Patents

Literature

127results about How to "Increase oil output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cleaning agent for strong adhesion stain and its application

InactiveCN1597896ASimple production processLow costOrganic detergent compounding agentsNon-ionic surface-active compoundsInorganic saltsFuel oil

The invention is a strongly adhesive fouling detergent and its application, composed of inorganic salt, anionicsurfactant, nonionic surfactant, dispersant, penetrating agent, and anti-sedimentation agent, and as used, it is only necessary to mix with water in a certain proportion. It can effectively eliminate fouling on the pipeline wall to make the pipeline smooth, reducing oil transporting pressure and increasing oil output, the corrosivity is extremely low, and it forms passive film on the pipeline wall to reduce fouling speed, having no pollution to the environment. It can be used to wash other metal surfaces, fuel oil devices.

Owner:山东恒冠化工科技有限公司

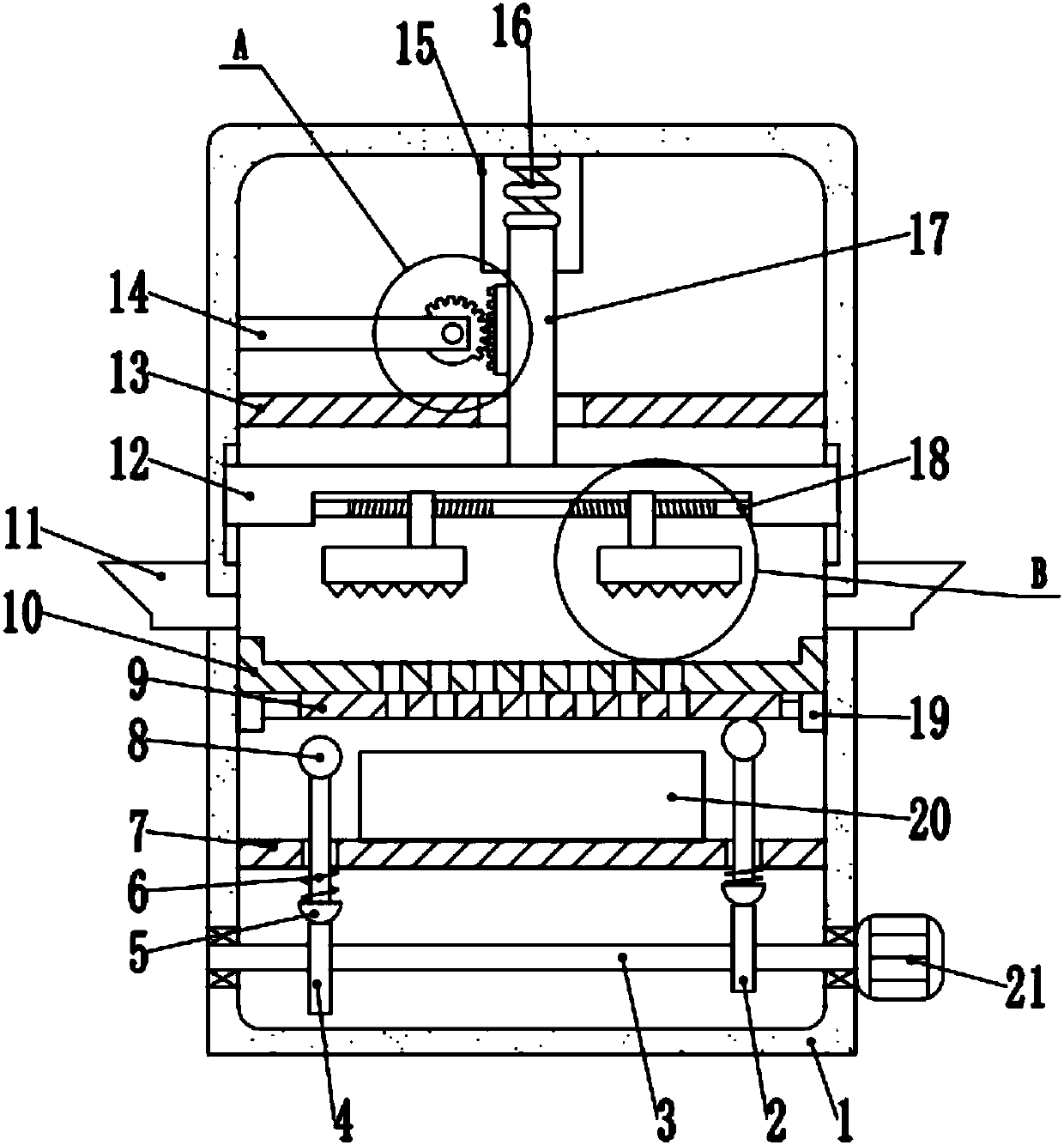

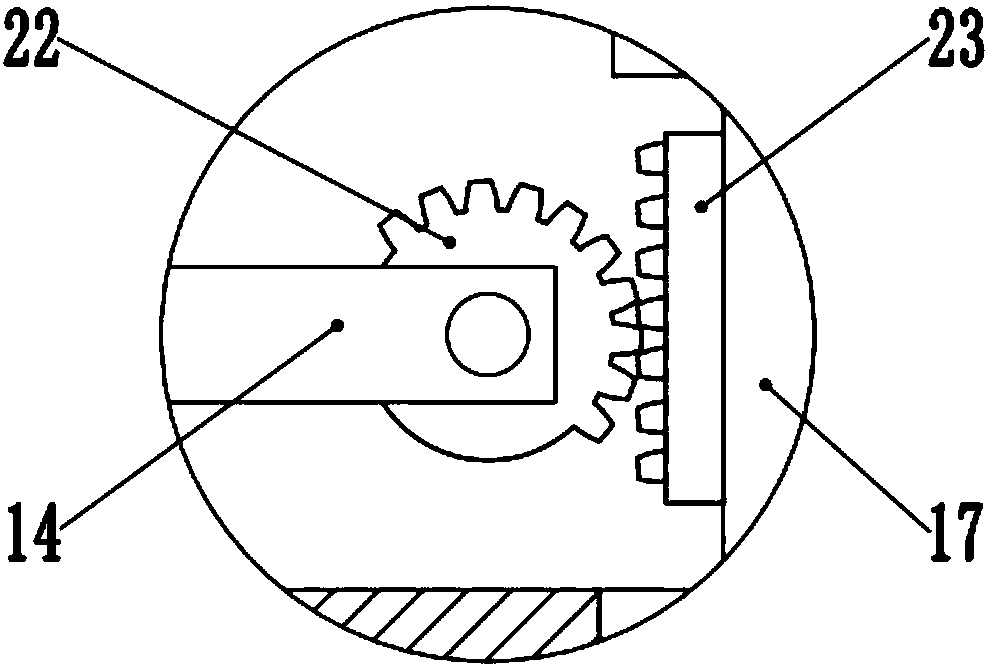

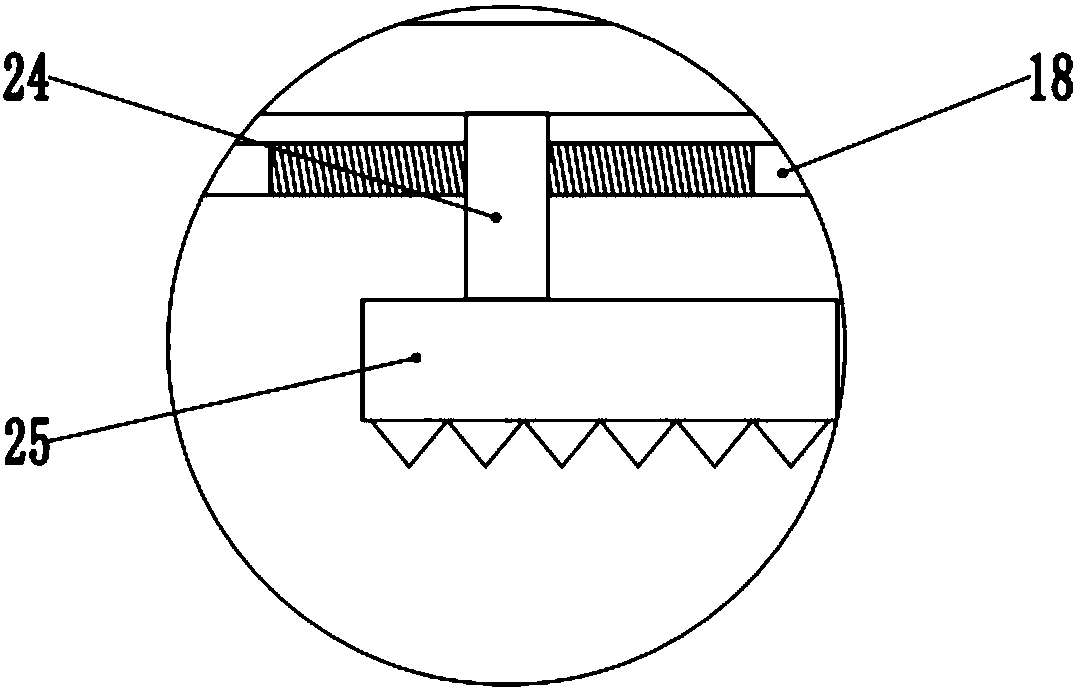

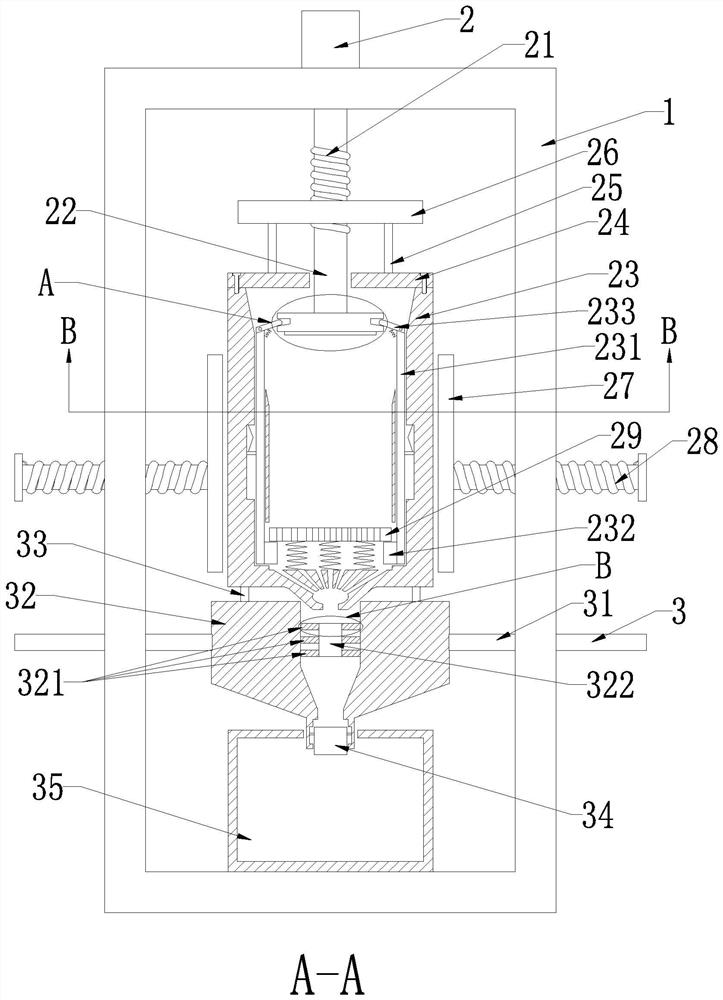

Non-transgenic soybean oil pressing device

The invention discloses a non-transgenic soybean oil pressing device which comprises a body, a push rod and two sliding blocks. A first partition plate and a second partition plate are fixedly installed inside the body, the first partition plate is located below the second partition plate, and the first partition plate and the second partition plate sequentially divide the interior of the body into a first driving chamber, a pressing chamber and a second driving chamber. The lower end of the push rod stretches into the pressing chamber and is fixedly connected with a movable base. The two sliding blocks are installed at the bottom of the movable base in a sliding mode. A squeezing plate is fixedly installed at the lower ends of the sliding blocks. A fixed base is fixedly installed inside the pressing chamber and located below the squeezing plate. A movable sieve plate is arranged inside the pressing chamber and located below the fixed base. Since the squeezing plate which can be movedup and down and moved left and right is arranged, and the bottom of the squeezing plate is provided with crushing teeth for pressing oil from soybeans, the oil pressing effect is excellent.

