Multi-modal phase-change thermal balance system for lithium battery pack of electric vehicle

An electric vehicle and phase change technology, applied in electric vehicles, battery/fuel cell control devices, circuits, etc., can solve the problems of decreased charging and discharging performance, low thermal conductivity, explosion of lithium batteries, etc., to reduce heat exchange. Frequency, improve heat transfer efficiency, and the effect of large heat transfer contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

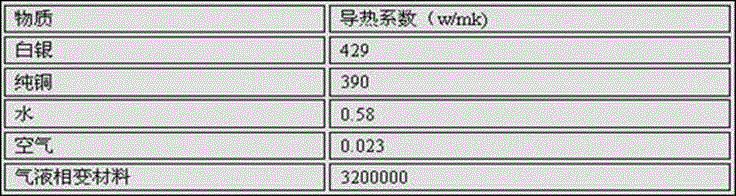

Method used

Image

Examples

Embodiment Construction

[0027] The multi-type phase change heat balance system of the present invention includes: a solid-liquid phase change energy storage body, a gas-liquid phase change heat conduction channel, an extension channel, a cylinder, a lithium battery cell, a vehicle-mounted cold and heat exchanger, a heat transfer sheet, and a heat transfer tube .

[0028] The gas-liquid phase change heat conduction channel includes a pair of extension channels arranged in parallel and a plurality of cylinders vertically passing through the pair of extension channels. All the cylinders communicate with the extension channels. The outer wall is closely matched with the inner wall of the cylinder (it can also be filled with heat-conducting silica gel and other heat-conducting media), and the cavities outside the circumference of each cylinder are filled with solid-liquid phase change energy storage bodies. A portion of the extension channel adjacent to the cylinder is wider than the rest of the extension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com