Patents

Literature

34 results about "Tubular fluid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tubular fluid is the fluid in the tubules of the kidney. It starts as a renal ultrafiltrate in the glomerulus, changes composition through the nephron, and ends up as urine leaving through the ureters.

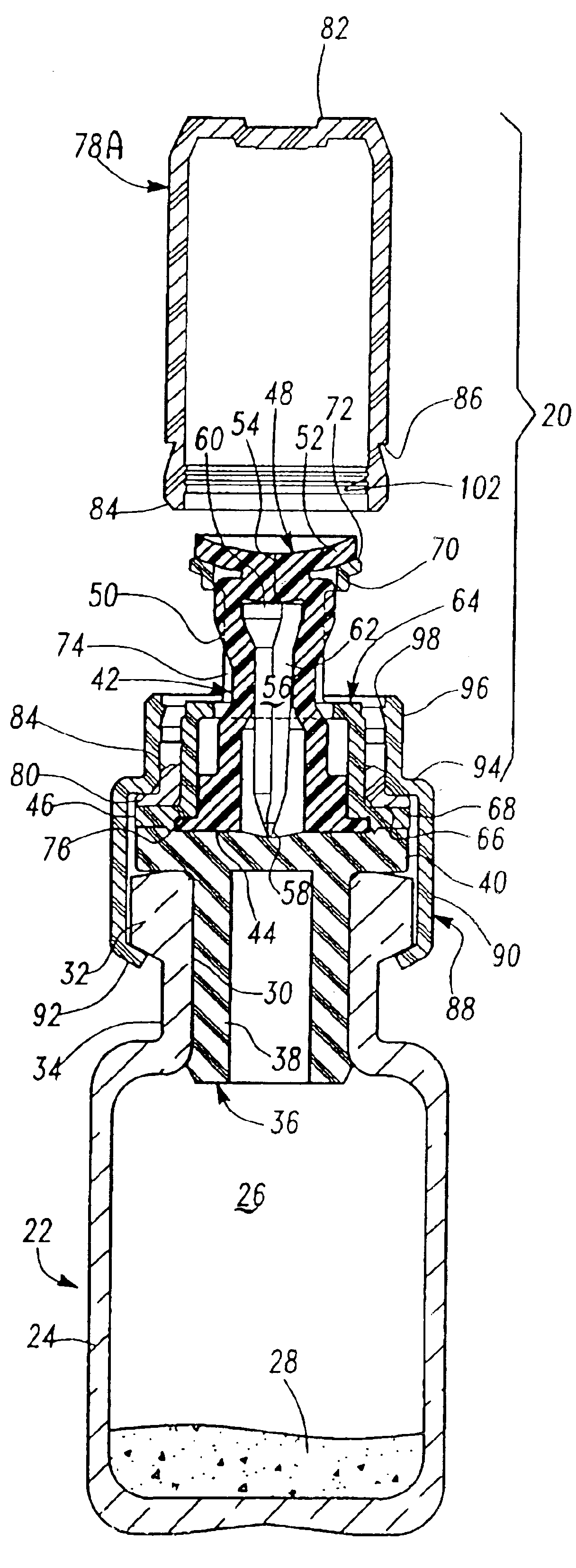

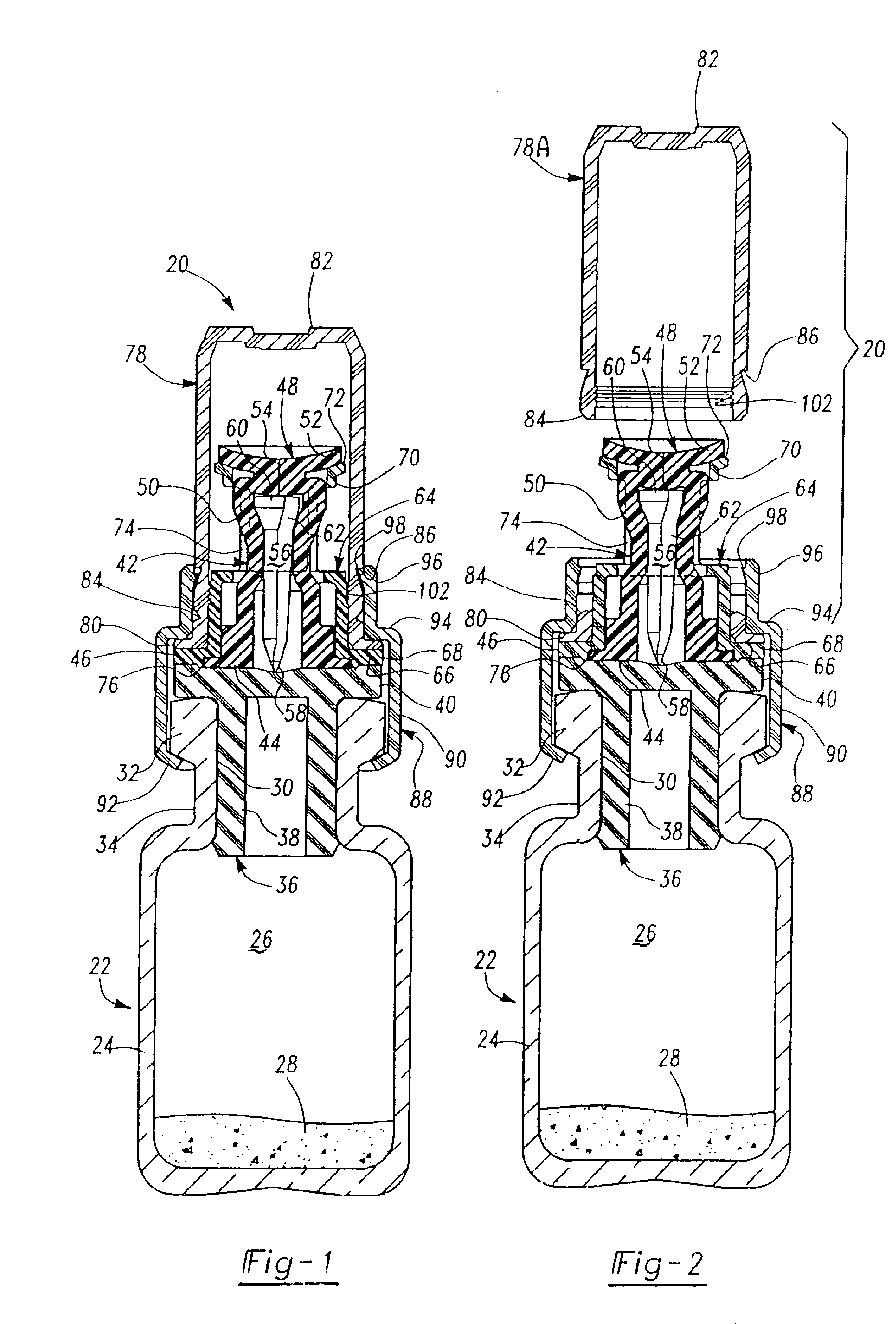

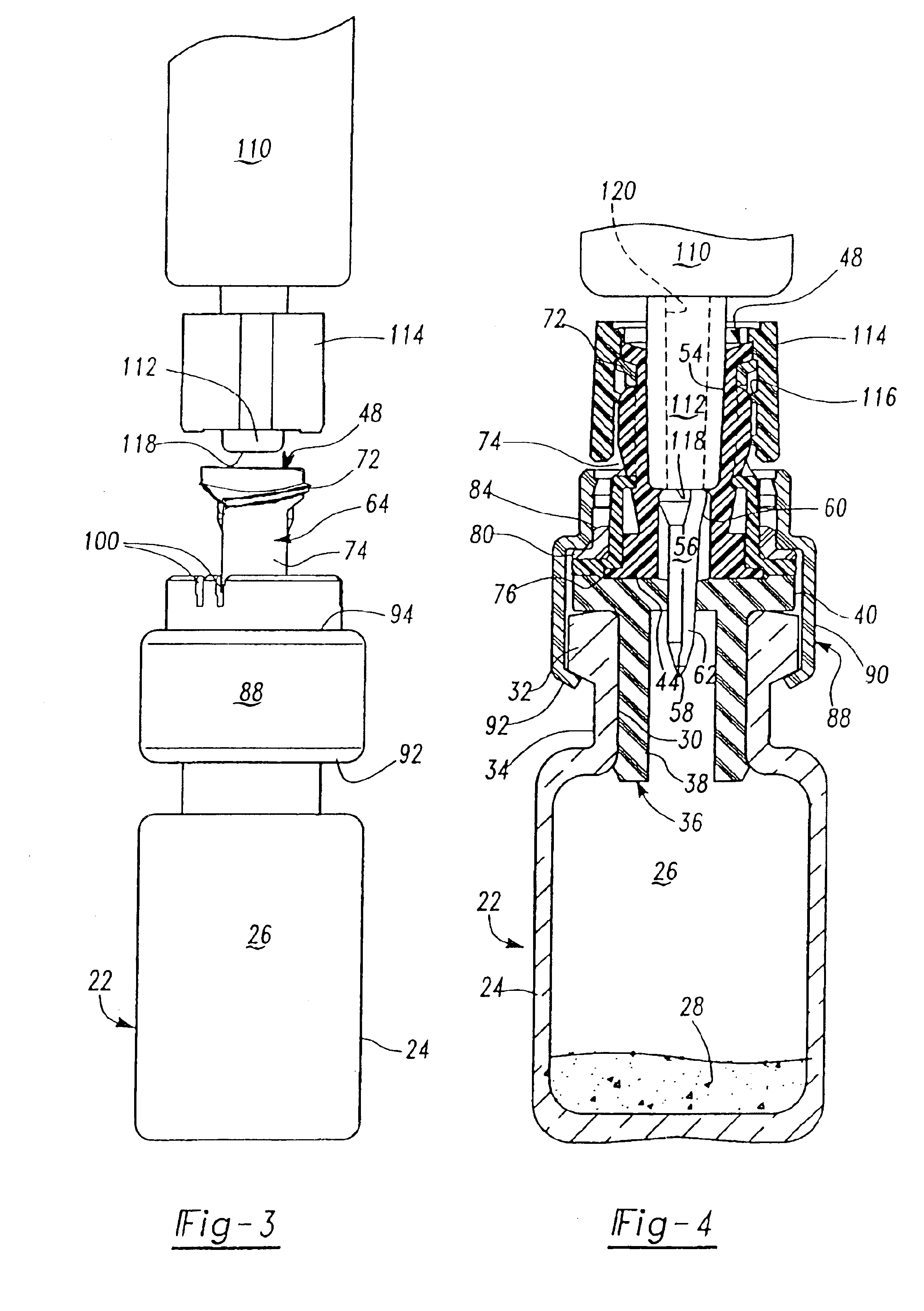

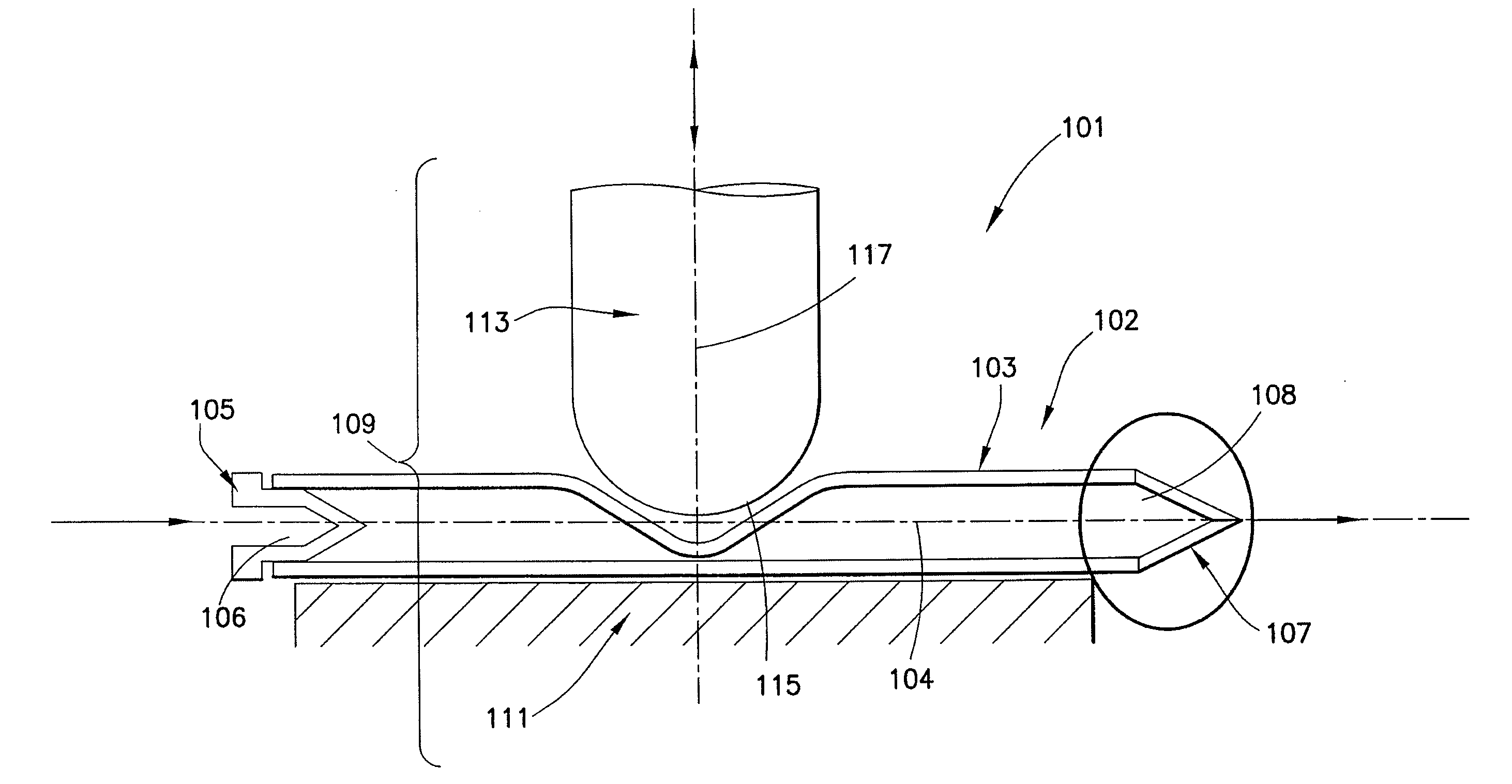

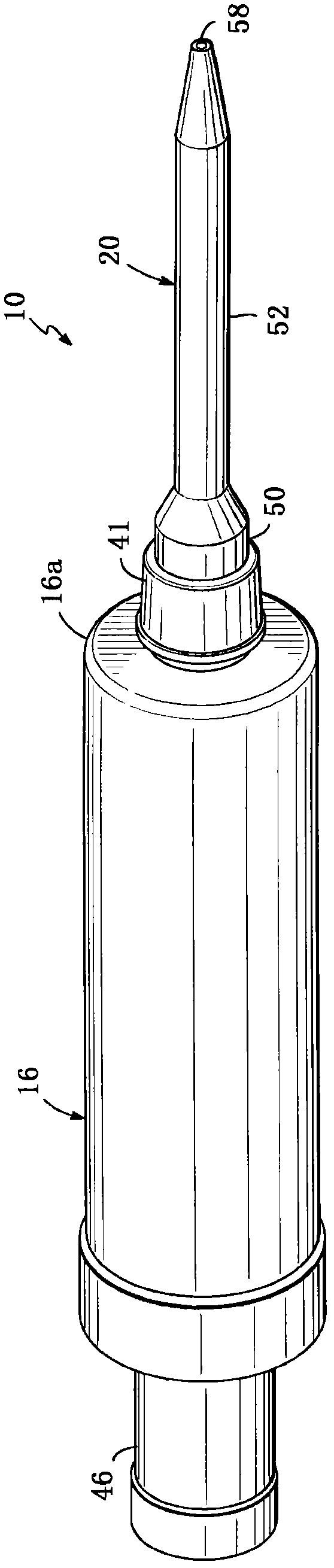

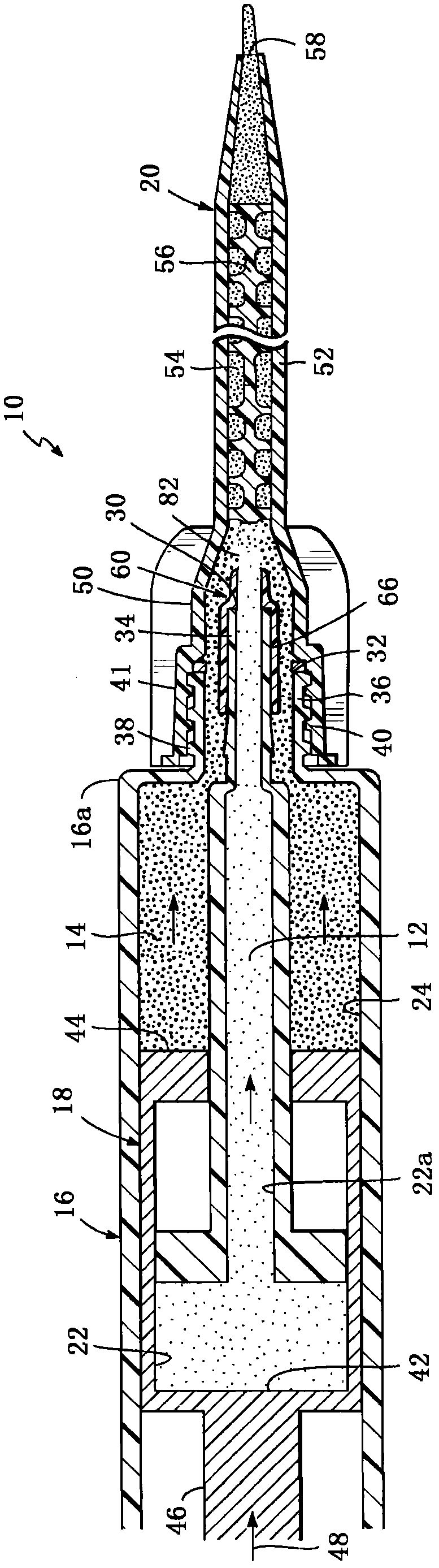

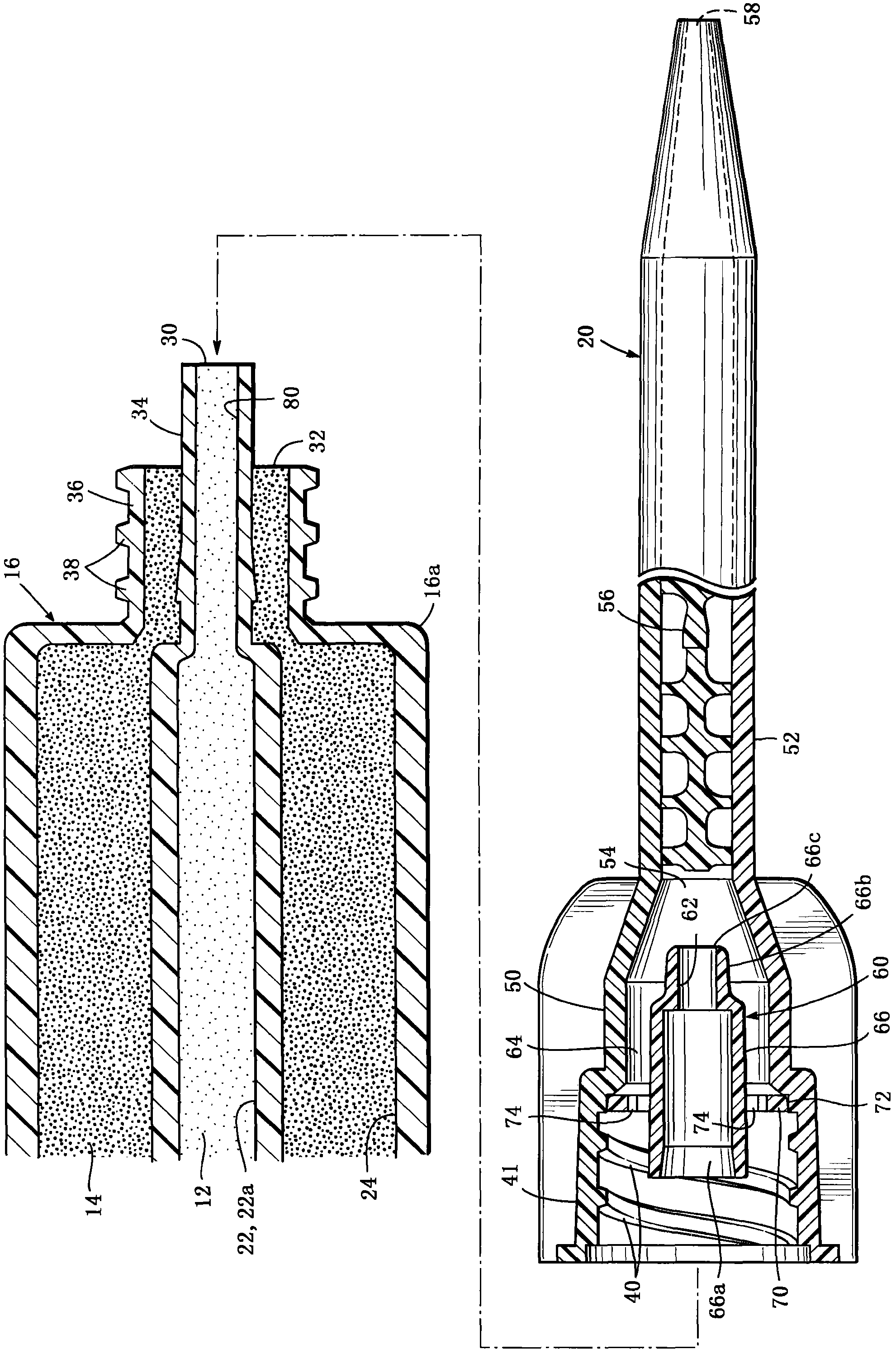

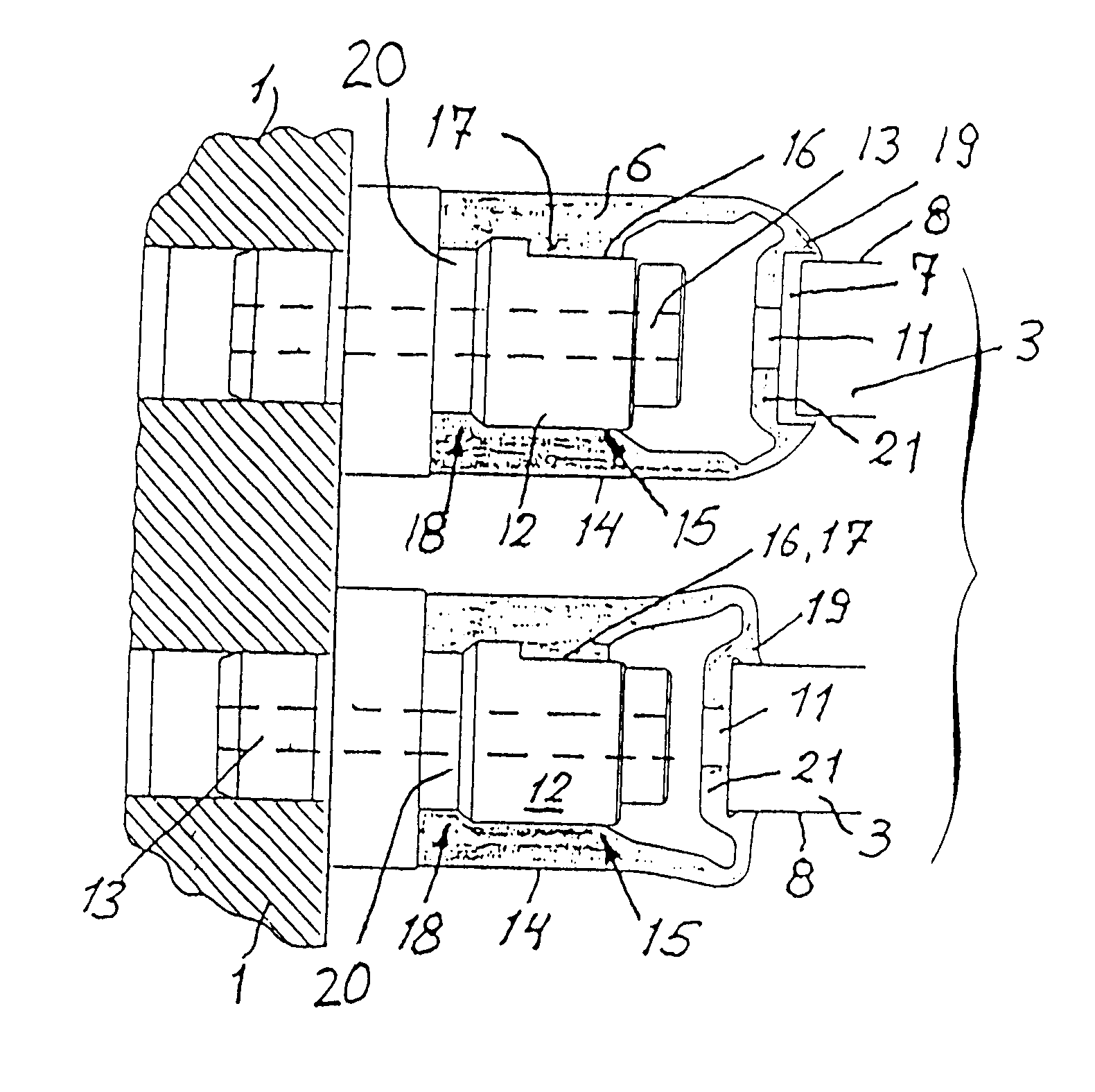

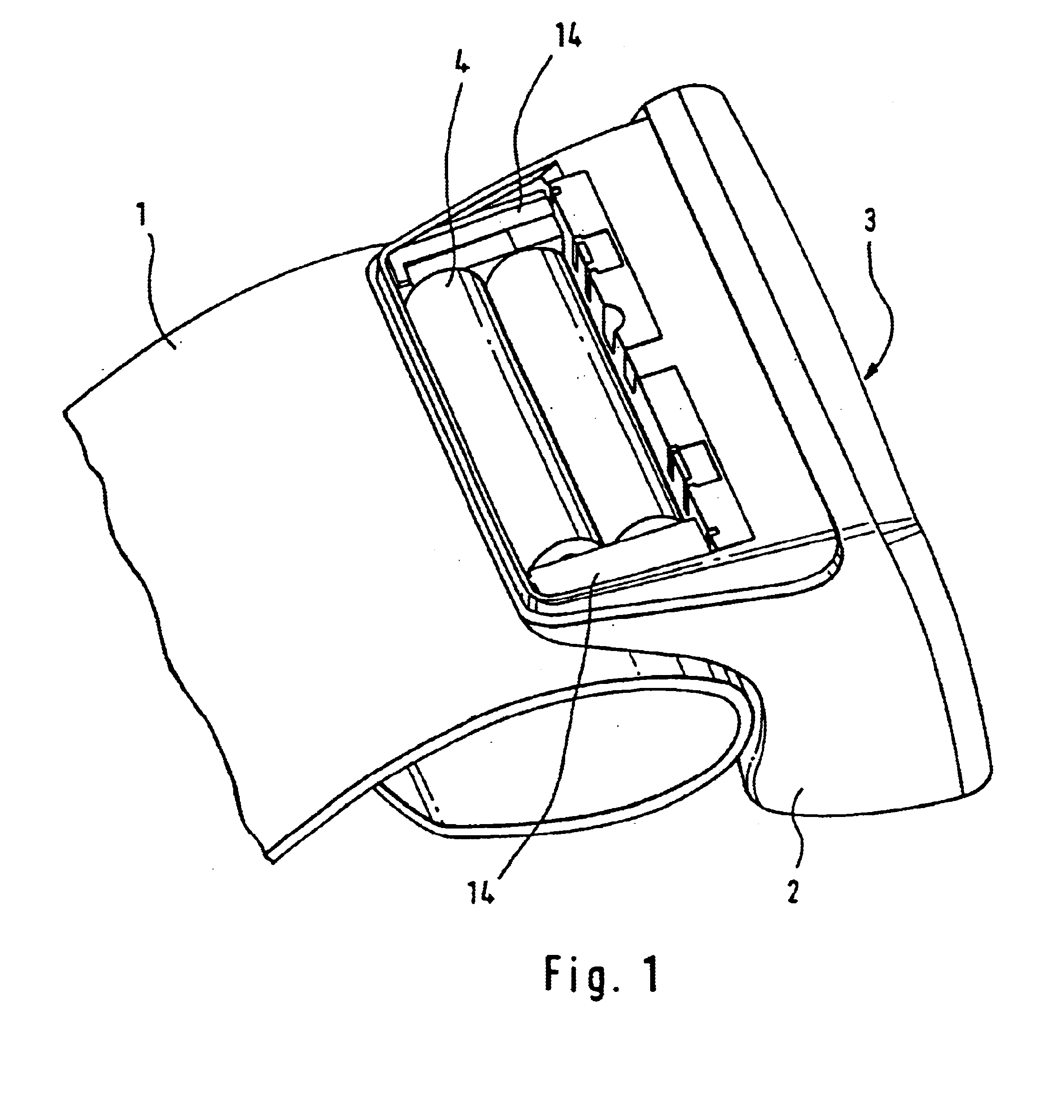

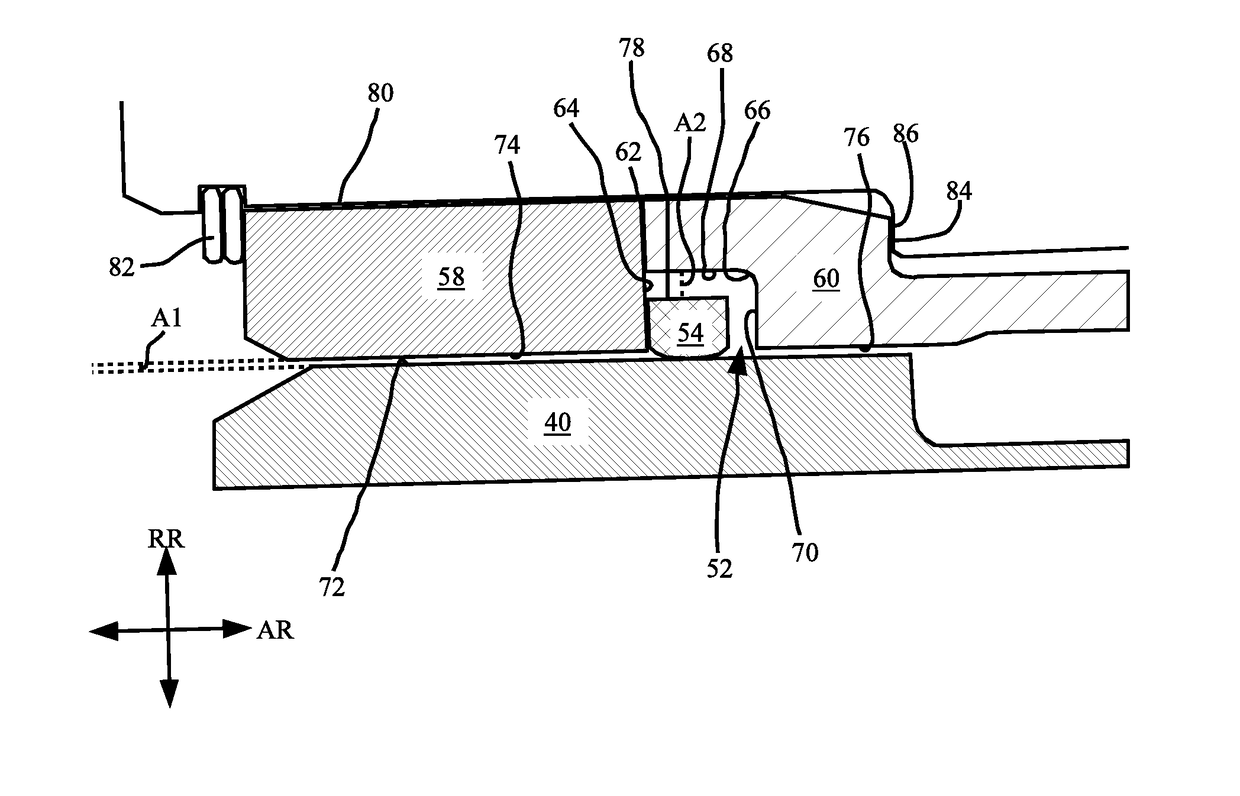

Resealable medical transfer set

InactiveUS6945417B2Simple designReduce manufacturing costCapsDiagnosticsElastomerBiomedical engineering

A transfer set for transferring fluid, including drugs, vaccines, medicaments, solutions and the like, between a first container, such as a conventional vial, and a second container, such as a conventional syringe having a unique multipurpose resealable member. The transfer set assembly includes an elastomeric tubular fluid transfer and resealable valve member preferably including an open end mounted on the pierceable closure or stopper of a vial and a generally closed distal end having a longitudinal slit and a piercing member is telescopically received within the fluid transfer valve member having a piercing end opposite the pierceable closure. The fluid transfer valve member is preferably formed of silicone and is surrounded by a generally tubular luer connector member having an open end mounted on the pierceable closure and a distal end having male luer threads. This assembly is enclosed within a cup-shaped closure and the assembly is retained to the first container or vial by a collar preferably secured to the vial by crimping. Upon removal of the cup-shaped closure, fluid communication between the vial and a second container, such as a syringe, is achieved by threading the luer connector of the syringe on the luer threads of the tubular luer connector member, which drives the tip through the slit of the elastomeric fluid transfer valve member against the distal end of the piercing member, driving the piercing end through the pierceable closure. In the preferred embodiment, the piercing member includes a generally longitudinal channel which establishes communication between the vial and the syringe through the tubular fluid transfer valve member.

