Pipe type fluid turbulence device capable of strengthening mass and heat transfer and operation method thereof

A fluid disturbance and fluid technology, used in heat transfer modification, heat exchange equipment, heat exchanger shells, etc., can solve the problems of large energy consumption and small injection disturbance operation flexibility, achieve low energy consumption, improve production conditions, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

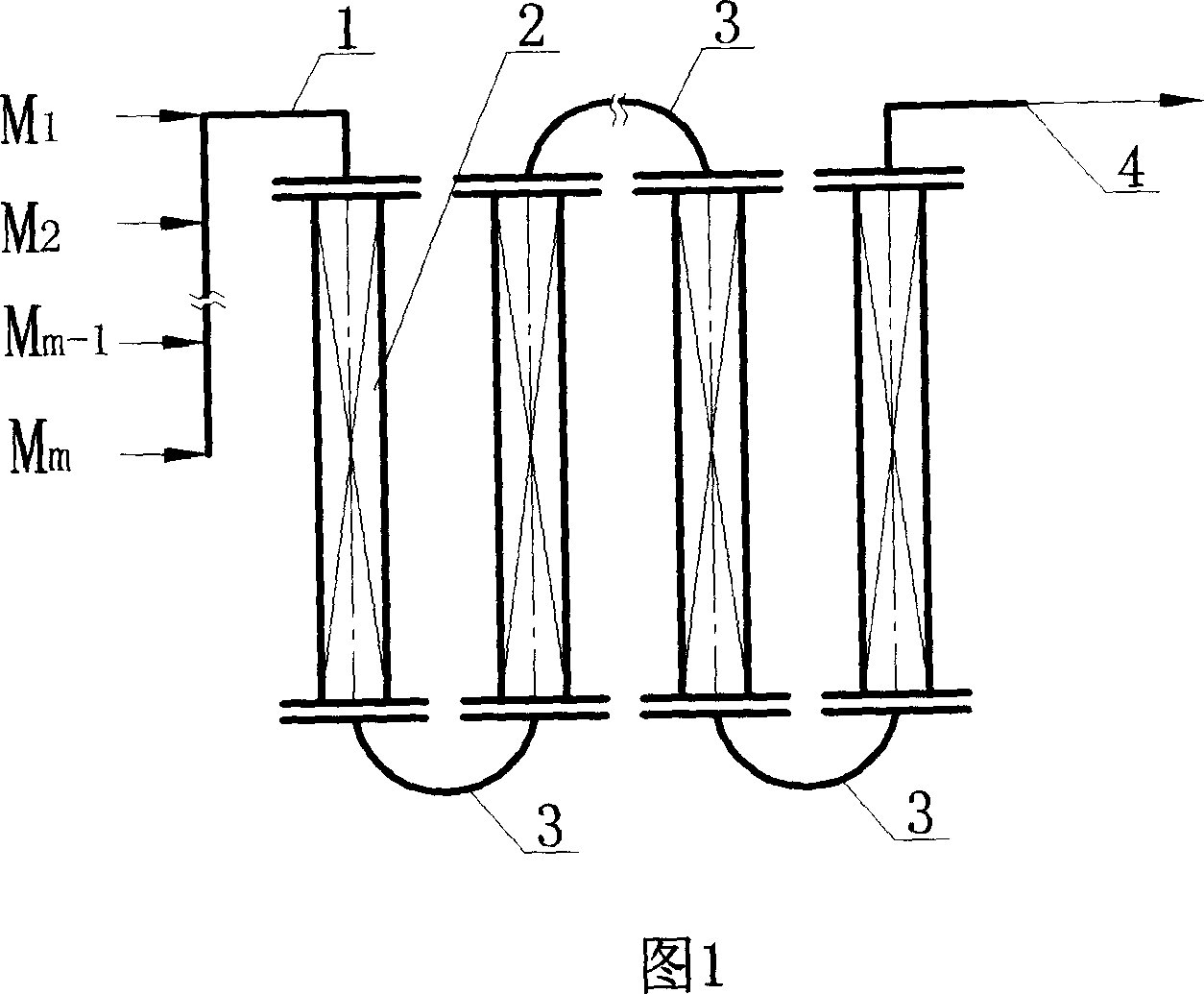

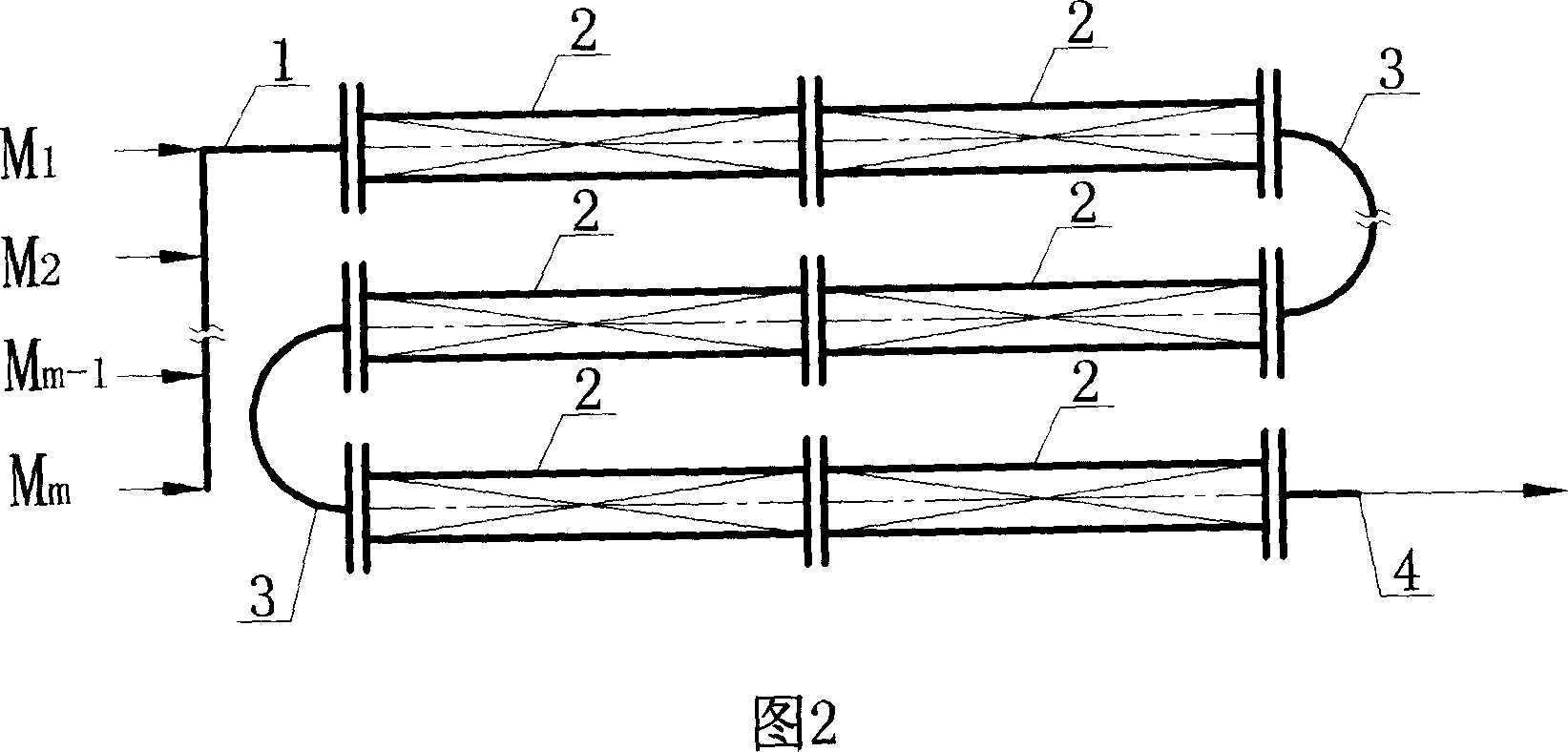

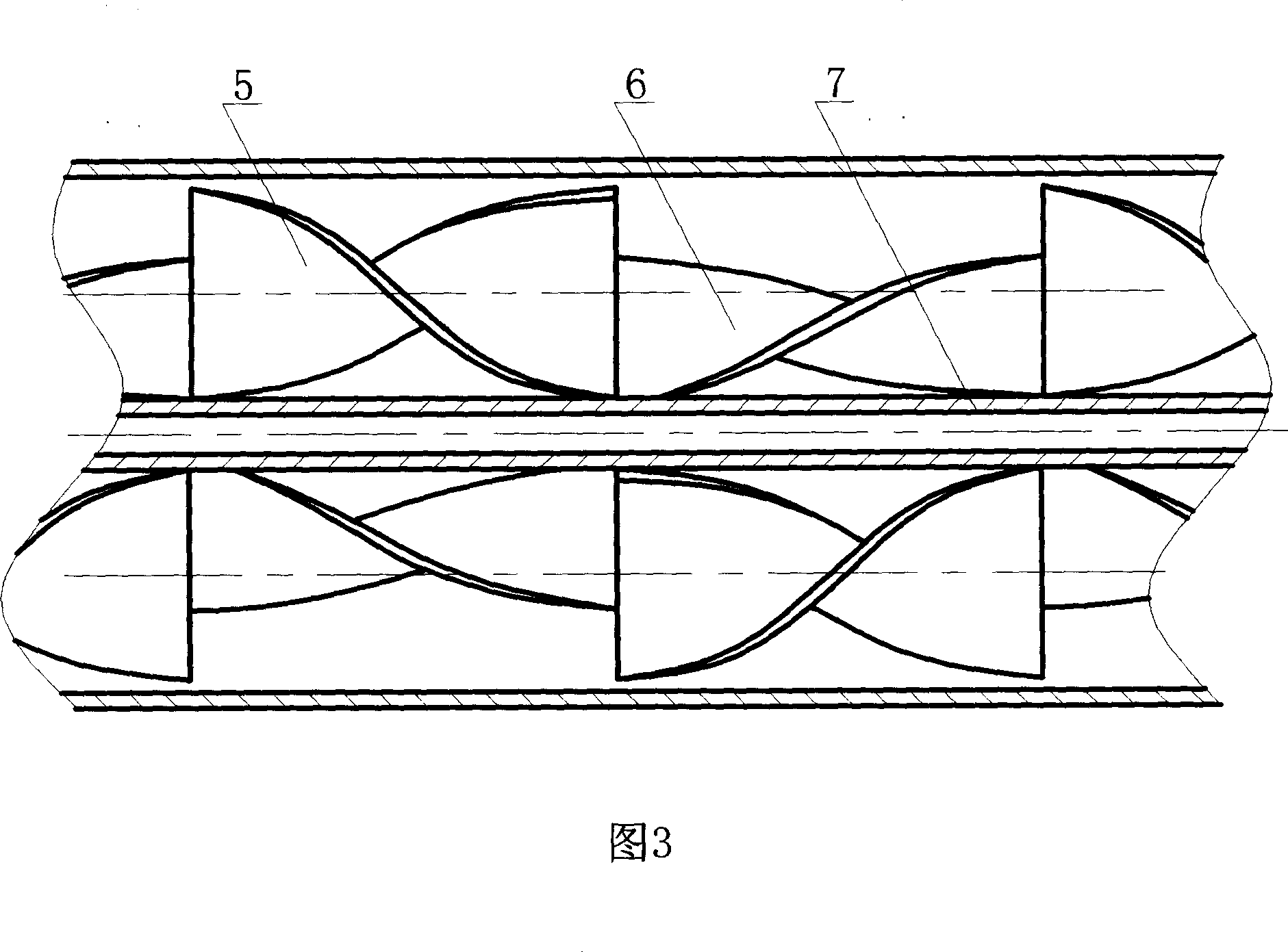

[0030] Tubular fluid disturbance device, including a fluid input pipeline 1 with three fluid inlets, four fluid disturbance pipes 2, three connecting pipes 3, a fluid outlet