High-temperature high-pressure rear pass coal economizer mounting structure of coal power station

A high-temperature, high-pressure, installation structure technology, applied in the direction of heat exchange equipment safety devices, feed water heaters, heat exchanger shells, etc., can solve problems such as poor stability and balance, unfavorable installation and maintenance, and poor flexible adjustment, so as to ensure Structural stability, easy installation and maintenance, and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

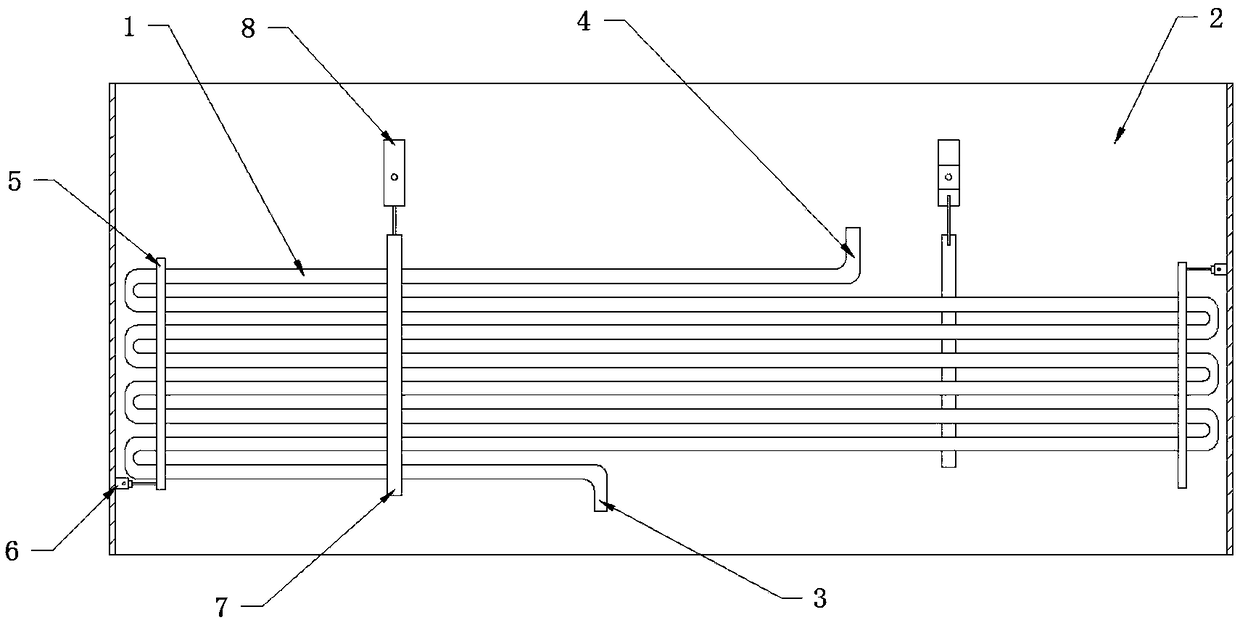

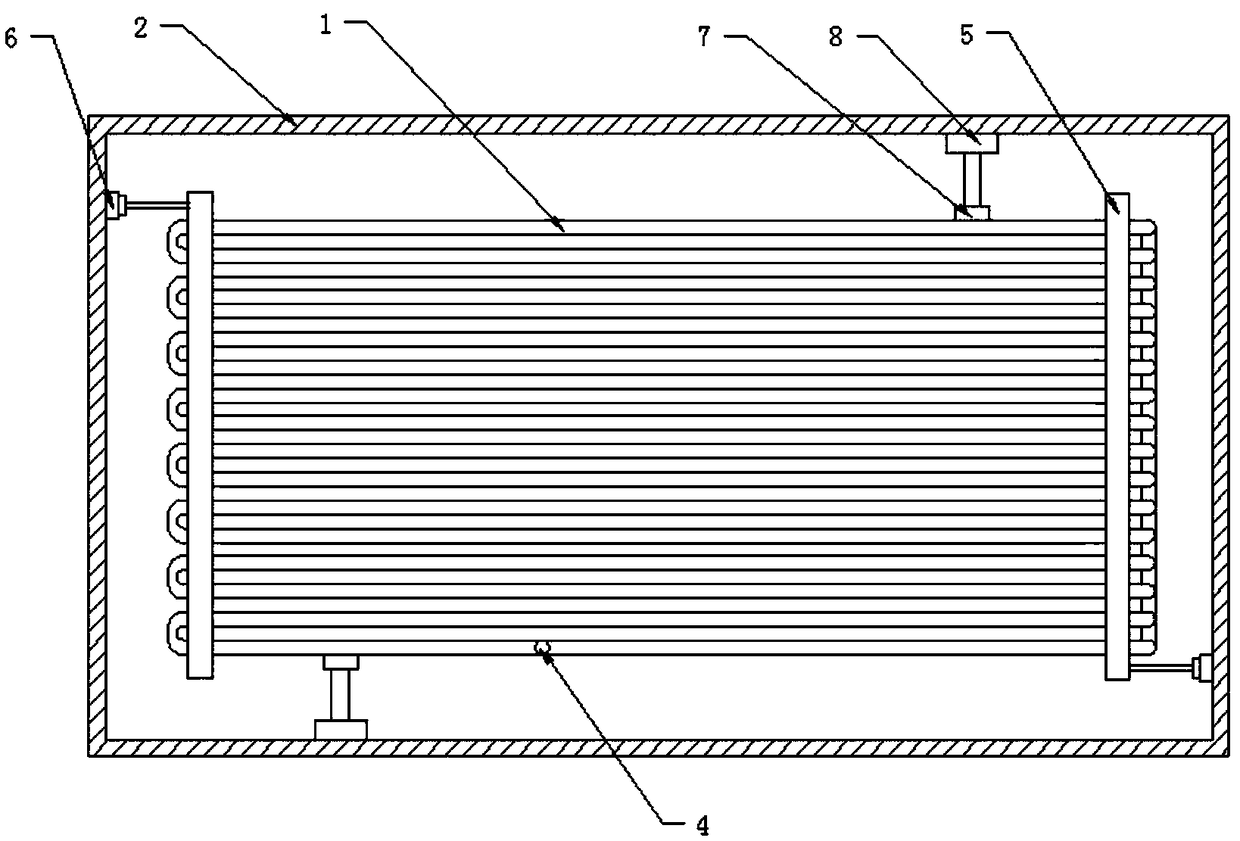

[0045] Such as figure 1 and 2 As shown, the installation structure of the high temperature and high pressure flue economizer of the power station in embodiment 1 includes the heat exchange flue 2 and the economizer hanging in the heat exchange flue 2; the economizer is composed of several rows of heat exchange The tube 1 is connected to form a heat exchange tube panel, and the heat exchange tube panel is provided with a water inlet 3 and a water outlet 4 that are connected with the water inlet main pipe and the water outlet main pipe; The swaying fixing plate 5 is vertically provided with a coordinating anti-swaying fixing mechanism 6 on the inner wall of the heat exchange flue 2, and the cooperating anti-swaying fixing mechanism 6 is connected with the anti-swaying fixing plate 5. Hanging rods 7 are vertically fixed on both sides of the heat exchange tube panel, and hanging fixtures 8 are arranged on the inner wall of the heat exchange flue.

[0046] Before installing the e...