Owner:BECTON DICKINSON & CO

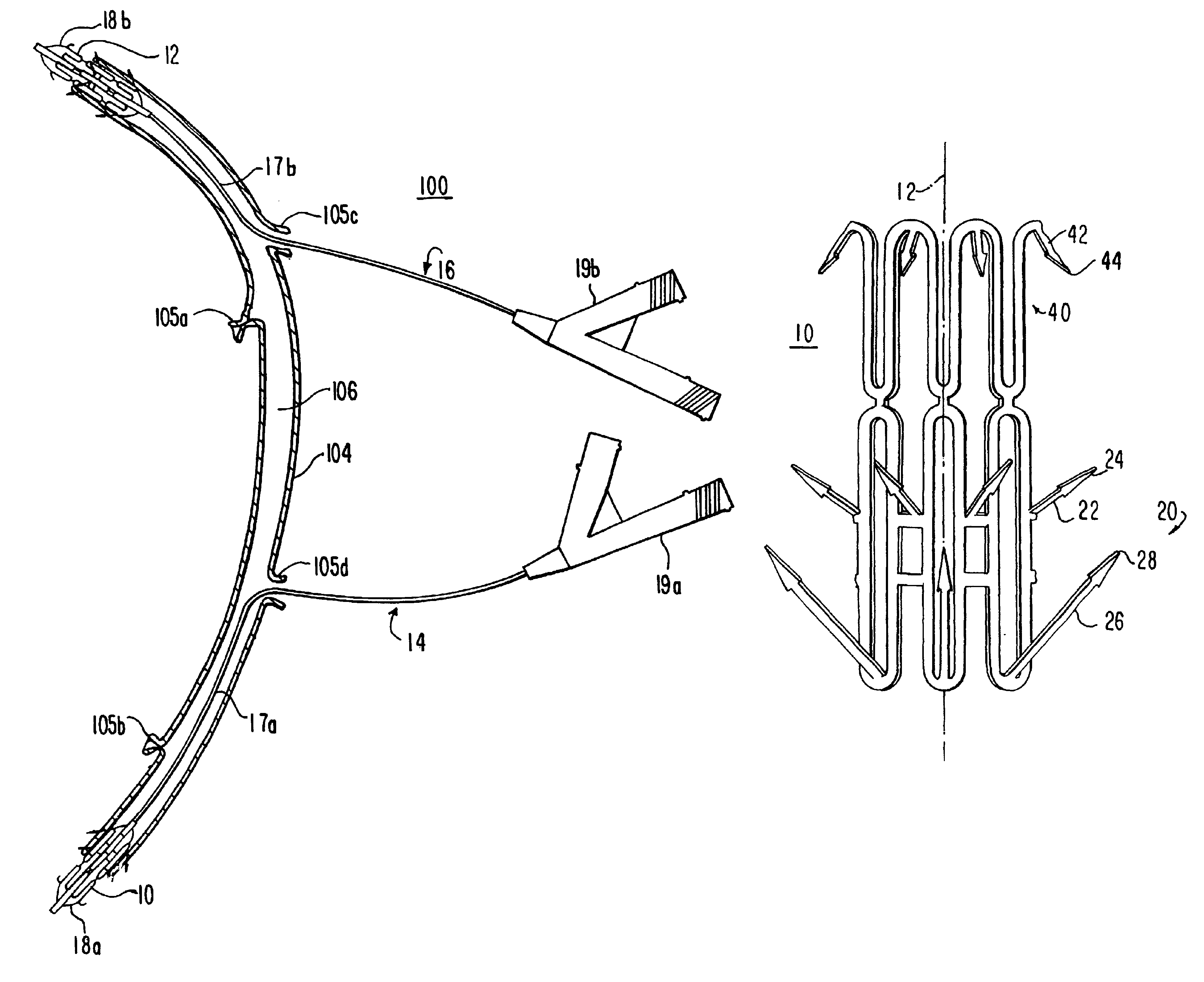

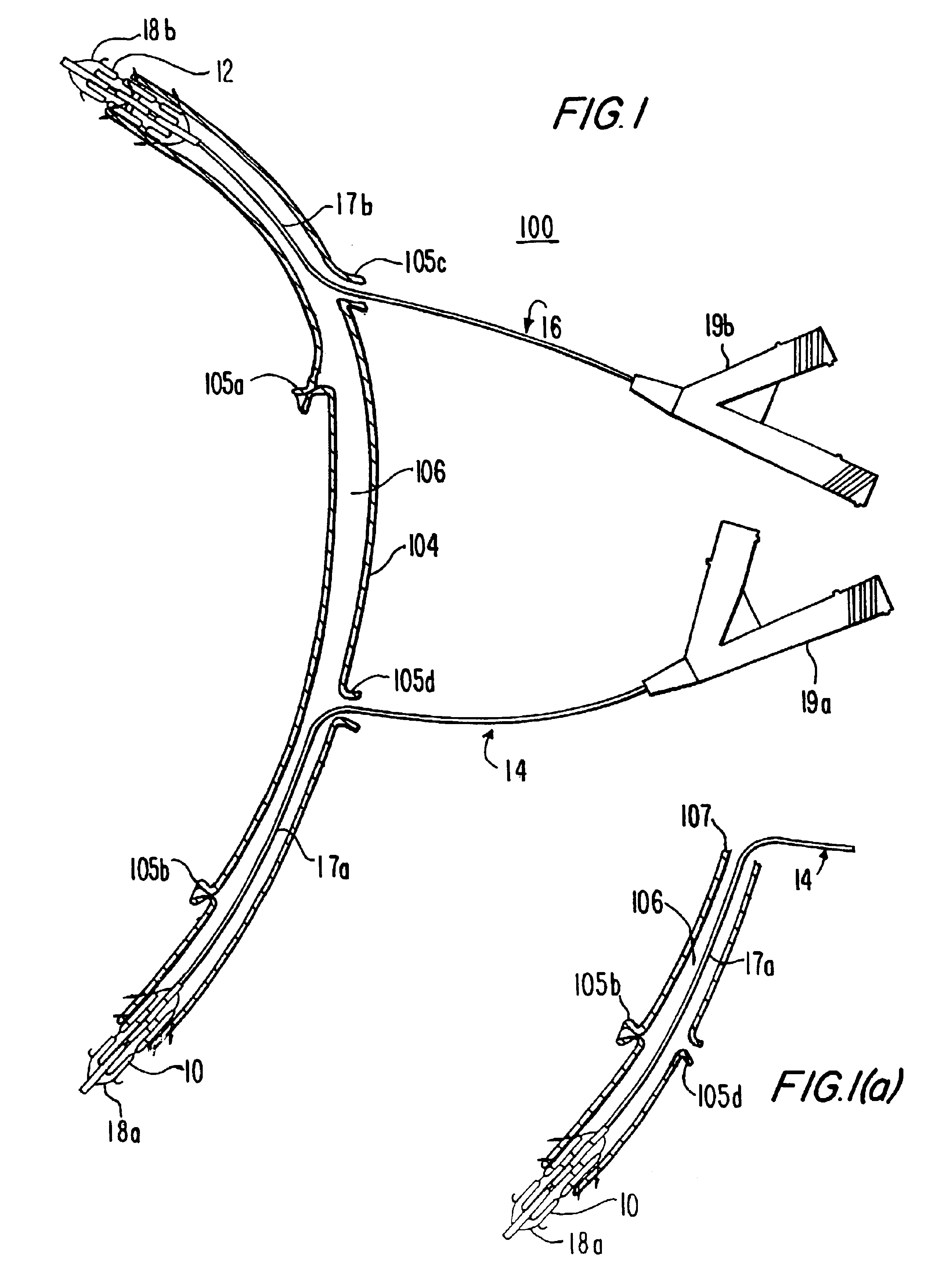

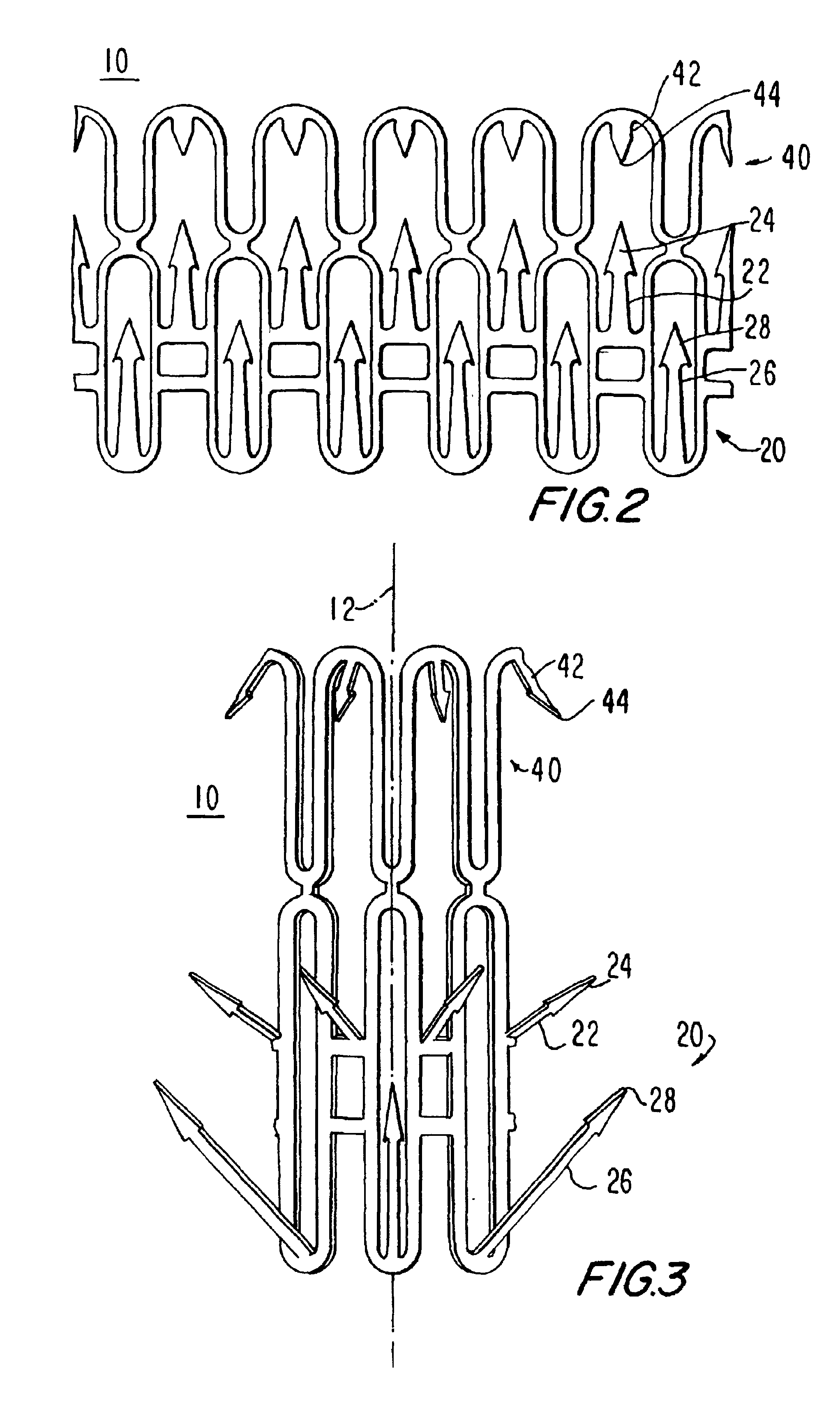

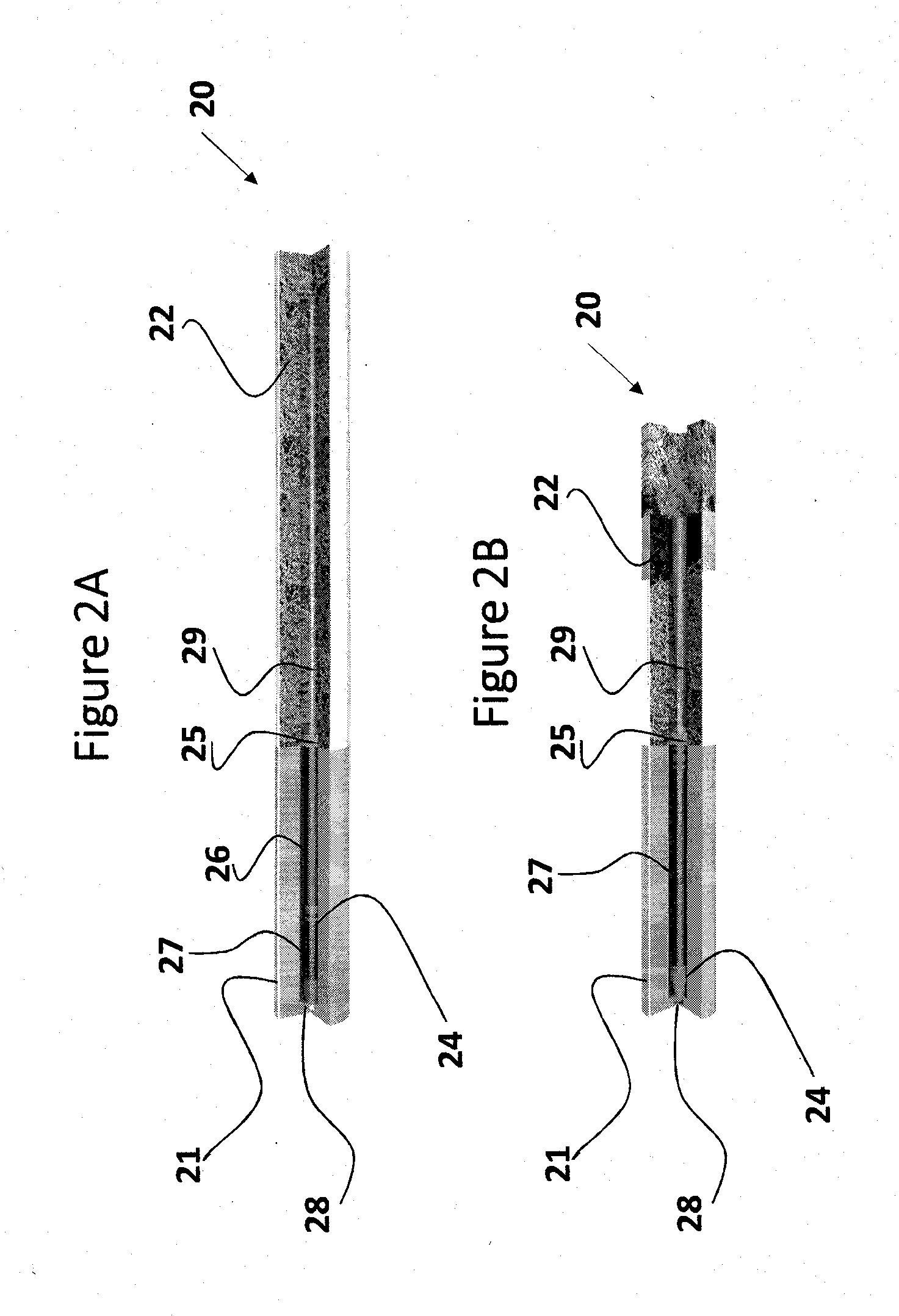

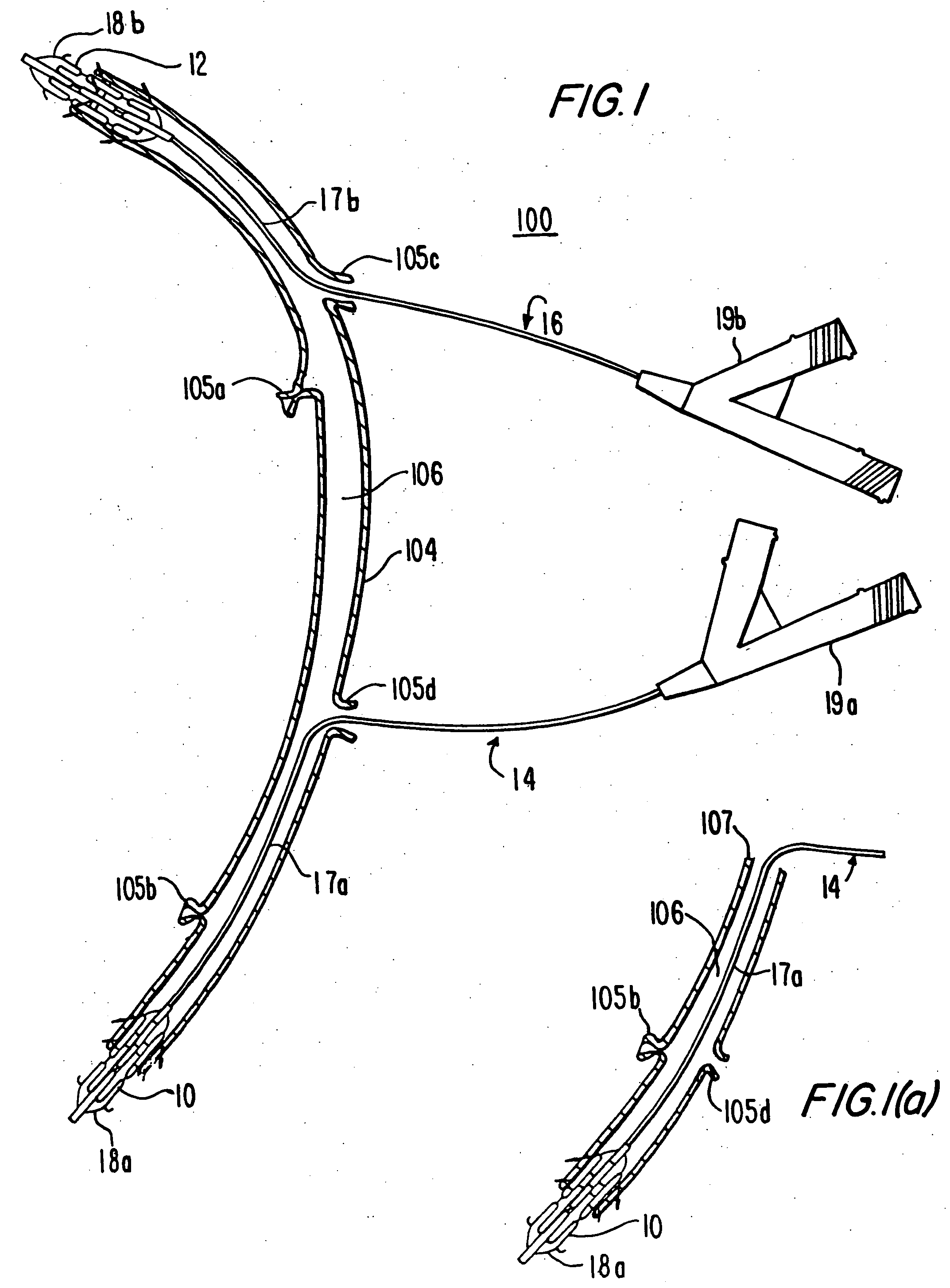

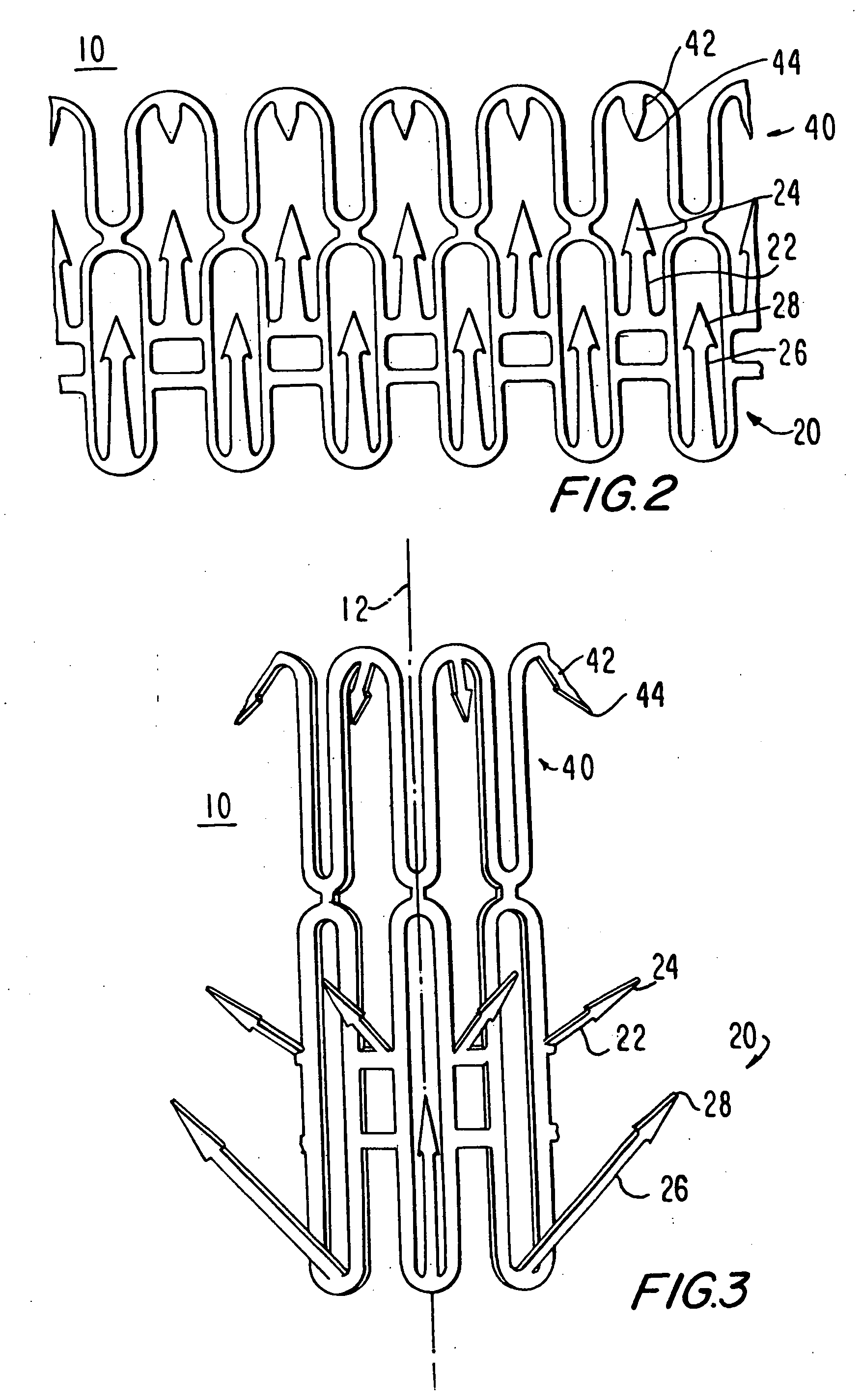

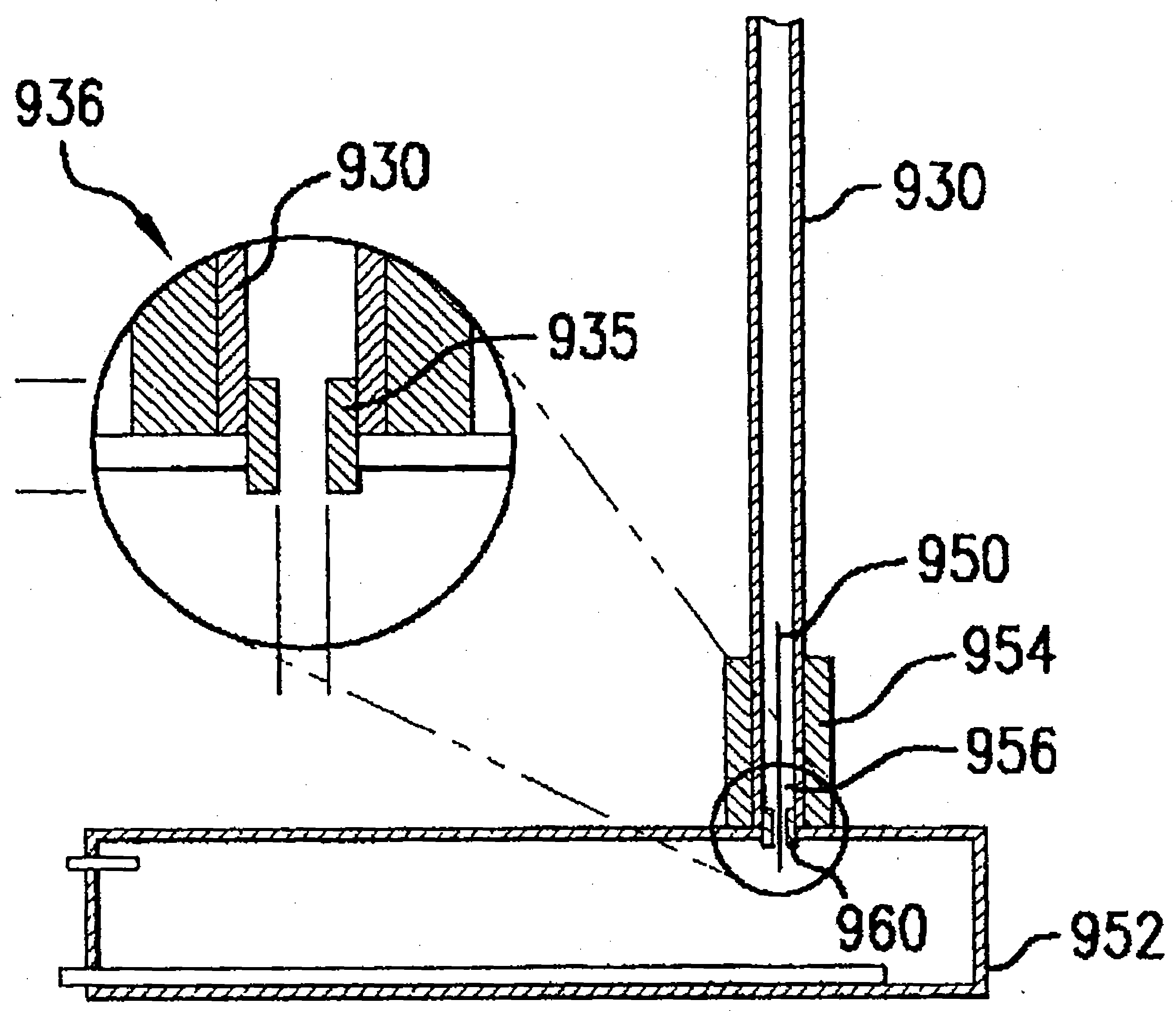

Medical grafting methods and apparatus

Methods and apparatus for making an anastomotic connection between first and second tubular fluid conduits are provided. For example, a connector may be configured for attachment to the first and second tubular fluid conduits and have an interior thereof substantially accessible to the interior of the first tubular fluid conduit. The connector may be configured for annular enlargement. An expandable structure is provided having a first portion configured to annularly enlarge the connector by engaging the interior of the connector. A second portion may be configured to extend through an opening in the medial portion of the first tubular fluid conduit.

