Valve mechanism for tubular fluid container

A technology of fluid container and valve mechanism, which is applied in the field of valve mechanism and can solve the problems such as no report on the valve mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

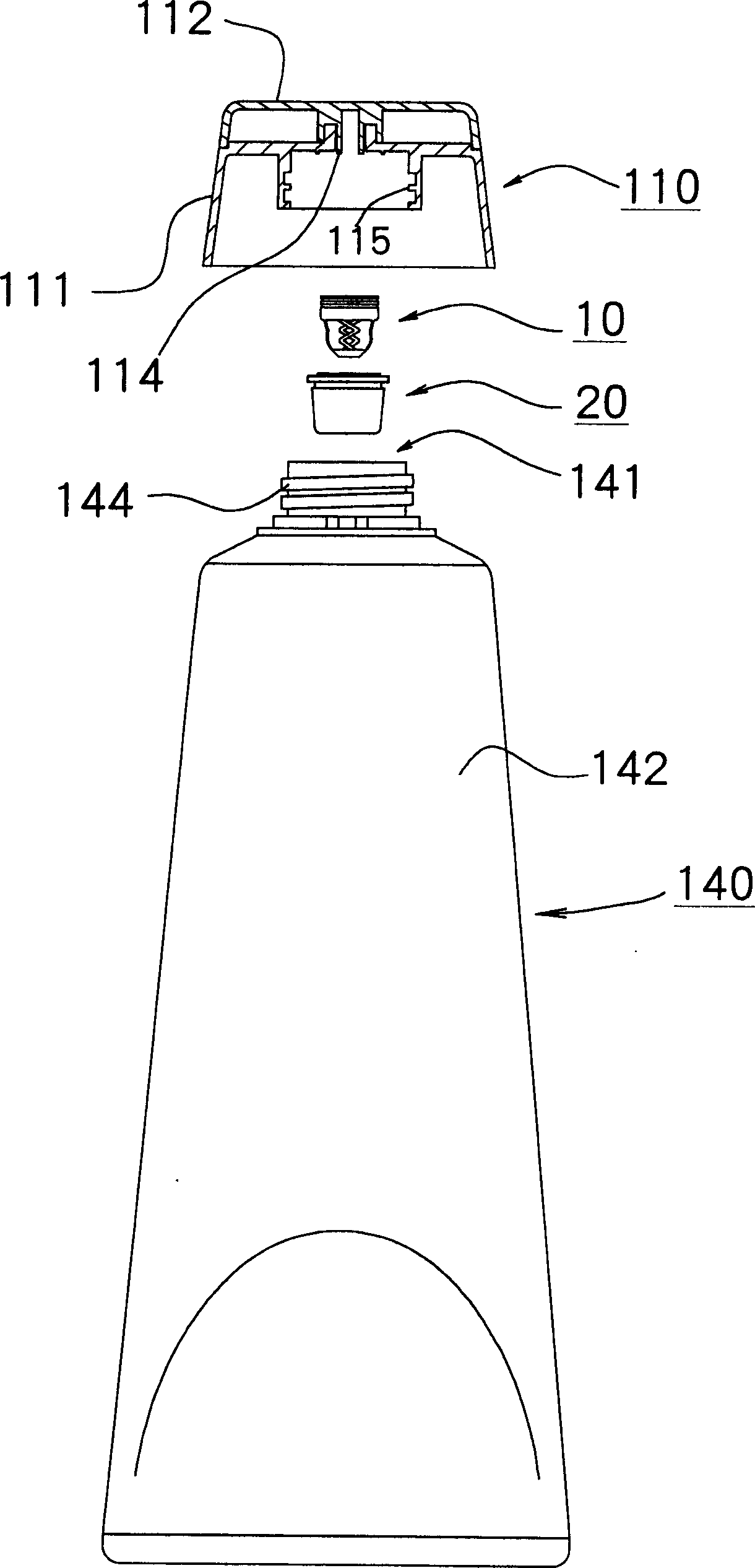

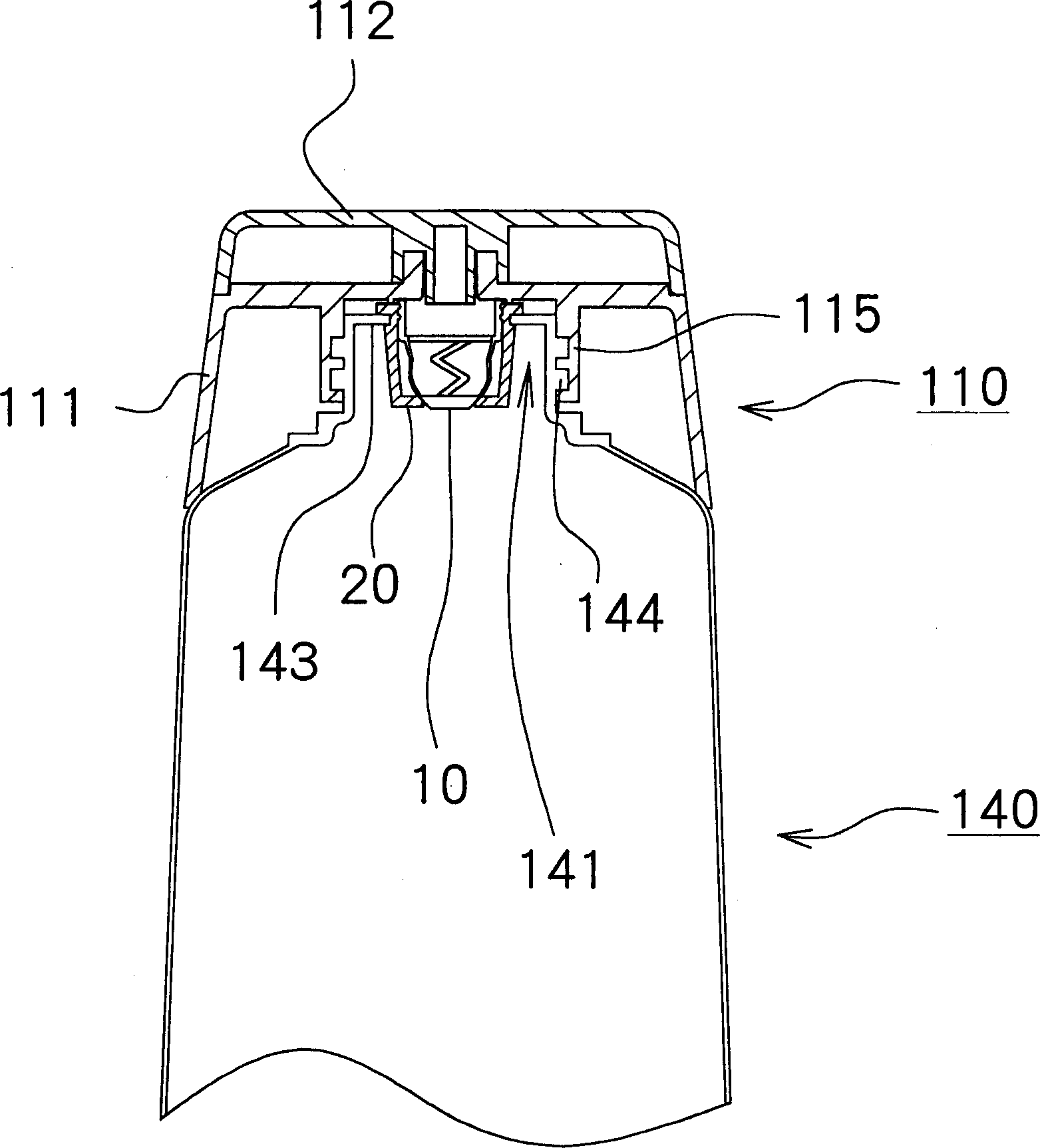

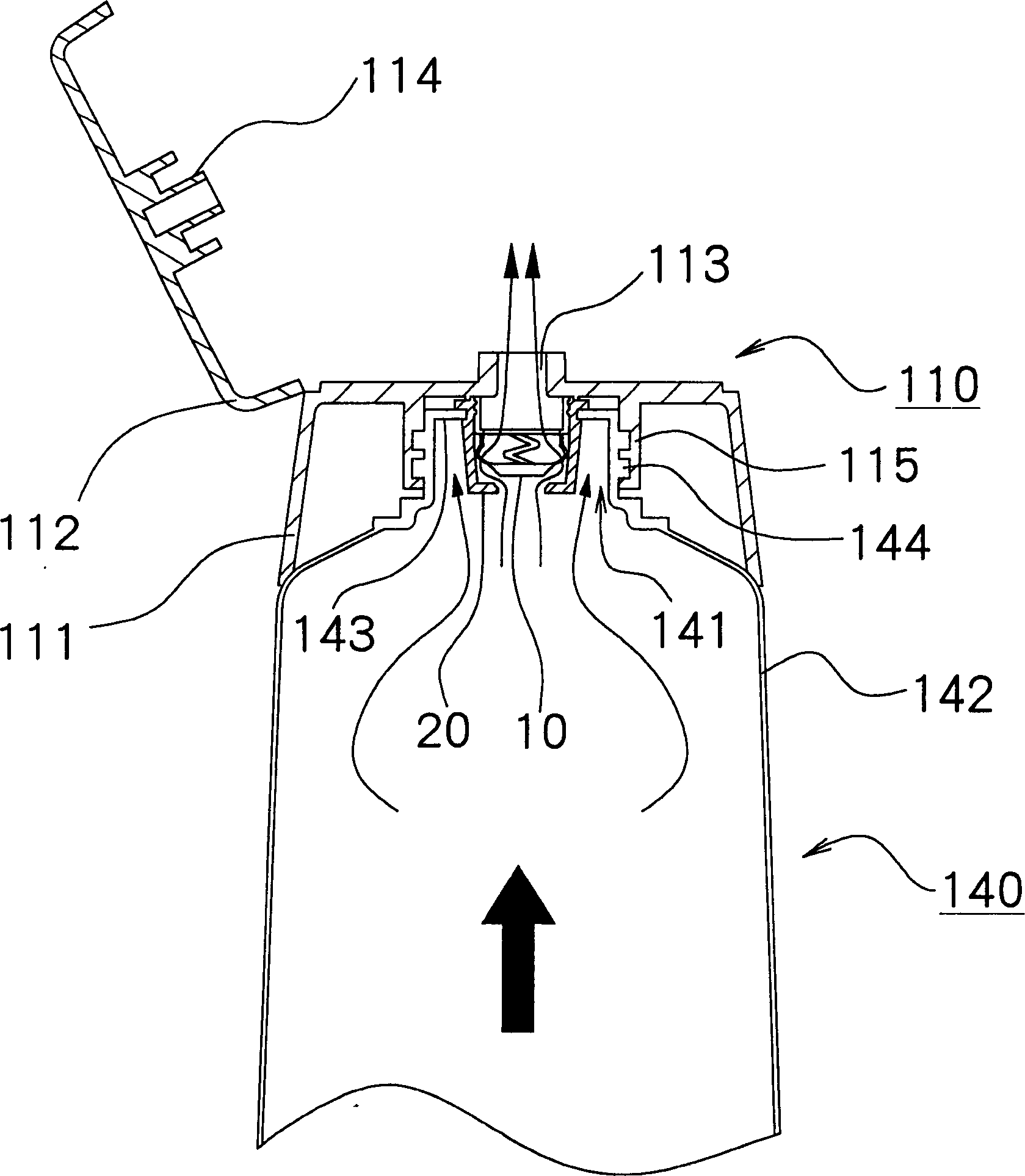

[0061] Preferred embodiments of the present invention will be described with reference to the accompanying drawings. The present invention is not limited to the Examples. figure 1 is an exploded view illustrating a tubular container to which a valve mechanism according to an embodiment of the present invention is applied; Figure 2 to Figure 4 is an enlarged view of relevant parts of a tubular container to which a valve mechanism according to an embodiment of the present invention is applied.

[0062]The tube-type container can be used for any suitable fluid container, including cosmetic products, which store gels (such as hair gels and cleansers) or creams (such as nourishing creams and cold creams used in the cosmetic field). Such tube-type containers can also be used as containers for medicines, solvents, foods, and the like.

[0063] In this illustration, highly viscous liquids, semi-fluids, gels of jelly-like substances solidified from sols, as well as creams and ordere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com