Owner:丁勇剑

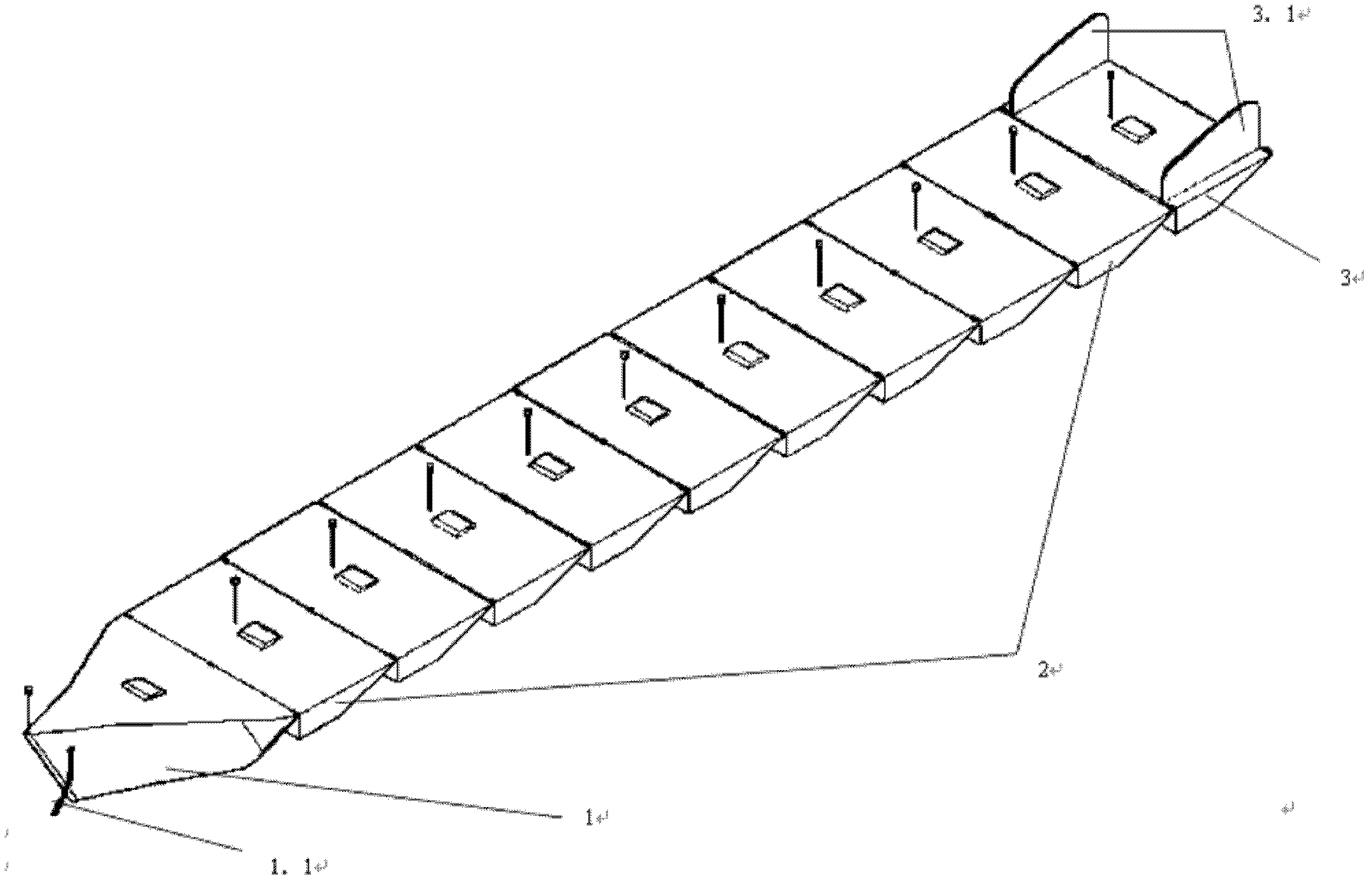

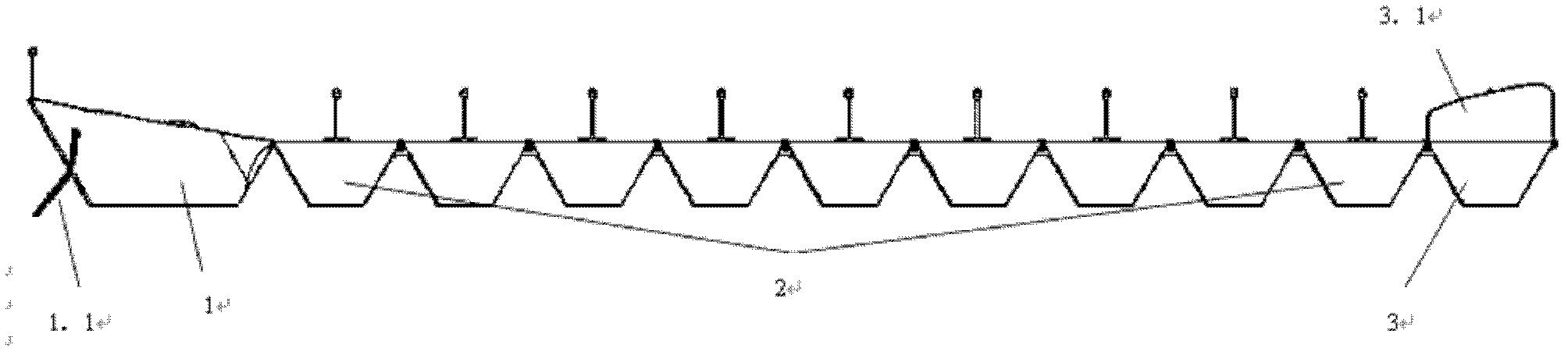

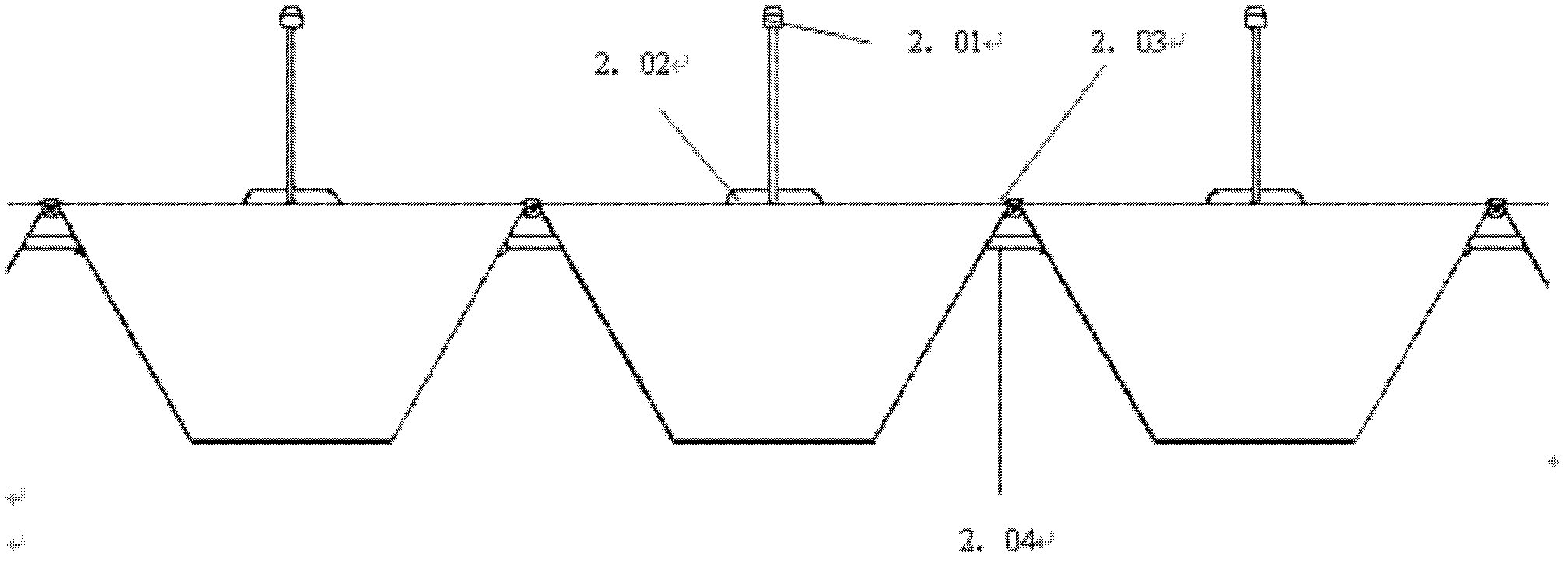

Wave energy collecting ship

InactiveCN102616341AHull structure improvementImprove collection efficiencyWaterborne vesselsMachines/enginesHydraulic cylinderSea waves

The invention discloses a wave energy collecting ship which is mainly formed by connecting more than two trapezoid buoys in series. According to the main working principle of the wave energy collecting ship, the trapezoid buoys are driven by wave to perform vertical bending motion; a hydraulic cylinder is arranged at an included angle for connecting two adjacent trapezoids; two adjacent buoys are bent under the fluctuation action of sea wave, so that the hydraulic cylinder at the included angle is stretched or extruded; two one-way valves are respectively connected to an oil inlet and an oil outlet of the hydraulic cylinder; the one-way valves and the hydraulic cylinder are formed into a plunger pump structure; and when the two adjacent buoys are bent for one time under the fluctuation action of the sea wave, a piston of the hydraulic cylinder is stretched for one time and oil is pumped outwards for two times by a plunger pump, so that the wave energy is collected and converted into hydraulic energy.

