High impact high gloss bimodal polystyrene material and preparation method thereof

A polystyrene, high-gloss technology, used in the preparation of high-impact and high-gloss bimodal polystyrene materials, and the field of high-impact and high-gloss bimodal polystyrene materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

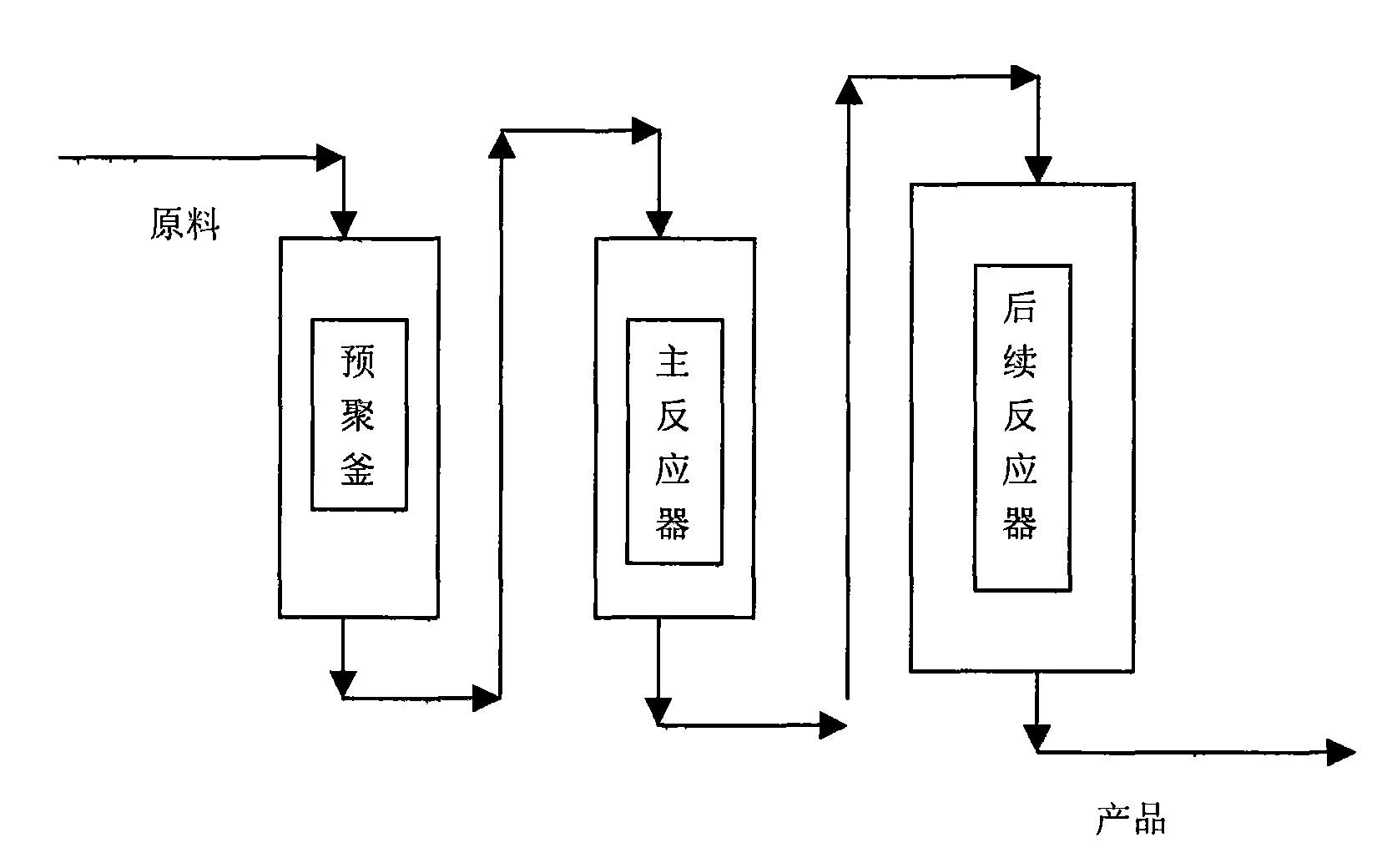

[0041] Preparation method of high-impact and high-gloss bimodal polystyrene material

[0042] A preparation method of a high-impact high-gloss bimodal polystyrene material provided by the invention comprises the following steps:

[0043] (a) providing a solution of polybutadiene rubber component in styrene monomer, wherein said polybutadiene rubber component is selected from high cis polybutadiene or low cis polybutadiene or a combination thereof , wherein the cis content of high cis polybutadiene is not less than 94 mole % (preferably such as 95 mole %-99 mole %), and the cis content of low cis polybutadiene is 33-40 mole %between;

[0044] (b) The solution in the step (a) is subjected to a prepolymerization reaction of styrene monomer to obtain a prepolymerization liquid system without phase transition;

[0045] (c) The pre-polymerization liquid system of the step (b) is further subjected to a polymerization reaction of styrene monomer under a shear force field until a pha...

