Clean production method of hesperidin

A clean production, hesperidin technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve problems such as the problem of hesperidin not being solved, and achieve increased farmers' income, energy saving, and obvious economic benefits. and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

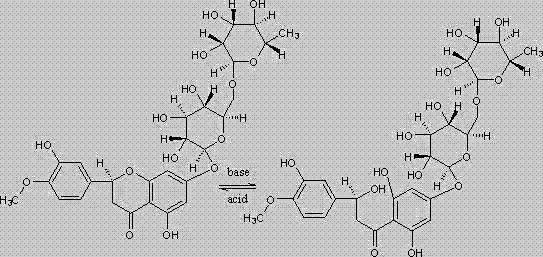

Image

Examples

Embodiment 1

[0015] Get 100g of Citrus aurantium powder that has been crushed through a 10-mesh sieve into a conical flask, add 500ml of 60% methanol solution (v / v) containing 0.7% potassium hydroxide, soak for 3 hours, filter to get the supernatant, and then add 400ml of 60% methanol solution (v / v) containing 0.7% potassium hydroxide, soak and extract for 3 hours, 3 hours, 3 hours and 2 hours respectively, filter, combine five extracts, add hydrochloric acid to adjust the pH to 4 while stirring . Let stand for 2 hours, filter with suction, wash the crystals with a small amount of 60% methanol and water, and dry at 80°C to obtain 29.3g of the product. The purity was 98.3% by HPLC, and the content by external standard method was 95.3%.

Embodiment 2

[0017] Get the Fructus Citrus Fructus Citrus powder 100g that has been pulverized through 10 mesh sieves in the leakage tube, add 85% ethanol solution (v / v) 300ml that contains 1.5% sodium hydroxide, soak for 3 hours, begin to leak, leak 1500ml altogether, The seepage was collected and stirred while adding hydrochloric acid to adjust the pH to 7. Stand still for 2 hours, filter with suction, wash the crystals with a small amount of 85% ethanol and water, and dry at 80°C to obtain 28.5g of the product. The purity was 98.7% by HPLC, and the content by external standard method was 95.5%.

Embodiment 3

[0019] Get the Fructus Citrus Fructus Citriifolia powder 100g that has been crushed through a 10 mesh sieve into the leakage tube, add 70% methanol solution (v / v) 300ml containing 0.8% sodium hydroxide, soak for 3 hours, start to leak, and leak 2500ml altogether, Collect the seepage while stirring and add acetic acid to adjust the pH to 6. Let it stand for 2 hours, filter with suction, wash the crystals with a small amount of 70% methanol and water, and dry at 80°C to obtain 30.3g of the product. The purity was 98.1% by HPLC, and the content by external standard method was 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com