Owner:袁媛

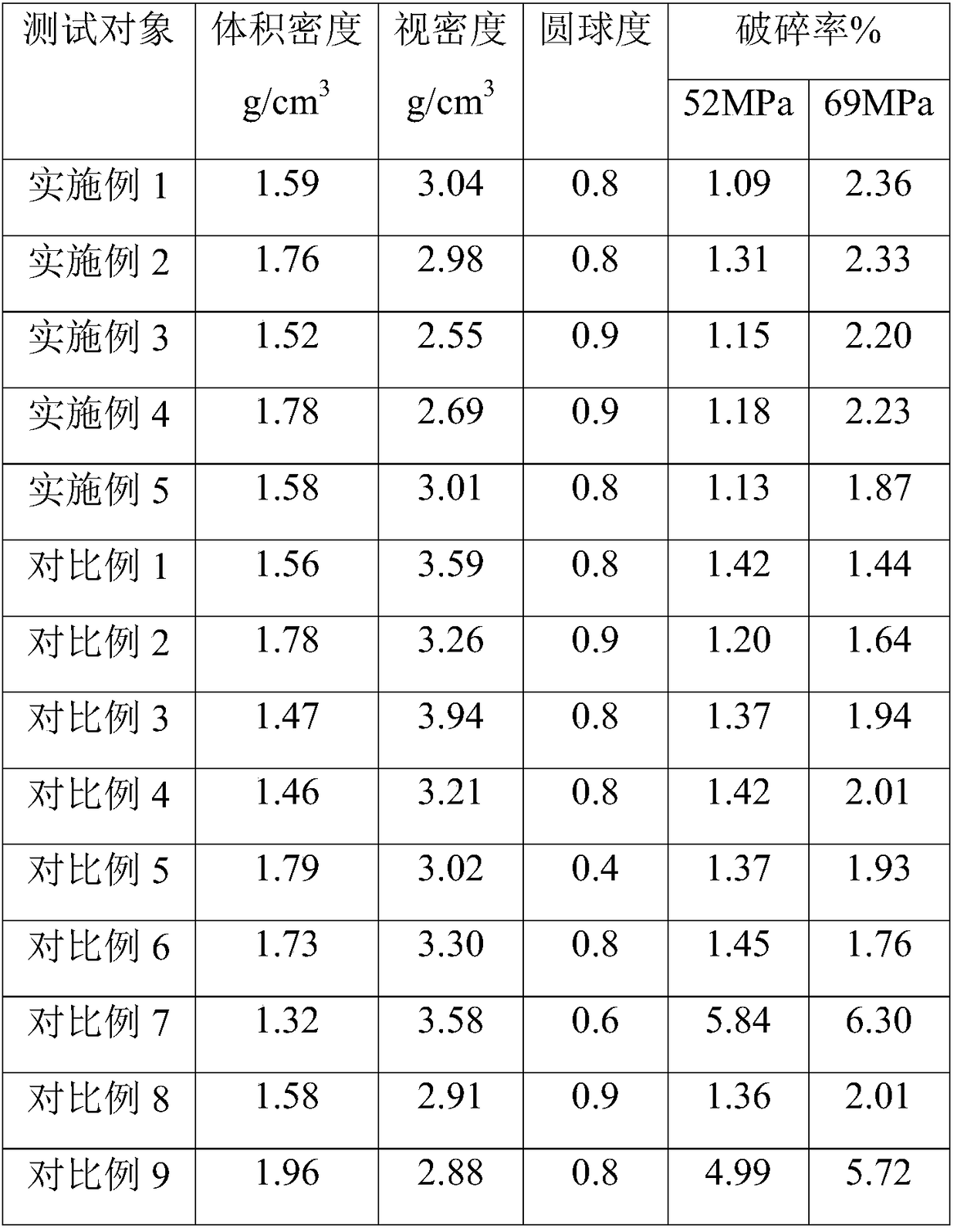

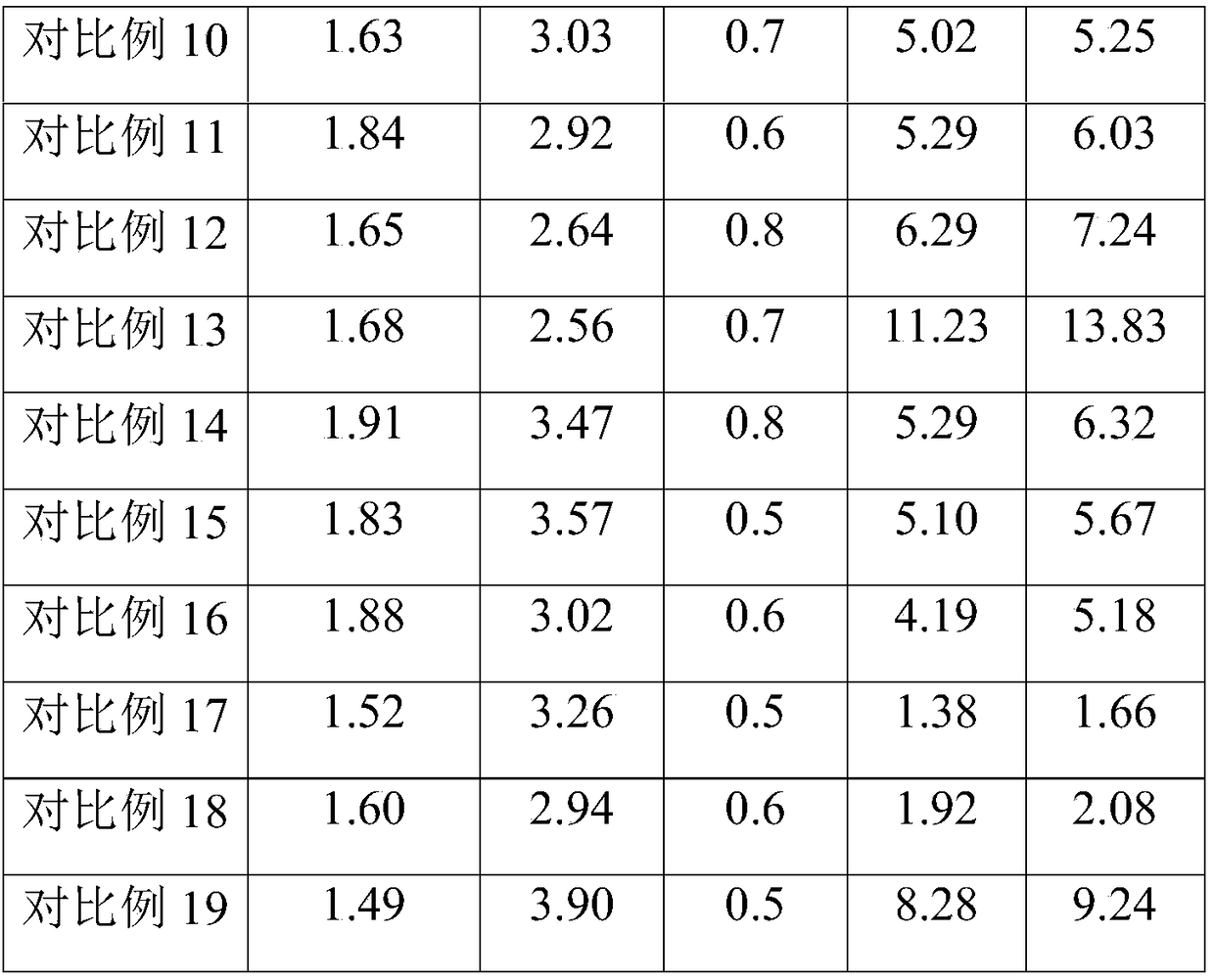

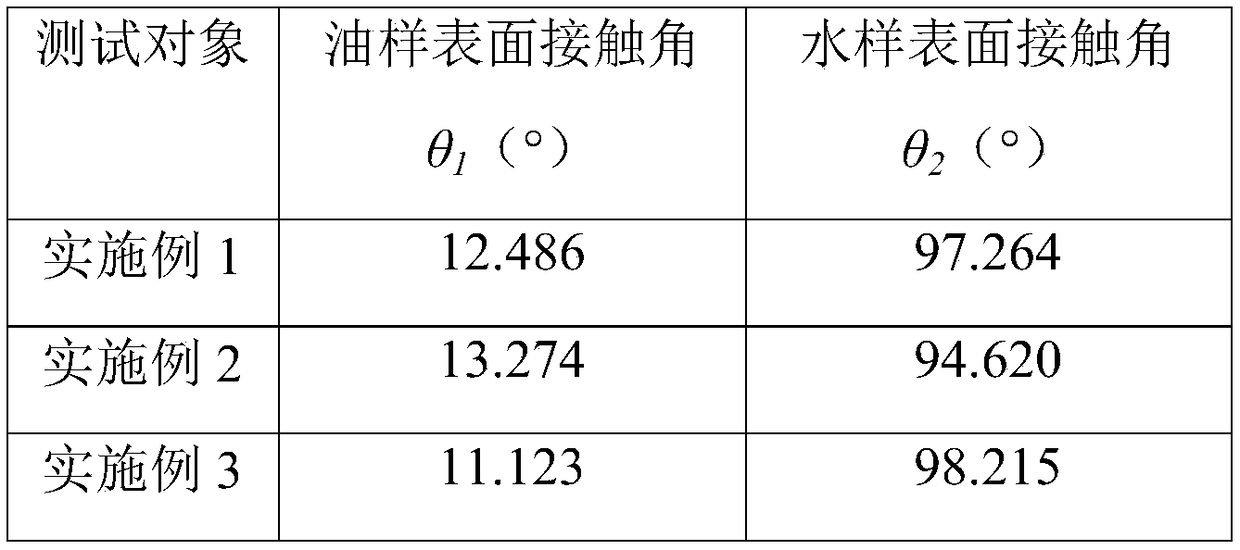

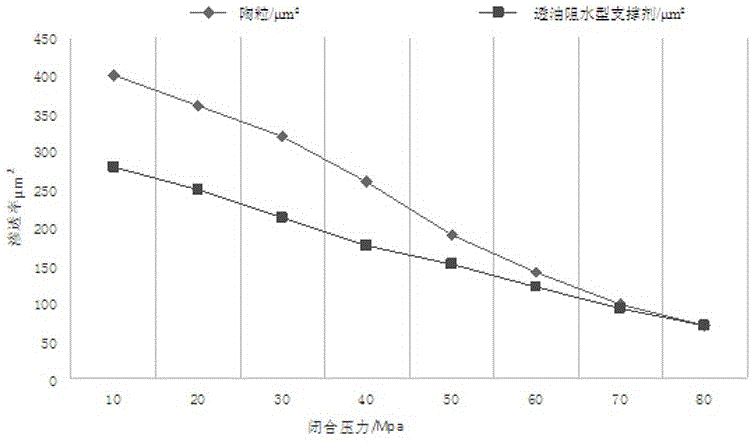

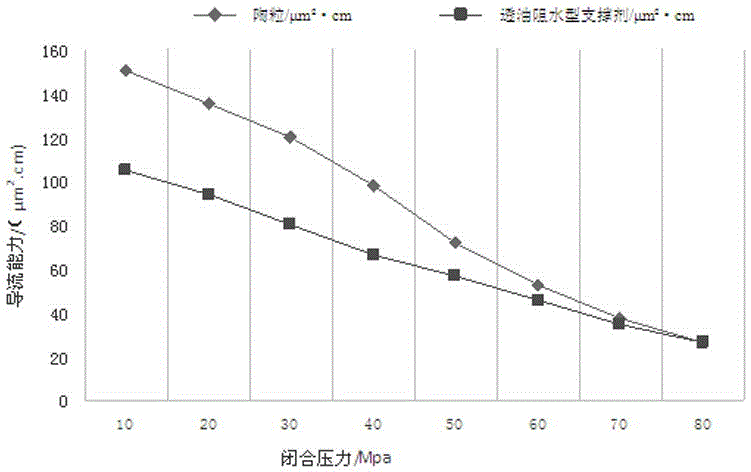

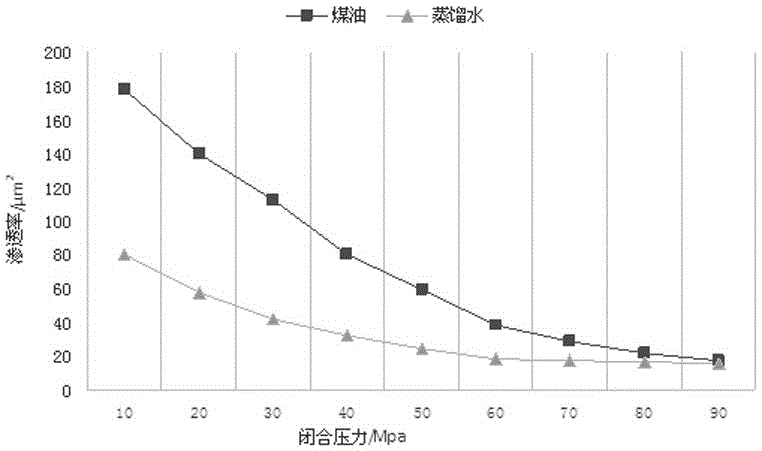

Hydrophobic membrane laminating propping agent as well as preparation method and application thereof

ActiveCN108976366AImprove antioxidant capacityImprove the diversion effectFluid removalDrilling compositionEnvironmental resistanceOil production

The invention discloses a hydrophobic membrane laminating propping agent as well as a preparation method and application thereof. The hydrophobic membrane laminating propping agent can be used for sticking bubbles and has excellent flow guide capability and transporting capability, and good hydrophobic property, lipophilic property and oil-penetration and water-resisting properties; the oil production amount of crude oil is improved and petroleum is easy to exploit; the method is simple and easy to popularize, and is suitable for industrialization; the cost is low, the damage level to a stratum is relatively low and environment protection and sustainable development are facilitated.