Owner:ST JUDE MEDICAL ATG

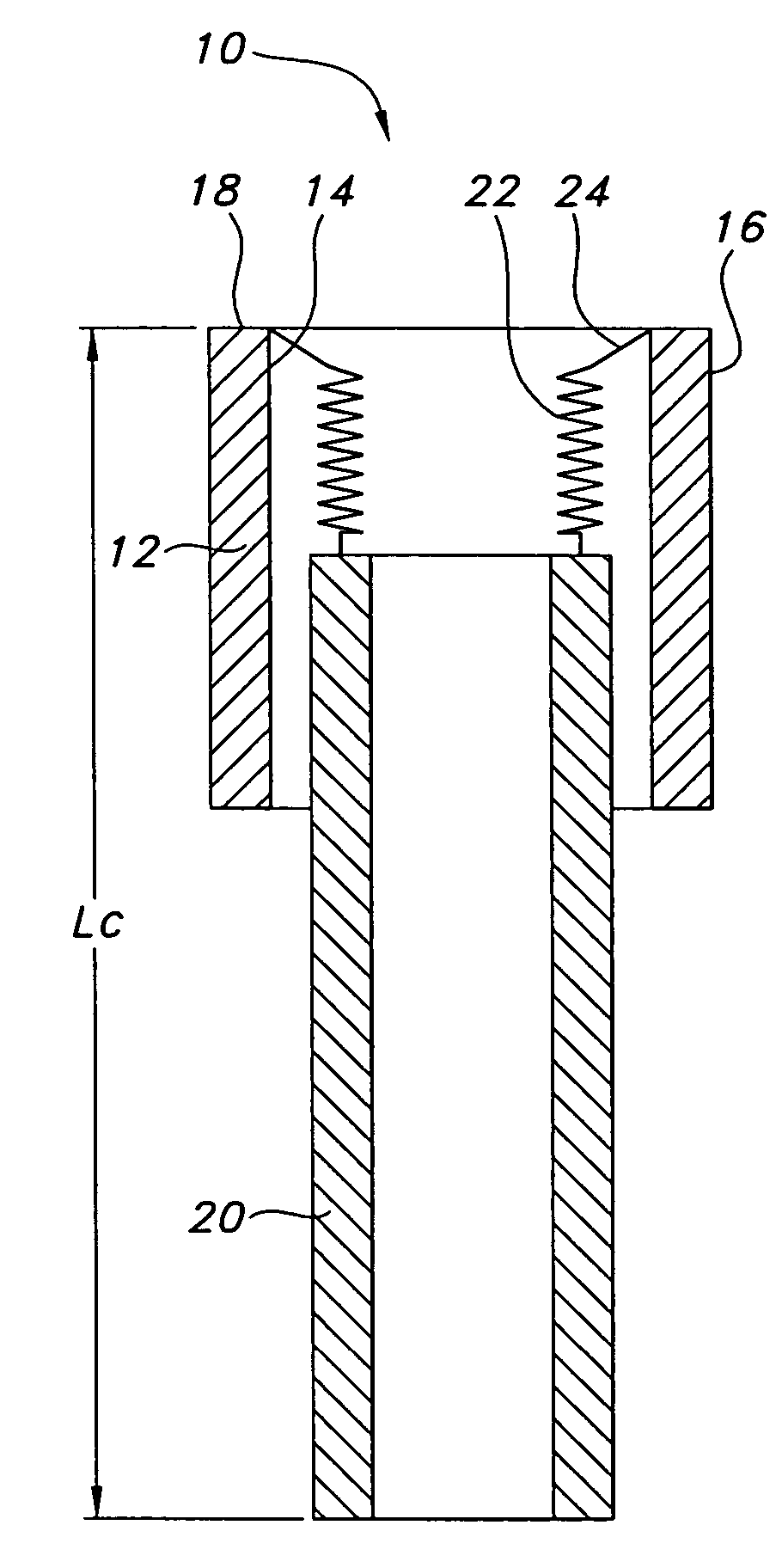

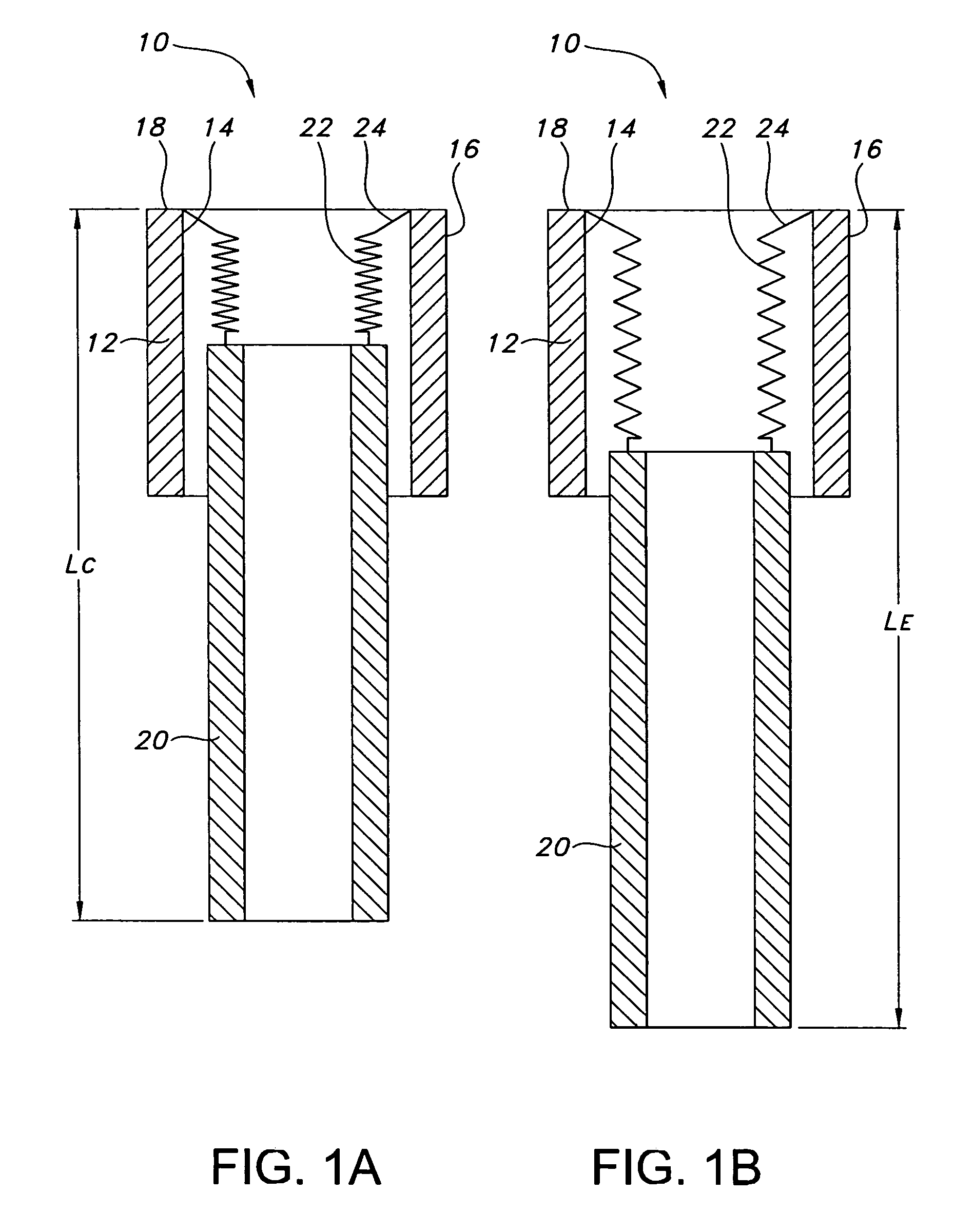

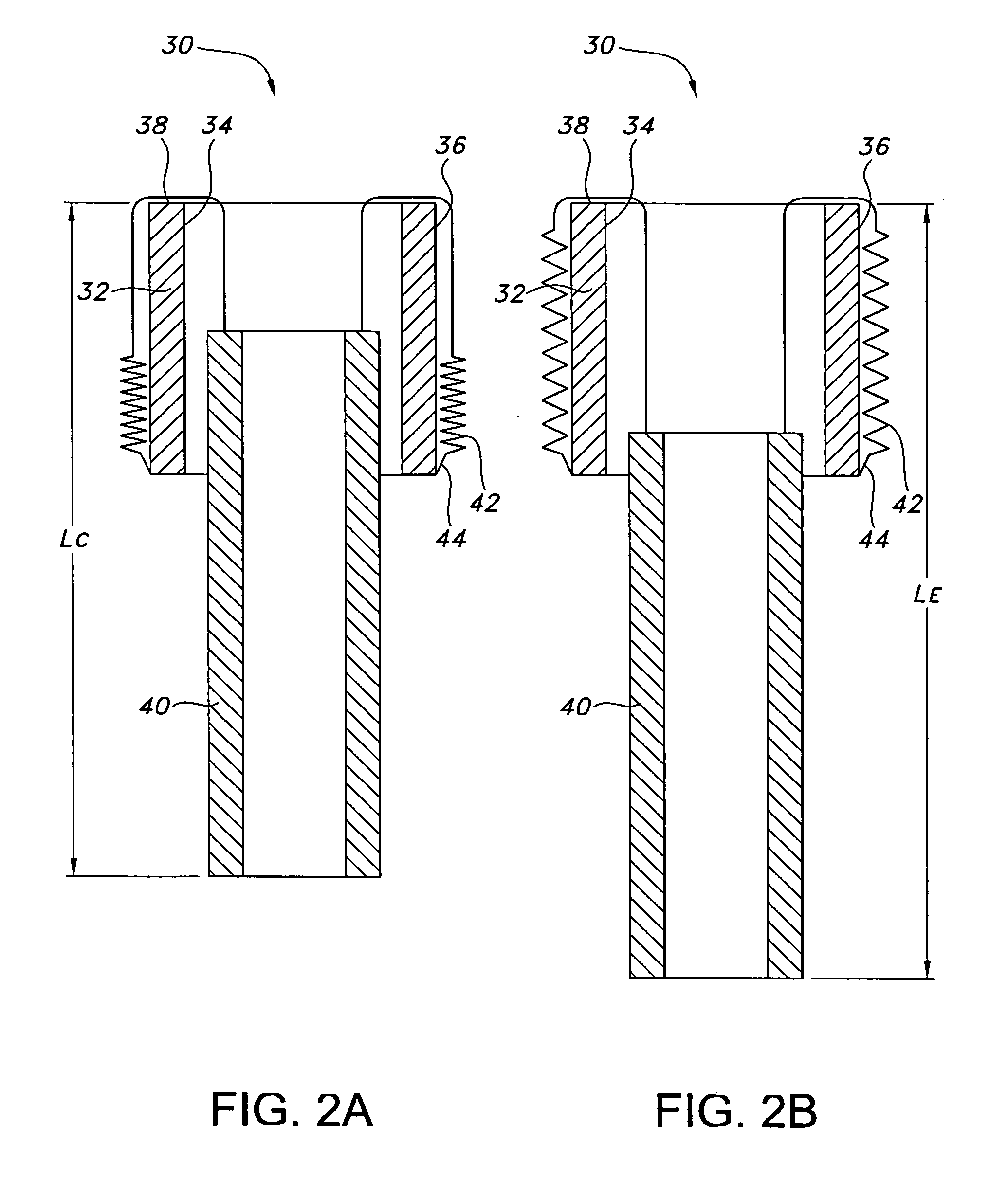

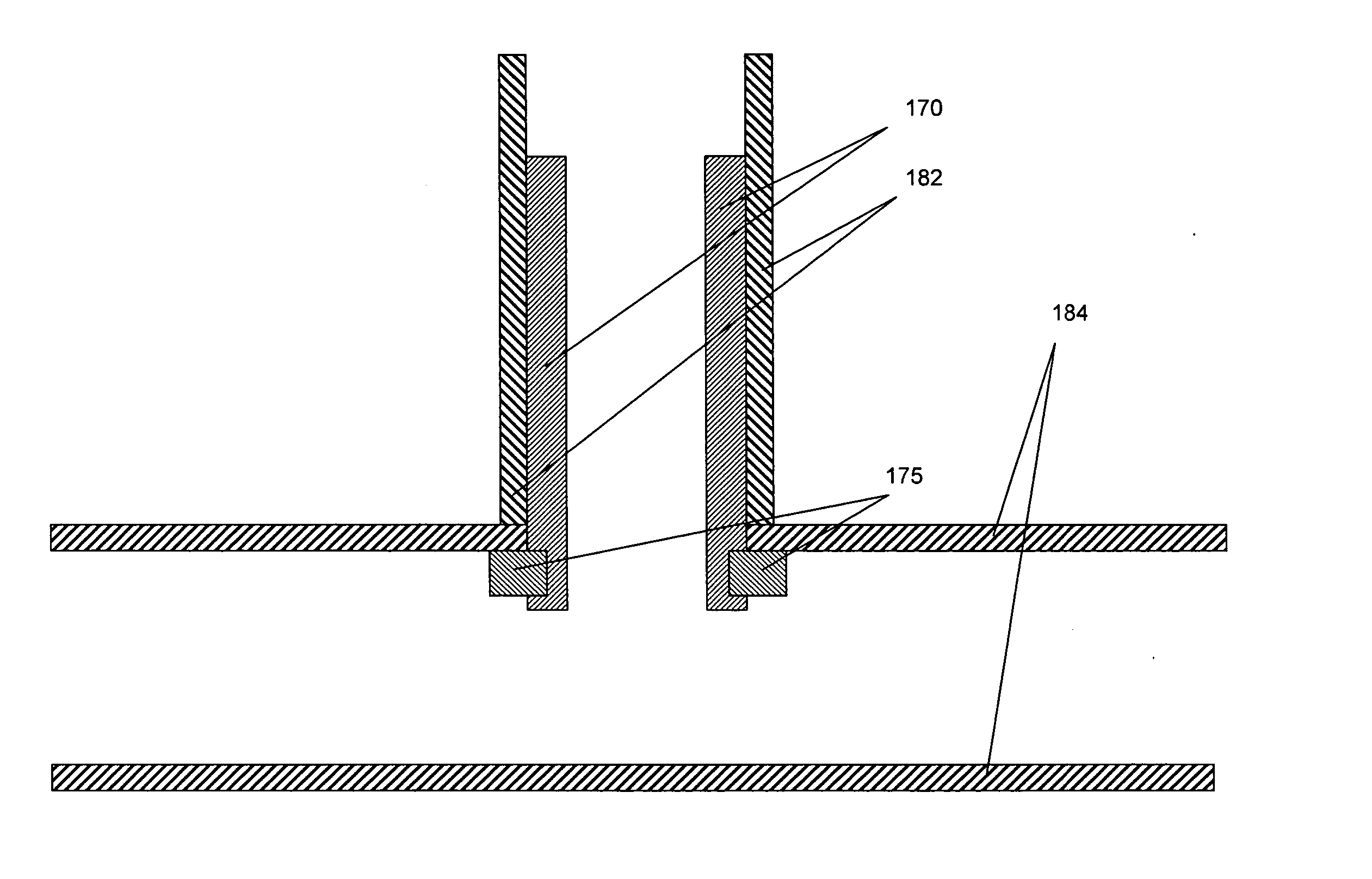

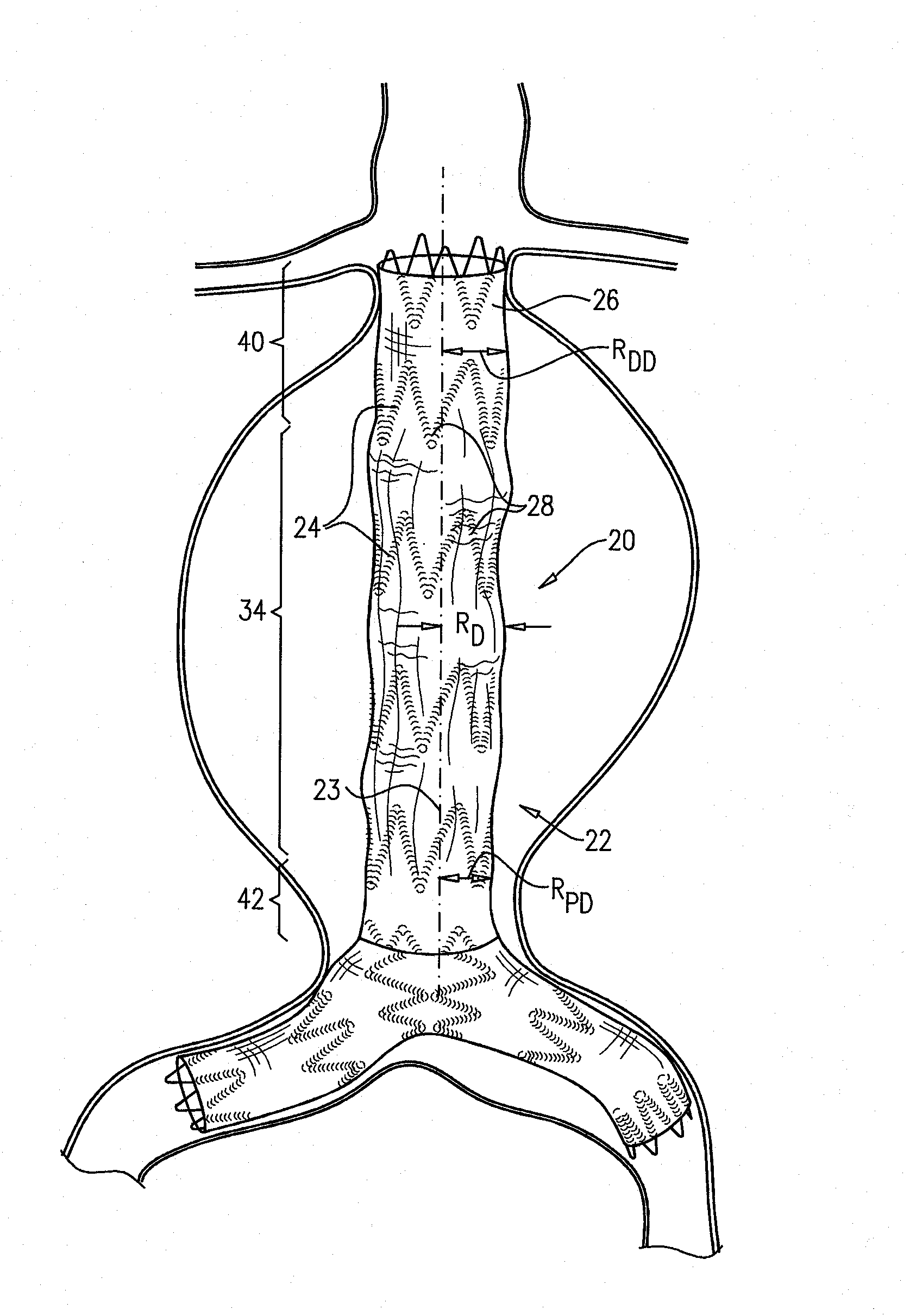

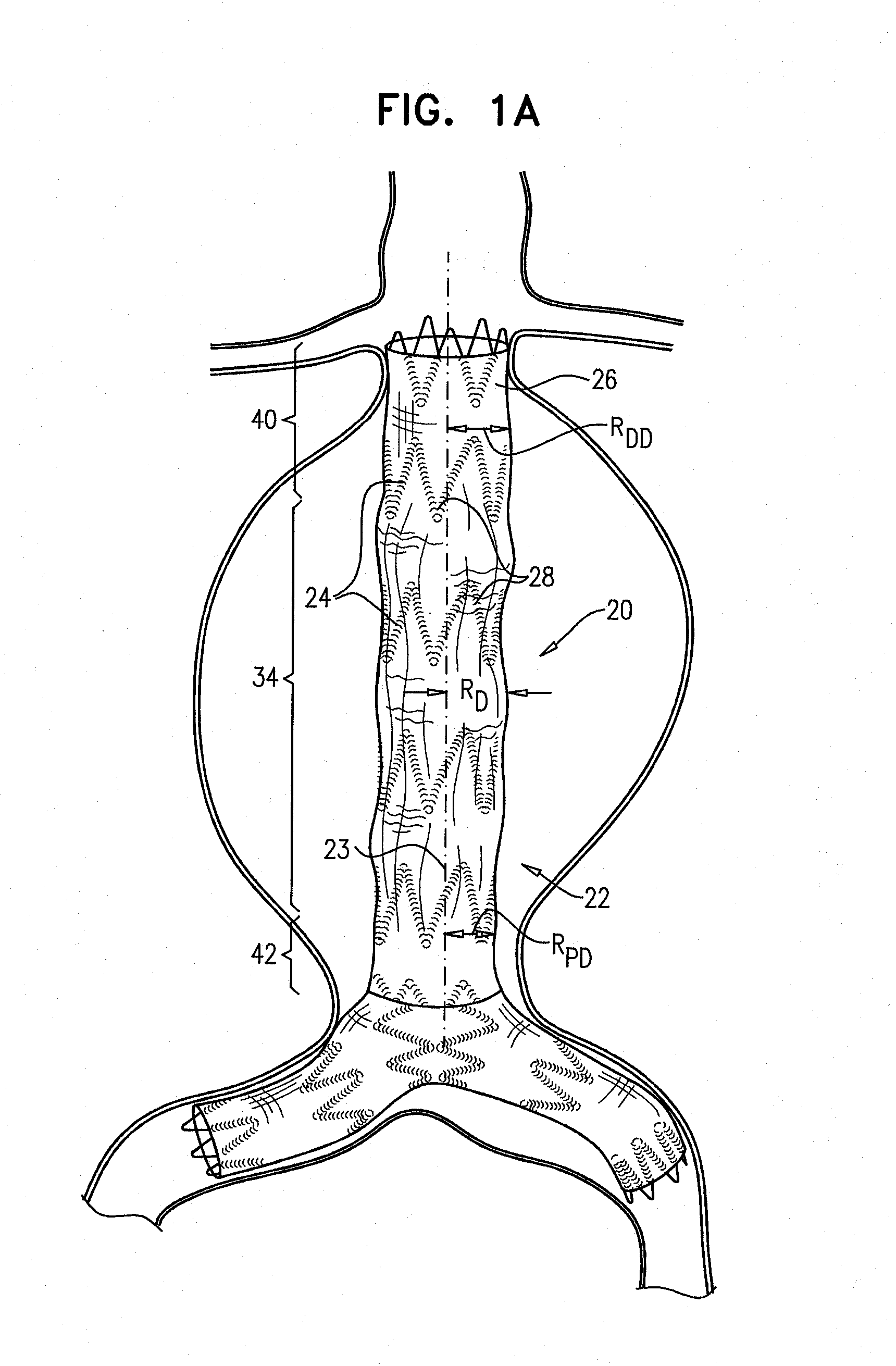

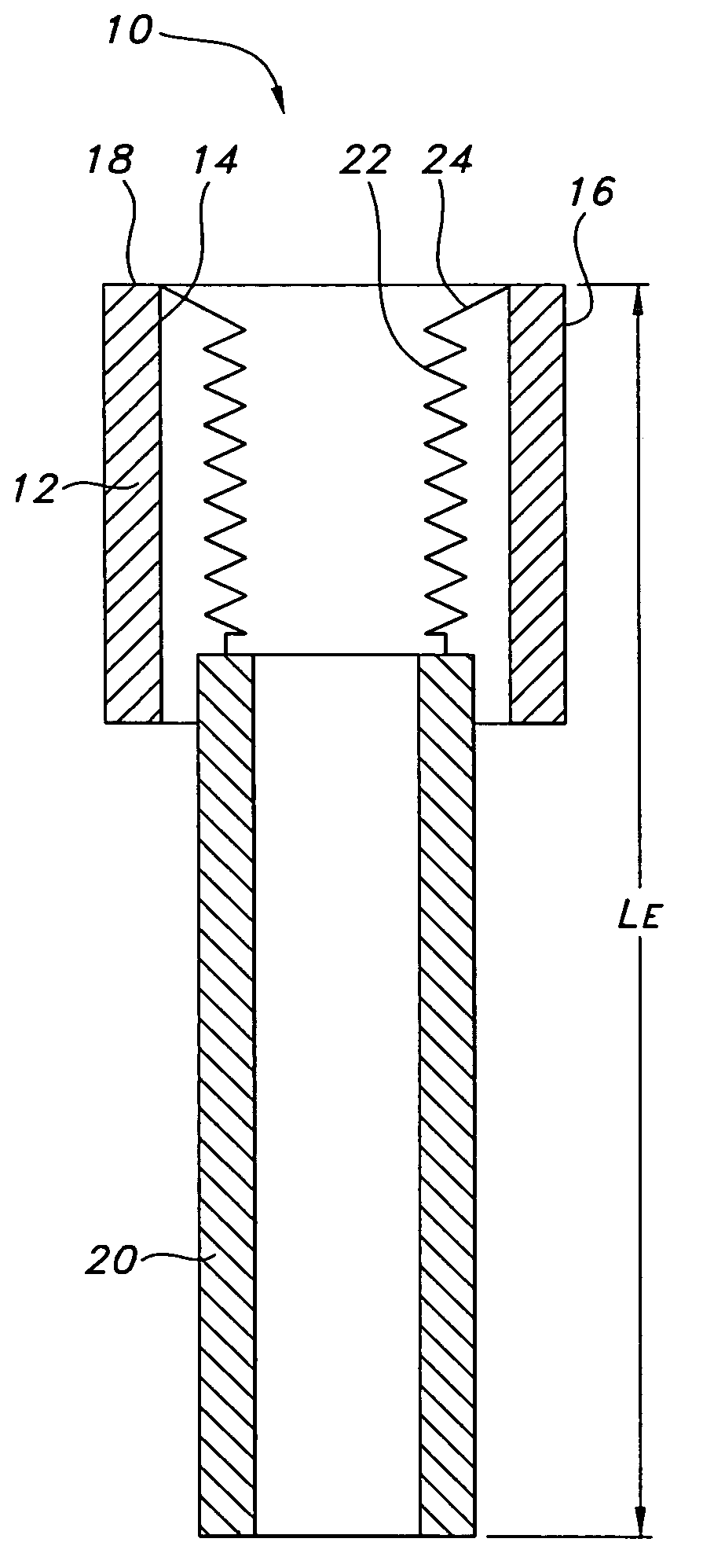

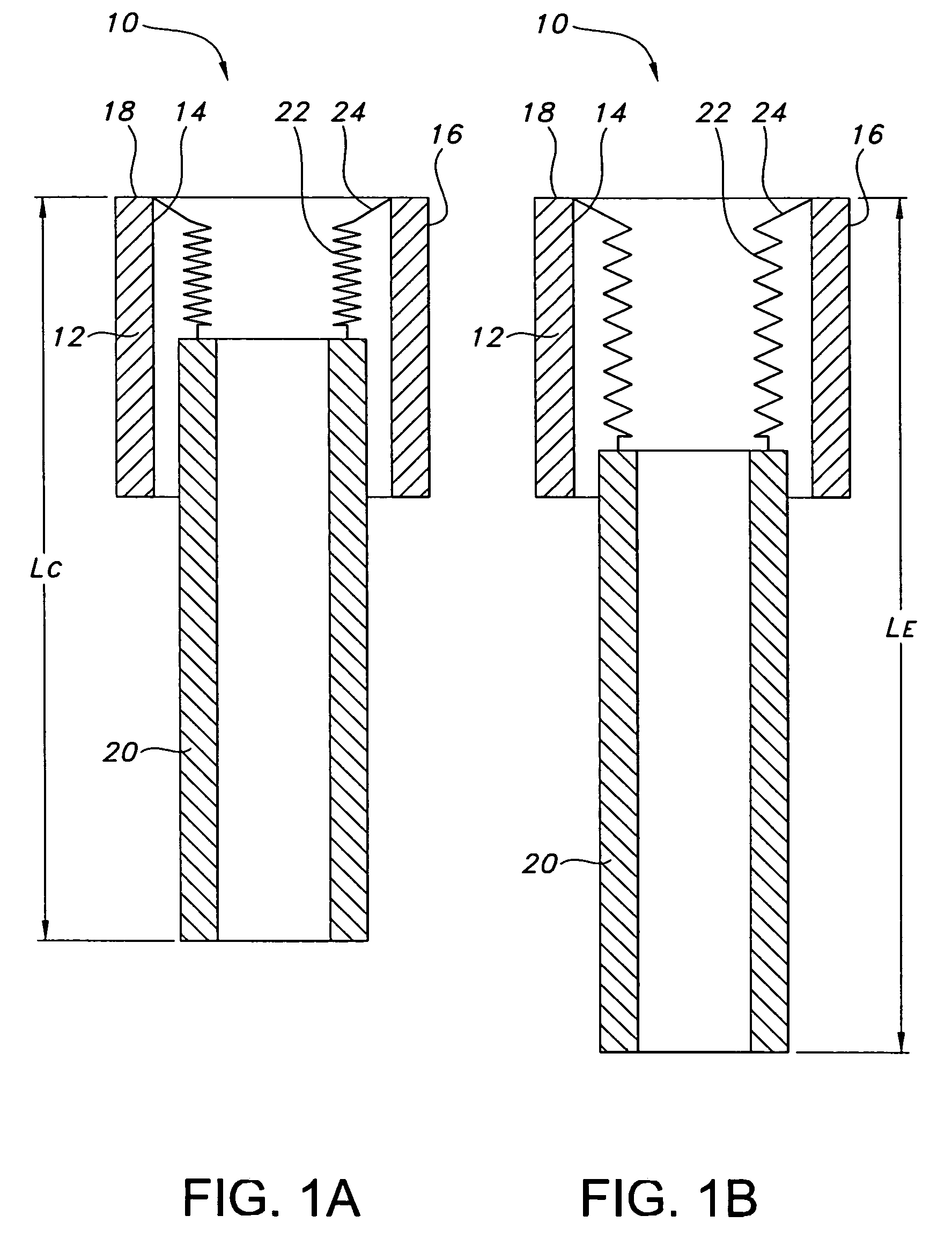

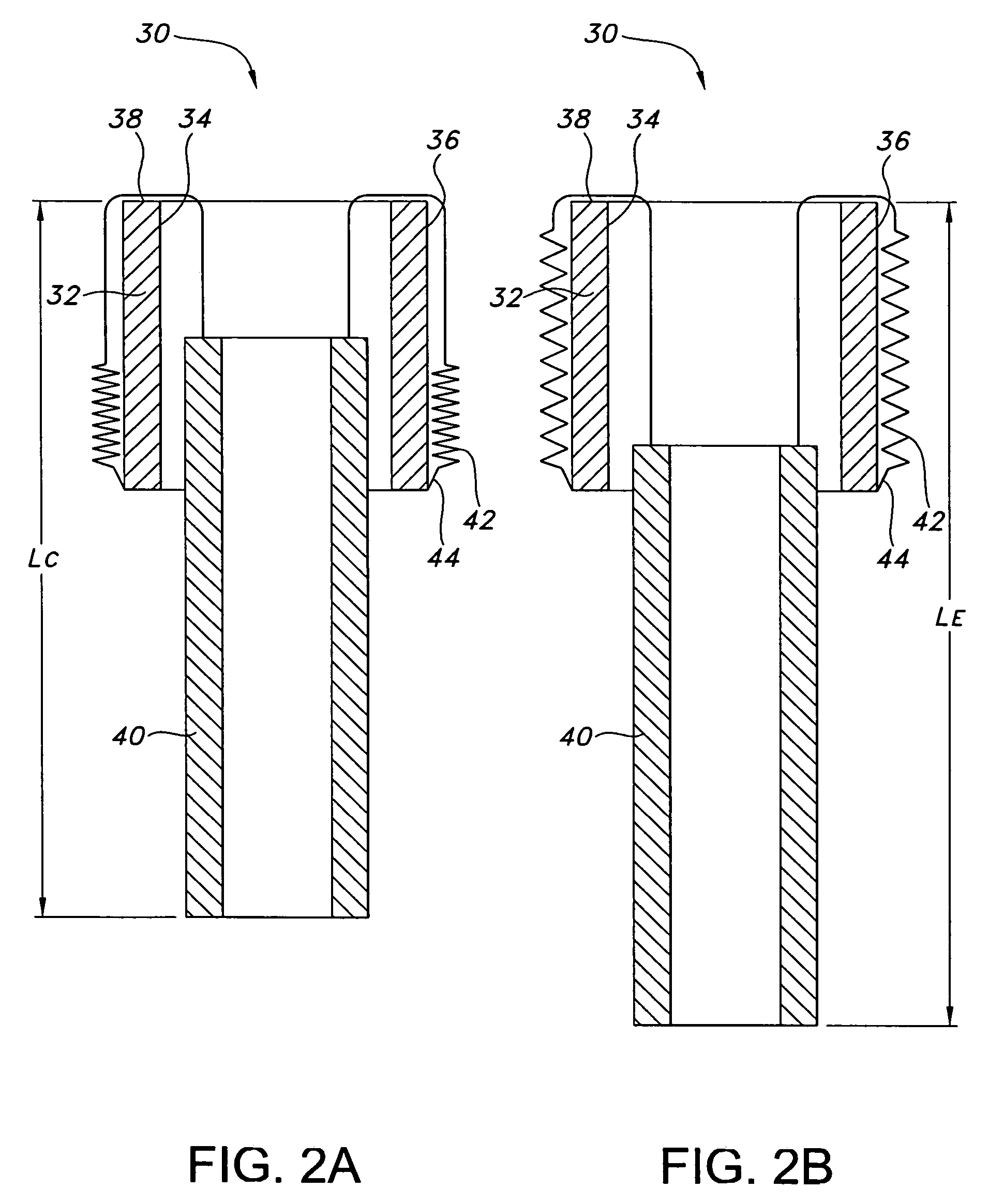

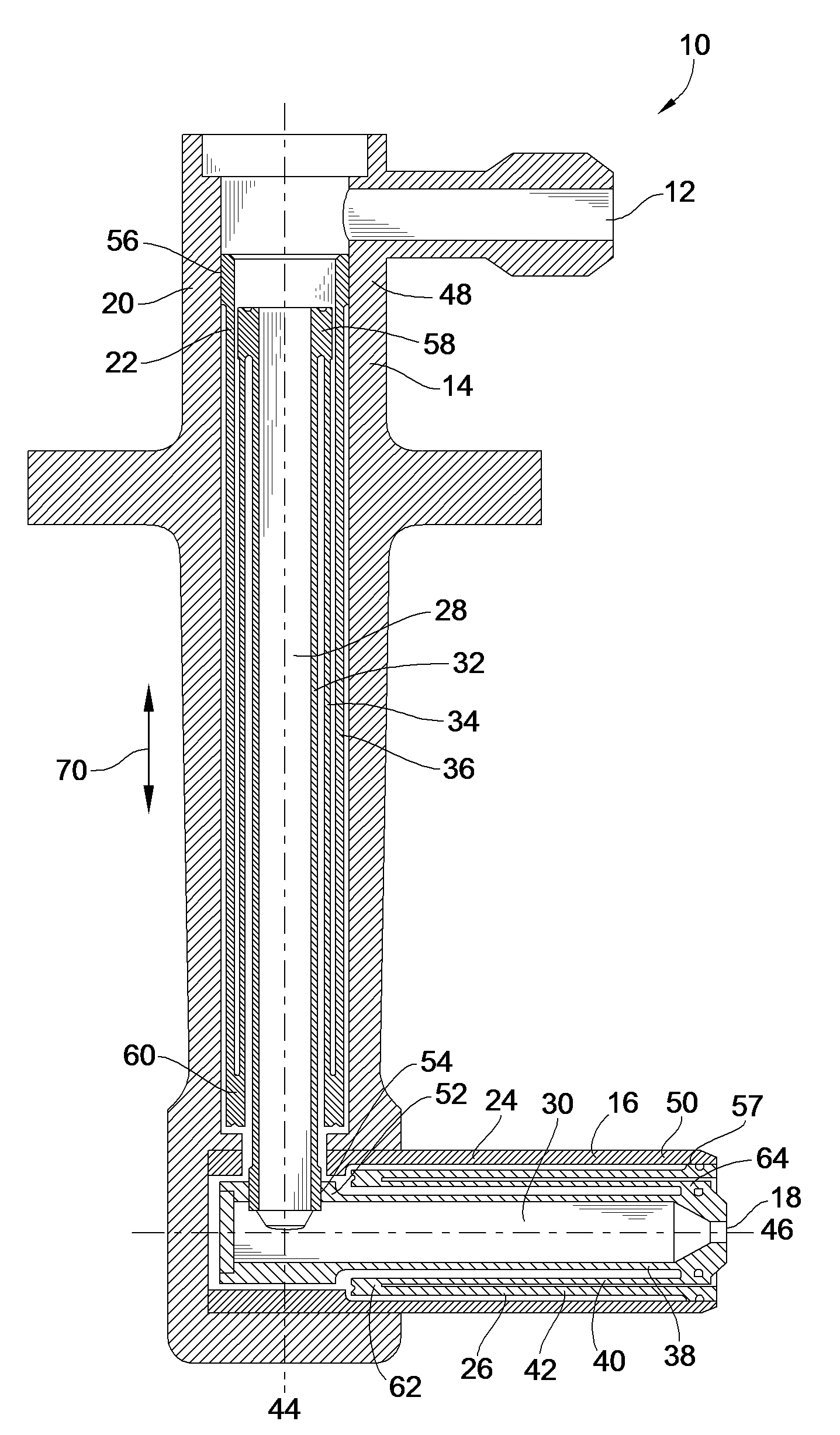

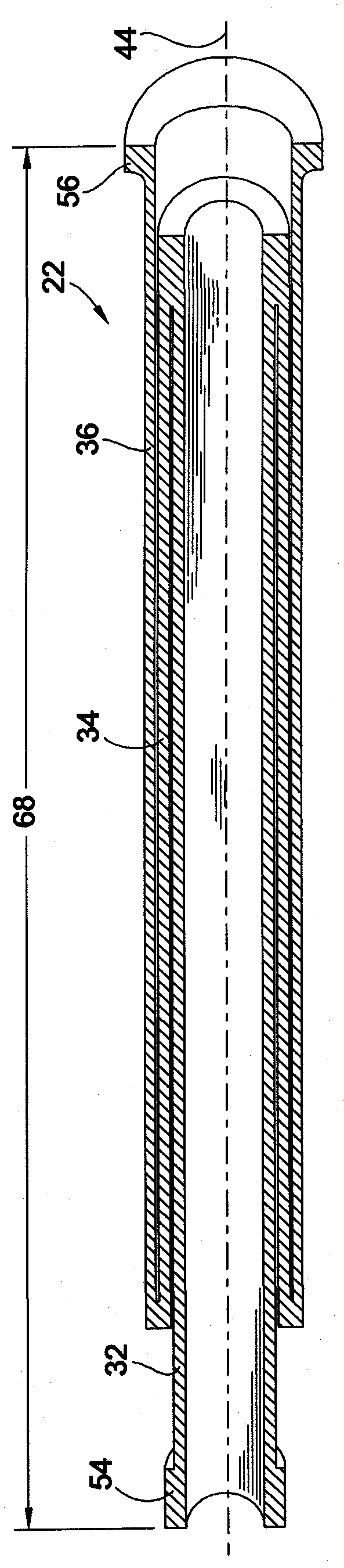

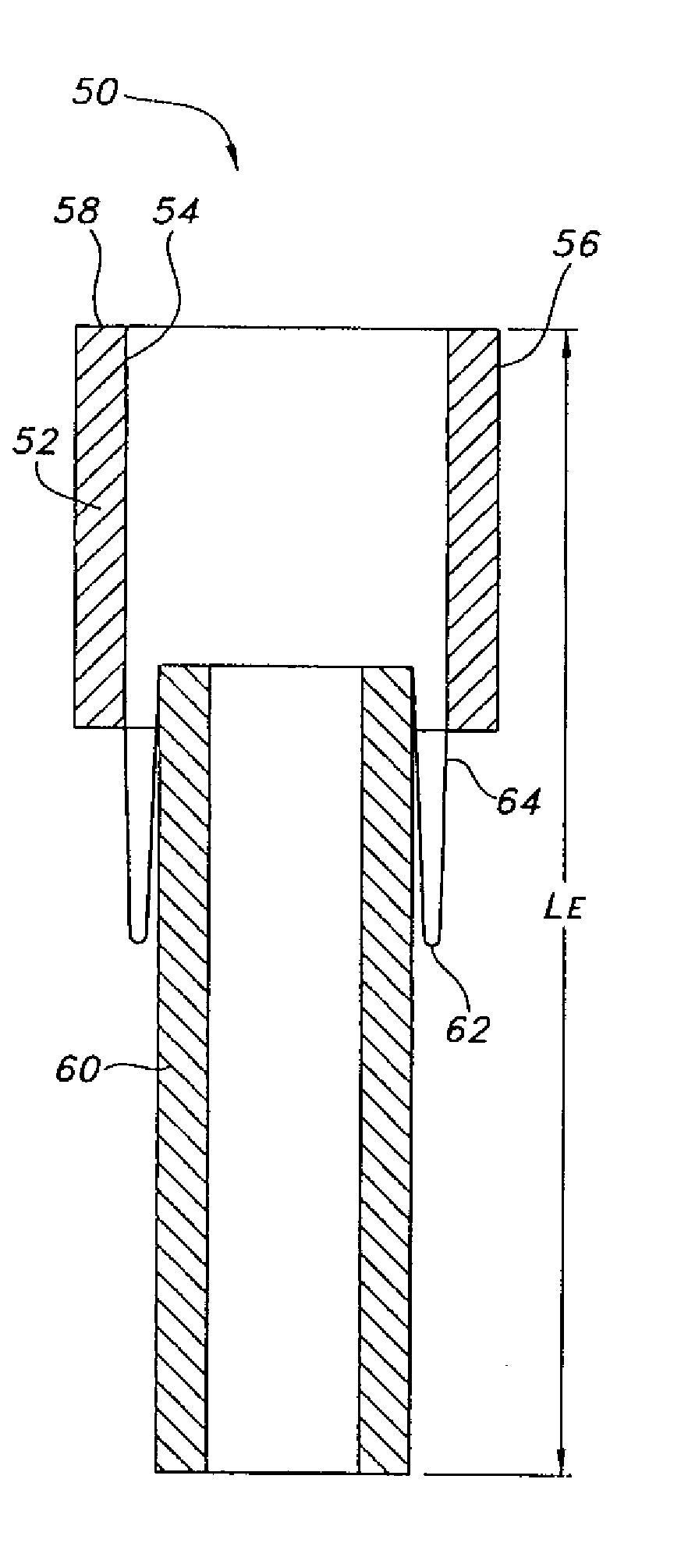

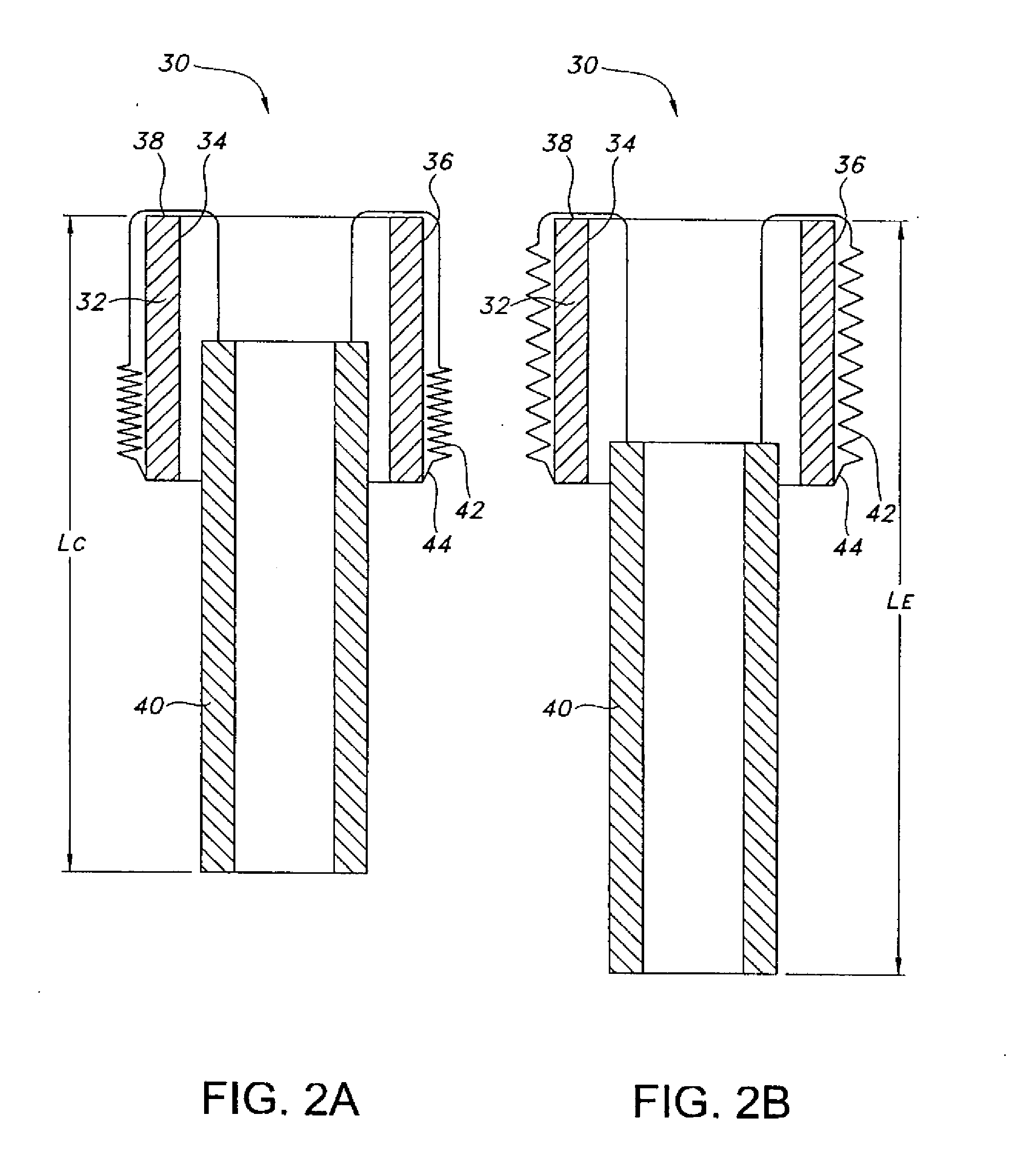

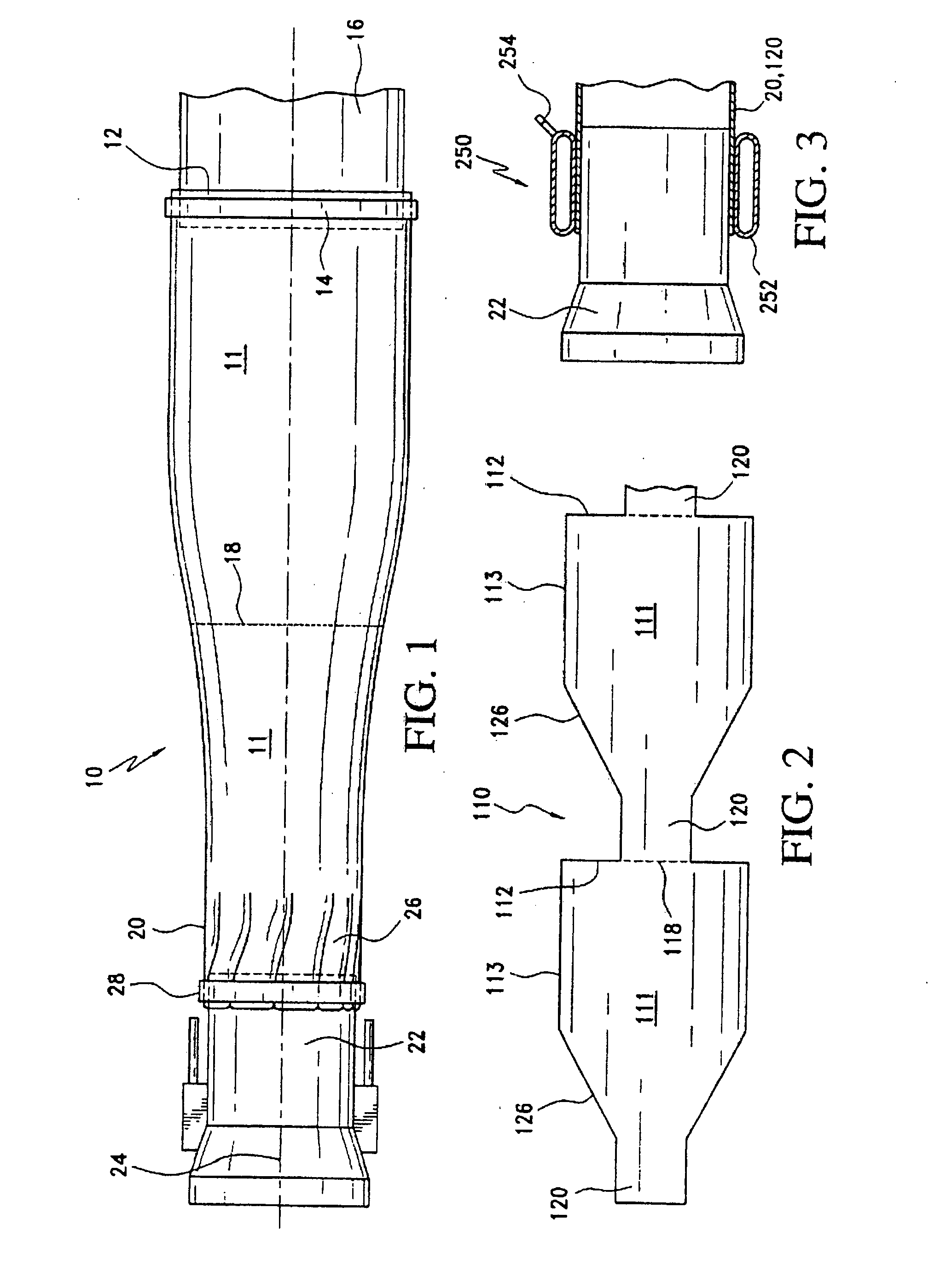

Variable length endovascular graft prosthesis adapted to prevent endoleaks

InactiveUS20060217796A1Prevent internal leakageFacilitate variable length engagementBlood vesselsEndovascular prosthesisBlood vessel

A variable length endovascular prosthesis adapted to prevent endoleaks is provided that includes a substantially tubular first graft member having an interior surface, an exterior surface, and a proximal end, and a substantially tubular second graft member slidably engaged coaxially within the first graft member. The prosthesis further includes a substantially tubular fluid-tight connecting member attached at one end to the first graft member and attached at another end to the second graft member. The connecting member is axially compressible and expandable to facilitate engagement of the second graft member within the first graft member while maintaining a seal between the graft members.

