Pre-cooling spray evaporation type condenser

A technology of spray evaporation and condenser, which is applied in the field of pre-cooling spray evaporation condenser, which can solve the problems of secondary corrosion or under-scaling corrosion, toxic cleaning waste liquid, and inability to completely remove scale, etc., so as to reduce the speed of scaling , prolong the service life, reduce the effect of maintenance and descaling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

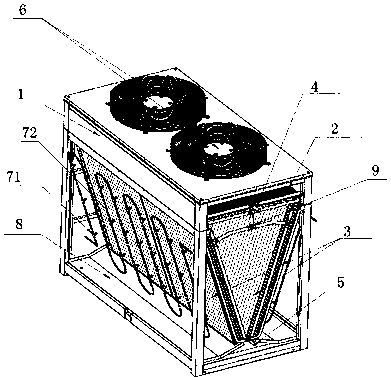

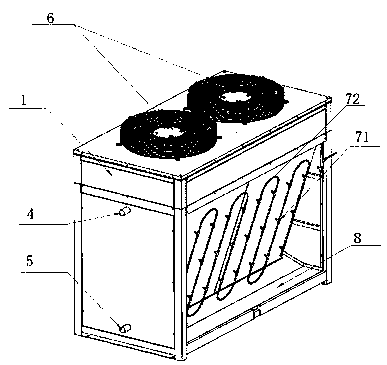

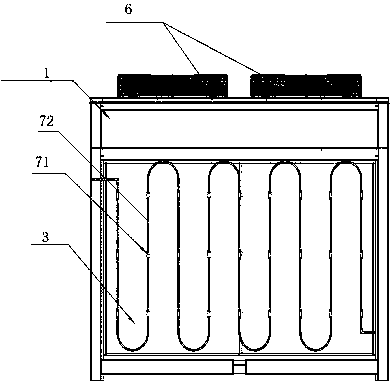

[0028] Example: see attached figure 1 , with figure 2 , with image 3 , with Figure 4 , with Figure 5A pre-cooling spray evaporative condenser shown includes a condenser shell 1, a water mist spray device and an air outlet device 6, and a pre-cooling heat exchange finned coil 2 is arranged inside the condenser shell 1. and two sets of condensing and heat-exchanging finned coils 3, the two sets of condensing and heat-exchanging finned coils 3 are placed inside the condenser shell 1 in a V shape, and the inside of the tube of the pre-cooling and heat-exchanging finned coils 2 and the condensing exchange Refrigerant circulates in the tube of the heat-exchanging fin coil 3, and the refrigerant inlet provided above the end of the condenser shell 1 communicates with the inlet port of the pre-cooling heat-exchanging fin coil 2, and the pre-cooling heat-exchanging fin coil The outlet port of 2 is connected with the inlet port of the condensing heat exchange fin coil 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com