Owner:河南祥盛陶粒有限公司

Sucker-rod pump oil extraction system for oil well

The invention relates to an oil extraction system for an oil well, and in particular relates to a sucker-rod pump oil extraction system used in mechanical oil extraction of the oil well, wherein the sucker-rod pump oil extraction system comprises a sleeve pipe and an oil pipe installed in the sleeve pipe; the oil pipe is internally provided with a rocker-rod oil extraction pump which comprises an oil-well pump and a sucker rod connected with the oil-well pump. The oil extraction system is characterized in that an oil sleeve annular space between the oil pipe and the sleeve pipe, close to the oil-well pump, is provided with a packer, thus the oil sleeve annular space is separated in upper and lower; the oil pipe corresponding to the above of the oil-well pump and the packer is connected with a hydraulic communicating valve; the crude oil pumped by the oil-well pump enters the oil sleeve annular space through the communicating valve; an oil outlet which is communicated with the sleeve pipe annular space is formed on the upper end of the sleeve pipe; and the oil pipe above the oil-well pump is internally filled with lubricating media. According to the invention, the abrasion between the rocker rod and the oil pipe can be relieved effectively; and the liquid flow quantity is great, the oil well oil extraction system can be used for a high-water-containing eccentric wear oil well with greater well depth, the construction is simple and convenient, and the cost is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

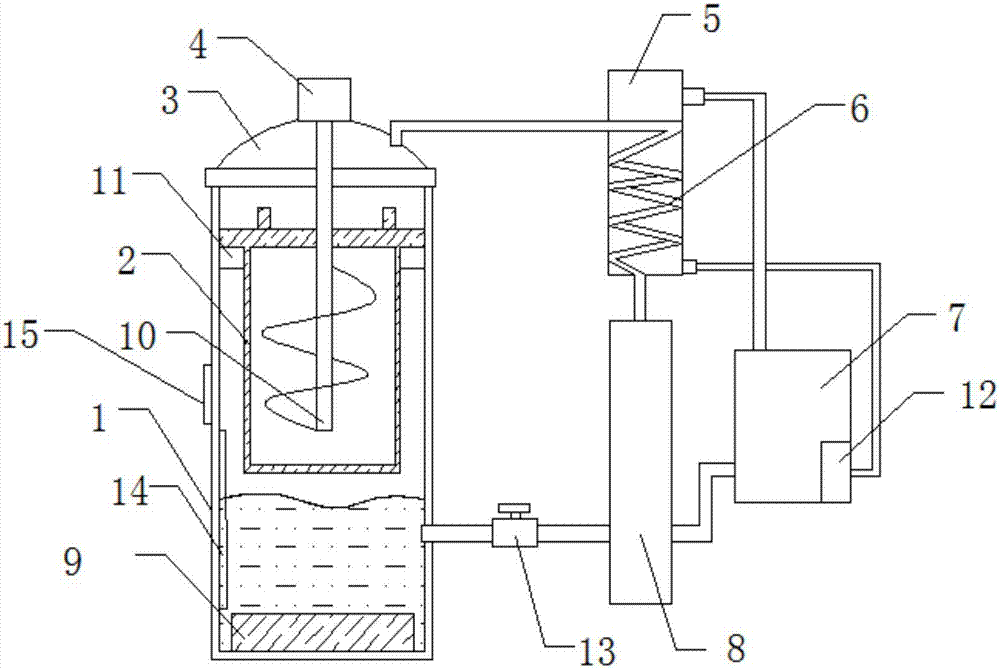

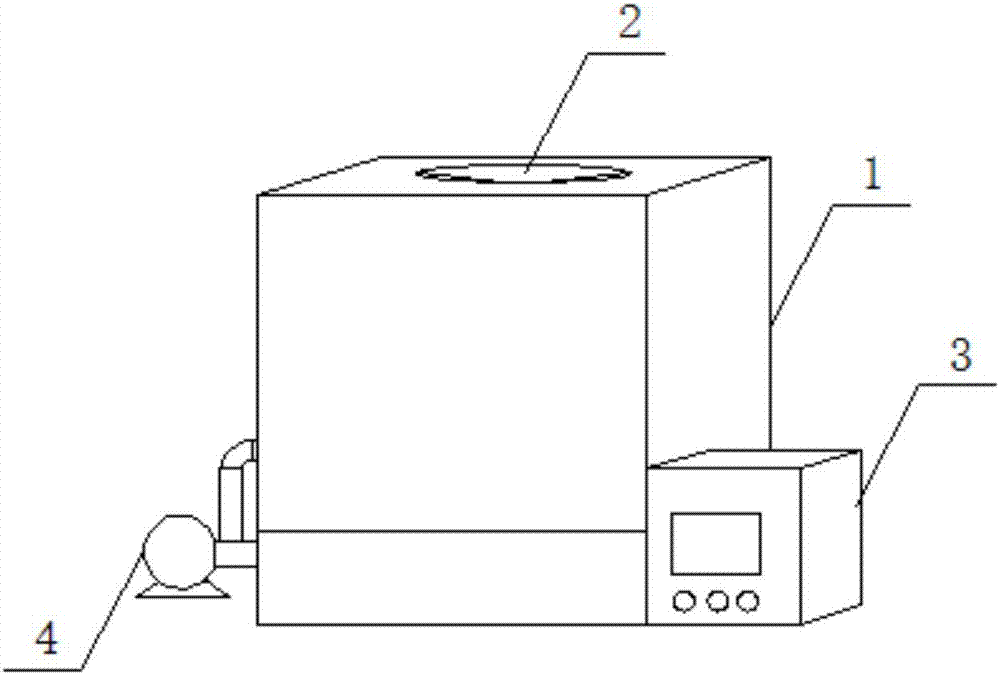

Raw material extraction device for industrial production

InactiveCN107325889AEasy accessEasy to understandEssential-oils/perfumesNatural resourceDistillation

The invention discloses a raw material extraction device for industrial production, which includes a distillation tank, a condenser, an oil-water separator and a water storage tank. A resistance heater is fixedly installed at the bottom of the inner cavity of the distillation tank. A distillation net cylinder is placed directly above the resistance heater, a top cover is installed on the top of the distillation tank, a stirring motor is fixedly installed on the upper surface of the top cover, and a stirring rod is connected to the stirring motor. A liquid level gauge is fixedly installed in the inner cavity, and a condensing pipe is arranged inside the condenser, and the top cover communicates with the air inlet of the condensing pipe in the condenser through an air guide pipe, and the air outlet of the condensing pipe is connected with the oil-water The liquid inlet of the separator is communicated, a circulating water pump is fixedly installed inside the water storage tank, and a control panel is installed on the side wall of the distillation tank. The invention has ingenious conception, reasonable design and fully utilizes natural resources.

Owner:LIANGXI HAOXING IND DESIGN OFFICE

Decaisnea insignis seed oil extraction method

InactiveCN103710138AReduce wearFast penetrationFatty-oils/fats productionEngineeringOrganic chemistry

The invention provides a decaisnea insignis seed oil extraction method, wherein the decaisnea insignis seed raw material utilization rate is high, and the extracted decaisnea insignis seed oil has high purity. The extraction method comprises: adopting decaisnea insignis seed as a raw material, carrying out drying, shelling, peeling and crushing on the decaisnea insignis seed, rolling the crushed decaisnea insignis seed, adding water to the obtained rolled billet, steaming, frying until achieving a drying state, and carrying out pressure increase squeezing, precipitation and filtration to obtain the decaisnea insignis seed oil. According to the present invention, the two-stage pressure increase technology is adopted, pre-squeezing is performed under the relatively low pressure, the pressure is increased after completing the pre-squeezing to make the oil yield of the oil material be rapidly increased, and the oil residue rate of the cake meal is reduced, wherein the oil residue of the cake being subjected to two-stage squeezing is less than 3%.

