Heat exchanger of heating pump for heating water

A technology for heat exchangers and water heating, applied in the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as inability to meet drinking water hygiene requirements, unsatisfactory heat exchange efficiency, etc., and achieve energy saving effects Significant, easy to clean, and ensure the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

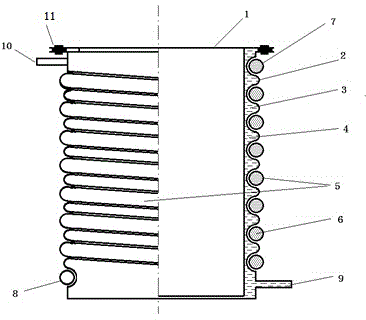

[0025] see figure 1 and figure 2 , a heat pump heat exchanger for heating water according to the present invention includes an inner tub 1 and an outer tub 2 that can be disassembled for easy cleaning, the inner tub 1 is nested inside the outer tub 2 and there is a water supply between them The flowing water flow channel 3, the water flow channel 3 in this embodiment is a spiral channel, the inward protrusions of the outer barrel 2 have the same height and are arranged at equal intervals, and the protrusions are close to the outer wall of the inner barrel 1 . In order to securely fix the inner barrel 1 and the outer barrel 2, a sealing and locking device 11 is arranged on the top of both.

[0026] The water inlet 9 is located at the bottom of the outer barrel 2, and the water outlet 10 is located at the top of the outer barrel 2 and is distributed on both sides of the outer barrel 2 with the water inlet 9; the outer peripheral wall of the outer barrel 2 is pressed to form a ...

Embodiment 2

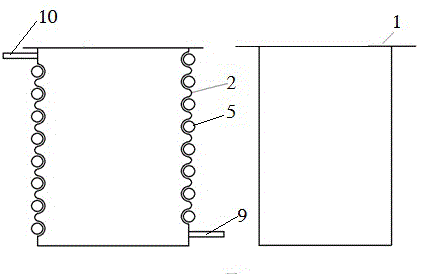

[0029] Same as embodiment 1, embodiment 2 also includes inner tub 1 and outer tub 2, the difference is that the water flow channel 3 of this embodiment is not a spiral channel, but a slit-shaped interlayer, see image 3 , that is to say, there is no contact between the inner barrel 1 and the outer barrel 2, such as Figure 6 As shown, the hollow arrow indicates the flow direction of the heating medium 6, and the solid arrow indicates the flow direction of the water flow. The heated water flows from bottom to top in the slit-like interlayer formed after the inner bucket 1 and the outer bucket 2 are nested, instead of The spiral channel of embodiment 1 flows, and in this way, since the cross-sectional area of the channel is larger than that of the spiral channel of embodiment 1, and the length of the channel is smaller, it is suitable for occasions where the water flow rate is large and the temperature rise range is small.

Embodiment 3

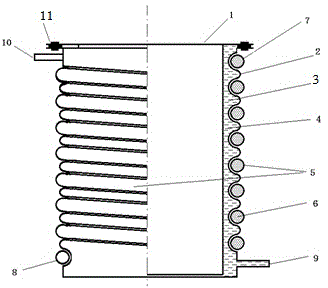

[0031] Same as Embodiment 1, Embodiment 3 also includes an inner tub 1 and an outer tub 2, the main difference being the water flow channel 3 and the heat exchange structure 5, such as Figure 4 shown. Specifically, the outer barrel 2 has a plurality of protrusions toward the direction of the inner barrel 1, and the depths of the protrusions are different. The protrusion closest to the inner barrel 1 is in contact with the outer wall of the inner barrel 1, and the inner wall of the spiral channel It is not smooth. In fact, the water flow channel 3 can be regarded as a structure of a spiral channel combined with a narrow slit channel. The heat exchange structure 5 is not formed by a single but by multiple parallel condensing pipes, that is to say, the spiral grooves formed on the outer peripheral wall of the outer tub 2 are not as regular and consistent as in Embodiment 1. Some of the grooves are far away from the inner bucket 1, and some are close to the inner bucket 1. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com