Semi-disposable pre-conditioned air supply hose conduit and connectors for attaching end portions of the same

A technology of end connection and pipe connector, applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fitting, passage element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

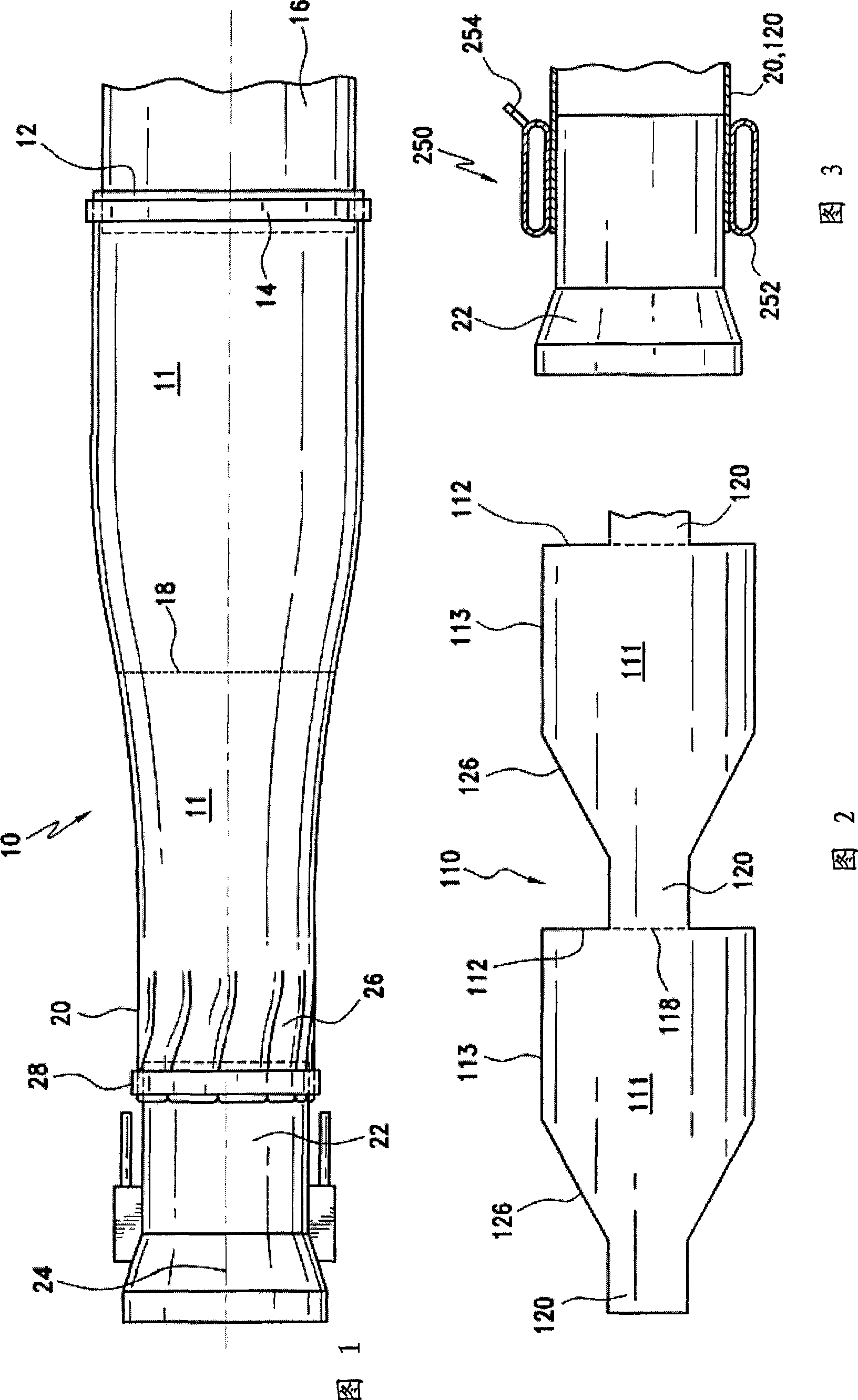

[0014] Referring now to the drawings, and in particular to FIG. 1 therein, there is disclosed a first embodiment of a new and improved tubular fluid conduit, which is particularly suitable for use when the aircraft is on the ground for maintenance and thus cannot provide passengers and crew. When preconditioned air itself, the aircraft is supplied with preconditioned air, generally indicated here by the reference numeral 10 . More notably, the new and improved tubular fluid conduit 10 is formed as a continuous tubular stamping from a suitable thermoplastic material, such as polyethylene or ethylene polymer, and may have a range of, for example, five to seven mil (0.005-0.007") thickness dimensions. The tubular fluid conduit 10 is stamped in the form of a flat tubular piece which can be folded or coiled on a reel for easy loading and storage, and according to Based on the principles and teachings of the first embodiment of the present invention, the tubular fluid conduit stampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com