Owner:ANKANG AGRI SCI RES INST

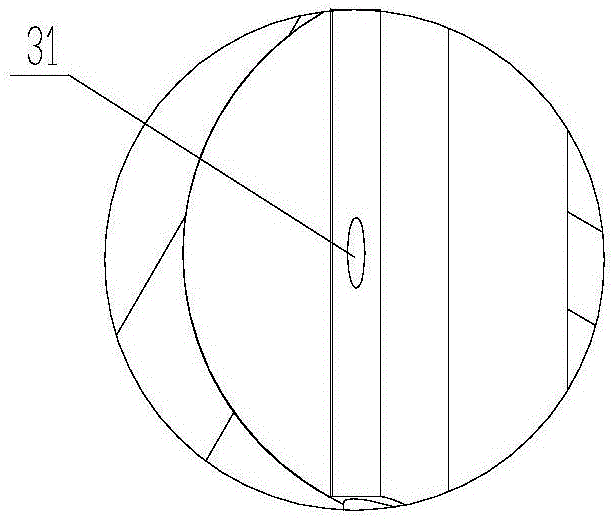

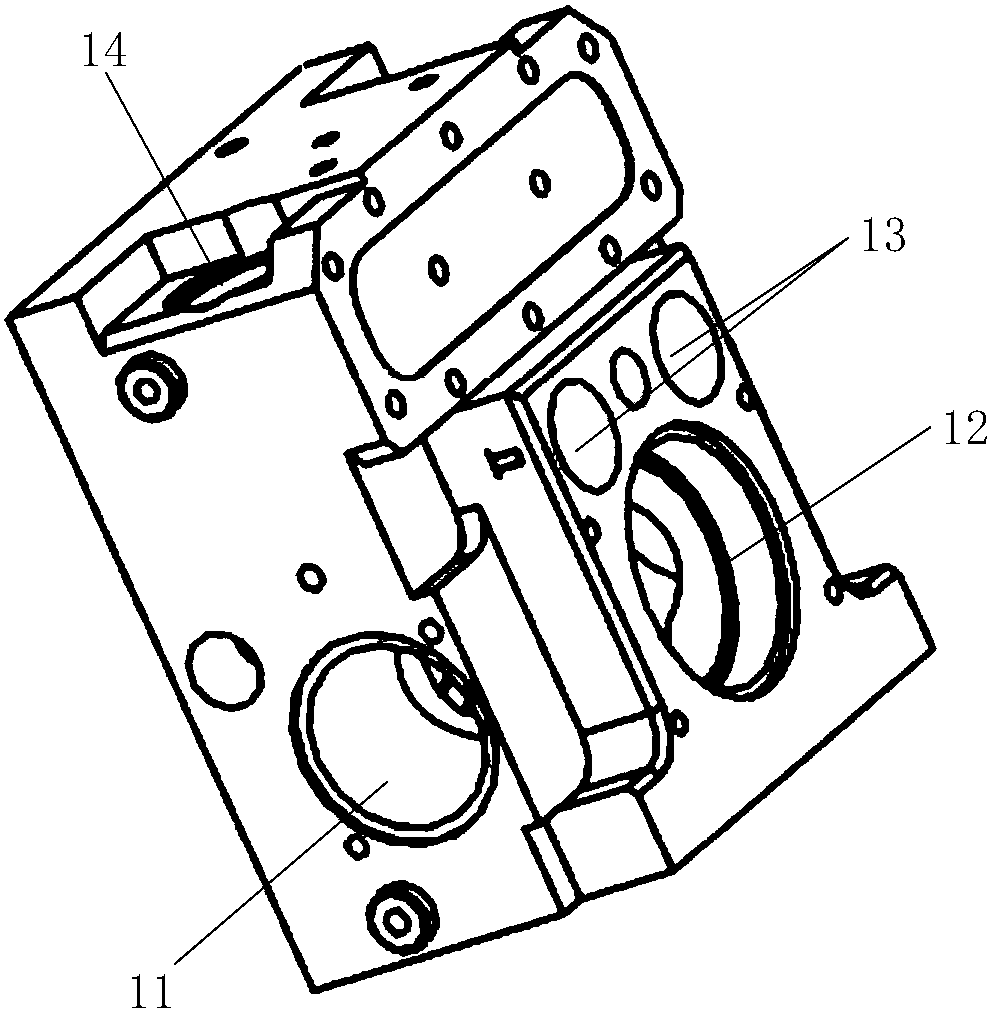

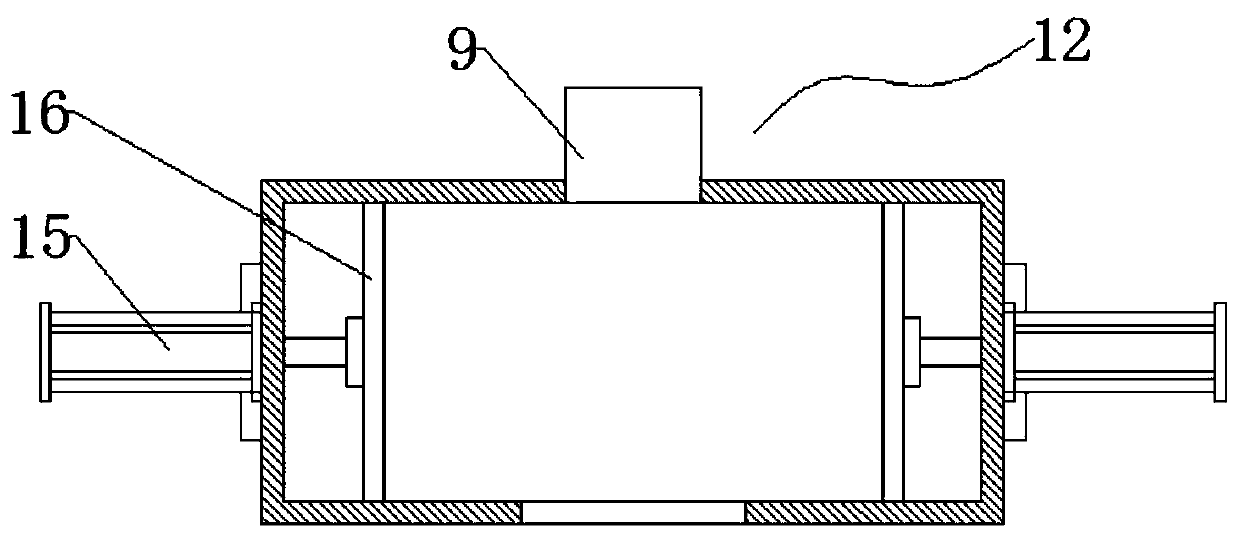

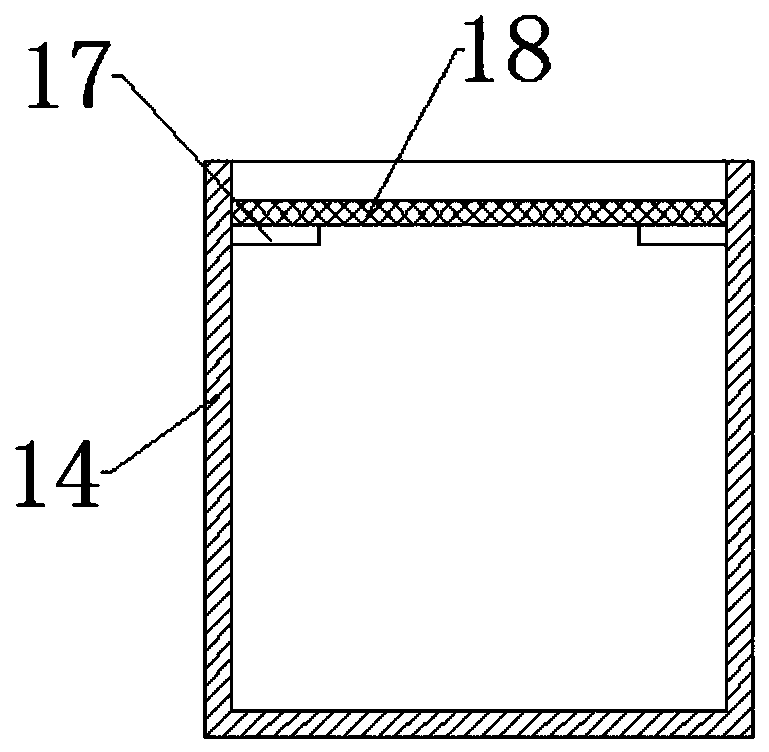

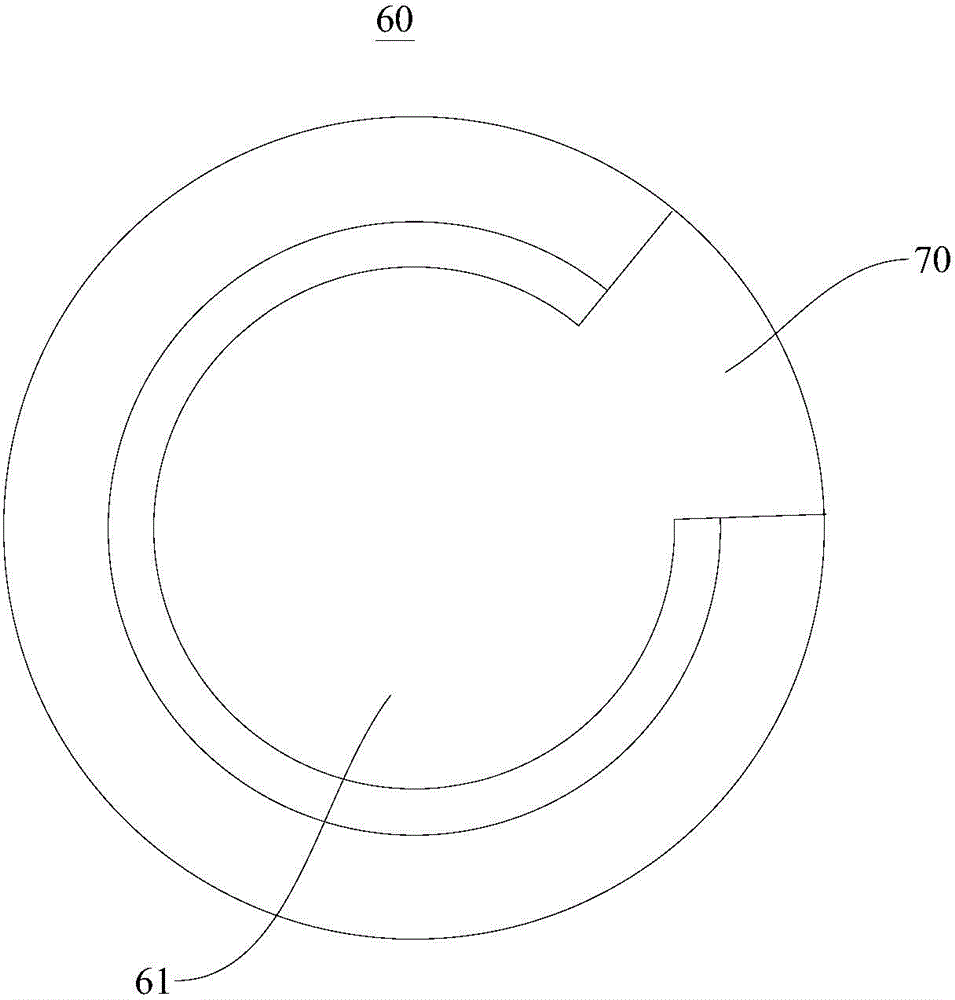

Pump body of rotary cylinder piston compressor and compressor adopting pump body

ActiveCN106015008AReduce oil resistanceIncrease oil outputRotary piston pumpsRotary piston liquid enginesEngineeringReturn channel

The invention relates to the technical field of compressors and particularly relates to a pump body of a rotary cylinder piston compressor and a compressor adopting the pump body. The pump body of the rotary cylinder piston compressor comprises a rotary shaft, a piston and an air cylinder, wherein the rotary shaft is internally provided with a rotary shaft hole; the air cylinder is internally provided with an oil-conducting channel communicated with the rotary shaft hole; a sinking groove is formed in the inner end face of the air cylinder; an oil path which is sealed relative to an air cylinder compression cavity is formed between the sinking groove and a piston; and the oil path is communicated with an oil path between the piston and the rotary shaft and is communicated with the oil-conducting channel through an oil returning channel. By setting the sinking groove and the oil returning channel, oil discharging resistance of an oil hole in the side face of the rotary shaft is reduced and the oil outlet quantity of the oil hole of the rotary shaft is increased; and the problem of abnormal abrasion caused by the fact that the lubrication between the side face of the rotary shaft and the piston is not enough under a heavy working condition is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC +1

Decaisnea insignis seed oil pressing technique

InactiveCN104987946ANo pollution in the processReduce wearFatty-oils/fats refiningFatty-oils/fats productionMicrowaveProtein molecules

The invention discloses a decaisnea insignis seed oil pressing technique. The decaisnea insignis seed oil pressing technique comprises the steps of decaisnea insignis seed screening, water content detection, embryo pressing, pressing and filtering and specifically comprises the following steps that a, decaisnea insignis seeds are screened, wherein the decaisnea insignis seeds are washed, and impurities are removed; b, the water content is detected; c, embryo pressing is conducted, wherein the decaisnea insignis seeds are husked, peeled and crushed, the walls of the decaisnea insignis seeds are broken through microwaves, and embryos are placed in an embryo pressing machine to be pressed; d, pressing is conducted, wherein embryo pieces are cold-pressed and pressurized; e, filtering is conducted, wherein fine filtering is conducted, phospholipids removal and centrifugal treatment are conducted by adding water, and oil on the upper layer is obtained. According to the decaisnea insignis seed oil pressing technique, a physical oil pressing method is adopted, microwave wall breaking and mechanical cell wall breaking are combined, and thus the oil yield is increased. By the adoption of the cold pressing method, the stability of unsaturated fatty acid structures in the seeds and the immutability of protein molecules can be kept, all nutritional ingredients of oil are basically reserved, and the transparency, color and luster of finished oil are improved. No chemical solvent is adopted in the whole production process, and the problem of chemical contamination of oil products is solved.

