Self-cleaning type reverse natural circulation evaporator

A technology of automatic cleaning and natural circulation, applied in evaporator accessories, evaporator adjustment/control, evaporation, etc., can solve the problems of prolonging the cleaning cycle, achieve the effect of reducing energy consumption, reducing difficulty, and slowing down the scaling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

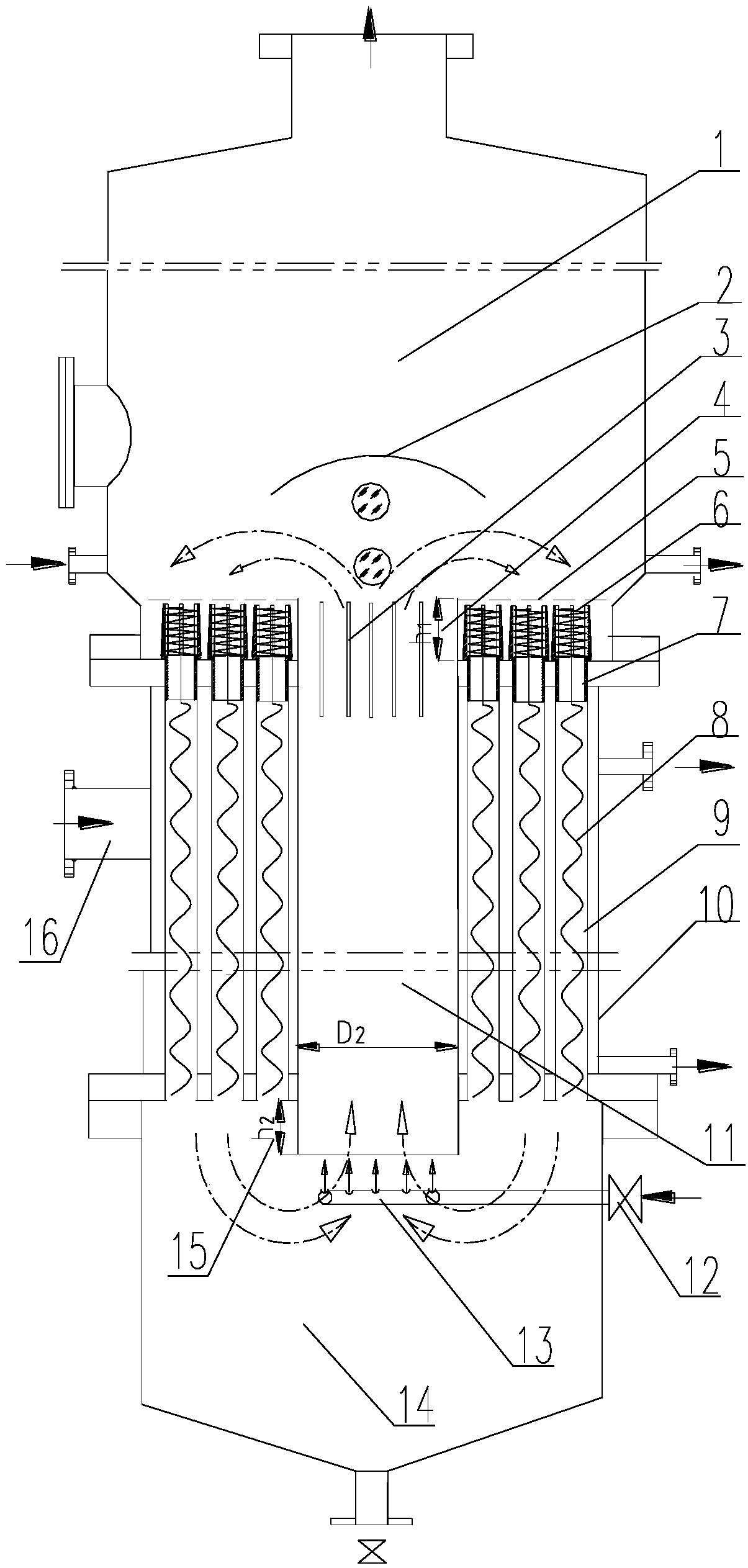

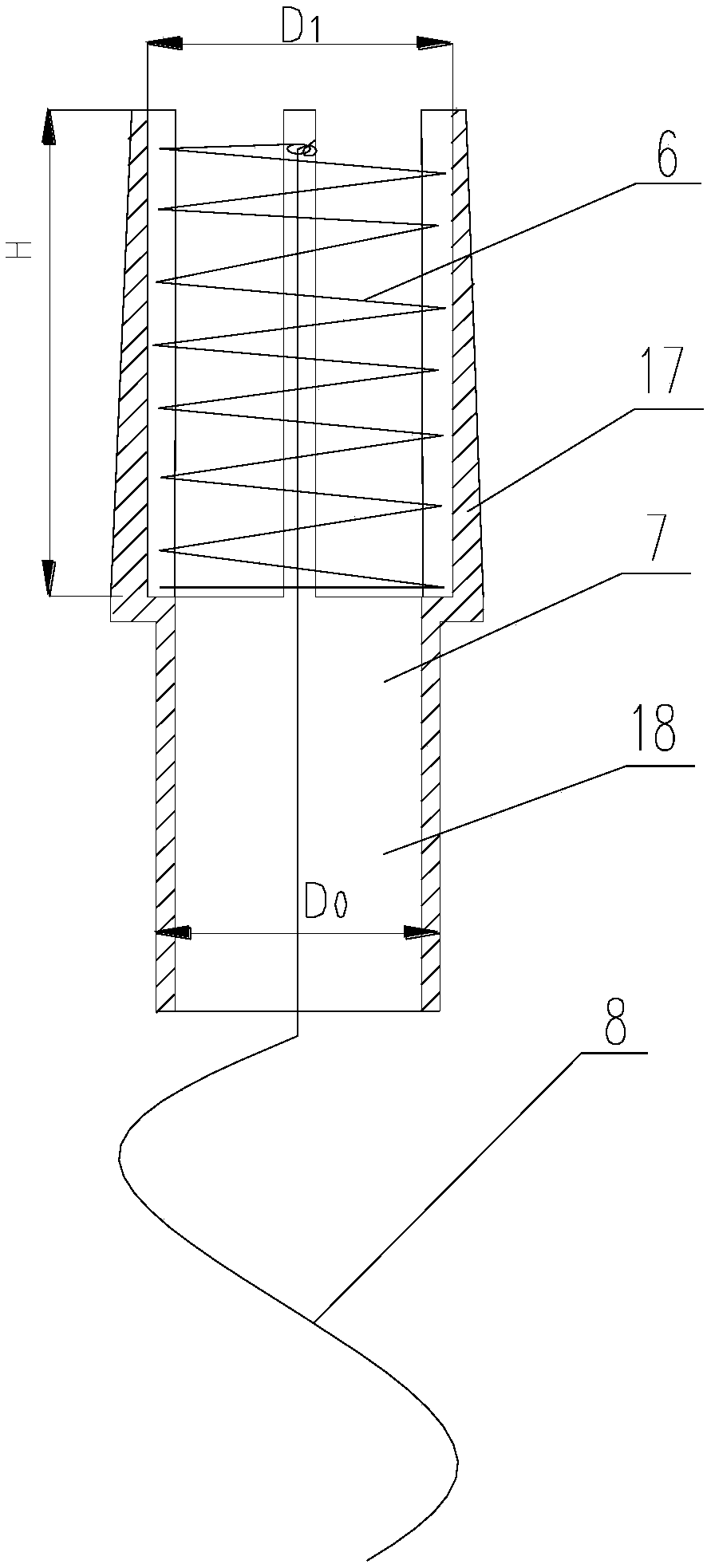

[0013] Attached below figure 1 , figure 2 , The present invention will be described in further detail.

[0014] An automatic cleaning reverse natural circulation evaporator. The main components are evaporation chamber 1, boiling circulation pipe 11, heating chamber 10, heating pipe 9, limit screen 5, cylindrical spring 6, steel wire spiral 8, limit frame 7 , Steam injection ring 13, bottom tank 14. It also includes an automatic cleaning mechanism composed of at least a steel wire spiral 8, a cylindrical spring 6, a limit frame 7, and a limit screen 5. The steel wire spiral 8 in the heating tube 9 is suspended on the upper end of the cylinder 6. When the cylinder spring 6 expands and contracts, rotates, and vibrates, the circumferential direction is restricted by the limit frame 7. The limit frame 7 is installed and fixed in the upper end of the heating tube 9. The limit screen 5 is installed 10-20 mm above the limit frame 7 to limit the highest position of the telescopic move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com