Treatment method for food waste or organic waste

A technology of organic waste and treatment method, applied in the field of organic waste, can solve the problems of expensive equipment, huge waste paper or waste cardboard, etc., and achieve the effect of strong water absorption, weight and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

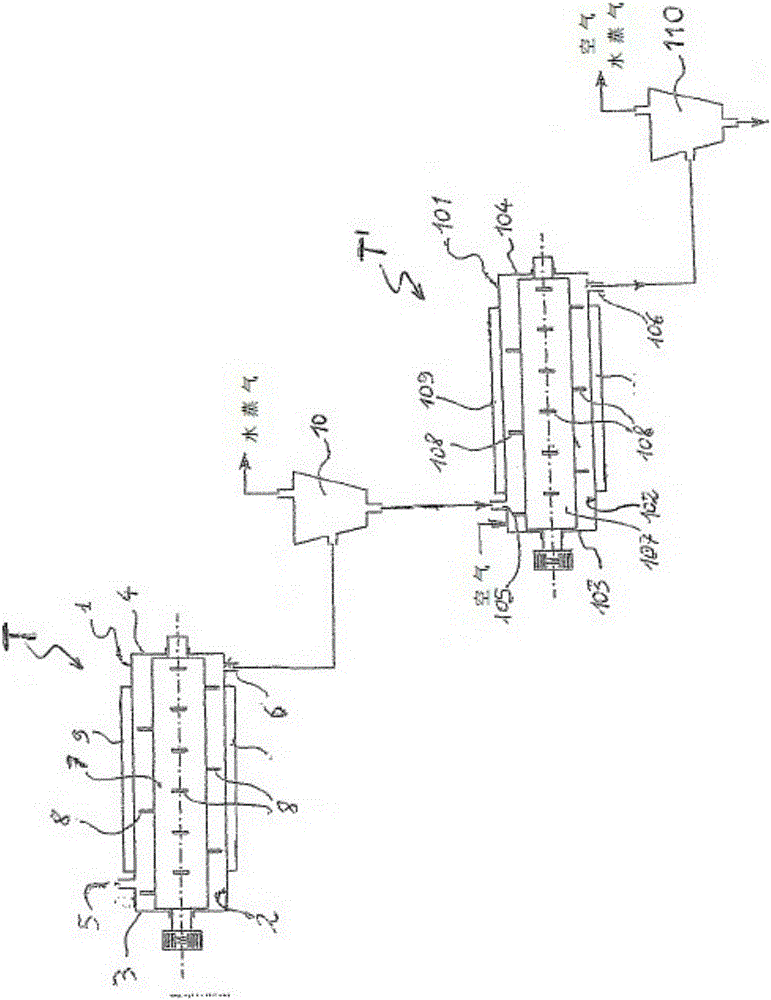

[0057] With reference to the accompanying drawings, a device for carrying out the method according to the invention comprises a turbocooker T comprising a cylindrical tubular body 1 with a heatable inner wall 2, closed at both ends by end plates 3, 4, set There is a feed opening 5 and a discharge opening 6, and inside there is a rotatably supported coaxial vane rotor 7 whose vanes 8 are arranged helically. The cylindrical tubular body 1 is externally coaxially provided with heating means 9, shown in schematic form, comprising a resistor or RF source disposed on the outer surface of the cylindrical tubular body 1 or coaxially on the outer jacket, heating A fluid is passed therethrough, the heating fluid preferably consisting of water vapor or a thermally transparent oil suitable for flow.

[0058] Said equipment also comprises a turbo dryer T' comprising a cylindrical tubular body 101 with a heatable inner wall 102, closed at both ends by end plates 103, 104, provided with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com