Owner:LIFESHIELD SCI +1

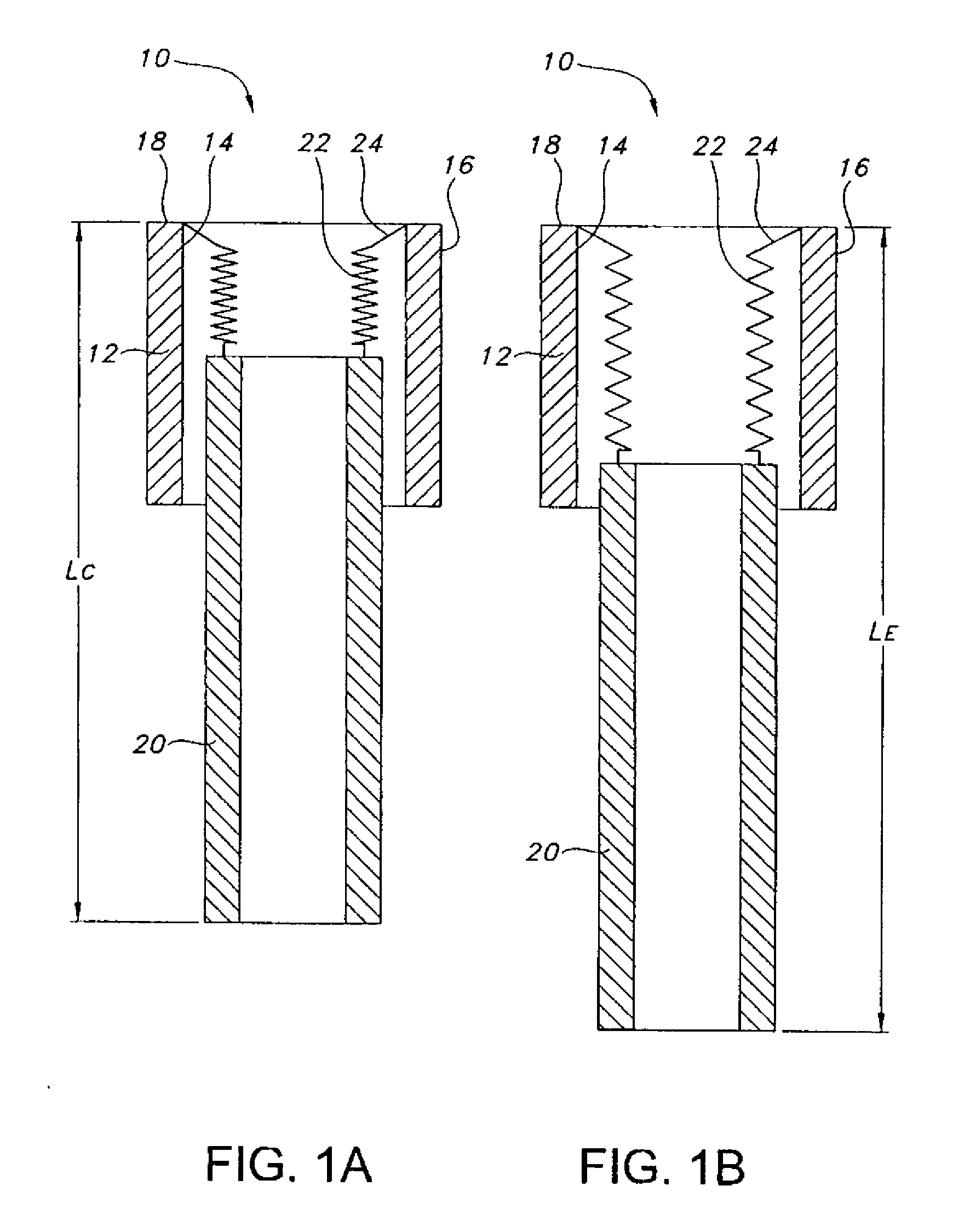

Electroactive polymer actuated medical devices

InactiveUS20060041264A1High degreeLimited accessStaplesCatheterElectroactive polymer actuatorsEngineering

The present invention is directed to novel apparatus for use in medical procedures relating to tubular body fluid conduits. According to a first aspect of the invention, a filter apparatus is provided for delivery over a guidewire within a tubular body conduit, such as a blood vessel. The filter apparatus comprises: (a) a filter element transformable between a collapsed state and a deployed state, wherein the filter element is adapted to filter particulate matter from fluid within the tubular body conduit while in the deployed state; and (b) a locking member comprising one or more electroactive polymer actuators which switch the locking member between (i) a locking state wherein the locking member securely engages the guidewire and (ii) a release state wherein the locking member is movable along the length of the guidewire. According to a second aspect of the invention, a connector apparatus is provided for use in making an anastomotic connection between first and second tubular fluid conduits in a patient. The connector apparatus comprises: (a) a locking member, which further comprises one or more electroactive polymer actuators that switch the locking member between a locking state and a release state; and (b) a connector body that is configured to permit flow of bodily fluid between the first and second tubular fluid conduits. The connector body has a first portion configured for insertion into an axial end of the first tubular fluid conduit and a second portion configured for insertion through a sidewall of the second tubular fluid conduit. The second portion of the connector body is further configured to securely engage the locking member when the locking member is in the locking state.

Owner:BOSTON SCI SCIMED INC

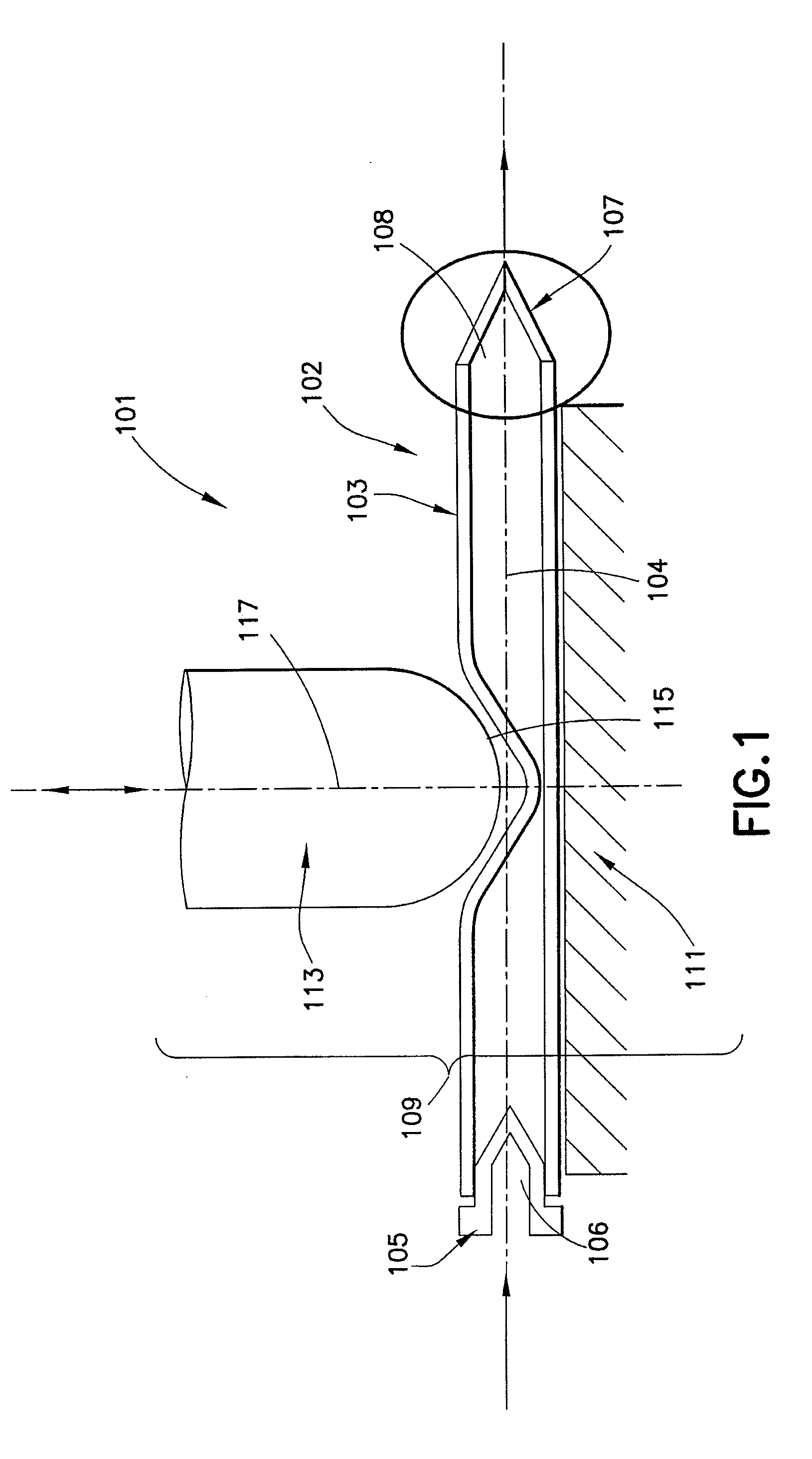

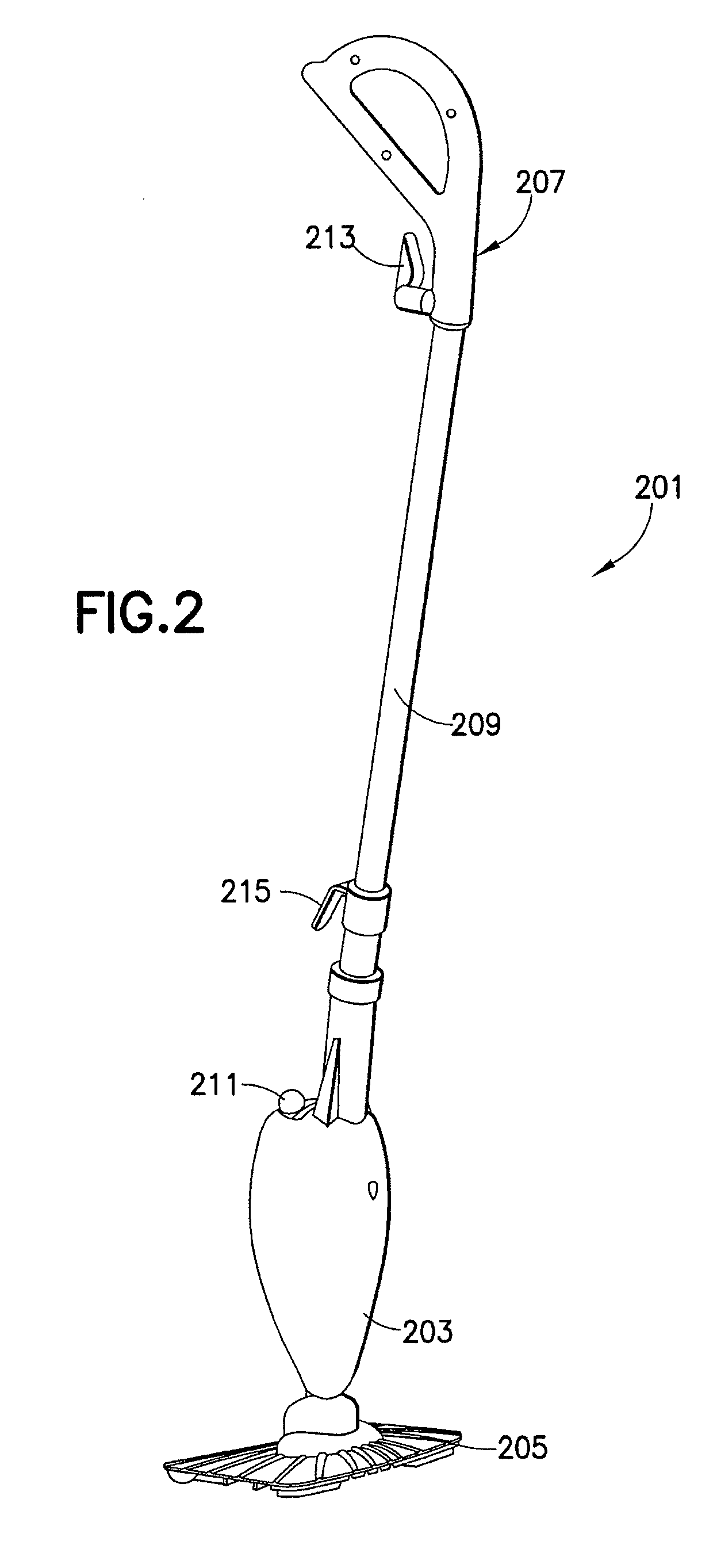

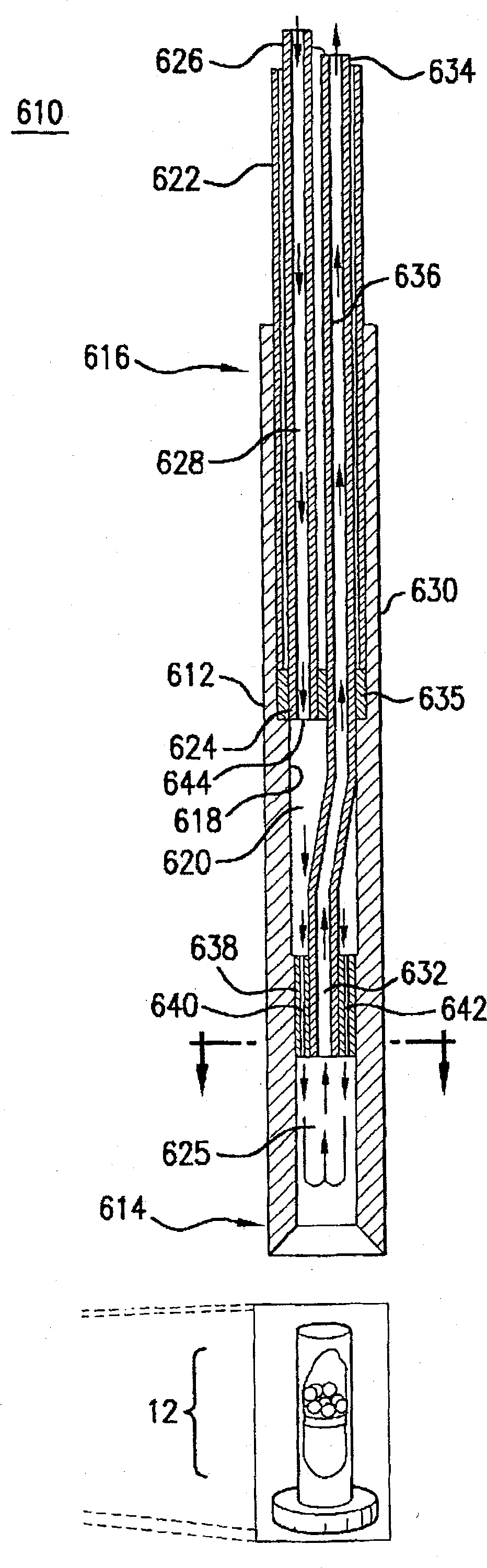

Tubular Pump

A tubular fluid pump is provided. The pump includes a chamber for receiving and discharging fluid, and a squeezing mechanism for pumping fluid through the chamber. The chamber has a first end with a first opening, a second end with a second opening, and a length of resilient tubular material extending between the first and second openings. One-way valves disposed at the openings cooperate to permit fluid to pass through the chamber in only one axial direction. The squeezing mechanism includes a substantially rigid base and a substantially rigid displaceable actuator. The tubular material is mounted on the base of the squeezing mechanism, and the actuator is aligned to alternately squeeze the tubular material against the base to pump fluid out of the chamber, and release the tubular material from the base to draw fluid into the chamber. A steam appliance incorporating a one-way tubular pump is also provided.

Owner:SHARKNINJA OPERATING LLC

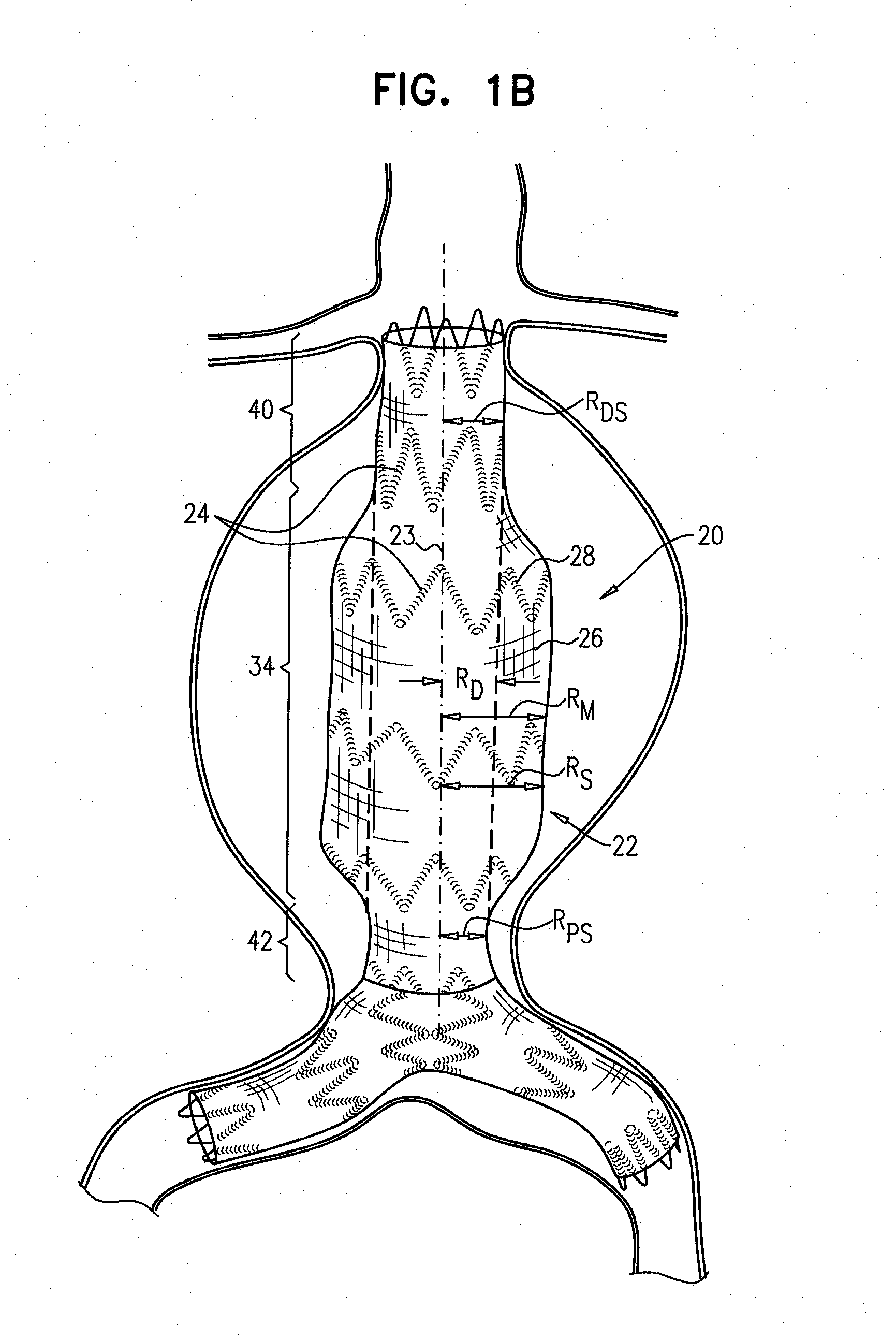

Stent-grafts with post-deployment variable radial displacement

ActiveUS20140324154A1High physiological complianceMinimize impactStentsBlood vesselsTubular fluidBiomedical engineering

An endovascular stent-graft includes a generally tubular body configured to assume a radially-compressed delivery state and a radially-expanded deployment state. The body includes a flexible stent member, and a tubular fluid flow guide attached to the stent member. The body includes a compliance-restoration body portion extending axially along a portion of the body, and including portions of the stent member and fluid flow guide. When the body is in the radially-expanded deployment state, the compliance-restoration body portion characterized by a greatest diastolic outer radius when the body is internally pressurized by fluid having a pressure of 80 mmHg, and radially expandable to a greatest systolic outer radius when the body is internally pressurized by fluid having a pressure of 120 mmHg. The greatest systolic outer radius (RS) is at least 5% greater than the greatest diastolic outer radius.