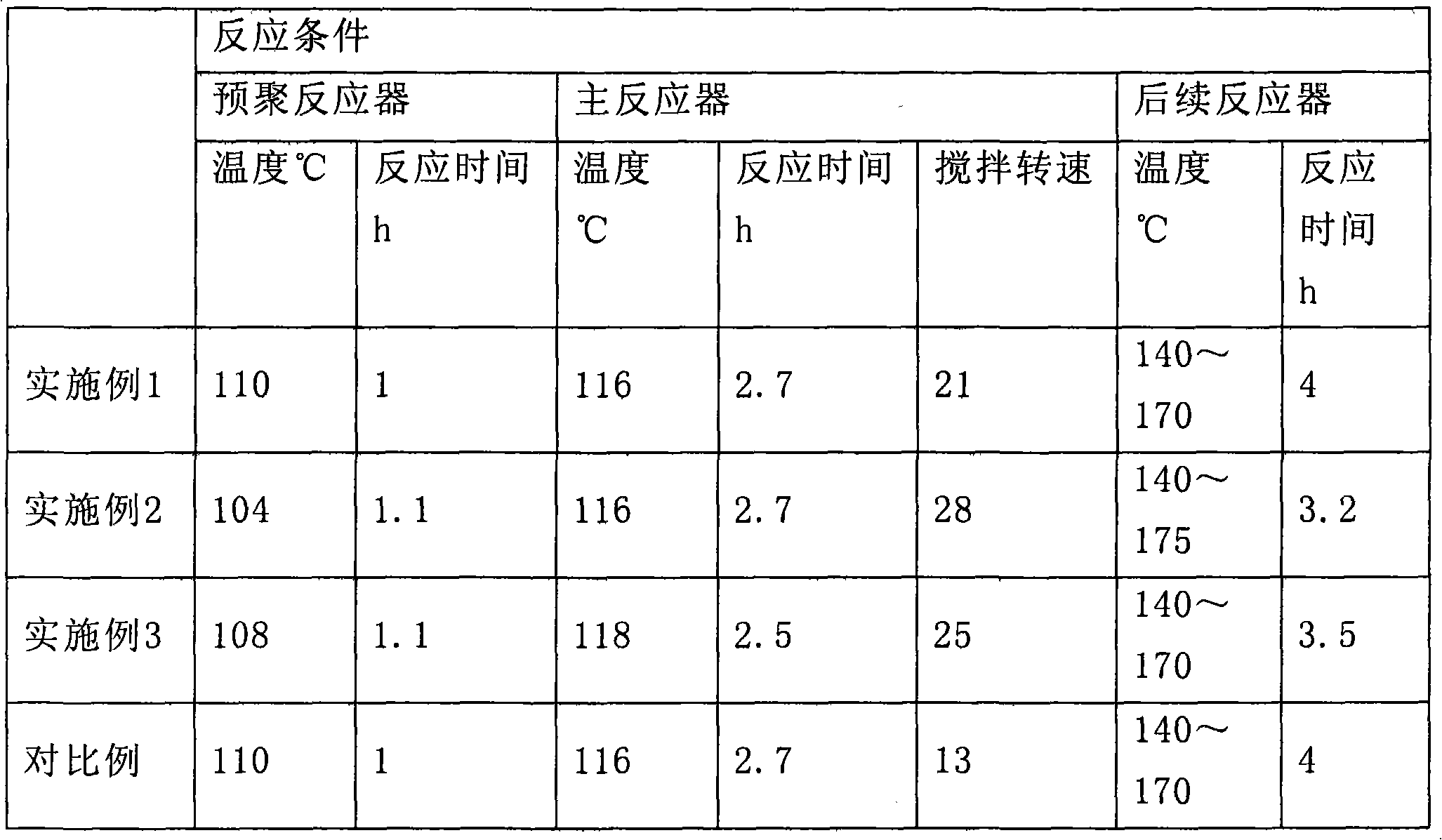

Embodiment 1

[0079] Example 1 Modification of high-cis polybutadiene rubber to produce high-impact polystyrene .

[0080] The proportioning ratio of prepolymerized feed is shown in Table 1 below:

[0081] The prepolymerization feed ratio of table 1 embodiment 1

[0082] material

parts by weight

other instructions

High cis polybutadiene rubber

7.5 parts by weight

The cis content is 96.5% by weight

82.5 parts by weight

9 parts by weight

1 part by weight

[0083] The rubber is fully dissolved in styrene, and the rubber solution is mixed with ethylbenzene, initiator, etc. according to a certain ratio to form the pre-polymerization feed, which is continuously fed into the pre-polymerization tank for pre-polymerization. The components are thoroughly mixed.

[0084] The prepolymerization tank is a continuous stirred tank reactor (CSTR), in which the reaction temperature is controll...

Embodiment 2

[0090] Example 2 Modified raw materials using a blend of low-cis polybutadiene rubber and high-cis polybutadiene rubber Produced in high impact polystyrene.

[0091] Adopt the method as embodiment 1 to prepare high-impact high-gloss polystyrene material, the difference is that the formula is as follows in Table 2 and the process conditions are according to Table 4:

[0092] The prepolymerized feed ratio of table 2 embodiment 2

[0093] material

[0094] Adjust the composition ratio of the materials entering the prepolymerization tank (and adjust according to the reaction conditions in Table 4), carry out prepolymerization in the prepolymerization tank to reach a certain conversion rate (measured as 9%), enter the main reactor, and carry out at 116 ° C. Reaction, the residence time is controlled to be 2.7h, so that styrene and rubber undergo grafting reaction, and a phase transition occurs, and the stirring speed is controlled at 28 rpm, so that the distribution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com