Owner:潘秀娟

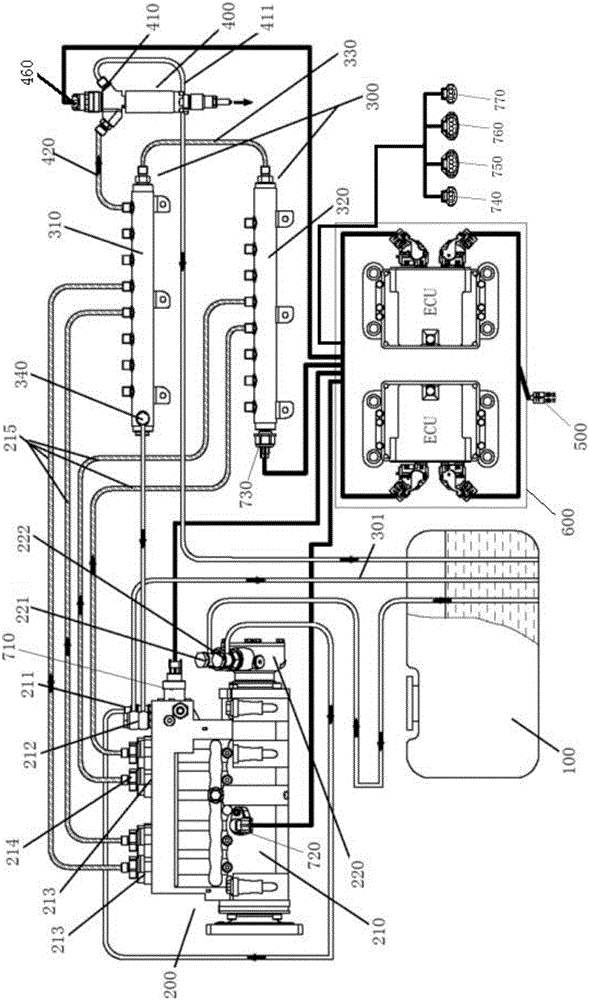

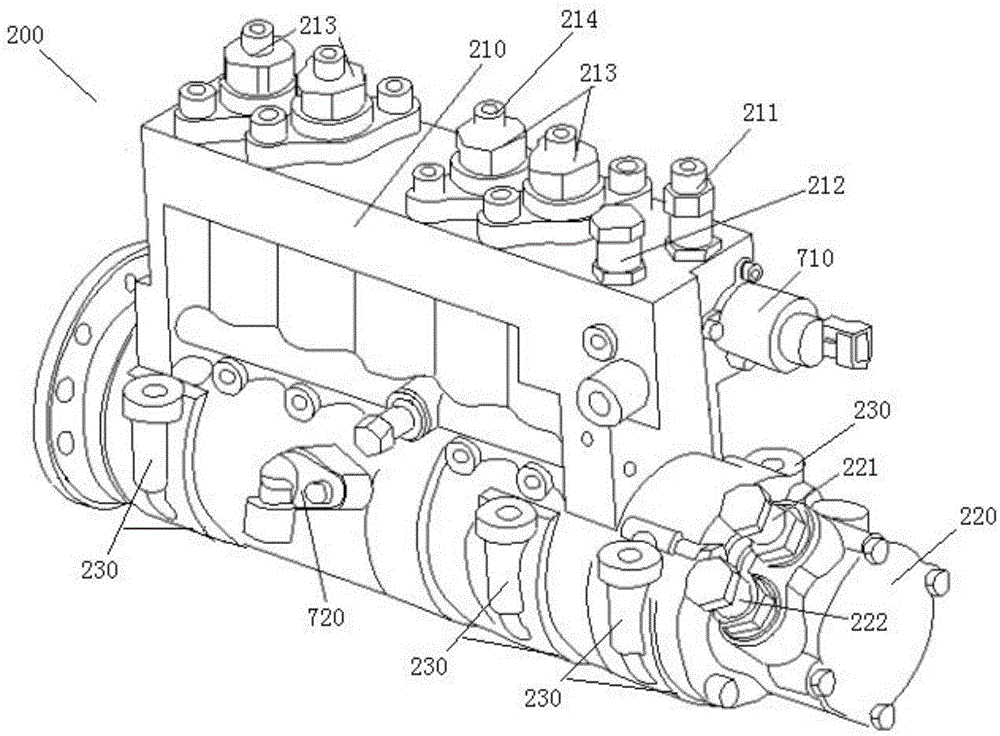

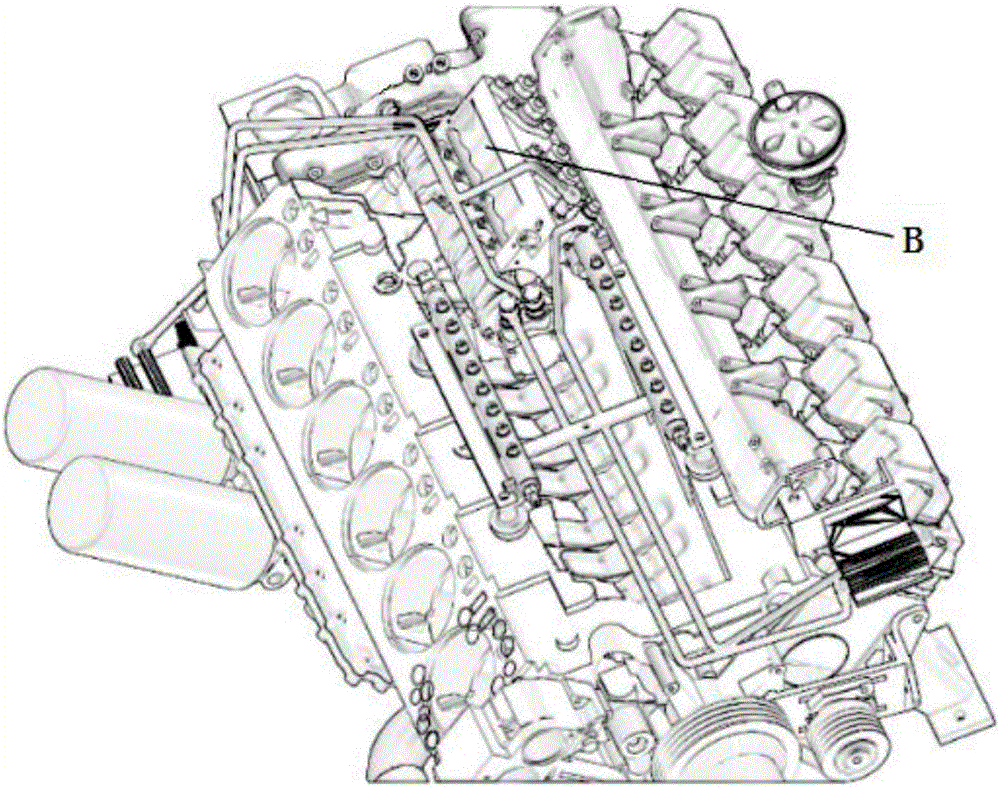

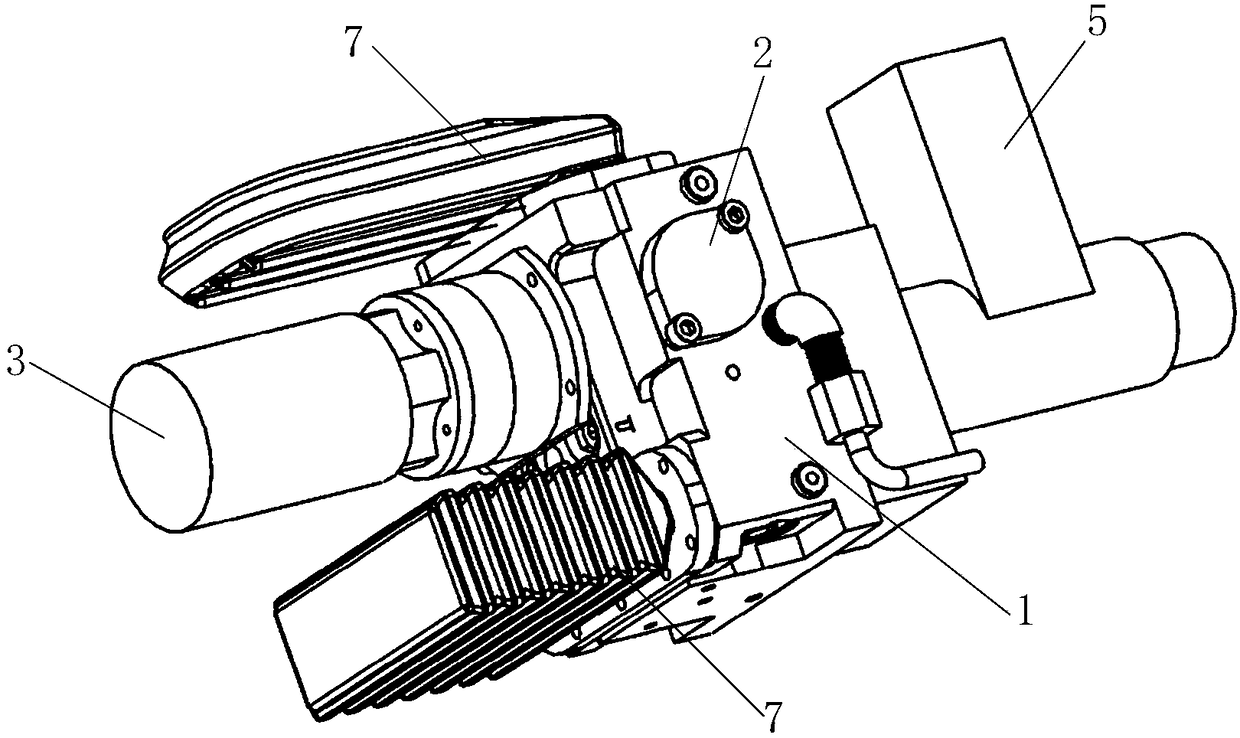

Diesel engine high-pressure common rail system

ActiveCN106523226ASatisfy oil balanceAccumulates pressure and distributes fuel wellElectrical controlFuel injection apparatusFuel tankMechanical system

The invention relates to a diesel engine high-pressure common rail system which is applicable to V-type diesel engines and provides support for improving diesel engines from the national II standard to the national III standard. The diesel engine high-pressure common rail system structurally comprises a mechanical system and an electric control system. The mechanical system comprises a fuel tank, a high pressure common rail fuel injection pump, a high pressure common rail pipe and fuel injectors. The high pressure common rail pipe comprises a first common rail pipe body and a second common rail pipe body, and main fuel paths of the first common rail pipe body and the second common rail pipe body are connected in series through a common rail fuel pipe. The multiple fuel injectors are arranged and are connected with the main fuel path of the first common rail pipe body or the main fuel path of the second common rail pipe body through second high pressure fuel pipes. The electric control system comprises an electric control unit, sensors and actuators. The electric control unit comprises two ECUs. The diesel engine high-pressure common rail system has the technical advantages that within the service life, the effect that the fuel delivery quantity is doubled and redoubled compared with that of a dual-plunger common rail fuel injection pump can be guaranteed under any working condition, the output fuel quantity of a fuel delivery pump, the flow of a fuel metering valve and the output fuel quantity of a high pressure pump are increased substantially, the maximum common rail pressure can reach 2000 bar, and the continuous working pressure can be kept at 1600 bar.