pipeline 4, and a core pipe 7, three fluids are input through the fluid The pipeline 1 enters the fluid spoiler tube 2, and each fluid spoiler tube 2 has a length of 3m and a nominal diameter of 200mm, and a core tube 7 with a nominal diameter of 25mm inside. The included angle between the spoilers is α=120°, two adjacent sets of spoilers are staggered by β=60°, the width of the spoilers is 80mm, and the length is 100mm.

[0031] Specific installation method:

[0032] The fluid input pipeline 1 with three fluid inlets and the inlet end of the fluid spoiler pipe 2 are connected by flanges; the four-section fluid spoiler pipe 2 and the three-section connecting pipe 3 are connected vertically by flanges; Core tube 7; spoilers 5 and 6 are fixed on the core tube 7, and the spoiler groups are connected end-to-e...

Embodiment 2

[0034] The second embodiment is basically the same as the first embodiment, except that the fluid input line 1 has two fluid inlets, and the device performs disturbance operation on the two fluids.

Embodiment 3

[0036] Embodiment three is basically the same as embodiment one, except that the spoilers 5 or 6 arranged inside the fluid spoiler tube 2 are 4 pieces in each group, and the included angle α=90° between the same group of spoilers, adjacent The two groups of spoilers are arranged with a staggered β=45°. A jacket is arranged outside the fluid spoiler tube, and no spoiler element is set between the spoiler tube 2 and the jacket tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com