Multi-tubular fluid transfer conduit

一种流体传输、导管的技术,应用在管子/管接头/管件、管子、管元件等方向,能够解决温度和压力上升、不能燃料提供发动机制造商热保护等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

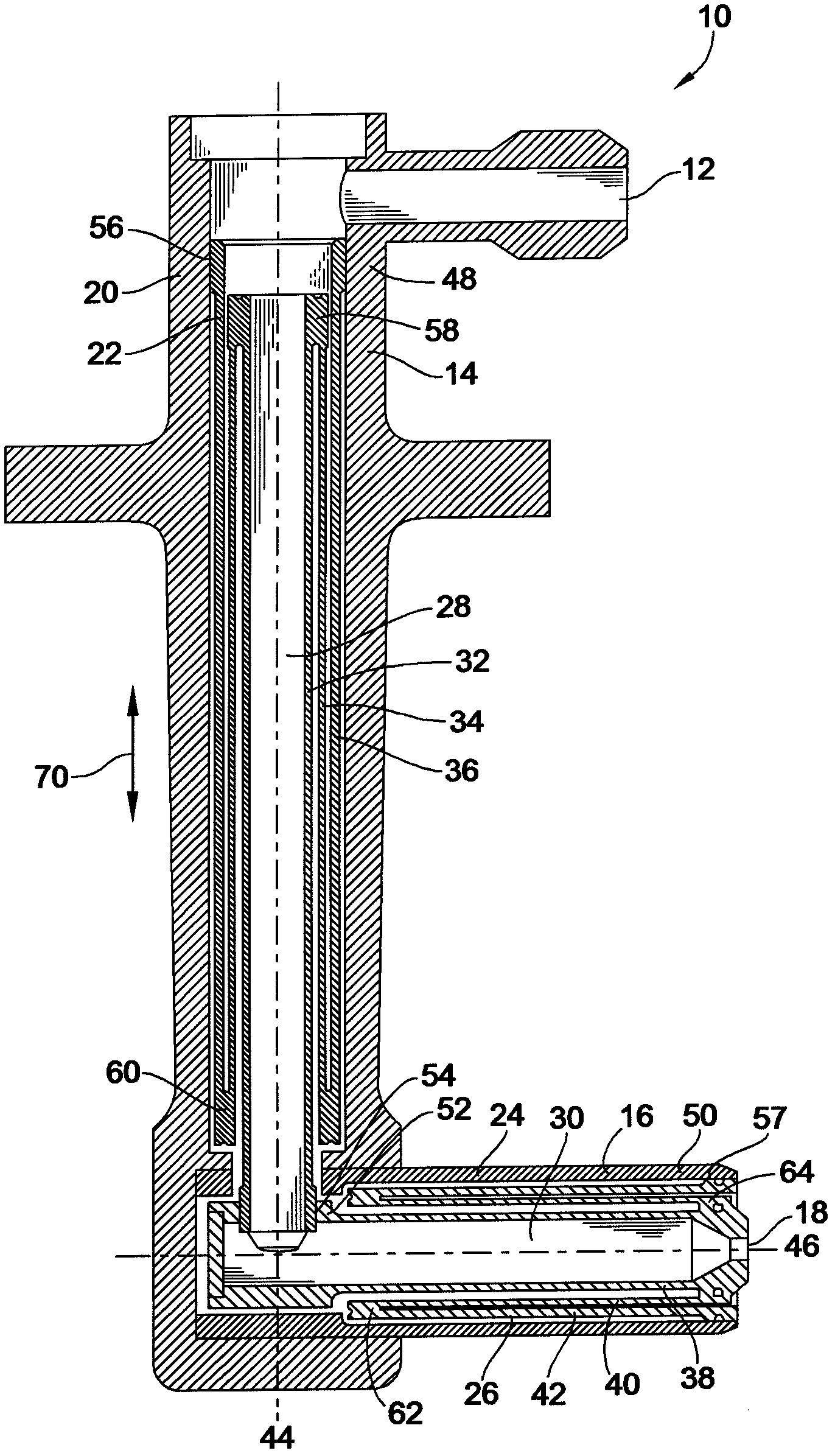

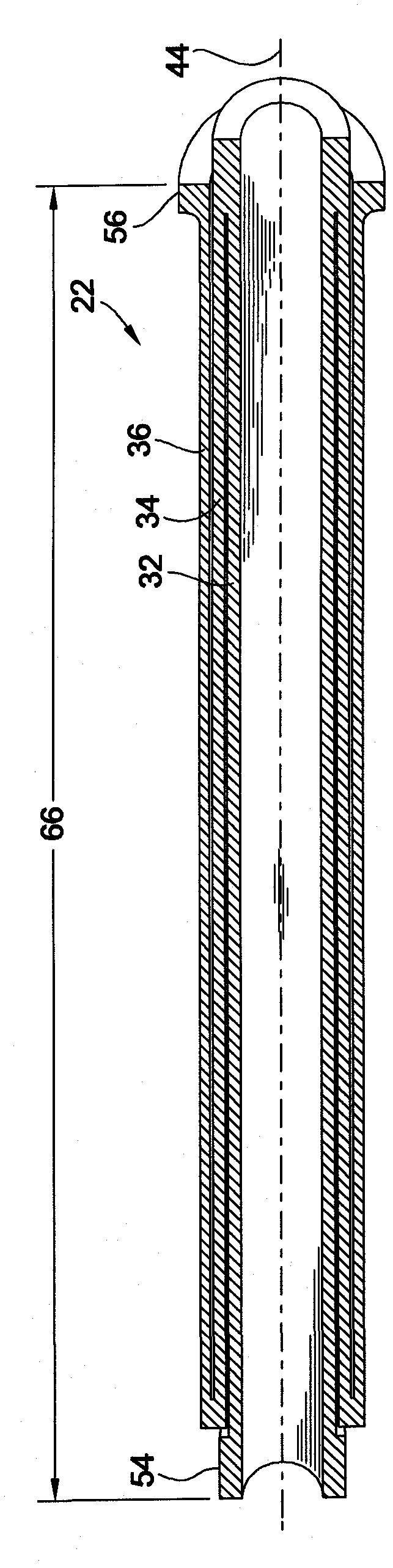

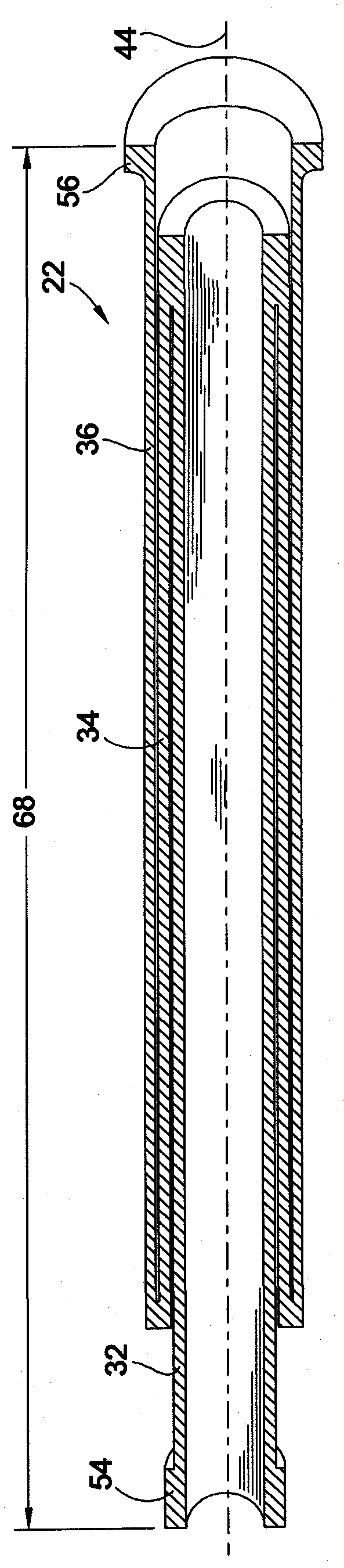

[0034] figure 1 A cross-sectional view of a fuel nozzle 10 including a fuel delivery duct 22 according to an embodiment of the present invention is shown. The fuel nozzle 10 may be implemented in a gas turbine system to inject fuel into a combustion chamber, where the fuel is mixed with air and burned at a high temperature while maintaining close to static pressure. The gas temperature required in the turbine varies according to the engine speed, so the combustion chamber must be capable of stable and effective combustion in a wide range of operating conditions, which can be maintained for an extended period of time. The temperature of the air leaving the main combustion zone can be about 1800°C and 2000°C. The fuel nozzle 10 includes an improved fuel delivery conduit 22, which can better receive structural stress caused by heat and better protect the fuel against the severe temperatures of the gas turbine system.

[0035] Although the fuel delivery duct 22 in this embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com