Owner:ENDOSPAN

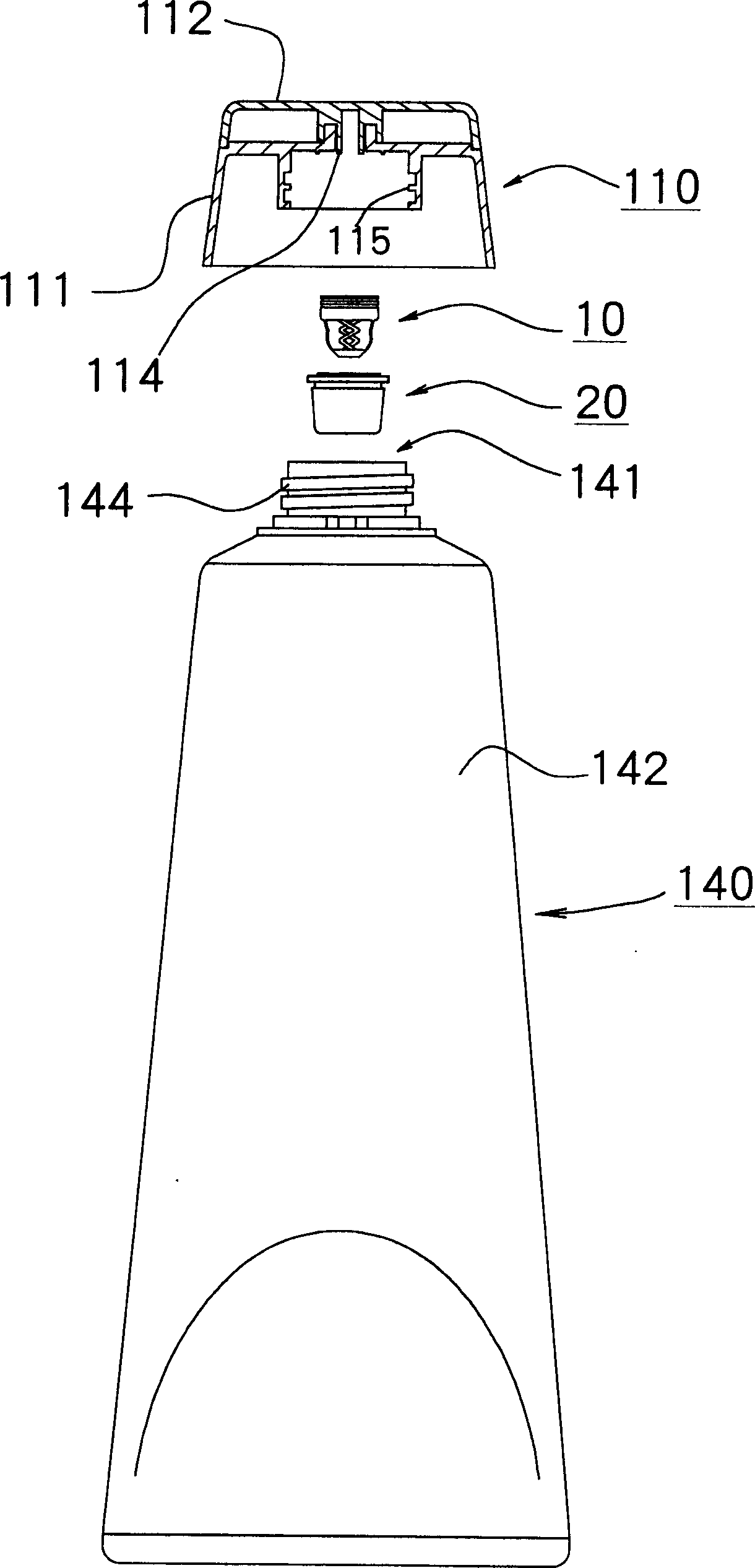

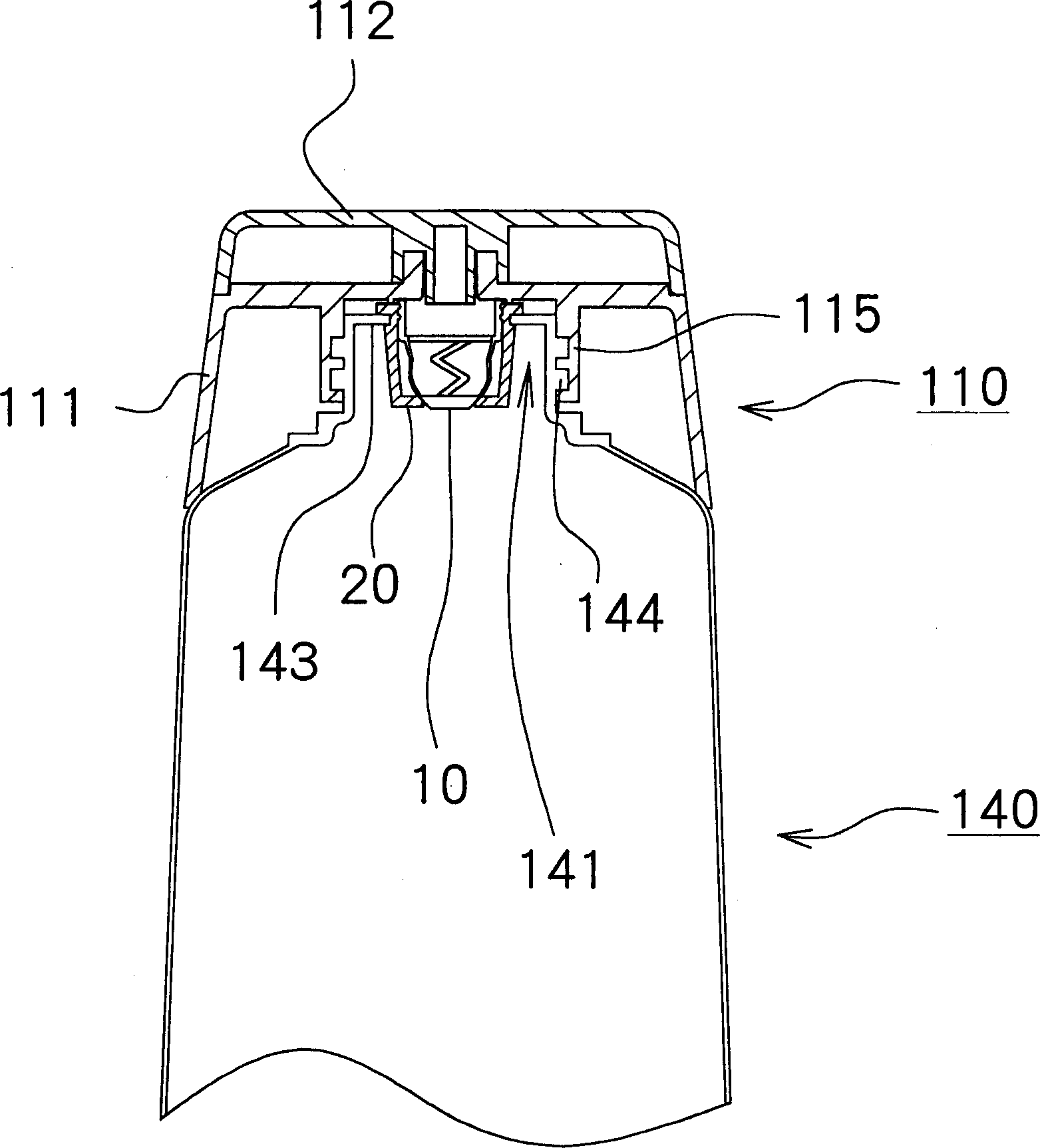

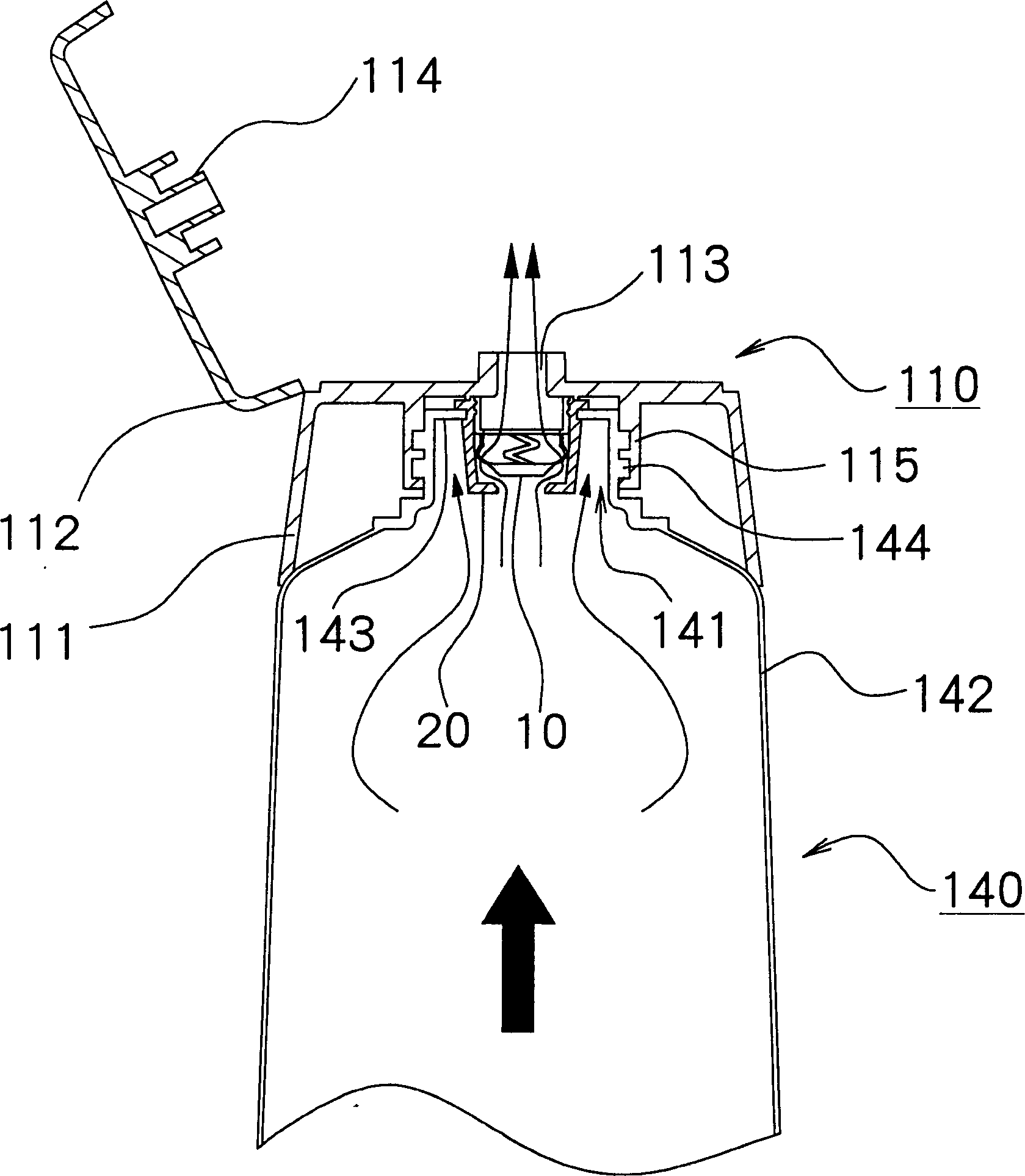

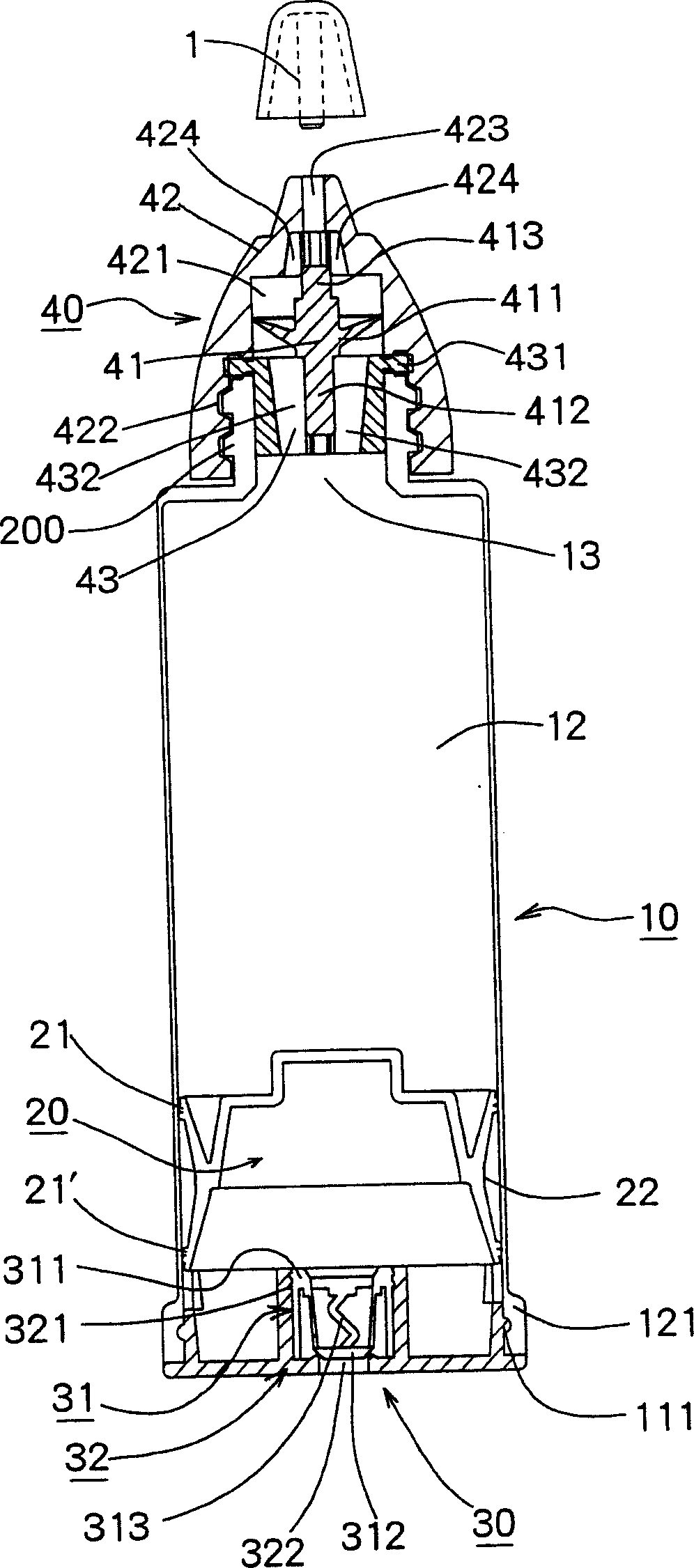

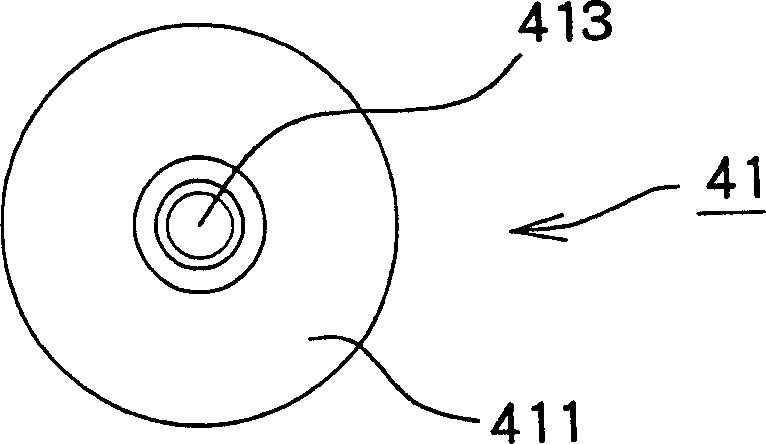

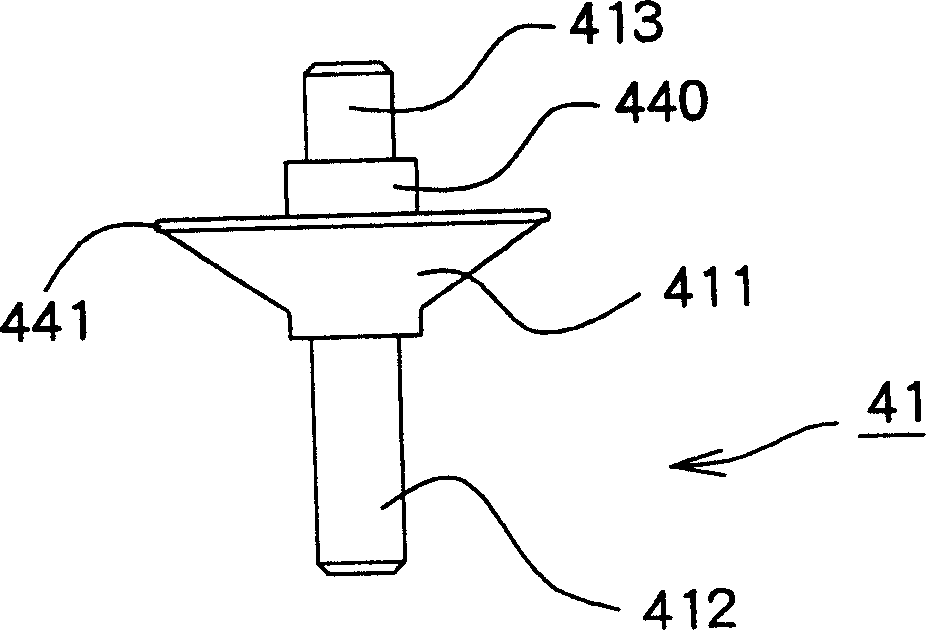

Valve mechanism for tubular fluid container

InactiveCN1470438APrevent improper tiltingImprove sealingClosuresDispensing apparatusCouplingEngineering

Owner:增田胜利

Multiple component dispensing cartridge, mixing nozzle and method for reducing contact between fluids

The present invention relates to a multiple component dispensing cartridge, a mixing nozzle and a method for reducing contact between fluids. A fluid cartridge for mixing and dispensing first and second luids includes a housing, a piston unit mounted in the housing, and a mixing nozzle. The mixing nozzle includes a first portion releasably attachable to a distal end of the housing and a second portion located distal to the first portion. An internal fluid passage communicates between the first and second portions. A static mixing element is located in the second portion and a distal dispensing opening communicates with the static mixing element. A tubular fluid separator element is located in the first portion and defines first and second flow passages. The first flow passage is a central passage and the second flow passage is radially outside of the first flow passage. The fluid separator element maintains the flow of the first fluid separate from the flow of the second fluid in the first portion of the mixing nozzle.

Owner:NORDSON CORP

Variable length endovascular graft prosthesis adapted to prevent endoleaks

InactiveUS7766959B2Facilitate variable length engagementImprove sealingBlood vesselsEndovascular prosthesisBlood vessel

A variable length endovascular prosthesis adapted to prevent endoleaks is provided that includes a substantially tubular first graft member having an interior surface, an exterior surface, and a proximal end, and a substantially tubular second graft member slidably engaged coaxially within the first graft member. The prosthesis further includes a substantially tubular fluid-tight connecting member attached at one end to the first graft member and attached at another end to the second graft member. The connecting member is axially compressible and expandable to facilitate engagement of the second graft member within the first graft member while maintaining a seal between the graft members.

Owner:LIFESHIELD SCI +1

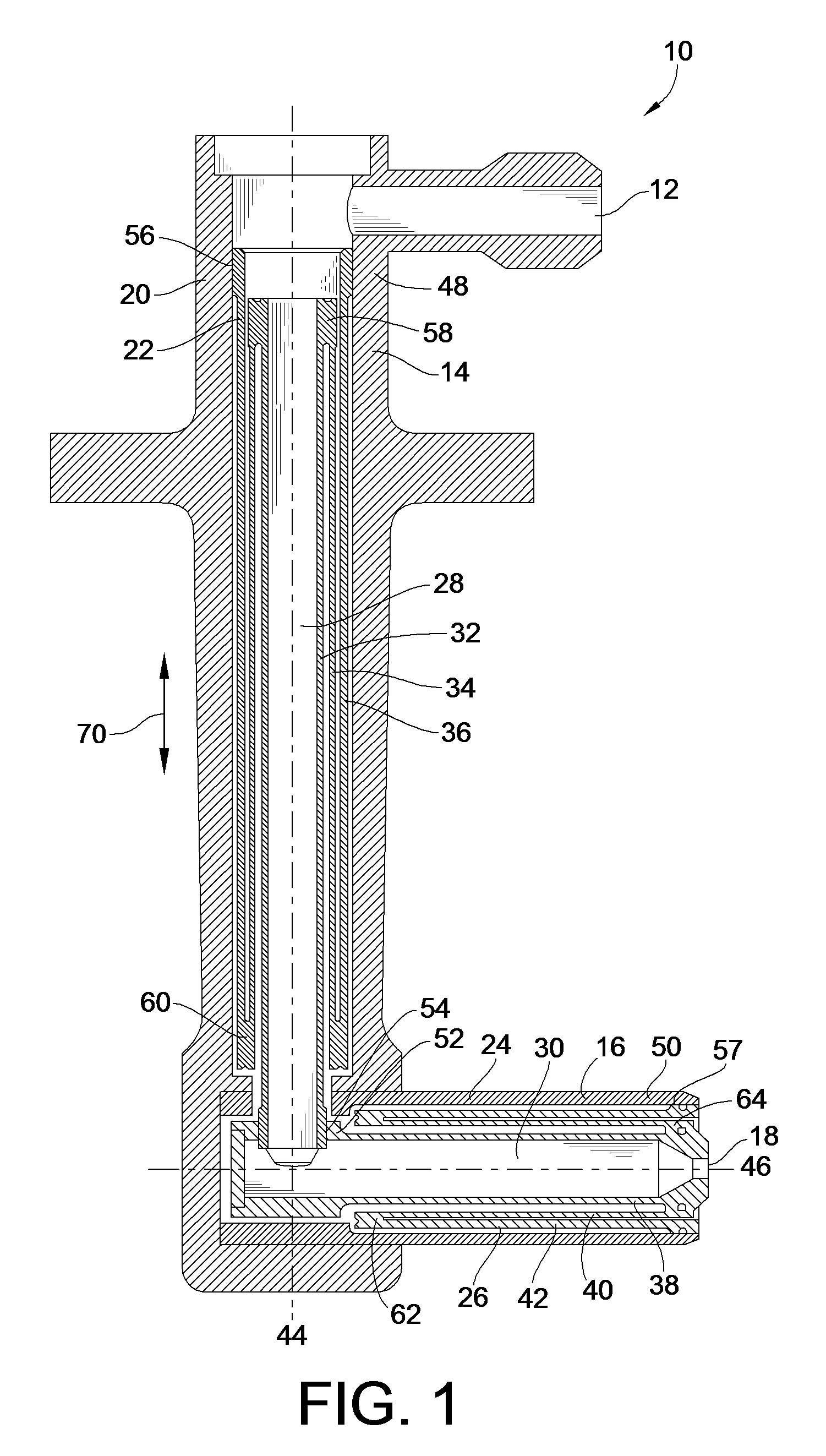

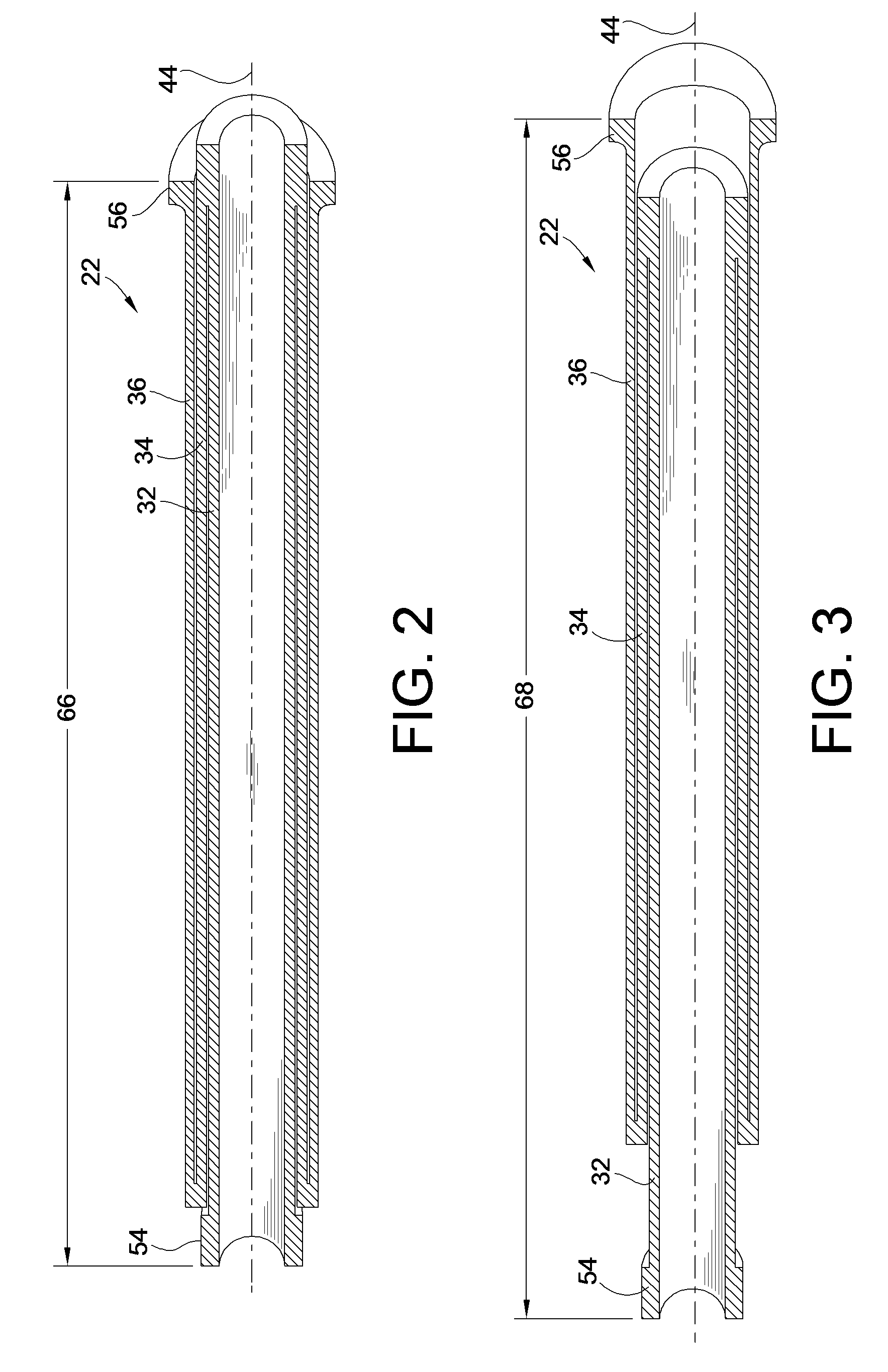

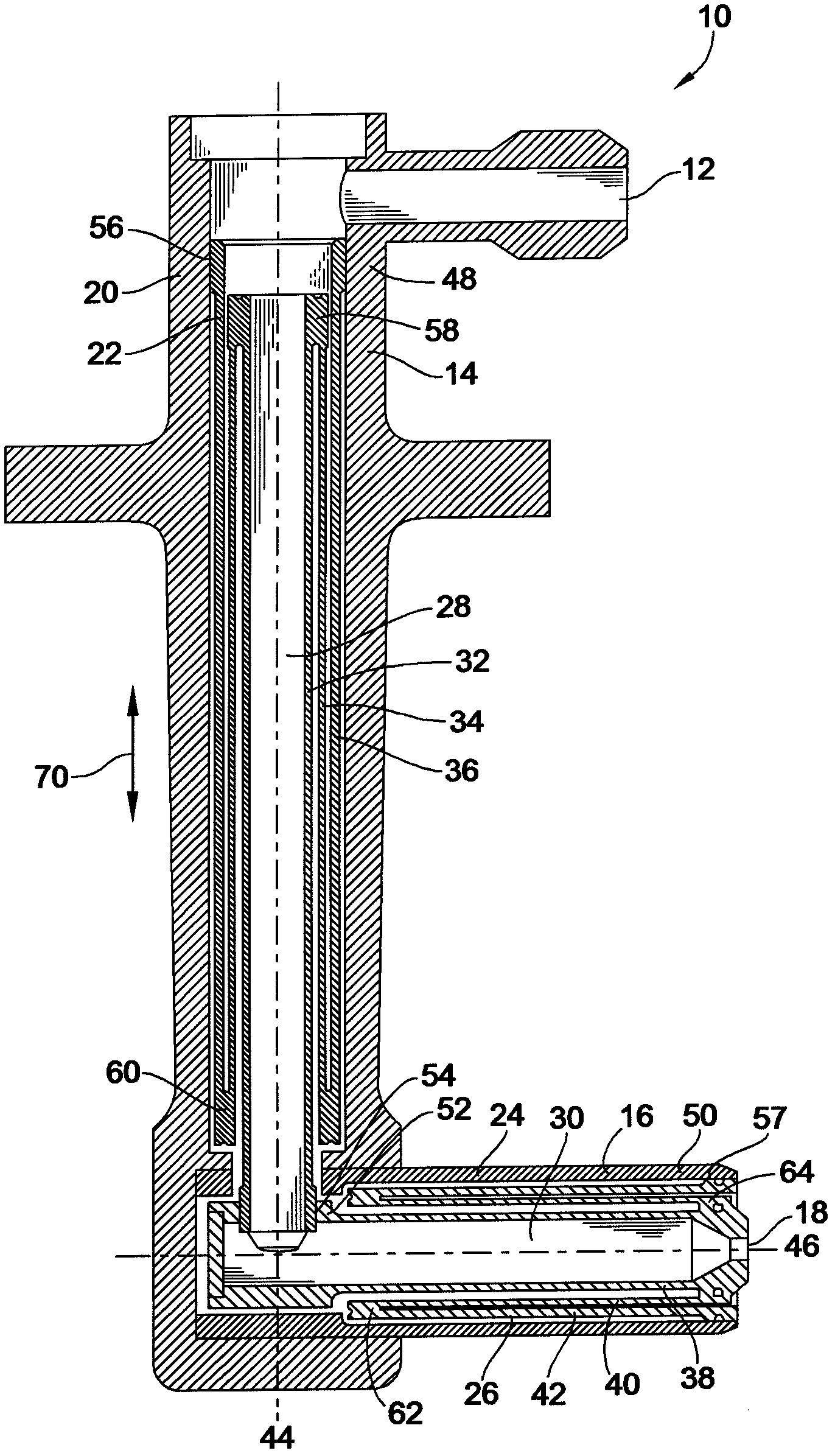

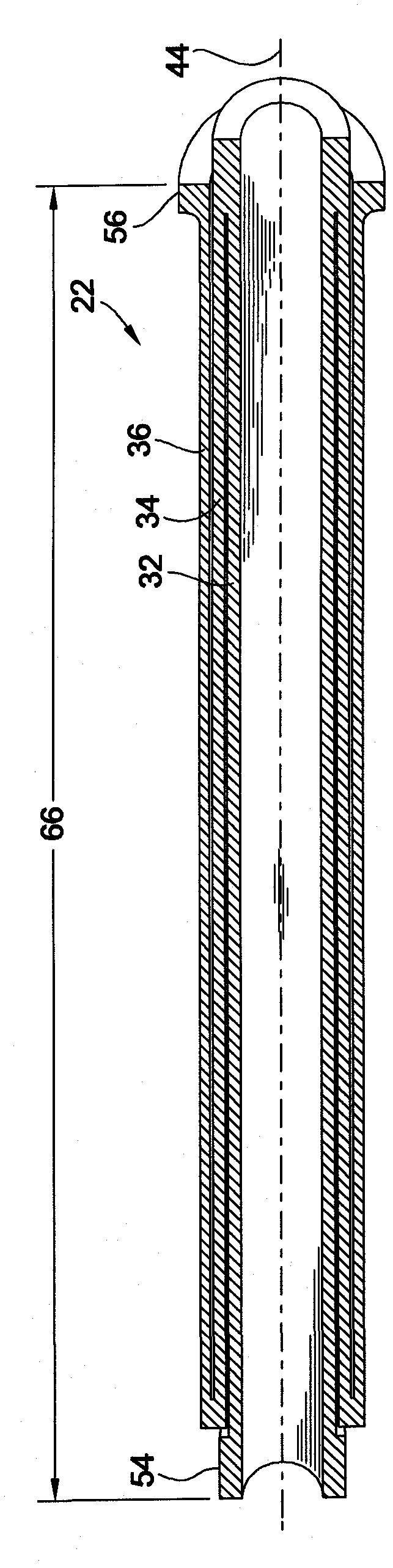

Multi-tubular fluid transfer conduit

ActiveUS8205643B2Improve insulation effectImprove stress conditionPipe supportsContinuous combustion chamberTransfer systemThermal insulation

A fluid transfer system having improved stress accommodation properties and thermal insulation properties is provided. The fluid transfer system includes a fluid transfer conduit comprising a plurality of concentric tubes configured to divide and distribute an axial stress induced in the fluid transfer conduit to each of the tubes and a vacuum cavity between the fluid transfer conduit and a structural support of the fluid transfer system to insulate fluid from a surrounding environment.

Owner:WOODWARD GOVERNOR CO

Multi-tubular fluid transfer conduit

ActiveCN102257304AContinuous combustion chamberPipeline expansion-compensationStress inducedTransfer system

A fluid transfer system having improved stress accommodation properties and thermal insulation properties is provided. The fluid transfer system includes a fluid transfer conduit comprising a plurality of concentric tubes configured to divide and distribute an axial stress induced in the fluid transfer conduit to each of the tubes and a vacuum cavity between the fluid transfer conduit and a structural support of the fluid transfer system to insulate fluid from a surrounding environment.

Owner:WOODWARD GOVERNOR CO

Fluid-storing and -dispensing container

A fluid-storing and -dispensing container includes a tubular fluid-storing portion 10; a piston 20 capable of traveling inside the fluid-storing portion 10 in the axial direction; an inflow valve mechanism 30 provided at the bottom of the fluid-storing portion 10 and enabling outer-air to flow into the fluid-storing portion 10; and an outflow valve mechanism 40 provided in an opening portion of the fluid-storing portion 10 and enabling a fluid to flow out from the fluid-storing portion 10.