Owner:常州威曼新能源有限公司

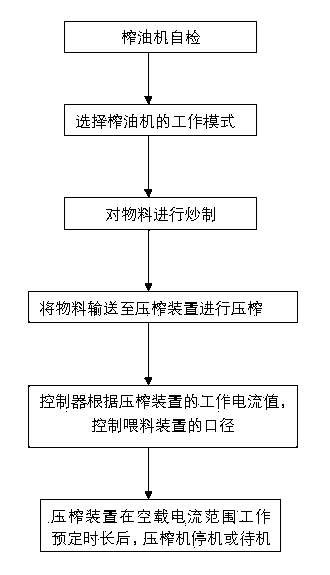

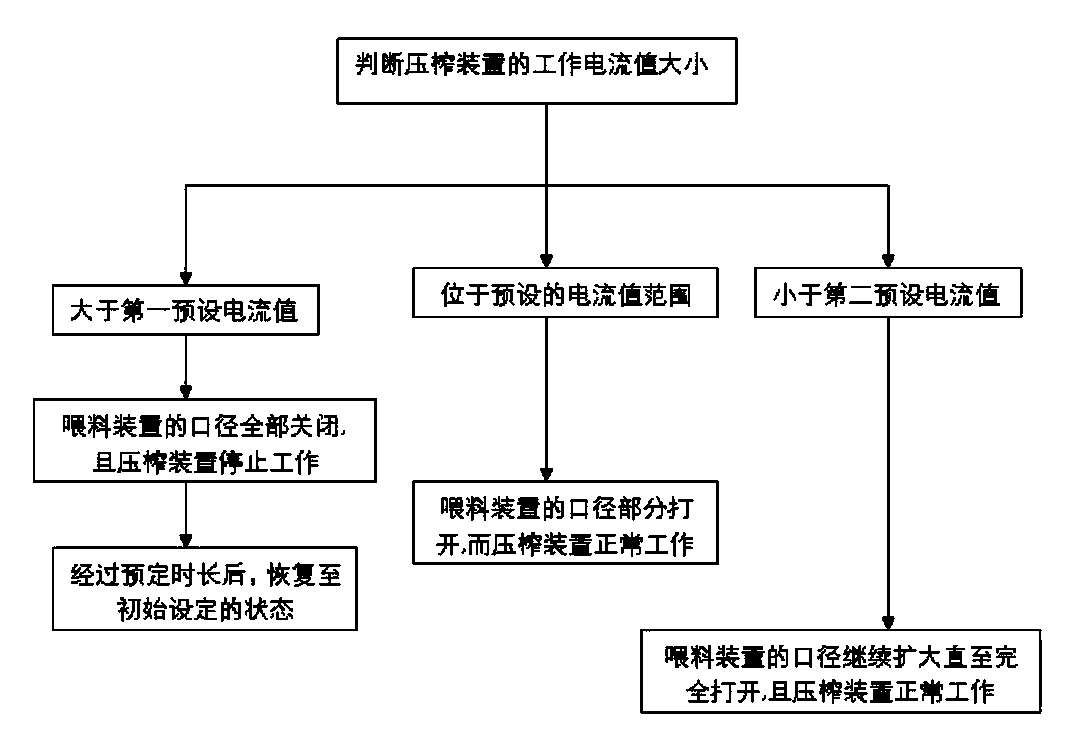

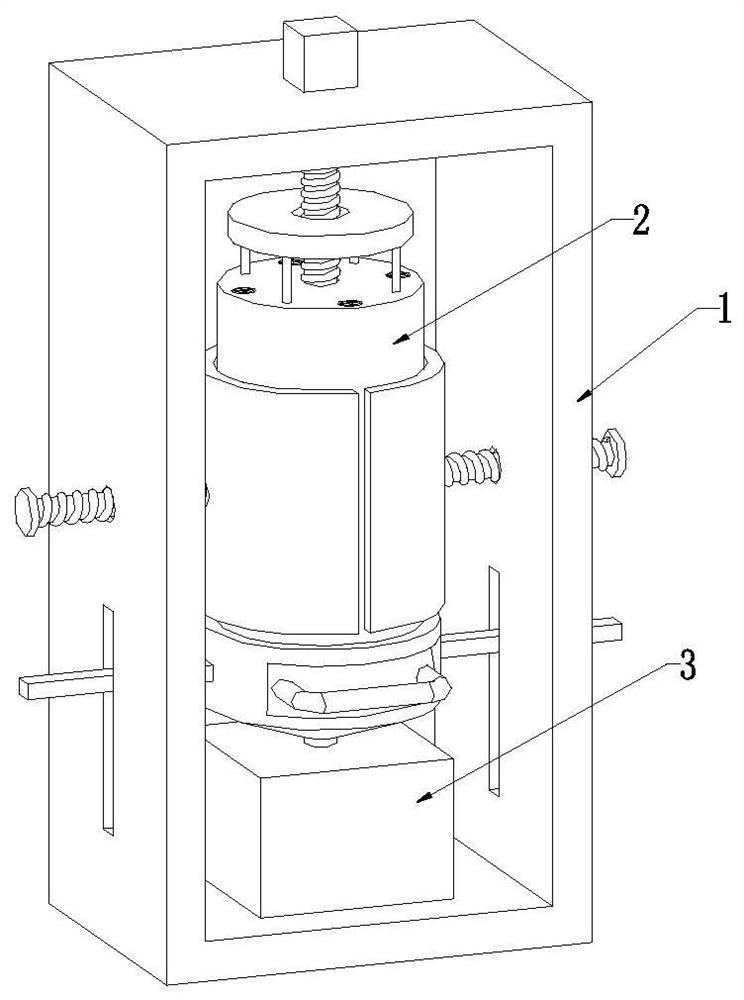

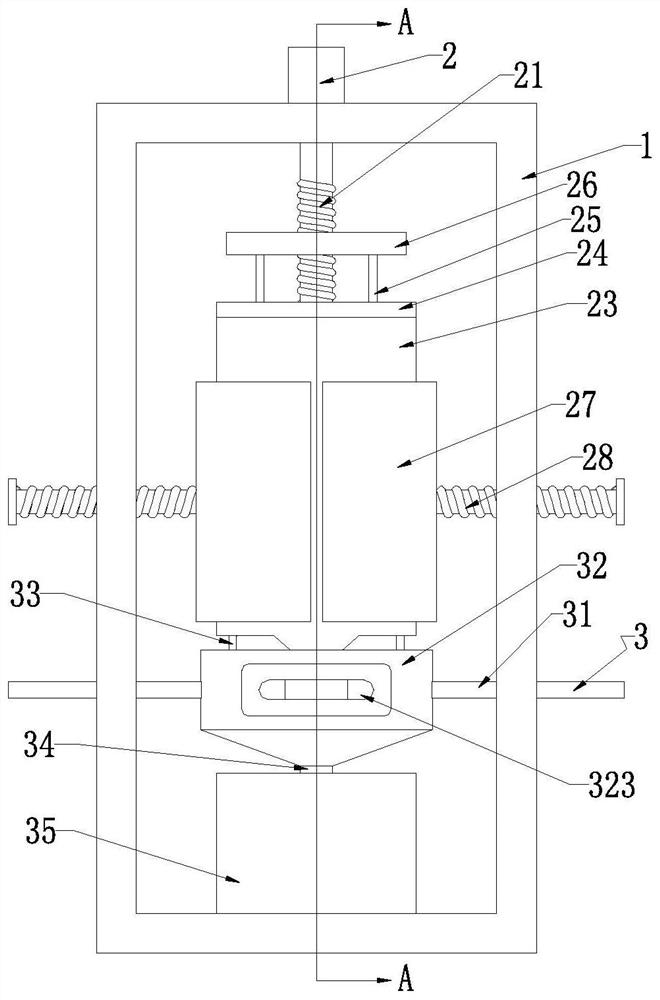

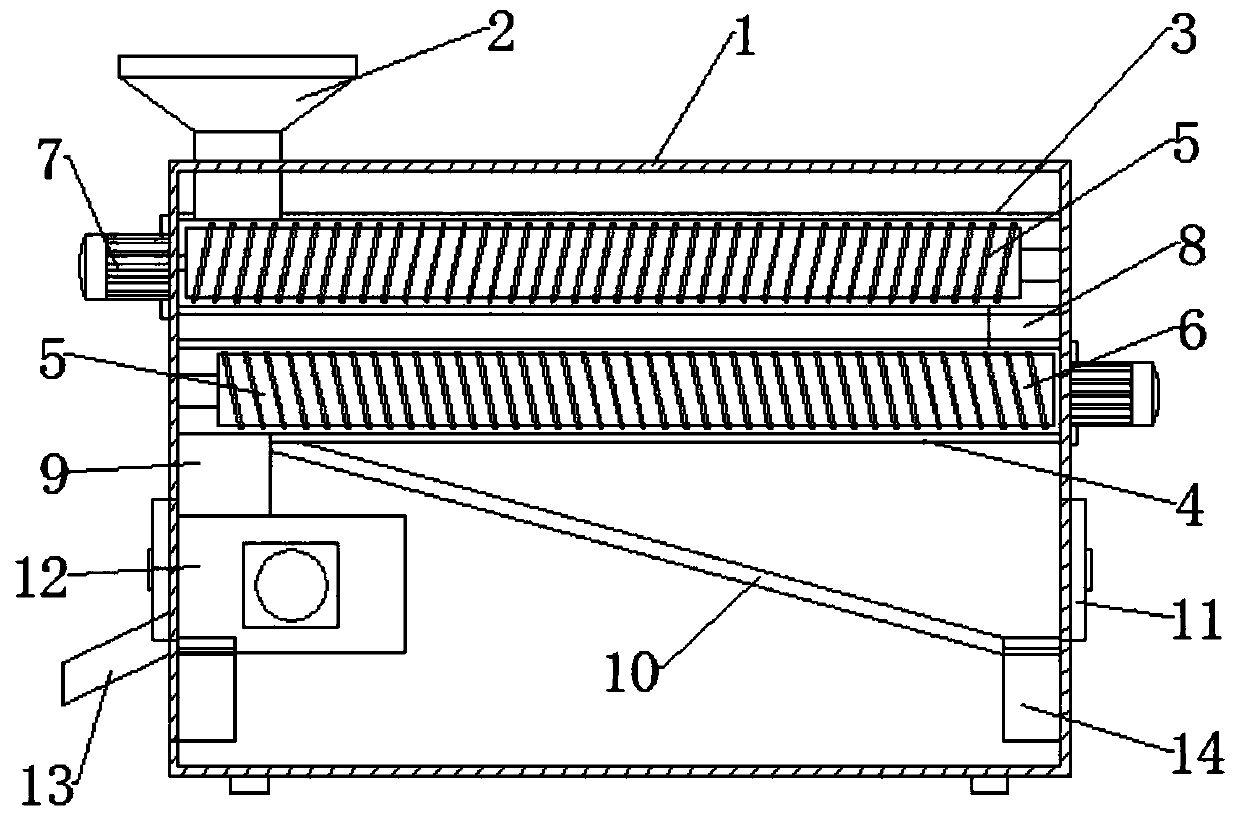

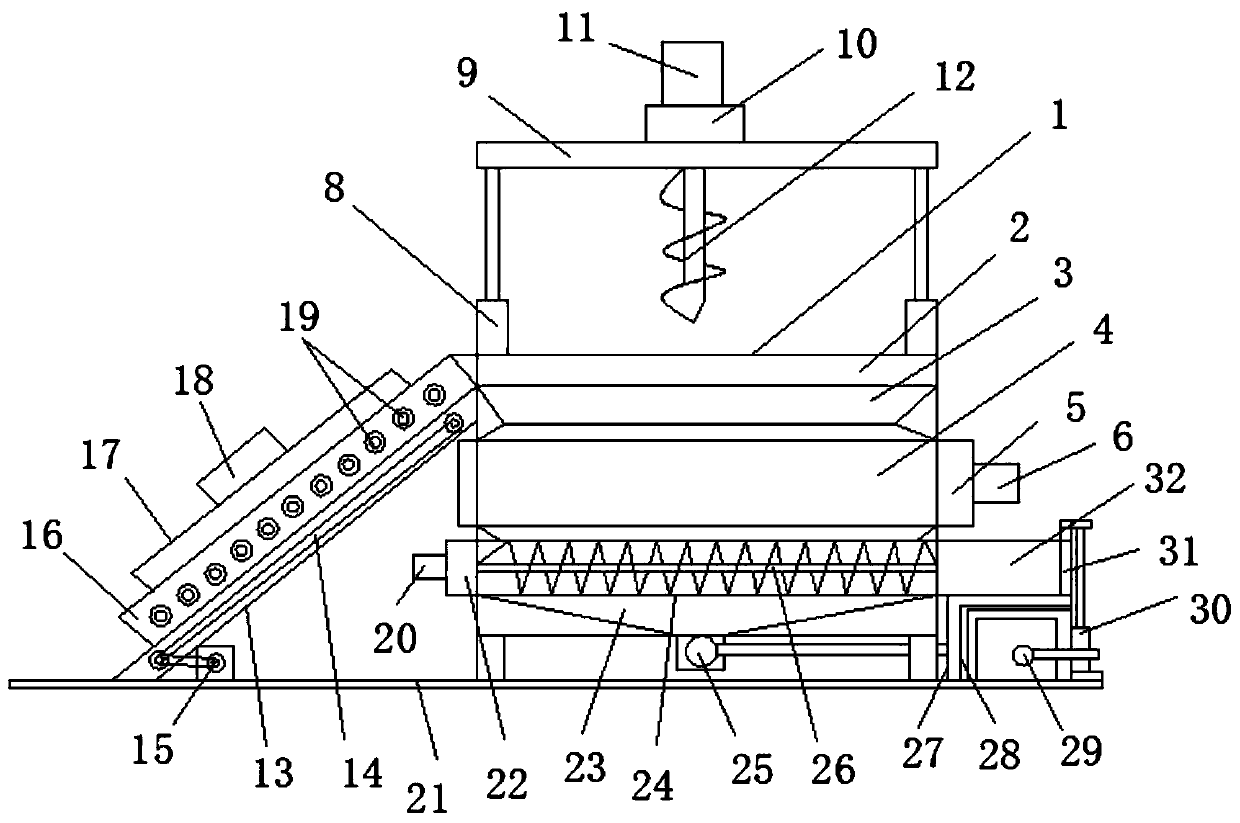

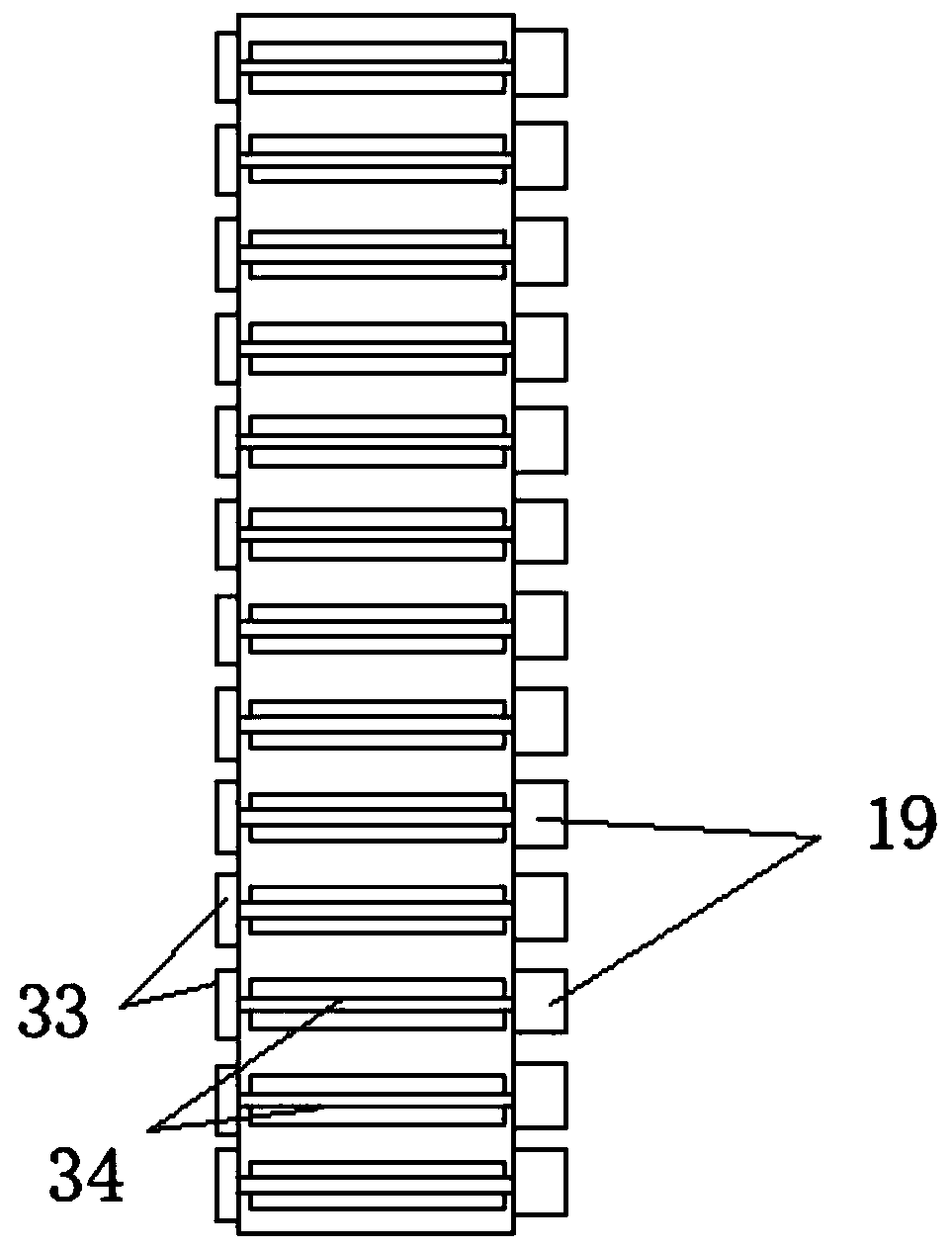

