluminum template is obtained;

[0054] (3) Evenly disperse 30 g of feldspar nanopowder with a particle size of 50 nm in 50 g of water containing Tween 80 to obtain a slurry, then coat the slurry on the surface of C with a coating thickness of 30 μm, and roll the roll after drying into a cylindrical shape and calcined at 1000°C for 2 hours to obtain a columnar ceramic D with a through-hole structure; the amount of Tween 80 added is 15g;

[0055] (4) 60g of yttrium-stabilized zirconia nanopo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com