Owner:增田胜利

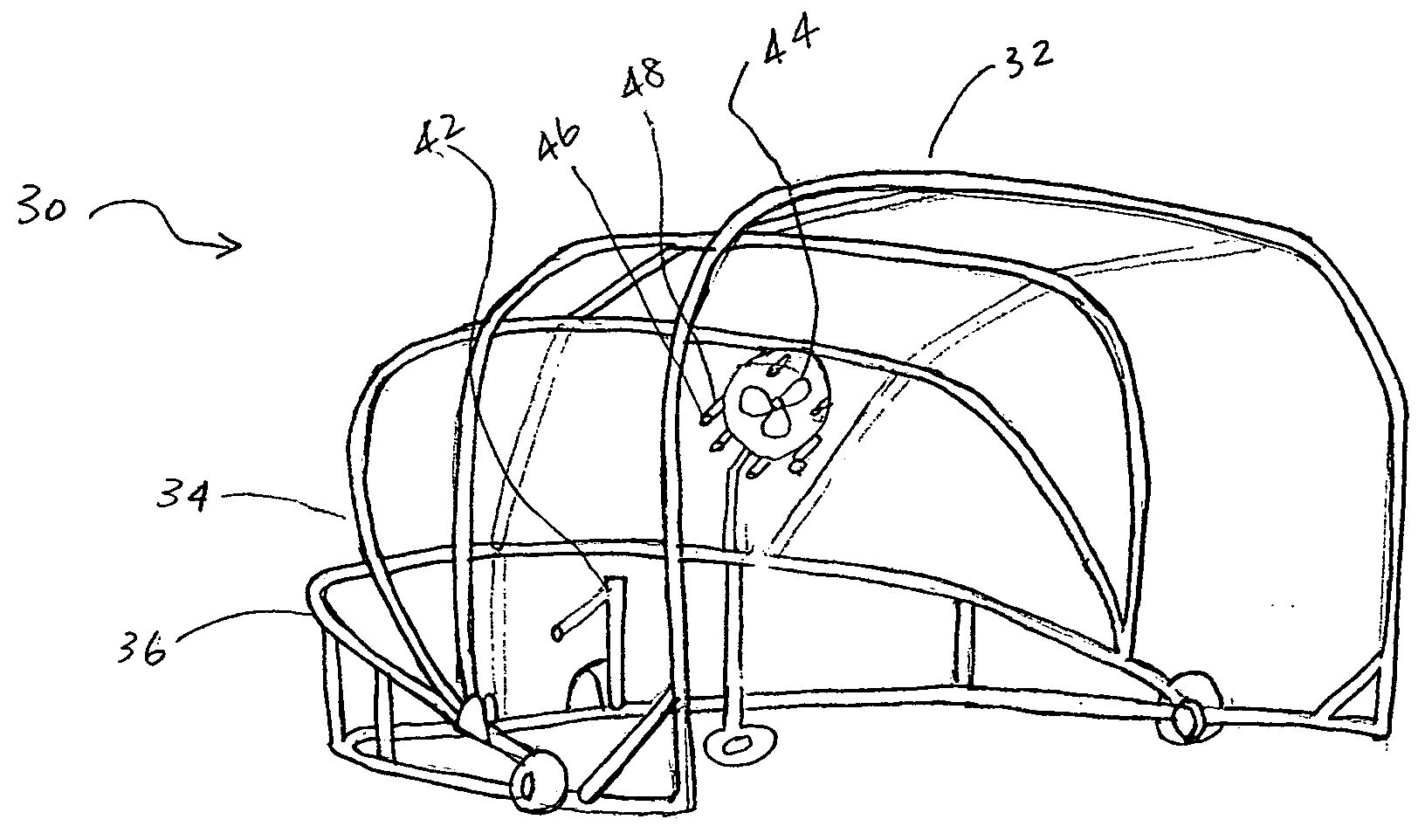

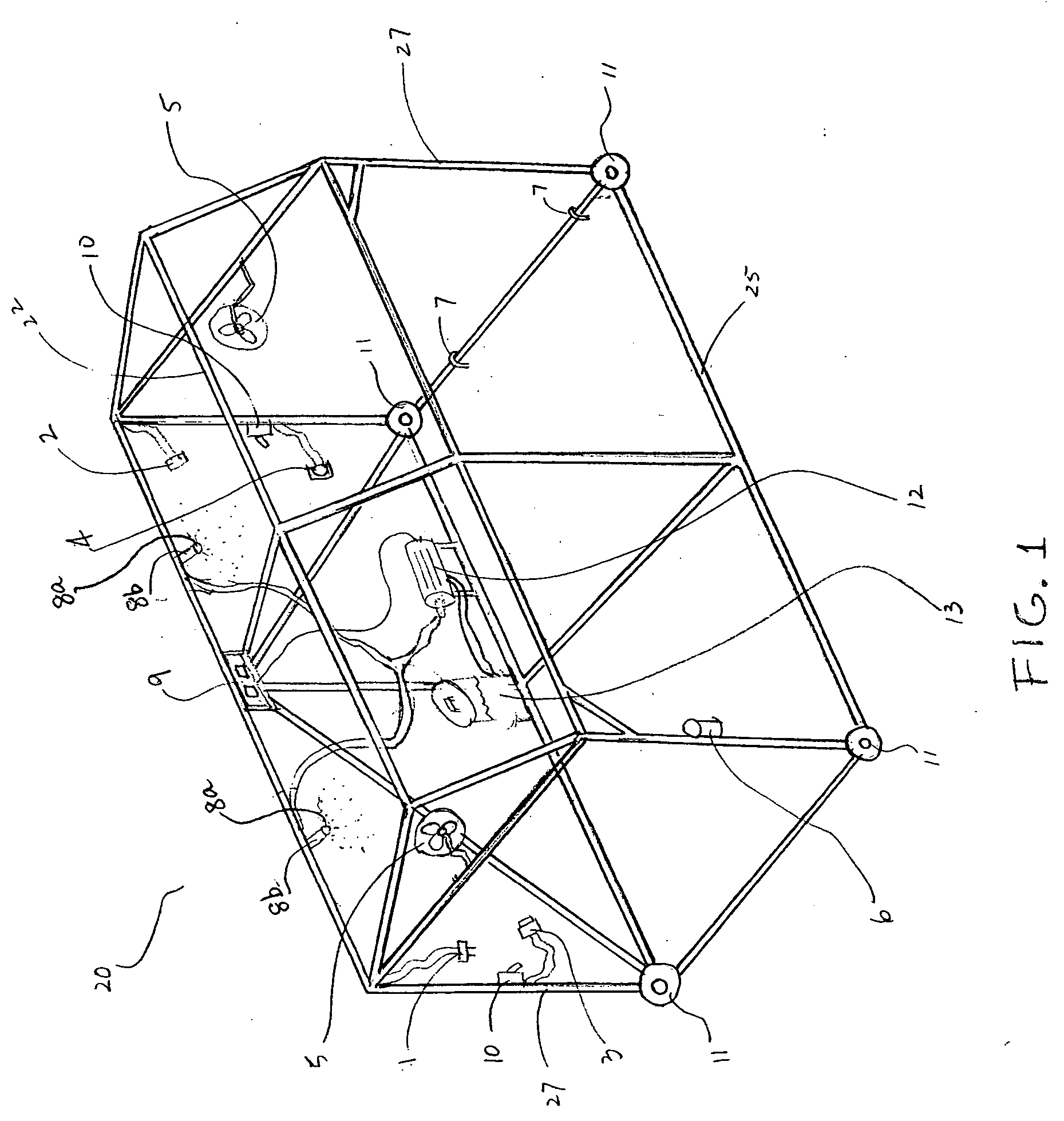

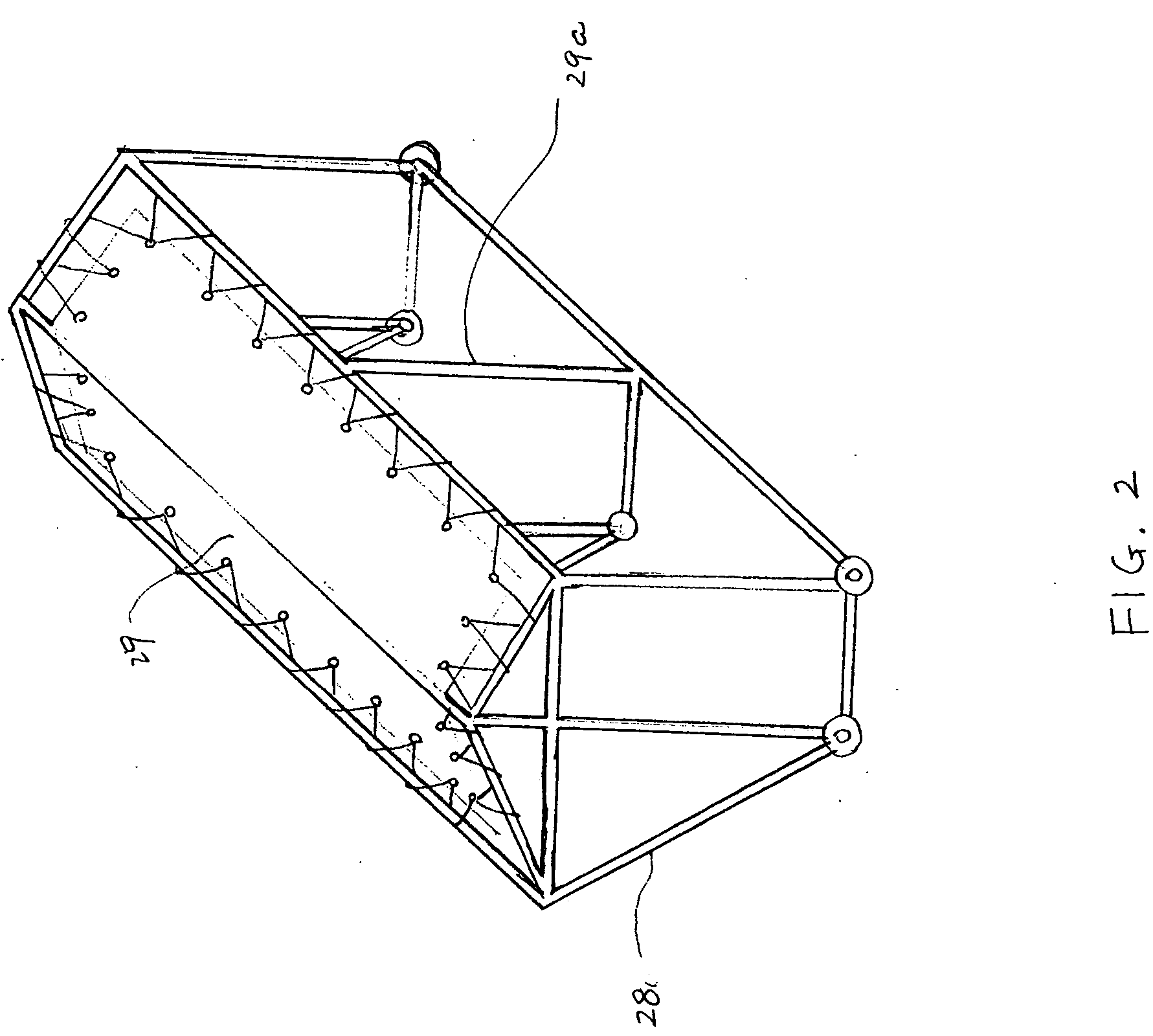

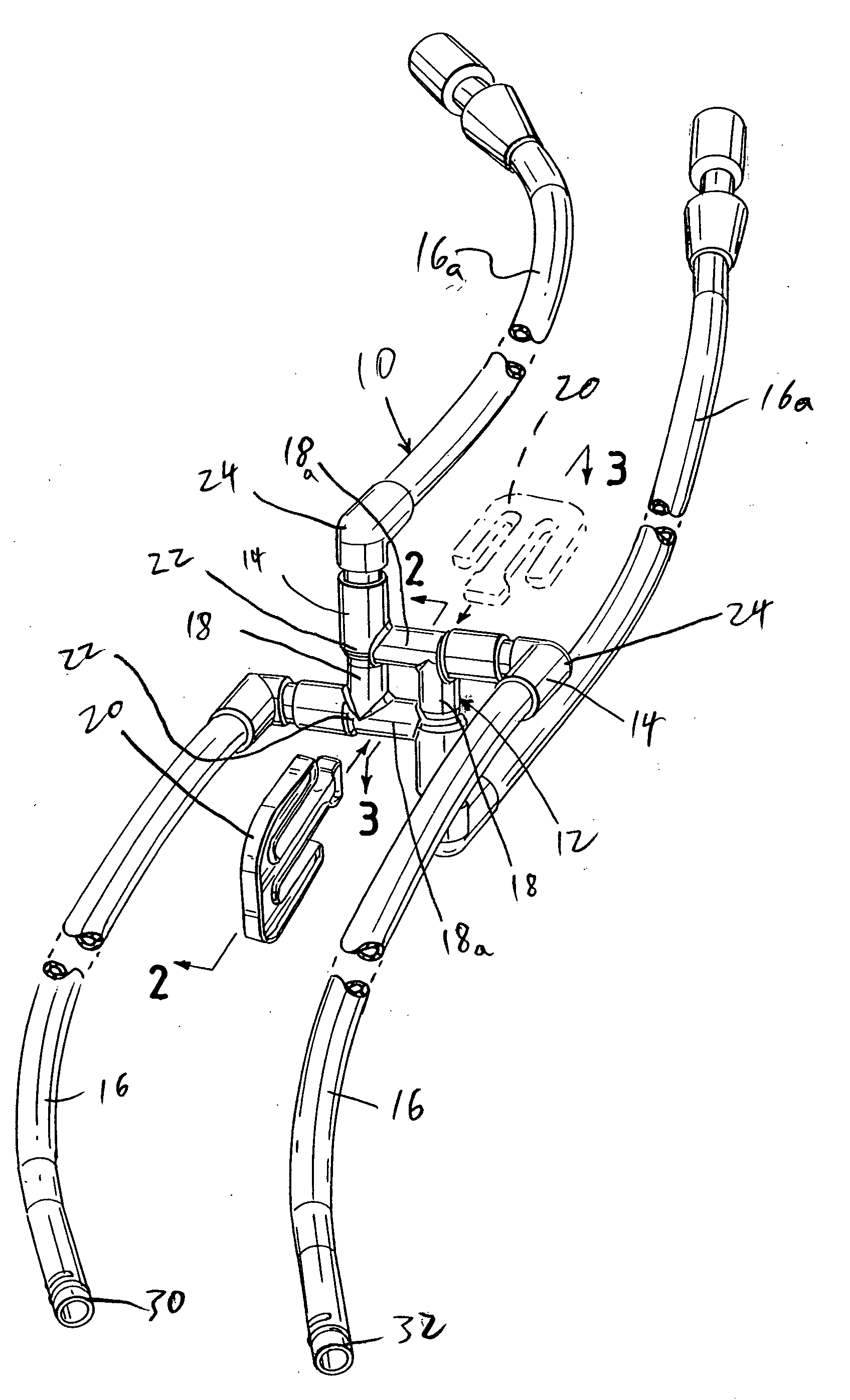

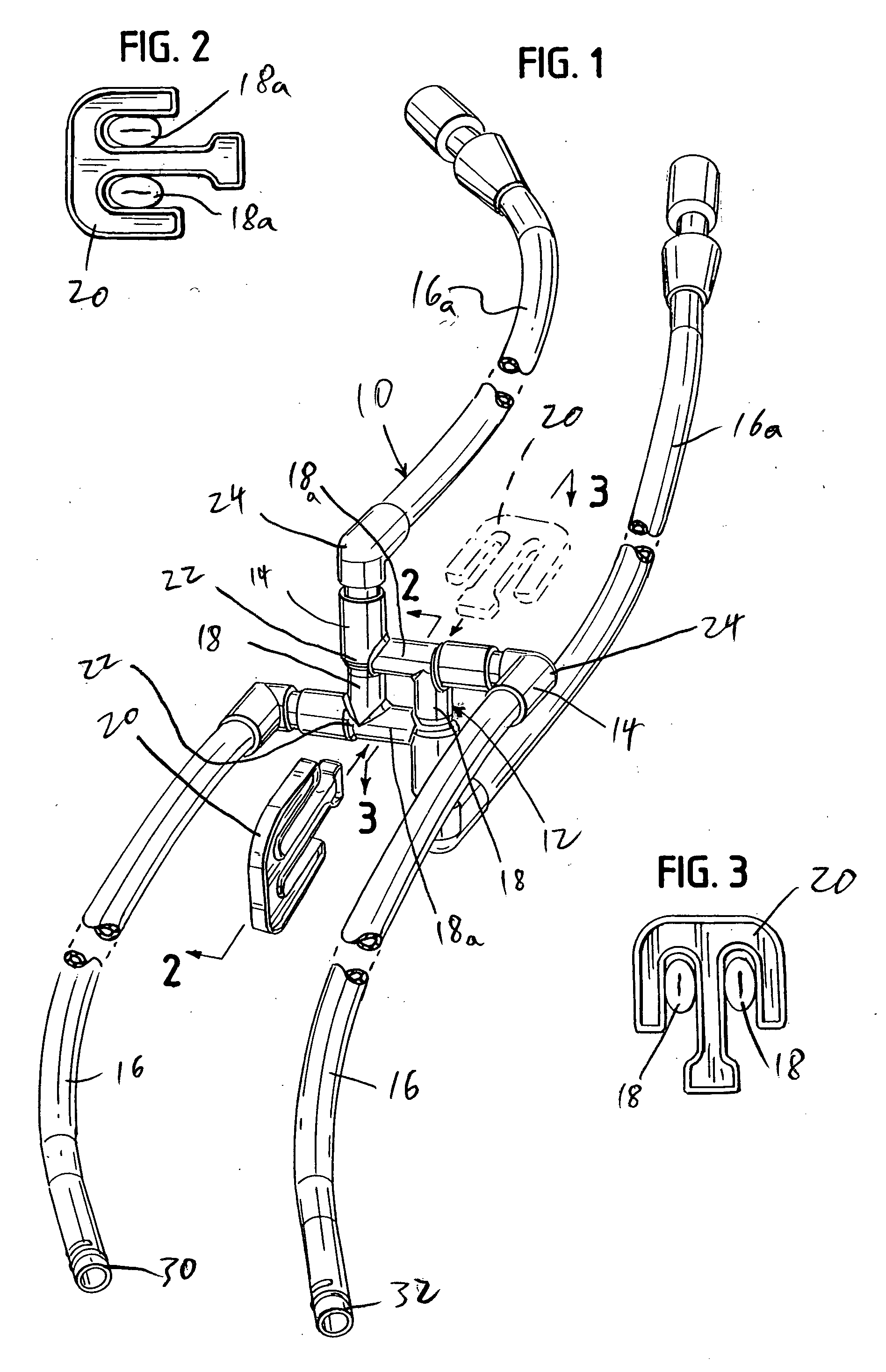

Portable misting system

InactiveUS20060091234A1Convenient to accommodateLow priceClimate change adaptationWatering devicesSpray nozzleBiomedical engineering

A portable misting system for cooling air, a portable misting apparatus and a method of cooling the air within a portable structure are disclosed. The portable misting system comprises a fluid supply, a tubular conveyance means releasably connected to the fluid supply, one or more fluid to mist conversion / dispersion nozzles attached to the tubular fluid conveyance means, and a portable structure housing the fluid supply, the tubular fluid conveyance means, and the one or more fluid to mist conversion / dispersion nozzles. The portable misting apparatus comprises a fluid supply, a tubular conveyance means releasably connected to the fluid supply, one or more fluid to mist conversion / dispersion nozzles attached to the tubular fluid conveyance means, and a support frame for supporting the portable misting system. The method of cooling the air within a portable structure is the method for using the portable misting apparatus.

Owner:WALLANDER JAMES J

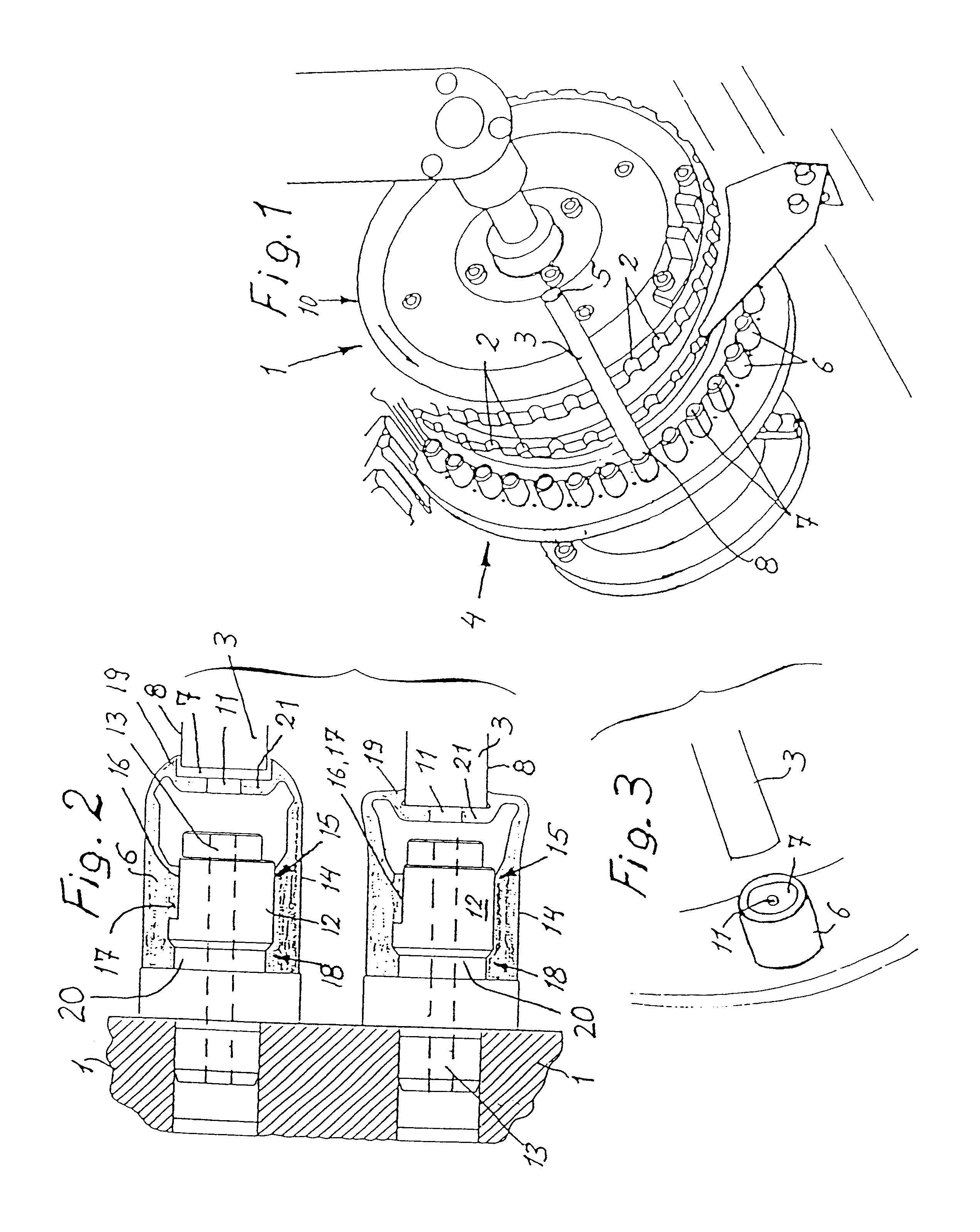

Sealing device for the end portions of rod-shaped smokers' products having non-circular cross-sectional outlines

InactiveUS6397663B1Rapidly and predictably mountedInternal-combustion engine testingDetection of fluid at leakage pointCircular dichroismMechanical engineering

A conveyor for testing successive plain or filter cigarettes or other rod-shaped smokers' products having non-circular (such as oval) cross-sectional outlines employs a rotary drum-shaped conveyor for sidewise transport of smokers' products toward, through and beyond a station where the products are tested by streams of a gaseous fluid entering the products at one axial end and issuing from satisfactory products at the other axial end. The end portions of the products are sealingly received in complementary sockets of elastically deformable sealing sleeves which are connected to their tubular fluid-conveying carriers in a manner to ensure that each sleeve remains in a selected position for optimum testing of the products. For example, each sleeve can be form-lockingly coupled to its carrier in such a way that the sleeve is held against any appreciable angular and / or axial movement relative to the carrier when the conveyor transports smokers' products but that the sleeve can be detached from the carrier, in response to adequate deformation, for the purpose of inspection, cleaning and / or replacement.

Owner:DECOUFLE R L

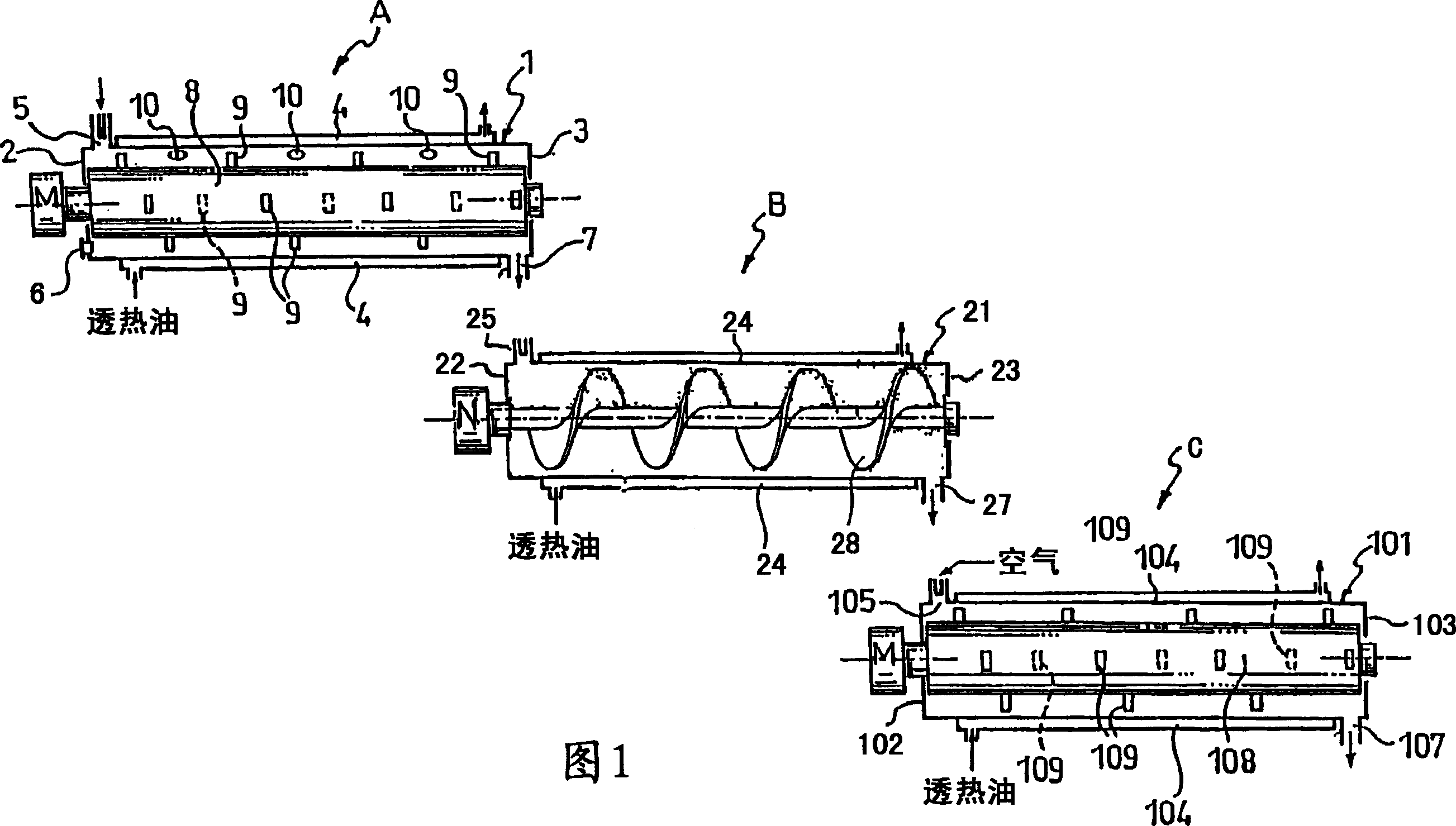

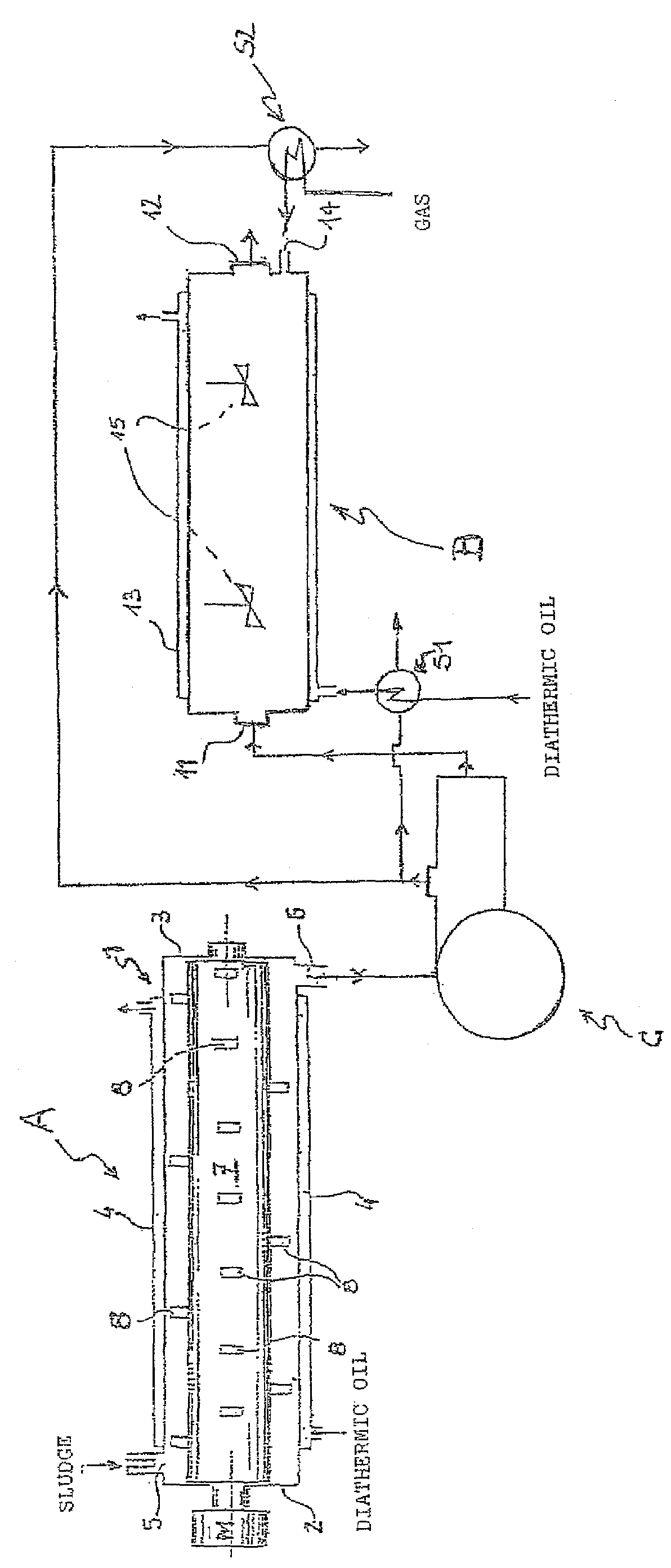

Process and plant for the production of animal meals and improved amino acid availability

Process for treating animal meals in order to improve their amino acid availability, comprising the steps of: a) feeding a continuous flow of animal meal to a turbo-reactor so as to disperse said continuous flow of animal meal in a flow of animal meal particles, b) feeding into said turbo-reactor, cocurrently with said animal meal flow, a continuous and finely divided flow of a reactant consisting of a concentrated aqueous hydrogen peroxide solution , c) centrifuging said animal meal particles and said reactant against the turbo-reactor inner wall heated at a temperature of at least 1000C, with formation of a thin tubular fluid layer, d) reacting said animal meal and said reactant within said thin layer while progressing in contact with said inner wall of the turbo-reactor, e) continuously discharging a flow of treated animal meal, having a humidity content of 30-50%, f) sending said flow of treated animal meal on to a maturation step at 60-90 DEG C / 30 min - 20 h and to a subsequent drying step to bring the humidity content of the end animal meal to 5-10%.

Owner:VOMM CHEMIPHARMA

Variable length endovascular graft prosthesis adapted to prevent endoleaks

InactiveUS20100256745A1Facilitate variable length engagementImprove sealingStentsBlood vesselsEndovascular prosthesisBlood vessel

A variable length endovascular prosthesis to prevent endoleaks includes a substantially tubular first graft member having an interior surface, an exterior surface, and an open end, and a substantially tubular second graft member engaged coaxially within the first graft member, the second graft member having a proximal end. The prosthesis further includes a substantially tubular fluid-tight connecting member attached at one end to the first graft member and attached at another end to the second graft member, where the connecting member is axially compressible and expandable to facilitate engagement of the proximal end of the second graft member within the first graft member while maintaining a seal between the proximal end of the second graft member and the open end of the first graft member.

Owner:LIFESHIELD SCI

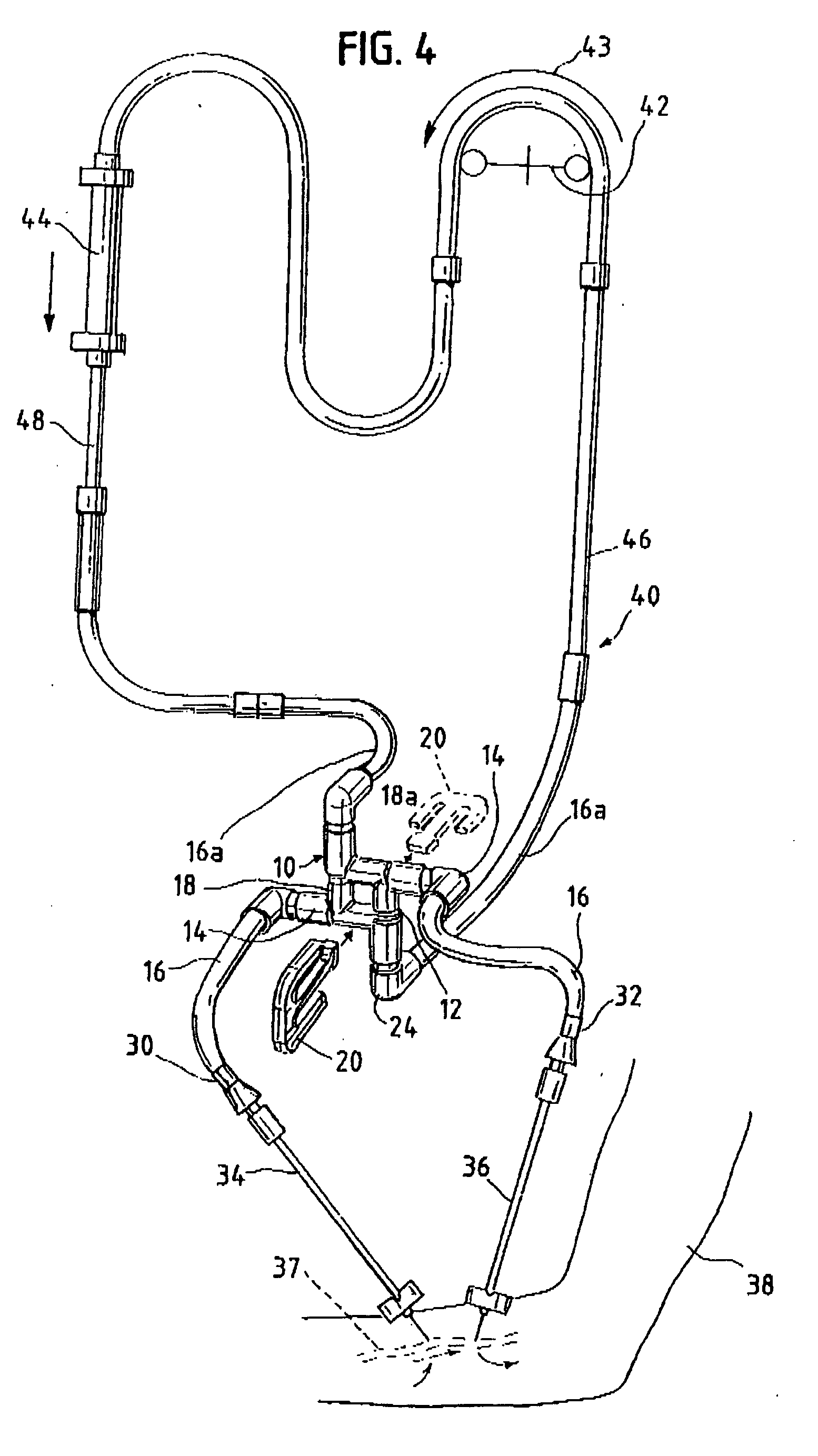

3D clampable valve flow reversing system

InactiveUS20060161094A1Improve directionEasy to operateMedical devicesSuction devicesBlood flowEngineering

A flow reversal valve for a tubular fluid flow set comprises at least four tubular branches and a tubular loop. The tubular loop separately connects with each of the tubular branches at ends thereof, the tubular loop having collapsible, clampable tube sections between connections with the branches. At least some of the tubular branches connect at a transverse, third dimensional angle to the tubular loop, either directly, or through a substantially rigid, angular bend in the blood flow tubing adjacent to the tubular loop.

Owner:DSU MEDICAL

Device for active and passive extinguishing of a cigarette

InactiveUS20160242459A1Extinguish cigaretteCigar manufactureTobacco smoke filtersEngineeringCigarette filter

A cigarette extinguishing device, including a tubular fluid receptacle configured to be disposed within a filter of a cigarette, the fluid receptacle having enclosed therein sufficient fluid to extinguish the cigarette, the fluid being under pressure from compressed air within the fluid receptacle, a diaphragm disposed at an end of the tubular fluid receptacle, the diaphragm being configured to be ruptured by at least one of pressure and heat and being more susceptible to pressure and heat than side walls of the tubular receptacle, and a tube connected to the diaphragm and extending through a tobacco region of the cigarette until a distal end of the cigarette, wherein, when the diaphragm is ruptured, the fluid flows from the fluid receptacle via the tube to a burn region of the cigarette, thereby extinguishing the cigarette.

Owner:DERI TZVI

Medical grafting methods and apparatus

InactiveUS20050240204A1Eliminate needReduce incision sizePipe elementsStaplesCatheterMechanical engineering

Methods and apparatus for making an anastomotic connection between first and second tubular fluid conduits are provided. For example, a connector may be configured for attachment to the first and second tubular fluid conduits and have an interior thereof substantially accessible to the interior of the first tubular fluid conduit. The connector may be configured for annular enlargement. An expandable structure is provided having a first portion configured to annularly enlarge the connector by engaging the interior of the connector. A second portion may be configured to extend through an opening in the medial portion of the first tubular fluid conduit.

Owner:ST JUDE MEDICAL ATG

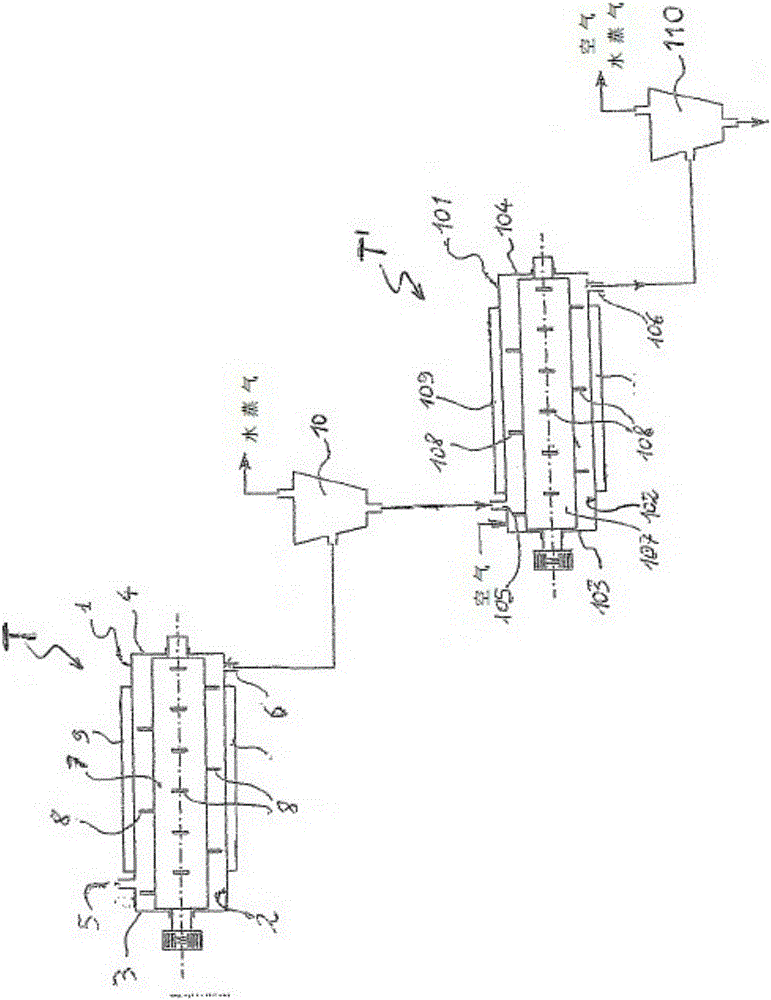

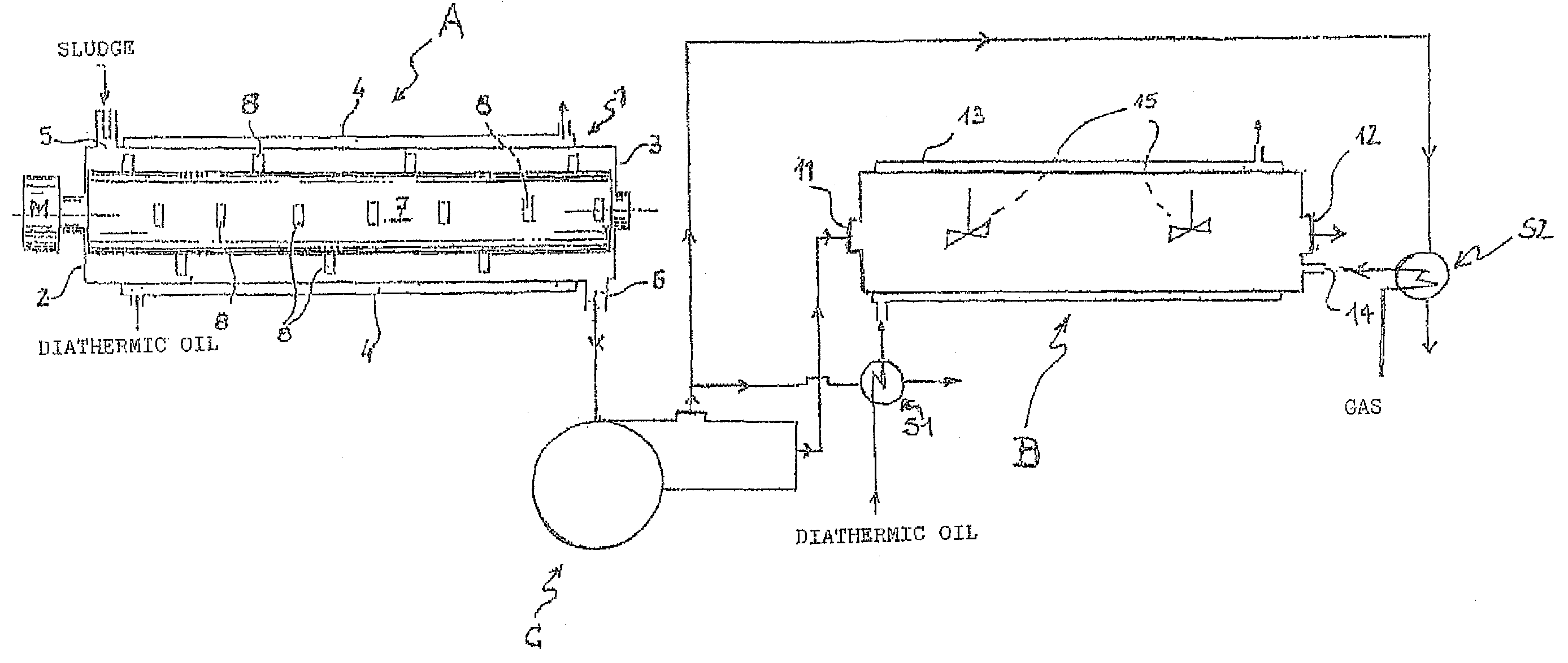

Treatment method for food waste or organic waste

The invention discloses a treatment method for food waste or organic waste which is composed of the food waste and cellulosic waste. According to the treatment method, the food waste is ground, boiled, disinfected and dried, and turbine cooking ware (T) is arranged for carrying out boiling and disinfection. The boiling and disinfection include the following steps that food waste continuous flow from the grinding step is conveyed into the turbine cooking ware (T), and a blade rotor (7) rotates at the speed of being higher than or equal to 150rpm inside the turbine cooking ware (T); the continuous flow makes centrifugal movement towards an inner wall (2) of the turbine cooking ware, so that a highly turbulent flow, dynamic, thin and tubular fluid layer is formed; ground food waste particles can be driven by blades (8) to move forwards and make contact with the inner wall of the turbine cooking ware, and the particles are heated to the temperature of at least 90 DEG C and move to a discharging outlet (6); and the disinfected and ground food waste continuous flow and water vapor continuous flow are discharged out of the discharging outlet.

Owner:AMBIENTE E NUTRIZIONE

System for making plants for drying solid organic substances in aqueous phase capable of causing explosive reactions safe and process for drying said substances

ActiveUS7877896B2Eliminate the risk of explosionLow costDrying solid materials with heatDrying solid materials without heatHorizontal axisContinuous flow

The present invention refers to a process for drying solid organic substances in aqueous phase including the steps of:feeding a continuous flow of such organic substances having a water content=50% by weight into a turbodrier having a cylindrical tubular body with horizontal axis, equipped with inlet and outlet openings, a heating jacket for bring the inner wall of the tubular body to a predetermined temperature, a bladed rotor extending inside the cylindrical tubular body (1) where it is made to rotate at speeds between 15 and 40 m / s, so as to disperse the continuous flow of organic substances into a flow of particles of organic substances;centrifuging the particles of organic substances against the inner wall of the turbodrier heated to a temperature above 130° C., with formation of a thin, dynamic, highly turbulent tubular fluid layer, which advances substantially in contact with the inner wall of the turbodrier towards the outlet opening;continuously discharging, from the turbodrier, a flow of organic substances in disgregated wet solid form having a water content=45% by weight;continuously feeding the flow of disgregated wet solid into an drier operating at a temperature lower than or equal to 160° C.;continuously discharging a flow of dry product having a water content=20% by weight from the drier.

