Process and plant for the production of animal meals and improved amino acid availability

An animal powder and amino acid technology, applied in application, food preparation, food science, etc., can solve the problems of not better quality and limited use, and achieve the effect of improving nutritional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

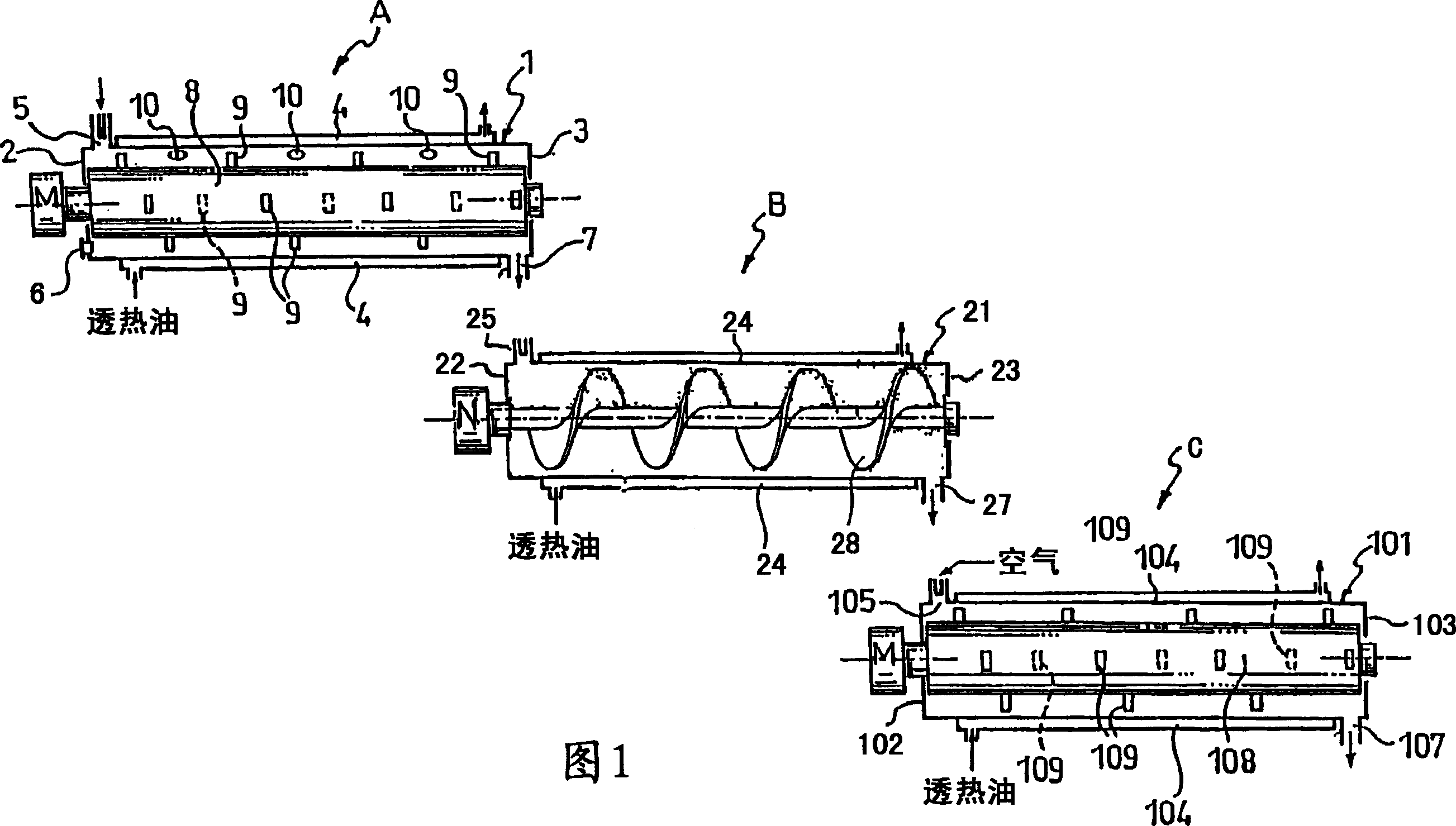

[0053] In a turbo reactor A, in which the bladed rotor rotates at a peripheral speed of about 30m / s, and in which the inner wall is kept at 150°C, a A quill-based animal meal fluid (about 7% moisture). At the same time, a 130-V (volume) hydrogen peroxide solution was continuously fed through the opening 6 and the opening 10 at a flow rate of 50 liters / hour.

[0054] Directly at the inlet of the turbo reactor A, the animal meal fluid is mechanically dispersed into very fine particles, which are immediately centrifuged against the inner walls of the turbo reactor itself, where they form a Dynamic tubular laminae.

[0055] At the same time, the aqueous hydrogen peroxide solution entering through the opening 6 is mechanically and finely atomized by the blades 9 of the rotor 8, which also easily produce a centrifugal effect on the obtained very small droplets. . In this way, they are introduced into the dynamic tubular lamina of the animal meal particles with which they interact...

Embodiment 2

[0064] In a turbo reactor A, in which the bladed rotor rotates at a peripheral speed of about 30 m / s, and in which the inner wall is kept at 130° C., a Fish based animal meal (about 7% moisture). At the same time, a 130-V hydrogen peroxide solution was continuously fed through opening 6 and opening 10 at a flow rate of 50 liters / hour.

[0065] Subsequent steps of the method were performed as described in Example 1 above.

[0066] The animal meal obtained had a moisture content of about 7% and when analyzed it showed a ratio of total nitrogen to ammoniacal nitrogen of 35 relative to the starting value of 60, the amount of total nitrogen remaining essentially the same as that of the starting food constant.

[0067] The powder is substantially odorless and sterilized from a microbiological point of view.

[0068] Thus, the ratio of total nitrogen to ammoniacal nitrogen was shown to be considerably reduced, and subsequent analysis of primary amines according to the Van Slyke me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com