Multiple component dispensing cartridge, mixing nozzle and method for reducing contact between fluids

A technology for mixing nozzles and fluids, used in chemical instruments and methods, mixers, fluid mixers, etc., and can solve problems such as difficulty and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

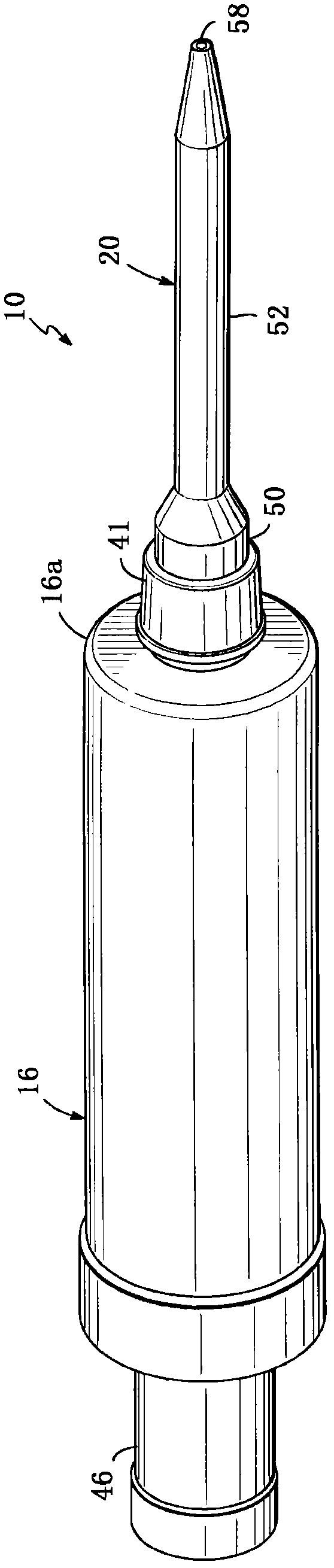

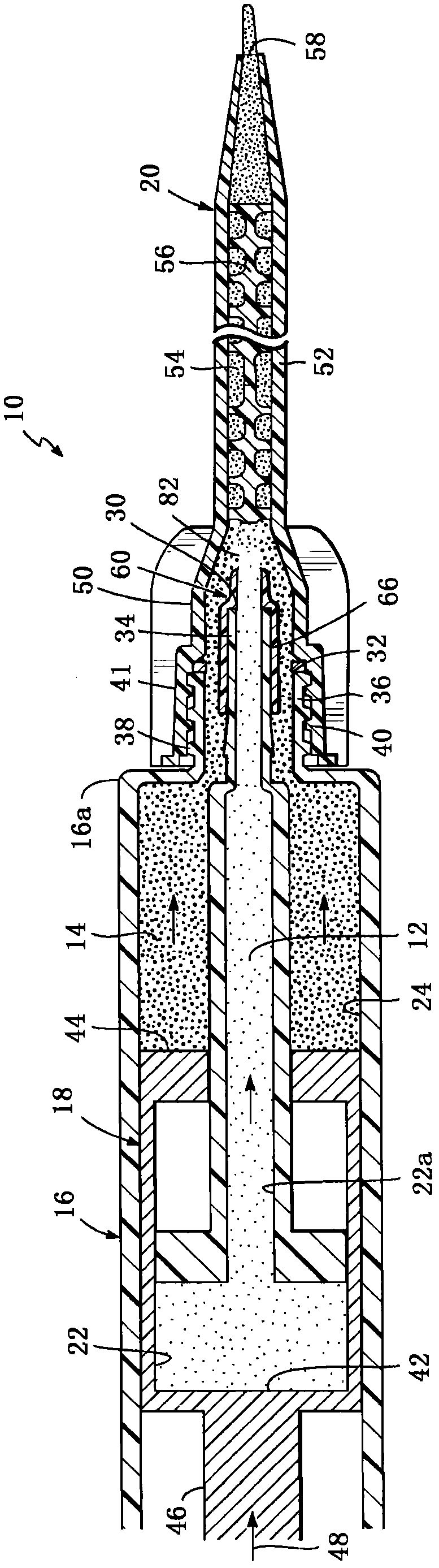

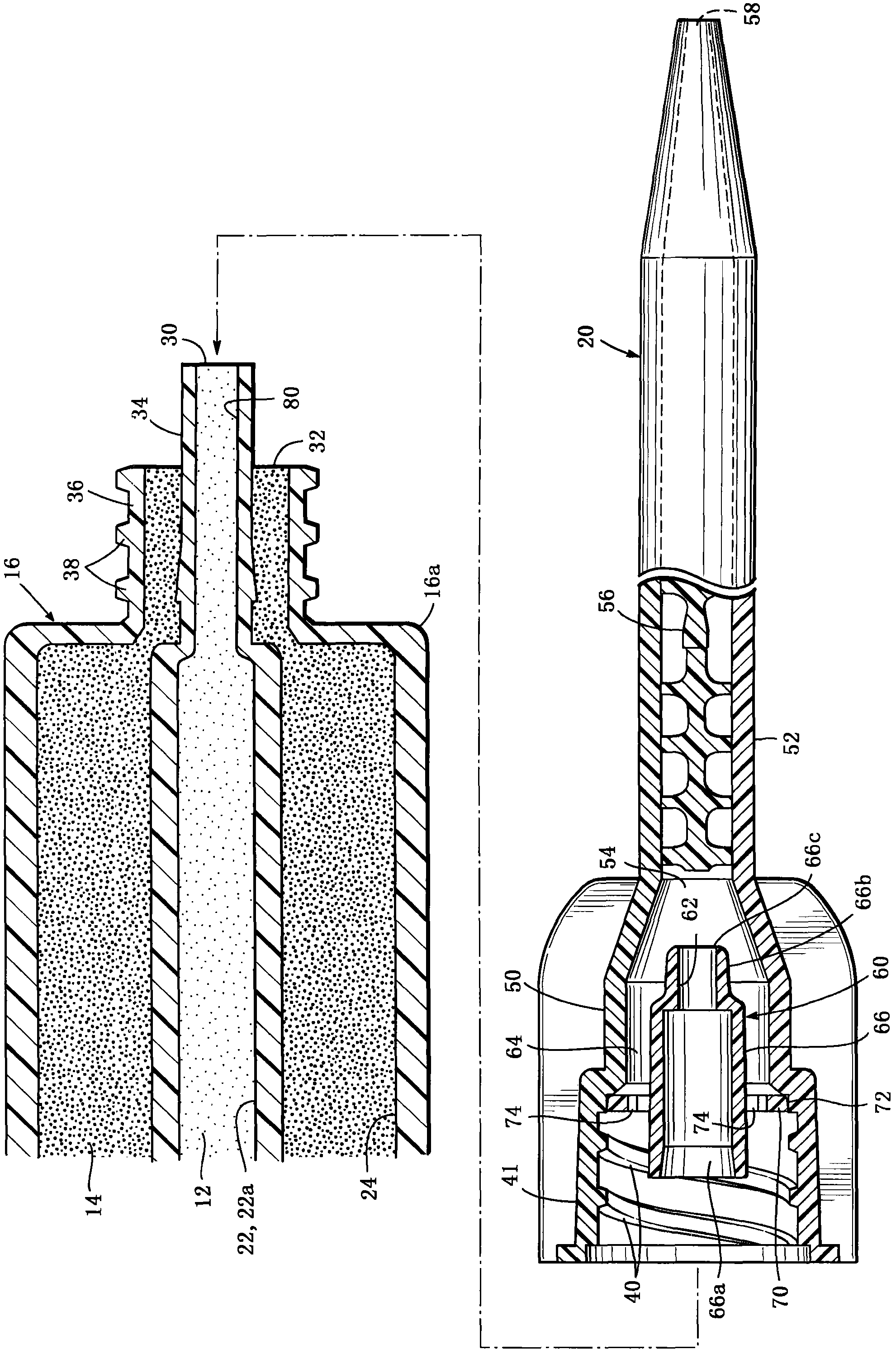

[0024] First refer to figure 1 and figure 2 , shows a fluid cartridge 10 for mixing and dispensing a first fluid 12 and a second fluid 14, and the fluid cartridge 10 generally includes a housing 16, a piston unit 18 mounted in the housing 16, and a piston unit 18 coupled to the housing The mixing nozzle 20 at the distal end 16a of the body 16. It should be understood that the housing 16 and piston unit 18 may take many different designs and that the designs shown here are for illustrative purposes only. For more details regarding the operation of the piston unit 18, reference may be made to US Patent No. 7,748,567, the disclosure of which is incorporated herein by reference.

[0025] Generally, the housing 16 includes first and second fluid chambers 22, 24 to hold the first and second fluids 12, 14, respectively. The second fluid chamber 24 is an annular chamber disposed in surrounding relationship with the front or distal portion 22a of the first chamber 22 . The piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com