Owner:GEOLINE

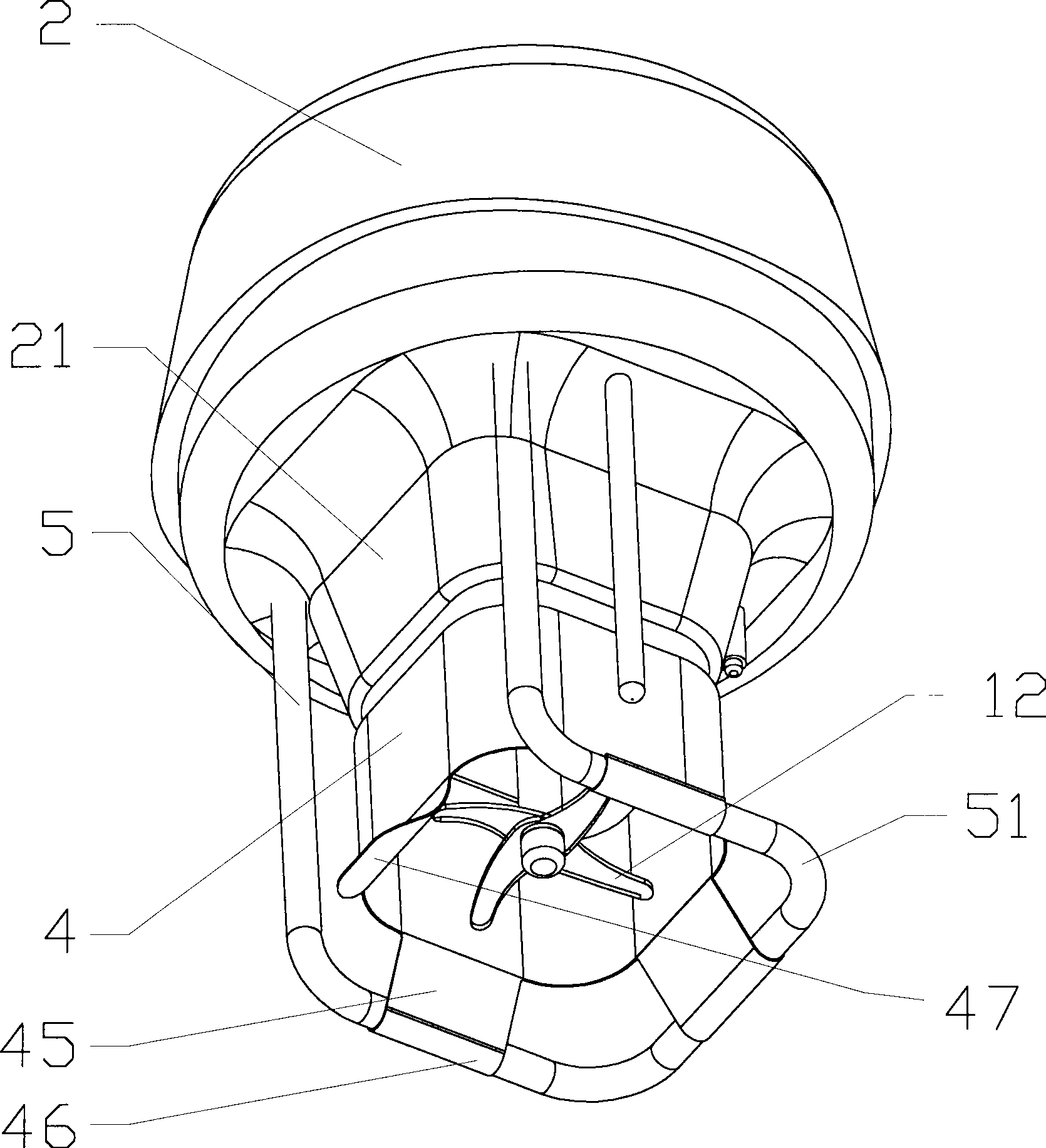

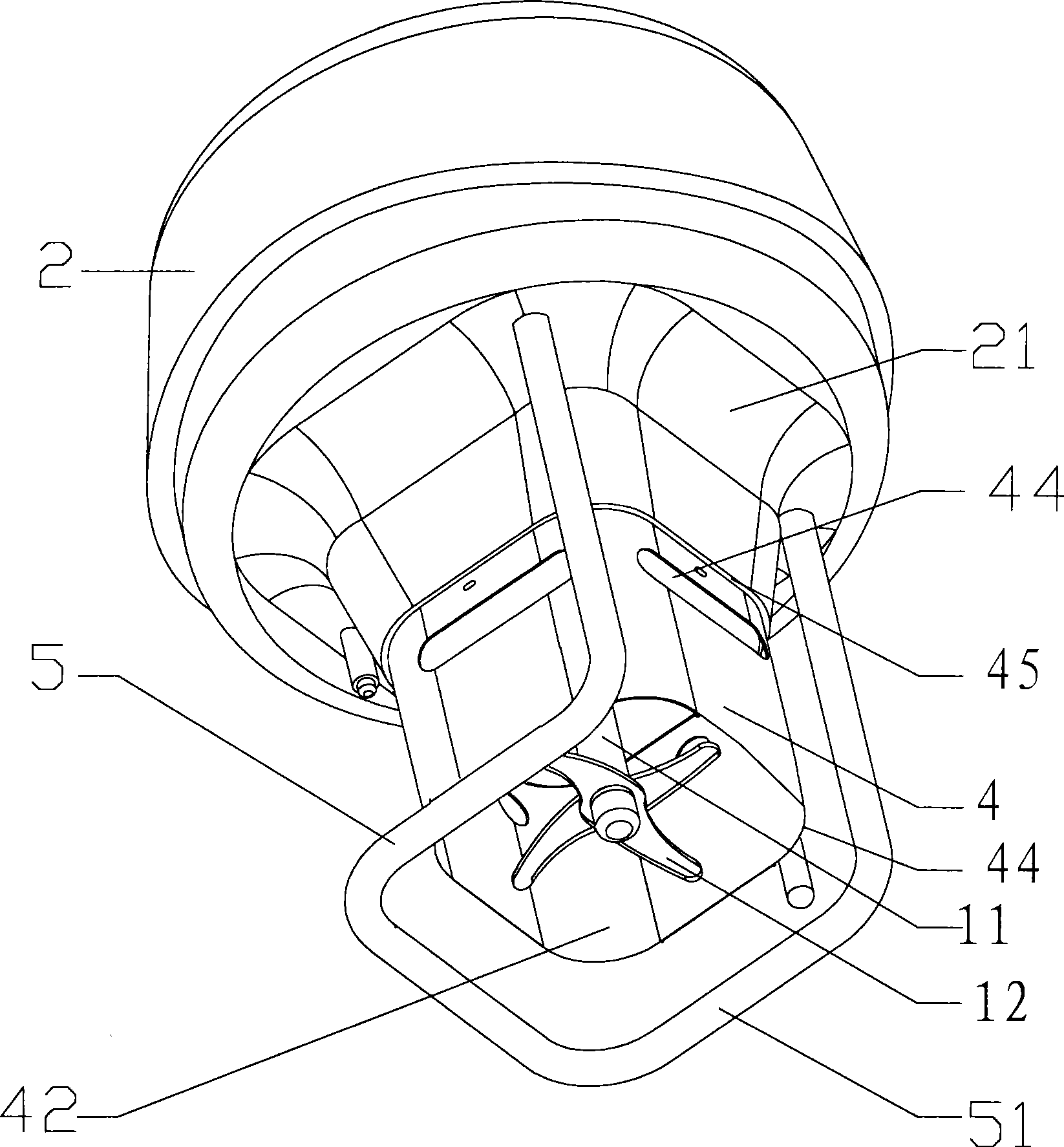

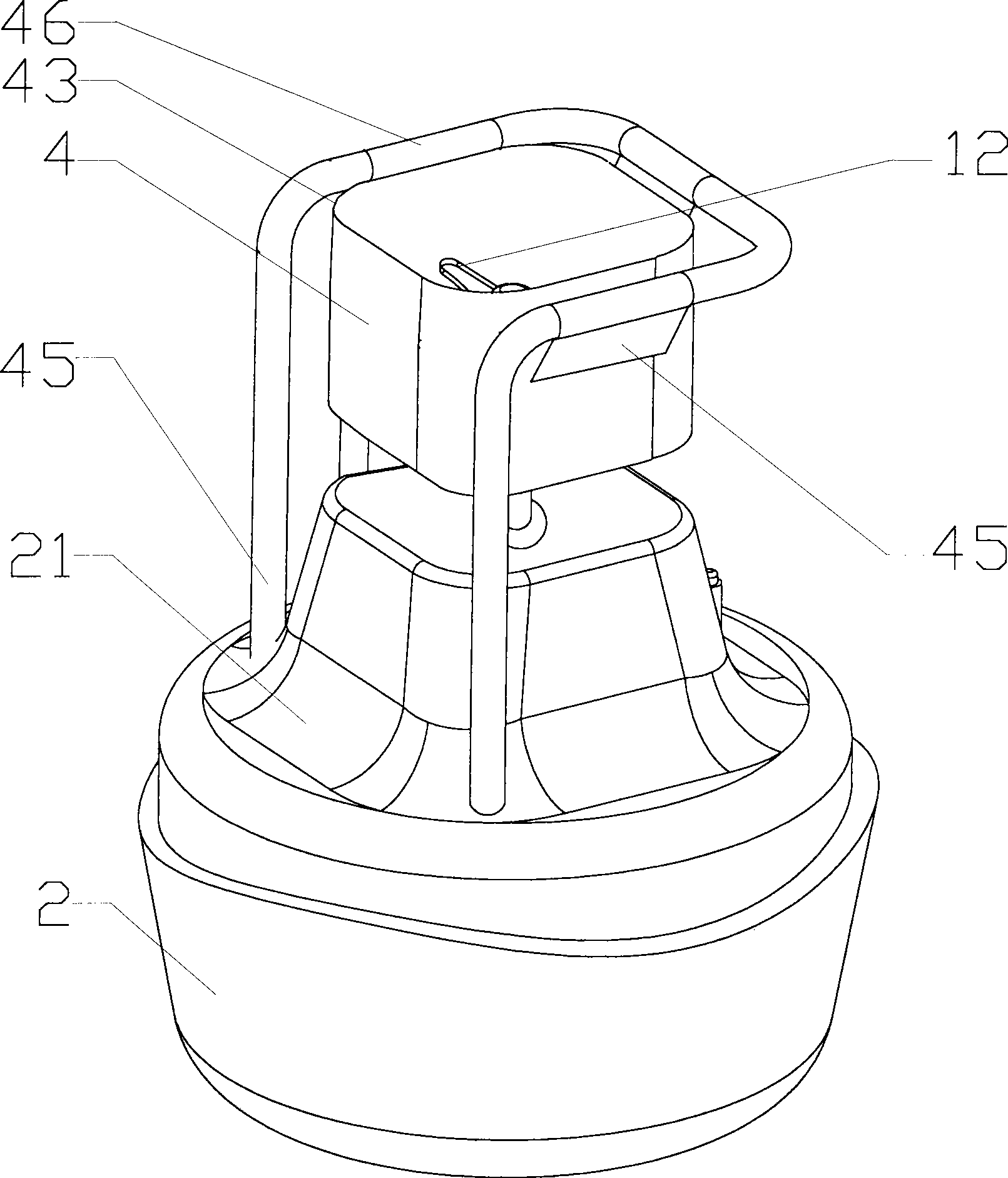

Fluid director of machine for making soya-bean milk

InactiveCN101433435AImprove crushing efficiencyEasy to cleanBeverage vesselsFood preparationAlong edgeBiomedical engineering

The invention relates to a device for making soymilk, rice paste, fruit and vegetables at home, in particular to a fluid director for a soymilk machine. The fluid director for the soymilk machine has high crushing efficiency and is easy to clean; and the fluid director for the soymilk machine is arranged in a cavity between the bottom of a cup cavity of the soymilk machine and a lower cover of a handpiece cover, and is fixed by a supporting element, and the cross section of the fluid director is in a geometrical tubular shape. The geometrical tubular fluid director is a square fluid director consisting of a square tube enclosed by four planes, and openings at two ends of the tube. The supporting element consists of pins for the fluid director, snap rings and a fluid director taking-out handle, wherein the pins for the fluid director extend outwards along edges of three planes of a tube mouth from the tube mouth at one end of the geometrical tubular fluid director, are coiled for buckling on the outer wall of an electrothermal tube to realize positioning; the snap rings are extended from the pins for the fluid director; and the fluid director taking-out handle is formed by extending the edge of the rest plane of the tube mouth outward.