Embodiment 2

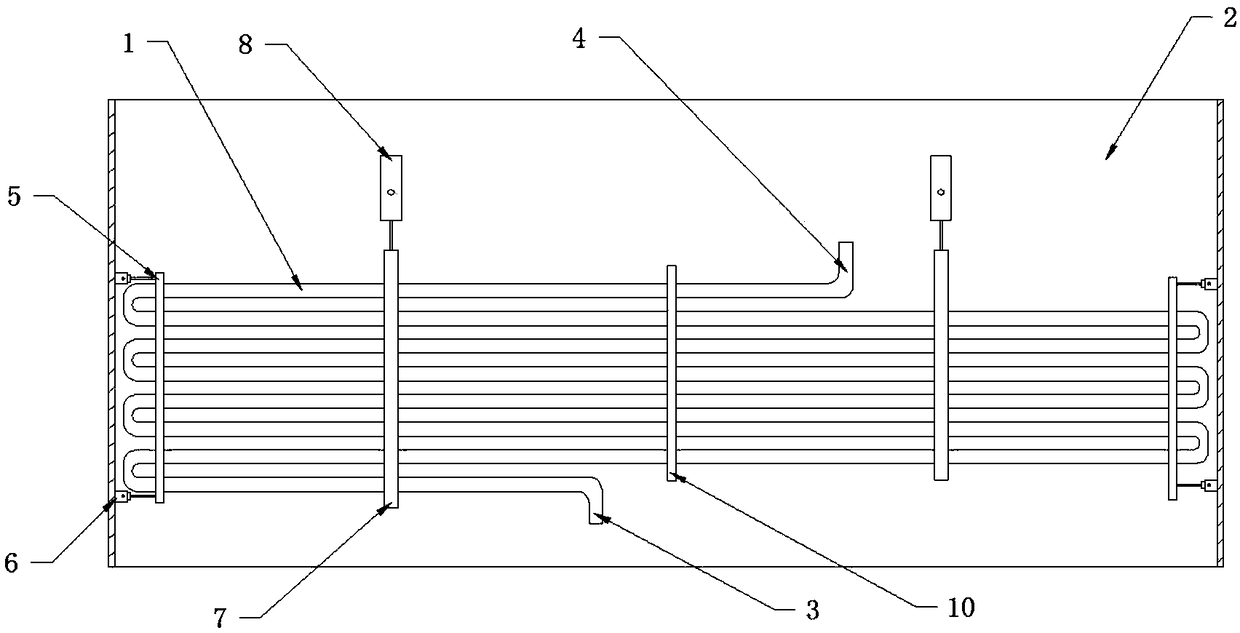

[0048] Further optimization to embodiment 1, such as Figures 3 to 6 As shown, the difference between Embodiment 2 and Embodiment 1 is that a number of horizontal support rods 9 are arranged in the heat exchange tube panel, and a plurality of heat exchange tubes 1 of the heat exchange tube panel are supported and connected to the lateral support rods 9, and the horizontal The two ends of the support rod 9 are fixedly connected with the adjacent hanging rod 7; the anti-shake fixing mechanism 6 is connected with the upper and lower ends of the anti-shake fixing plate 5; The connecting plate 10 and the heat exchange tube 1 are passed through the opening 11 .

Embodiment 3

[0050] Further optimization to embodiment 2, such as Figures 7 to 10 As shown, the difference between embodiment 3 and embodiment 2 is that the anti-sway fixing mechanism 6 includes an anti-sway base 6-1 and an anti-sway connecting rod 6-2, and one end surface of the anti-sway base 6-1 is fixedly connected to the replacement On the inner wall of the hot flue 2, the other end of the anti-shake base 6-1 is fixedly connected to one end of the anti-shake connecting rod 6-2; the outer end of the anti-shake connecting rod 6-2 passes through the anti-shake fixing plate 5, and passes through The nut 12 is fixedly connected with the anti-sway fixed plate 5, and a gasket 13 is also arranged between the nut 12 and the anti-sway fixed plate 5; In the hole of the plate 14; between the nut 12 and the gasket 13, there is also an expansion piece 15, the expansion piece 15 is installed on the anti-shake connecting rod 6-2; the expansion piece 15 is locked between the nut 12 and the gasket 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com