Owner:东莞市逸迅通信科技有限公司

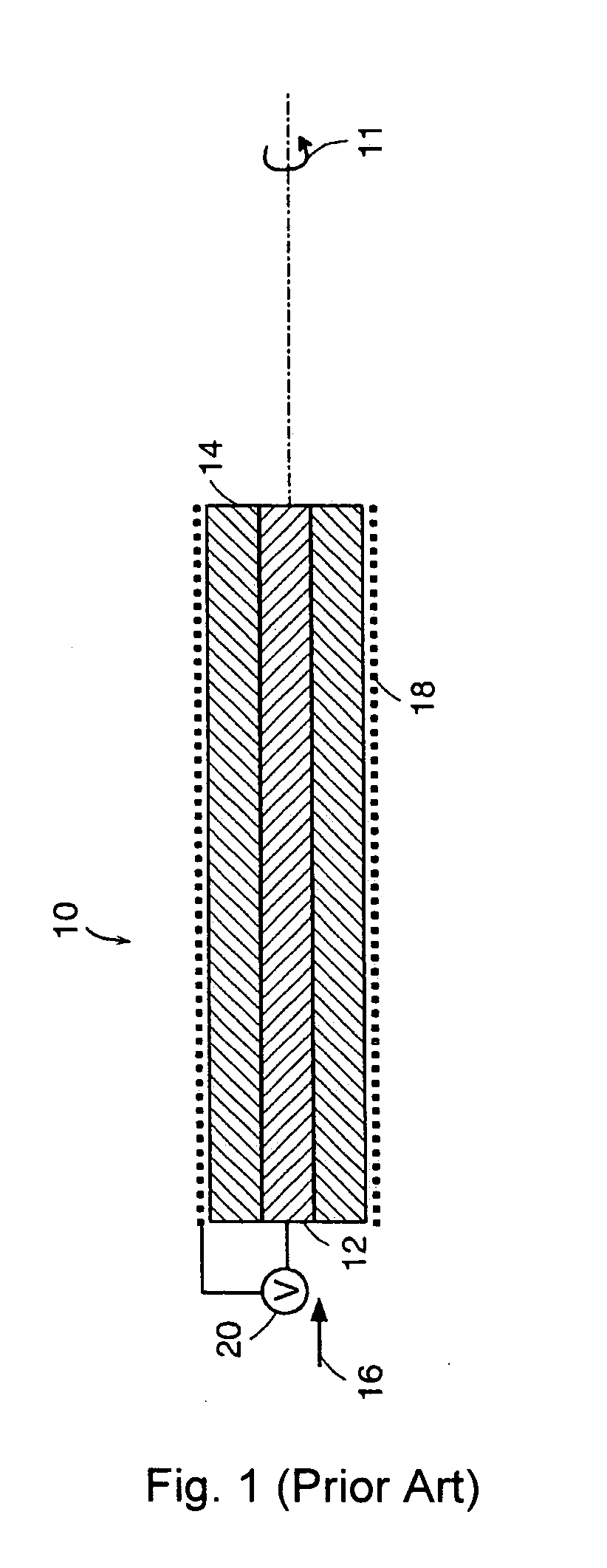

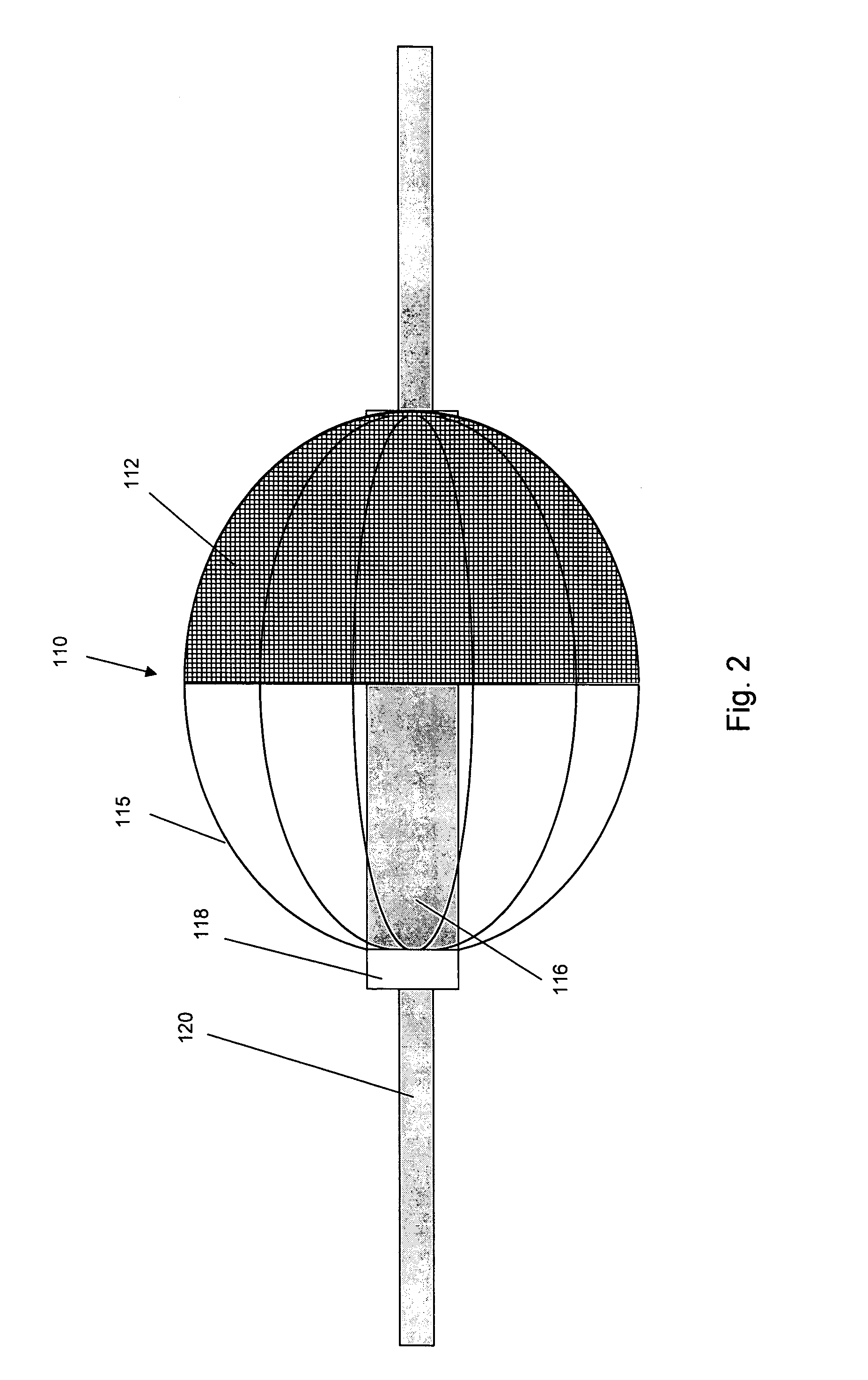

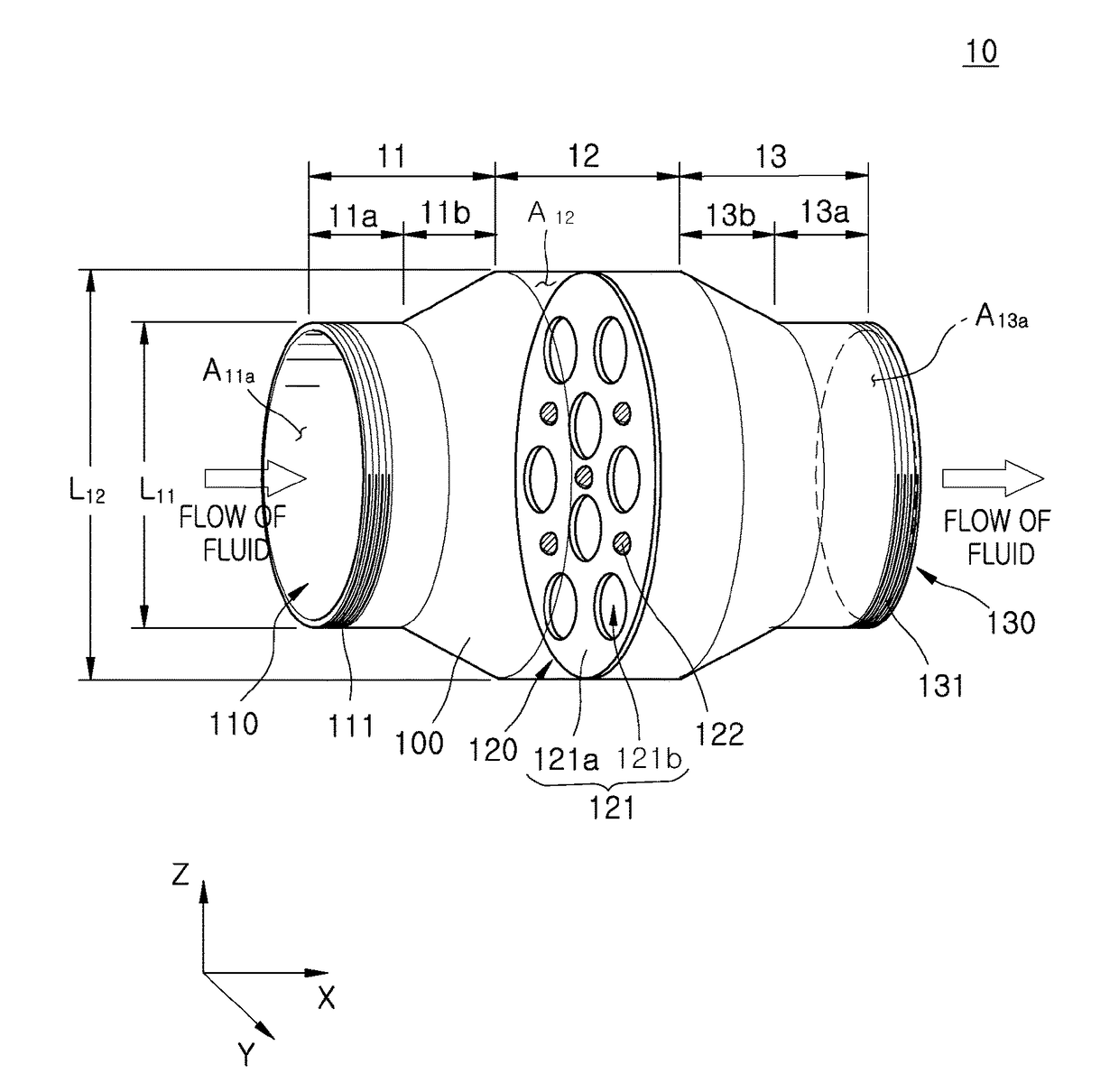

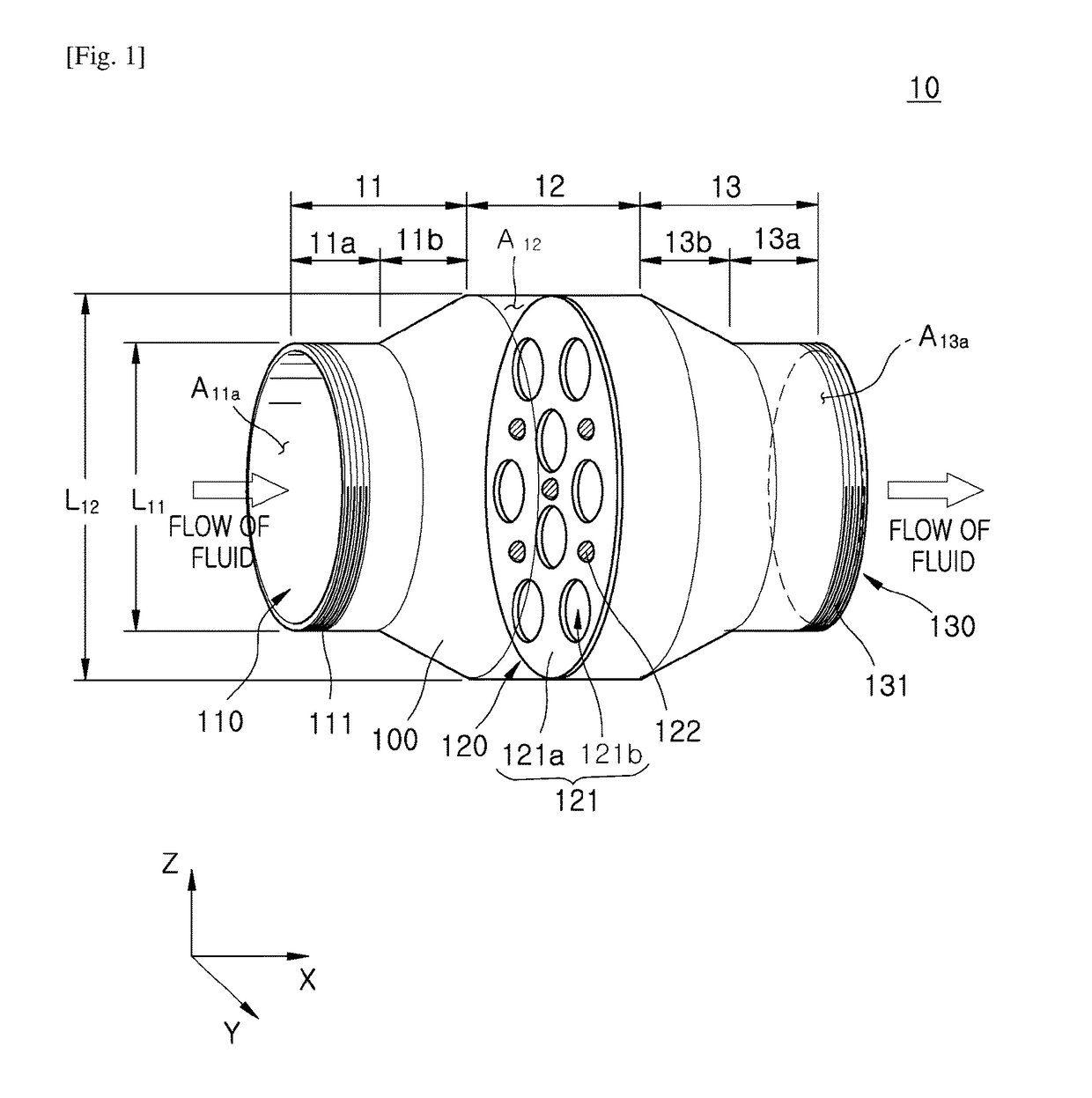

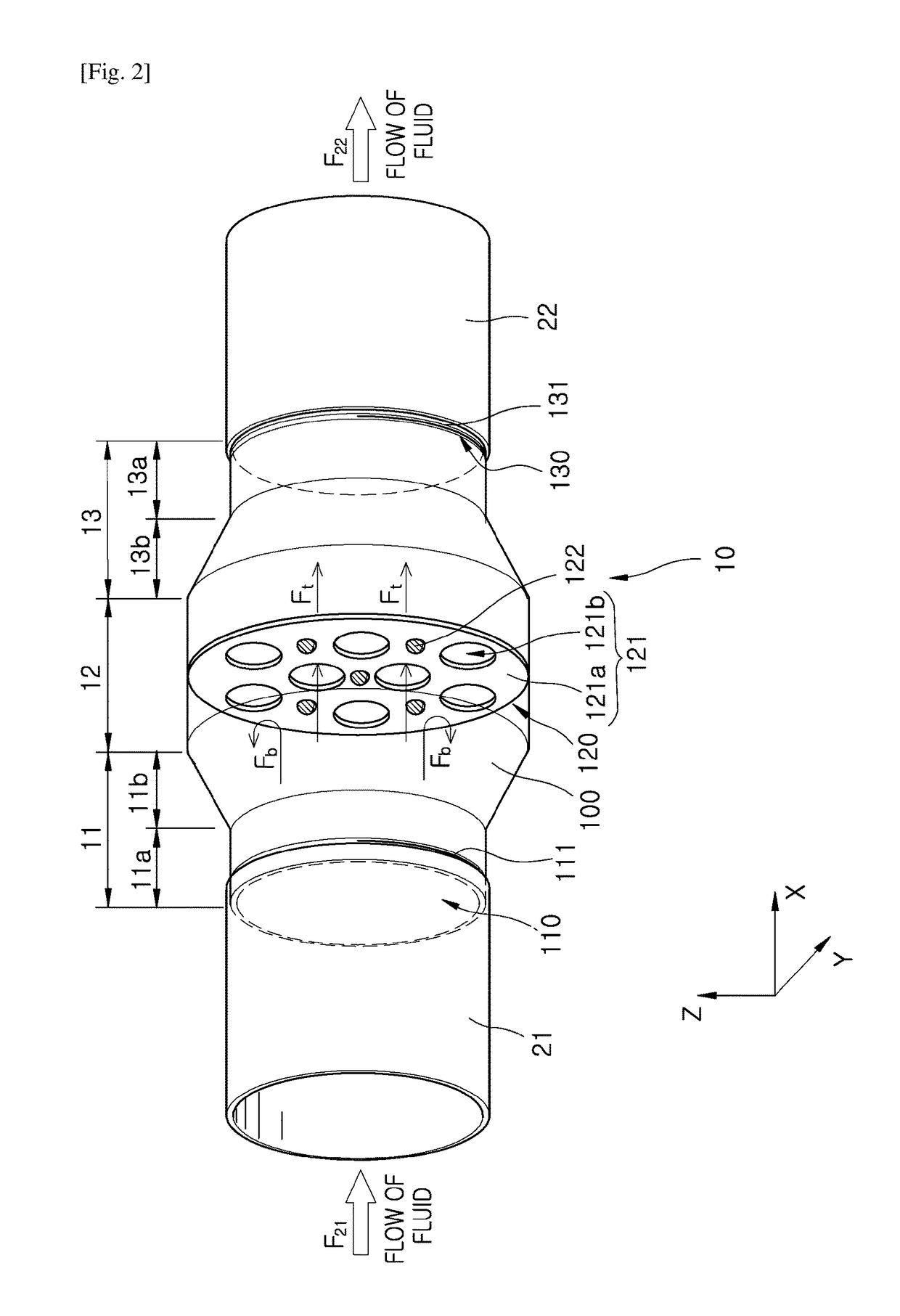

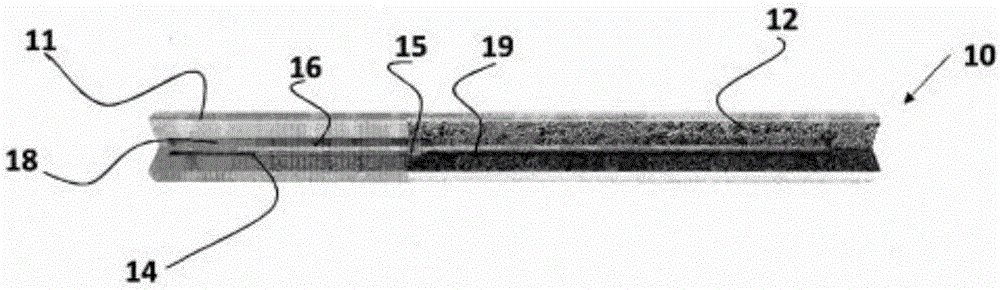

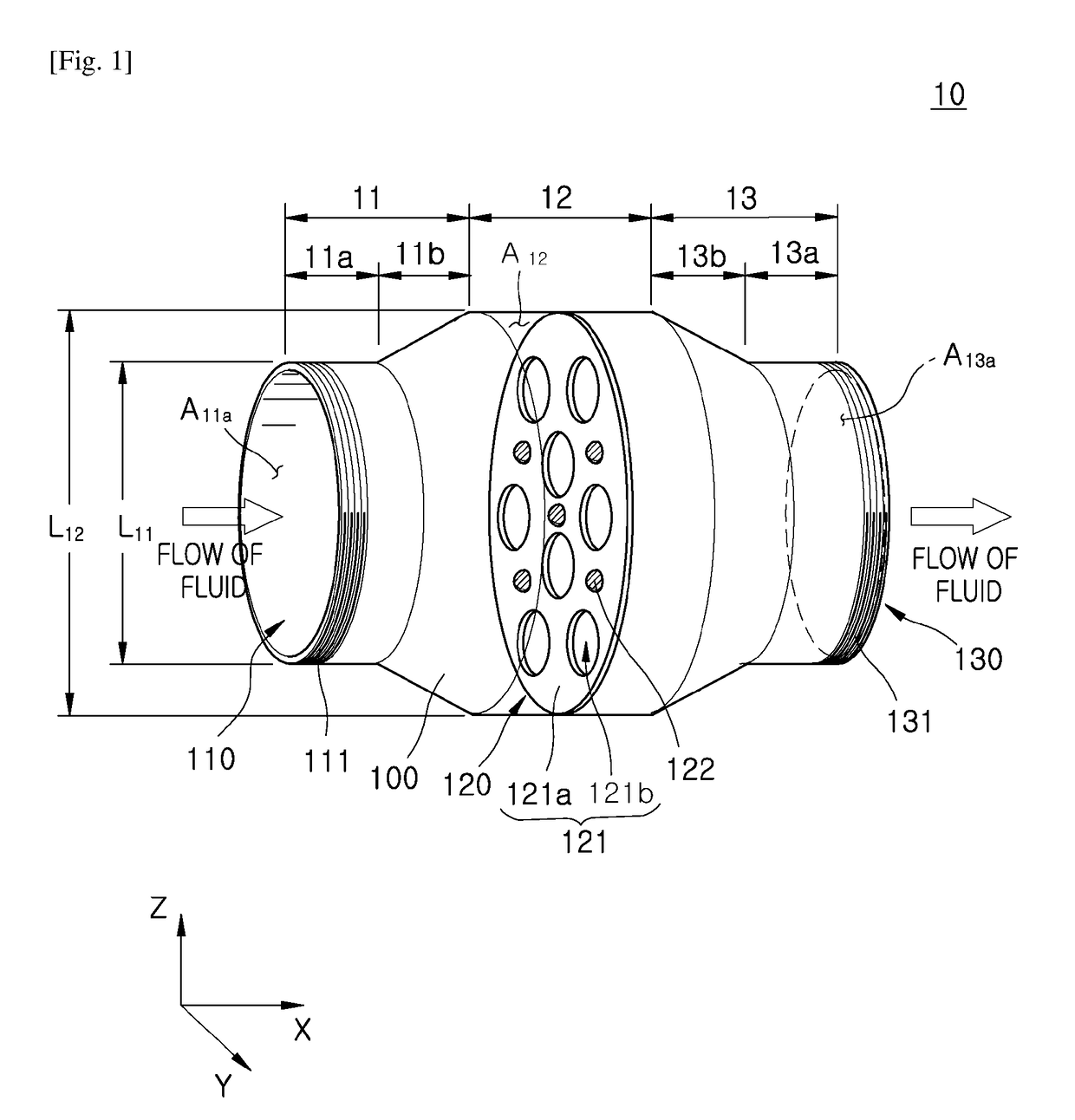

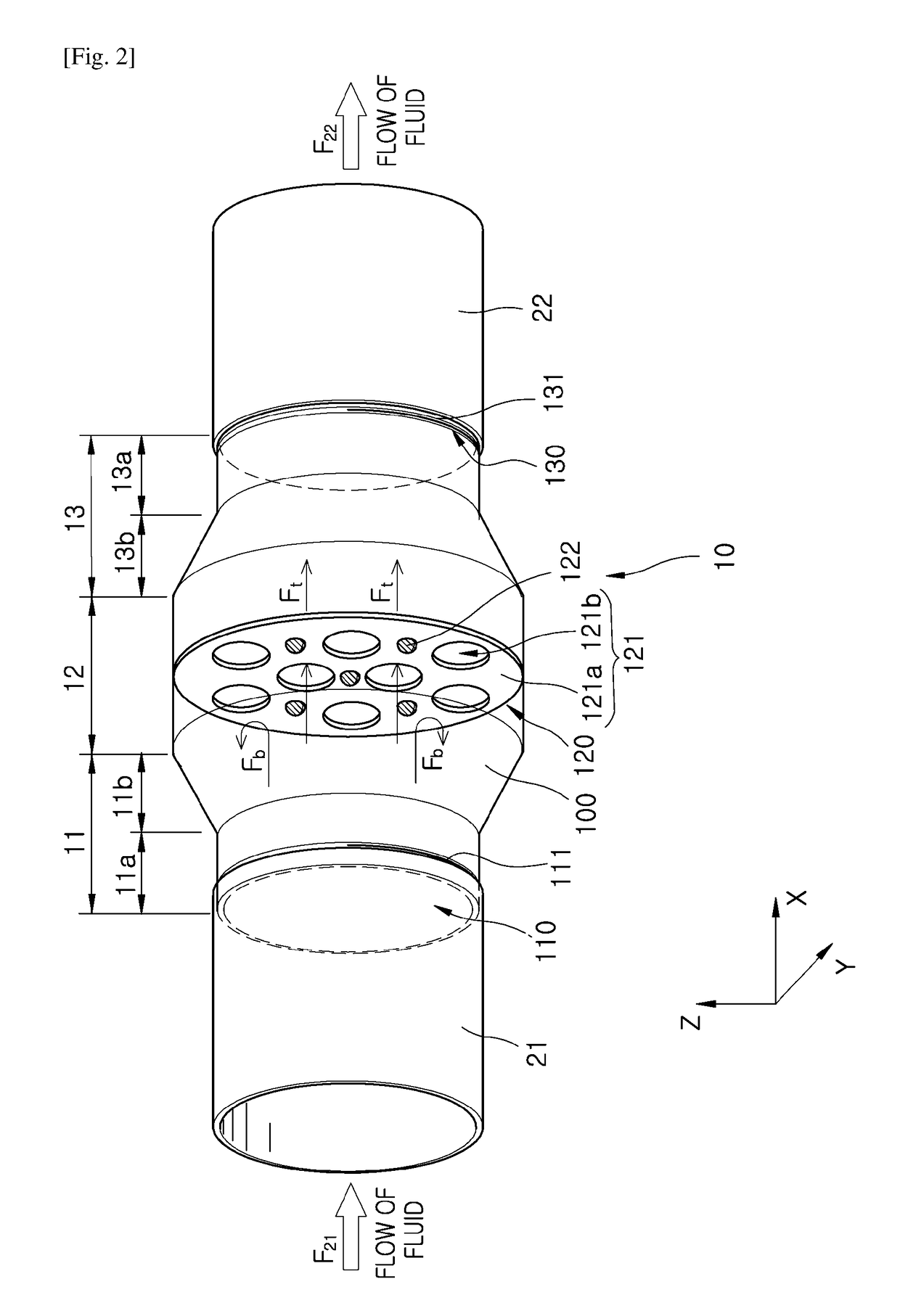

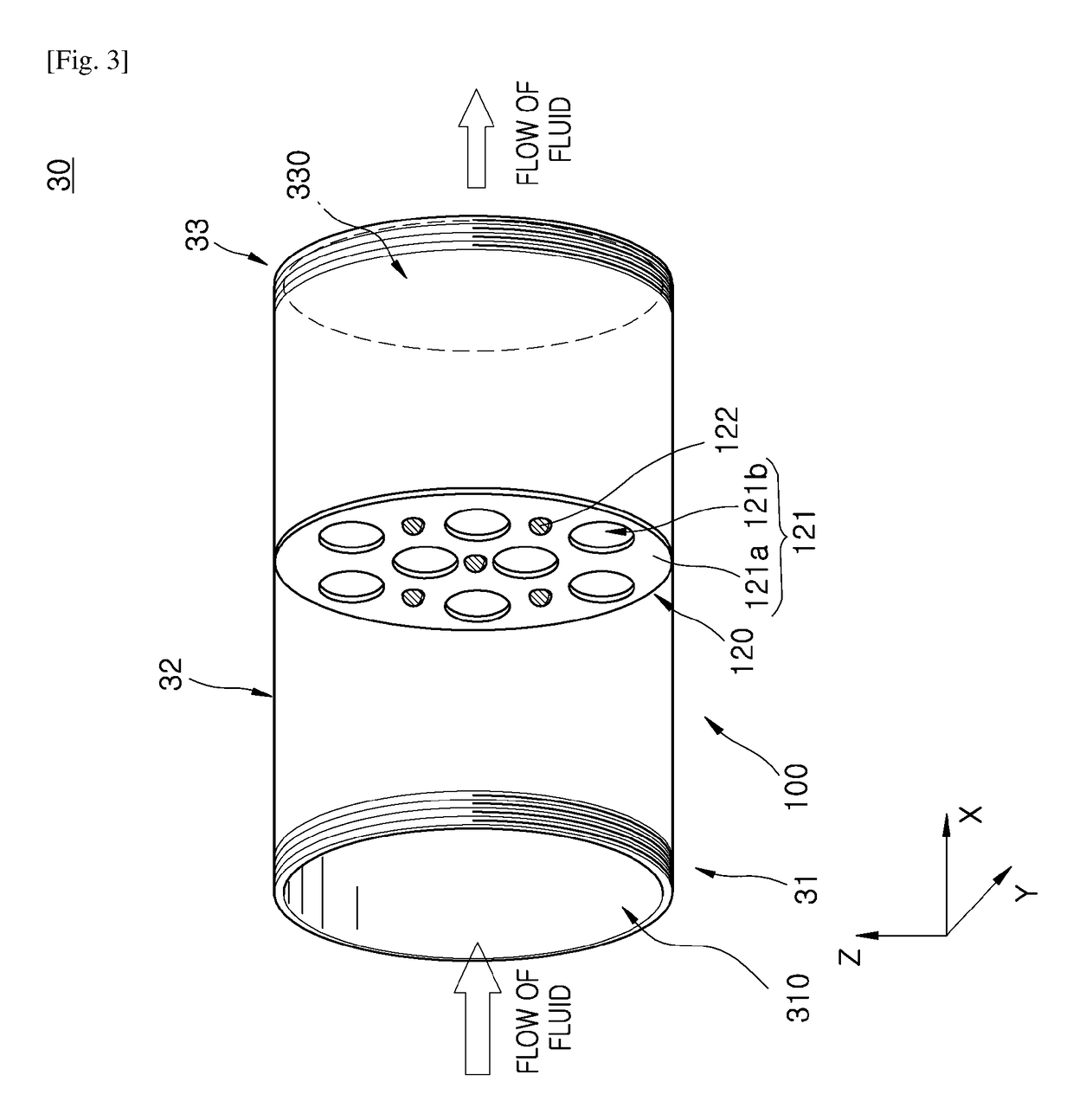

Tubular fluid purification apparatus

ActiveUS20170355622A1Efficient purificationHigh trafficWater/sewage treatment by centrifugal separationWater/sewage treatment by irradiationUltraviolet lightsLight-emitting diode

A tubular fluid purification apparatus includes a guide part provided with an inlet port into which fluid is drawn, a discharge part provided with an outlet port from which the fluid is discharged, a conduit part configured to provide a space for flow of the fluid between the guide part and the discharge part, and a purification of unit supported on an inner surface of the conduit part and disposed to face the fluid flowing from the guide part to the discharge part. The purification unit includes a vortex generation part including a support and an opening formed in the support, and a light emitting diode disposed on the support at a position adjacent to the opening and configured to provide ultraviolet light.

Owner:SEOUL VIOSYS CO LTD

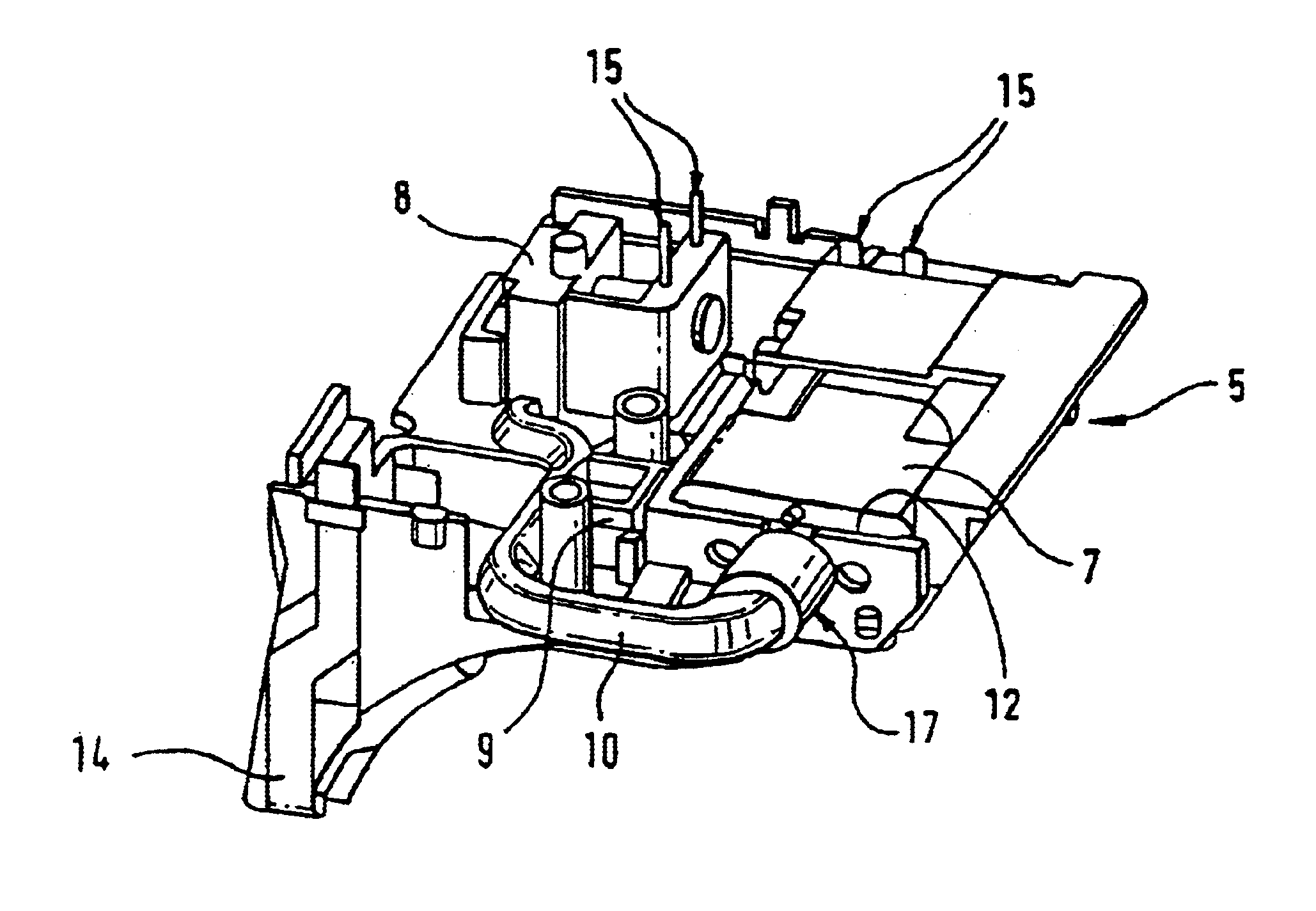

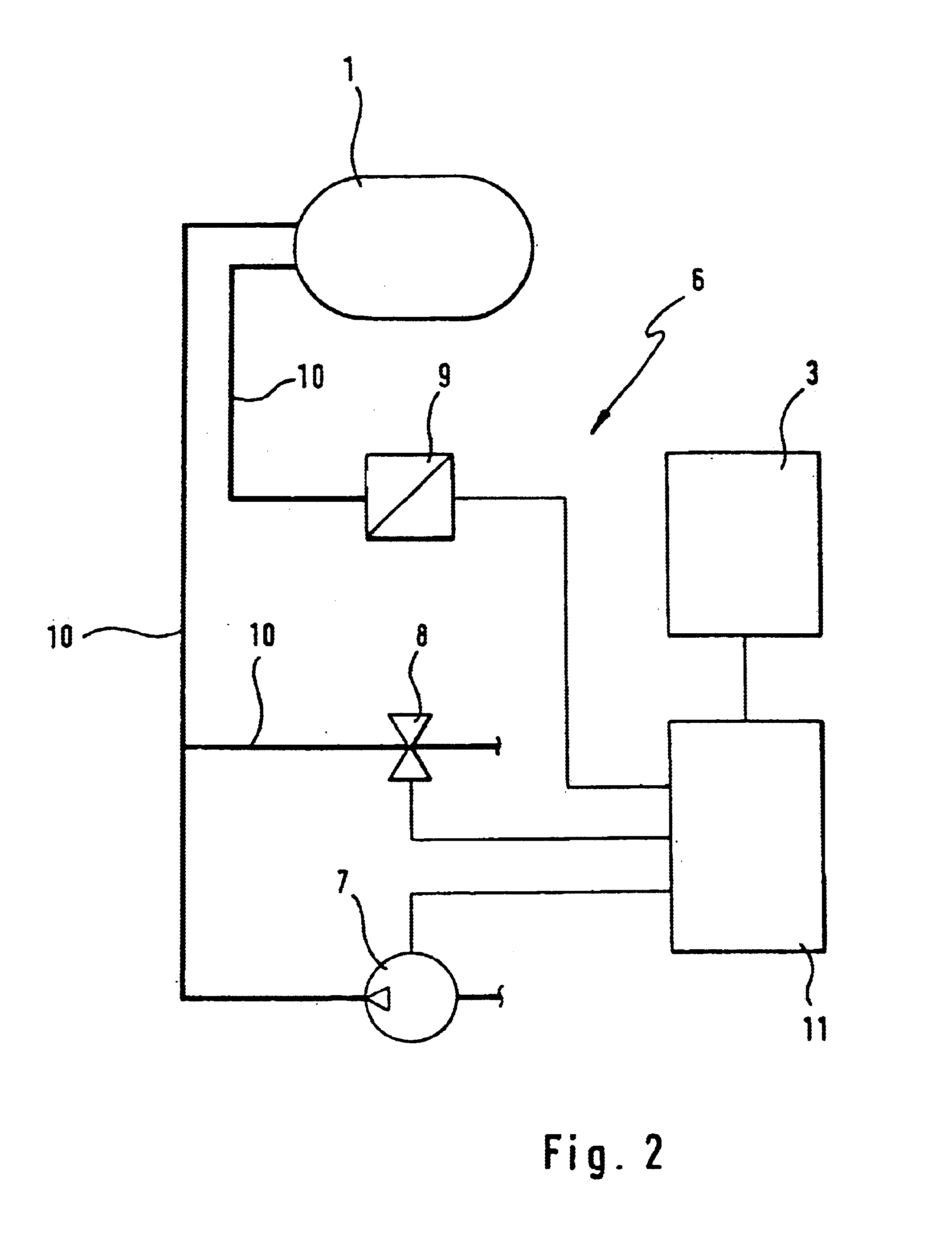

Blood pressure monitoring device and method of manufacturing a parts mounting module of a blood pressure monitoring device

InactiveUS6843773B2Improve the immunityEasy to manufactureEvaluation of blood vesselsCatheterLiquid coreCompressed fluid

The invention is directed to a blood pressure monitoring device comprising a central parts mounting module and to a method of manufacturing this parts mounting module. According to the invention fluid channels are produced by gas injection into the interior of the parts mounting module, the walls bounding the fluid channels being completely formed by the material of the parts mounting module. The injection of gas continues for as long as a core of the parts mounting module is still in the liquid phase in the area of the fluid channel, whilst an outer area surrounding the core has already solidified, so that the pressure fluid expels the liquid core area, producing a tubular fluid channel.

Owner:KAZ USA

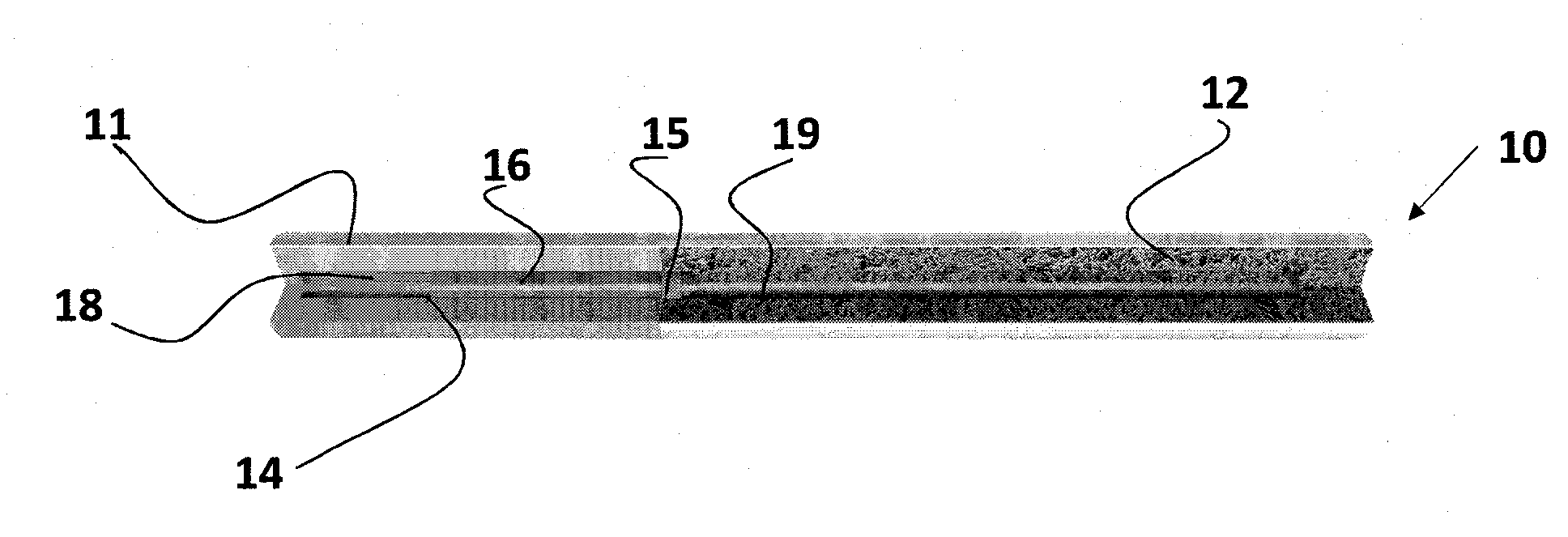

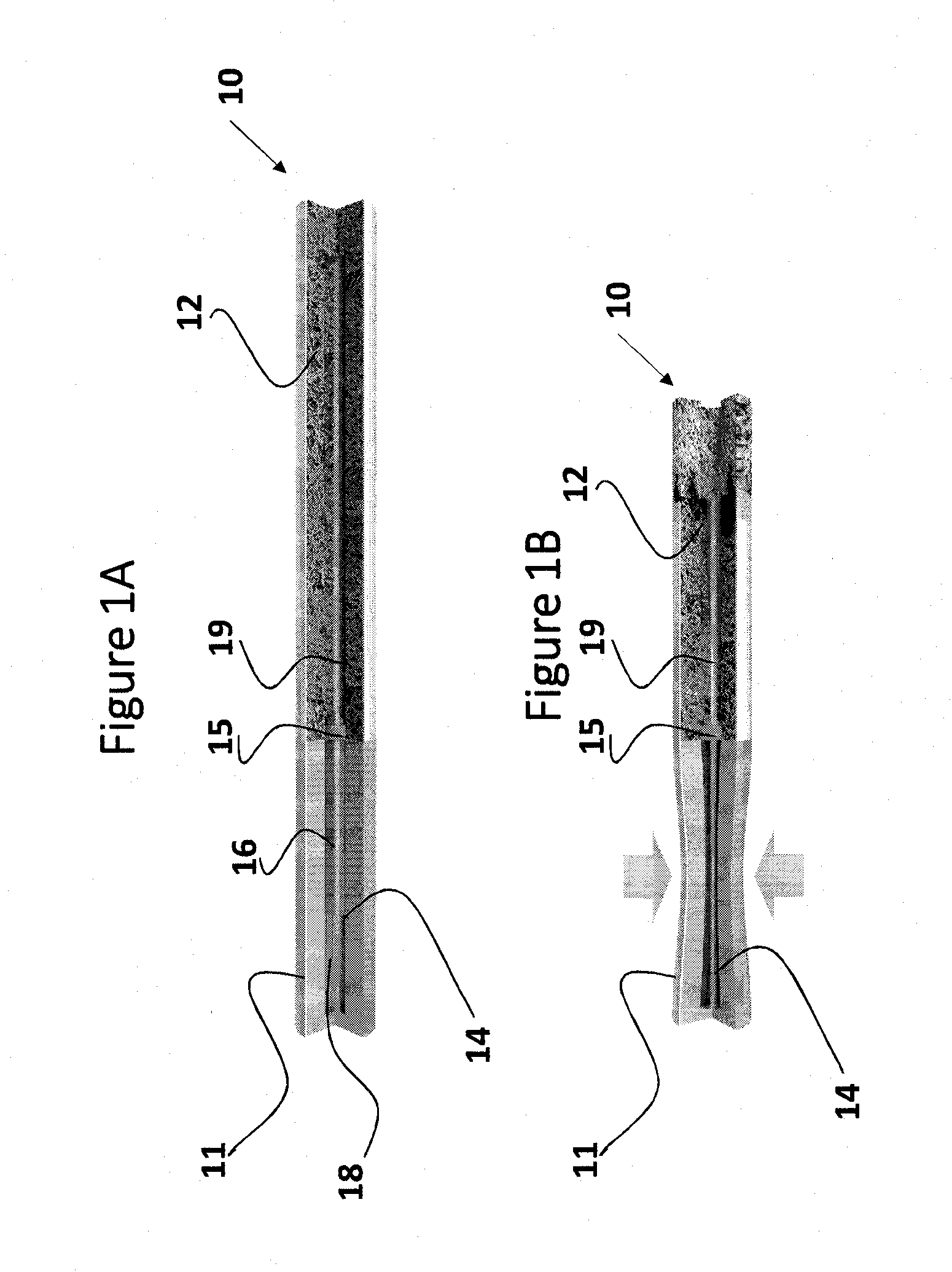

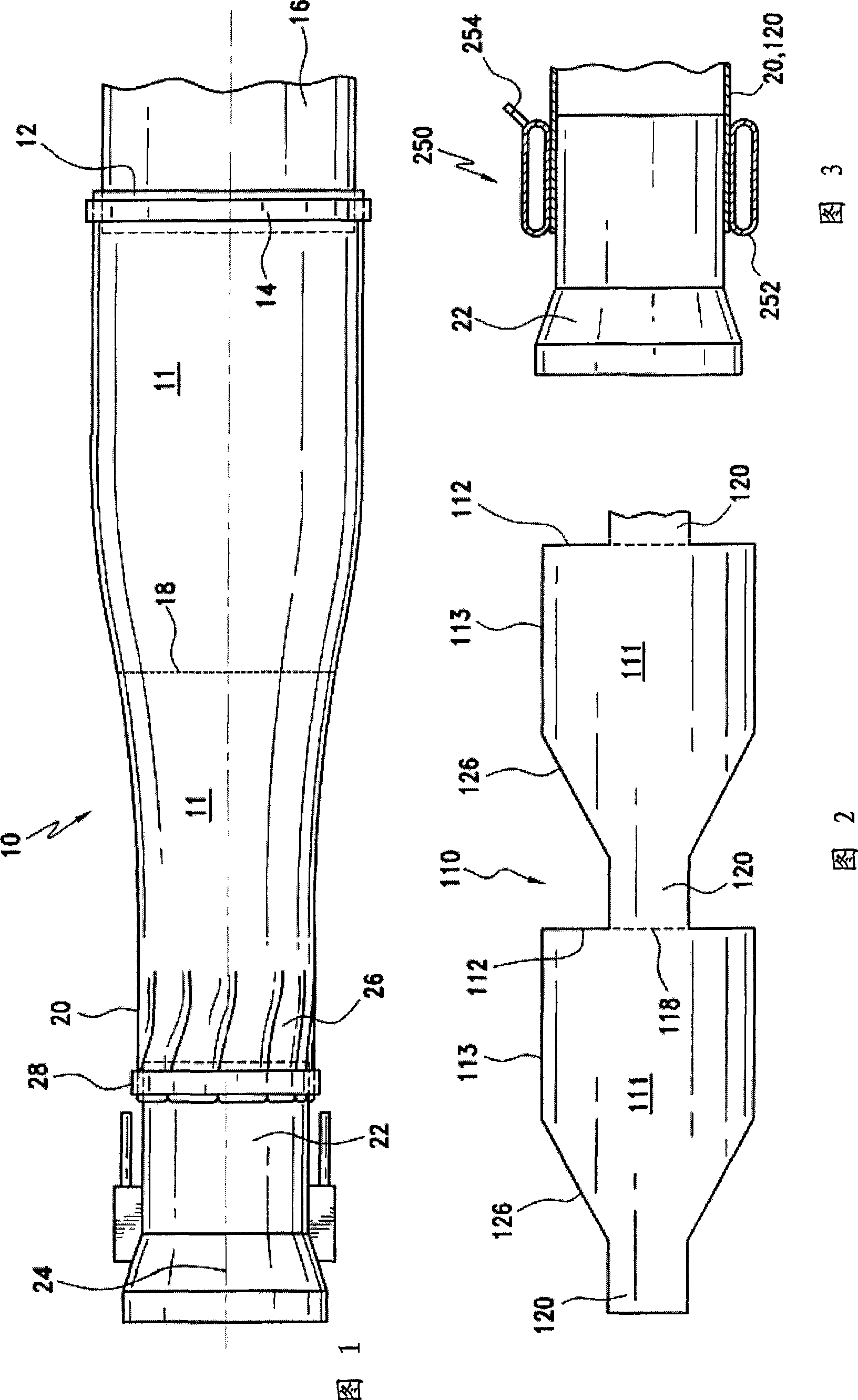

Semi-disposable pre-conditioned air supply hose conduit and connectors for attaching end portions of the same

InactiveCN101400935AFirmly connectedEasy to usePipe-jointsPipe connection arrangementsPre-conditionPre conditioning

A tubular fluid conduit (10) which is especially adapted for use in supplying preconditioned air to an aircraft being serviced, wherein the tubular conduit (10) may be fabricated as a thermoplastic extrusion having a constant diameter dimension, whereby a first end portion (12) may be fluidically connected to a large diameter supply conduit while a second end portion (20) may be fluidically connected to a small diameter use conduit as a result of spiral wrapping (26) the second end portion (20) around the use conduit. Alternatively, the tubular conduit may be fabricated as a thermoplastic extrusion having repetitive sections with each section comprising relatively large diameter and relatively small diameter portions.

Owner:ILLINOIS TOOL WORKS INC

Semi-disposable pre-conditioned air supply hose conduit and connectors for attaching end portions of the same

ActiveUS20070216155A1Readily and easily folded, unfolded, or disposedReadily and easilyCouplingsPipe-jointsPre-conditionPre conditioning

A tubular fluid conduit which is especially adapted for use in supplying pre-conditioned air to an aircraft being serviced, wherein the tubular conduit may be fabricated as a thermoplastic extrusion having a constant diameter dimension, whereby a first end portion may be fluidically connected to a large diameter supply conduit while a second end portion may be fluidically connected to a small diameter use conduit as a result of spiral wrapping the second end portion around the use conduit. Alternatively, the tubular conduit may be fabricated as a thermoplastic extrusion having repetitive sections with each section comprising relatively large diameter and relatively small diameter portions.

Owner:ILLINOIS TOOL WORKS INC

Apparatus for dissolving frozen polarized sample and applications

InactiveCN104076308APreparing sample for investigationMeasurements using double resonanceDynamic nuclear polarisationEngineering

DNP polarizer comprising a housing receiving a free end of a tubular fluid conduit positioned in fluid communication with a nozzle supported by said housing, said nozzle including an input port, a dispense port and a tapering inner surface or a stepped inner surface defining a nozzle flowpath extending in fluid communication between said input port and said dispense port.

Owner:GE HEALTHCARE LTD

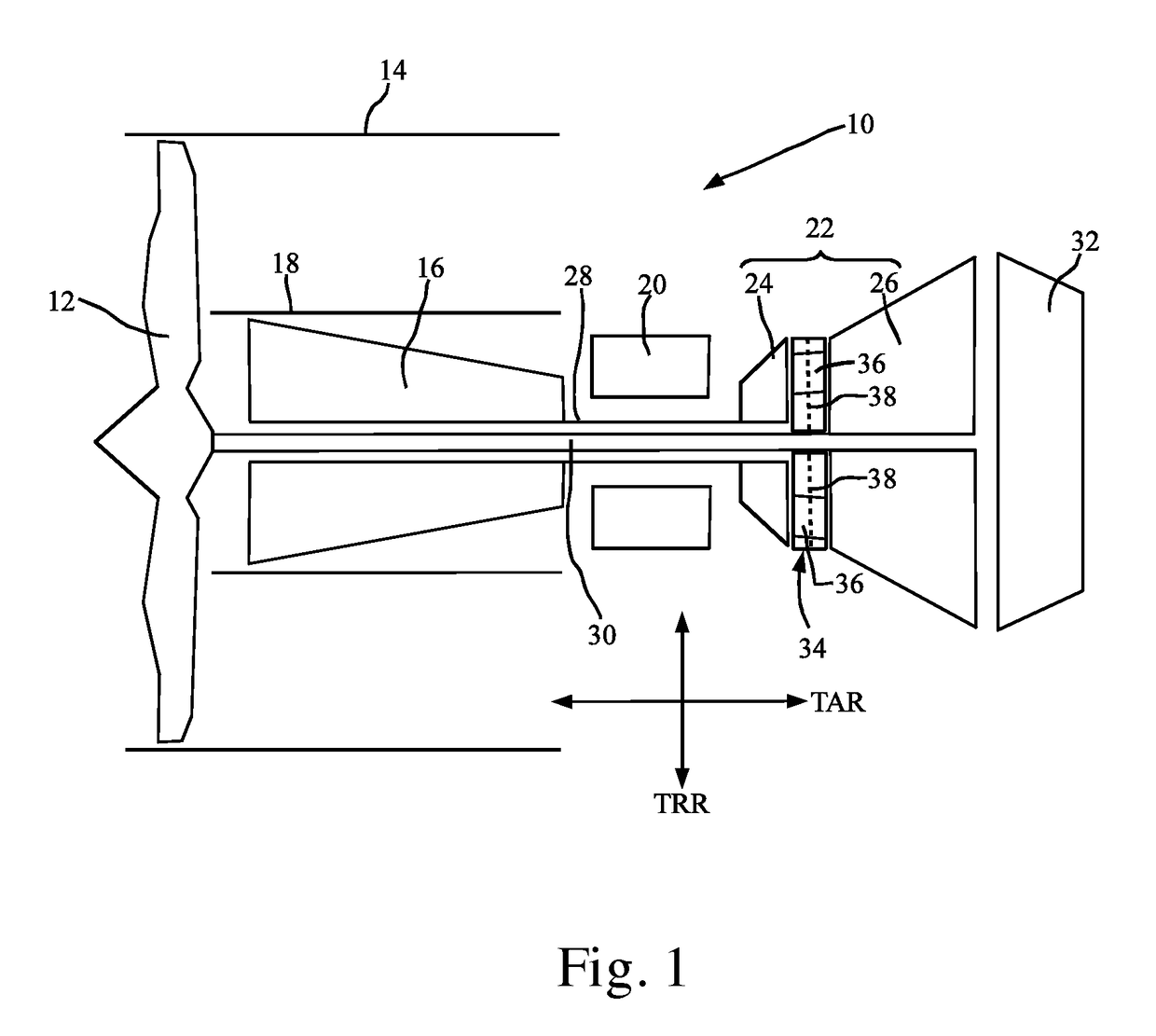

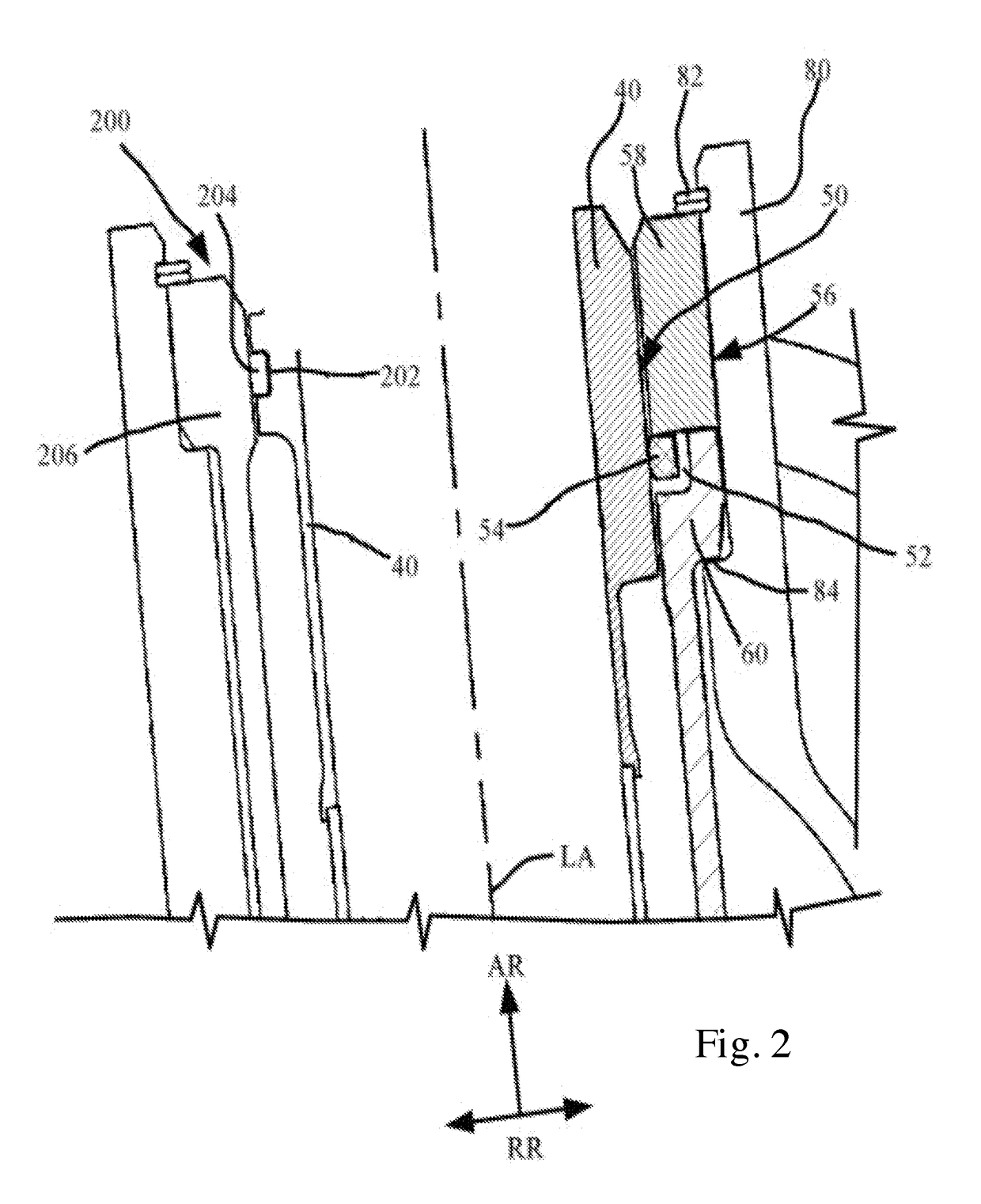

Seal arrangement for a mid turbine frame of a gas turbine

The seal arrangement for a mid turbine frame of a gas turbine, especially an aircraft gas turbine, includes a tubular fluid duct, especially an oil duct, which extends along an axial direction, a bearing sleeve surrounding the fluid duct radially outside and in the peripheral direction, and at least one seal ring arranged between fluid duct and bearing sleeve in the radial direction, this ring being arranged around the fluid duct. The seal ring is taken up at least partly in a groove provided in the bearing sleeve.

Owner:MTU AERO ENGINES GMBH

Tubular fluid purification apparatus

ActiveUS10173909B2Efficient purificationHigh trafficWater/sewage treatment by centrifugal separationWater/sewage treatment by irradiationUltraviolet lightsLight-emitting diode

A tubular fluid purification apparatus includes a guide part provided with an inlet port into which fluid is drawn, a discharge part provided with an outlet port from which the fluid is discharged, a conduit part configured to provide a space for flow of the fluid between the guide part and the discharge part, and a purification of unit supported on an inner surface of the conduit part and disposed to face the fluid flowing from the guide part to the discharge part. The purification unit includes a vortex generation part including a support and an opening formed in the support, and a light emitting diode disposed on the support at a position adjacent to the opening and configured to provide ultraviolet light.

Owner:SEOUL VIOSYS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com