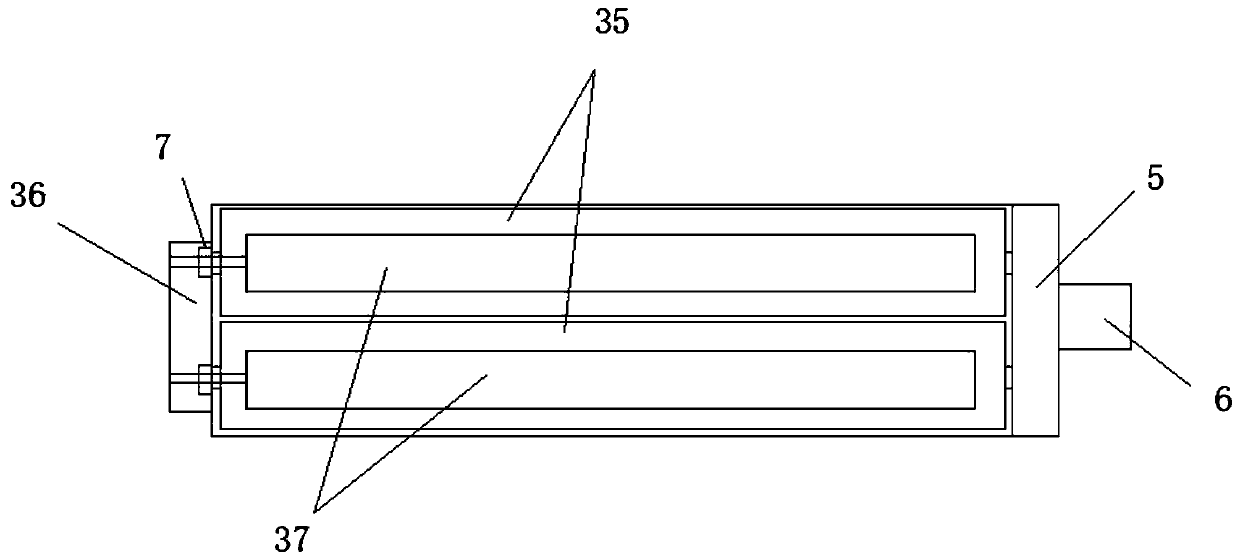

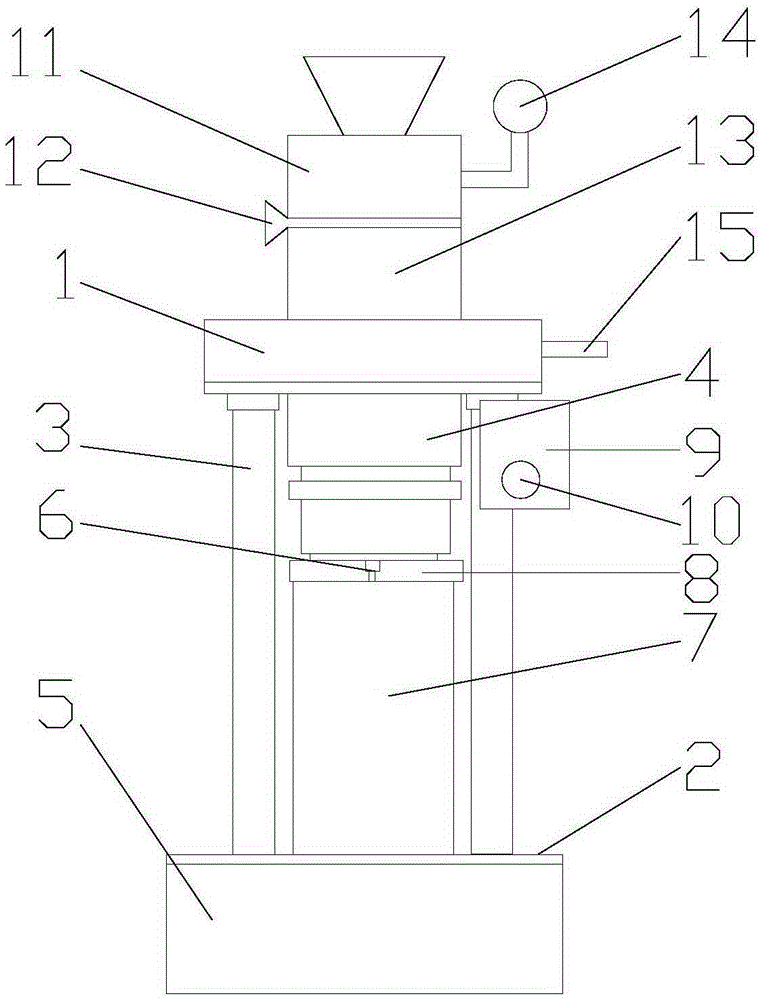

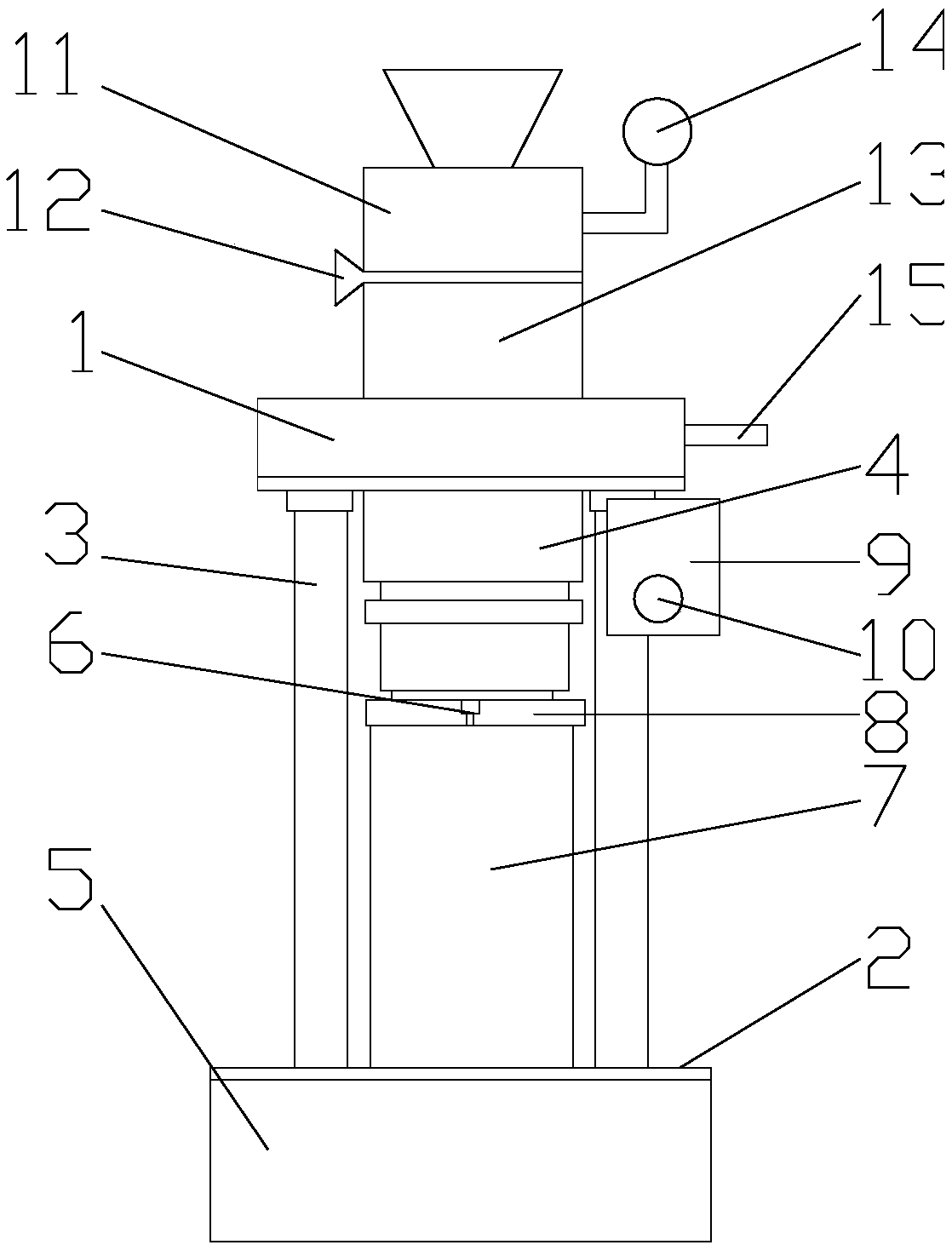

Oil press and control method thereof

ActiveCN103879008AReal-time monitoring of power changesAutomatically adjust the size of the blanking caliberPressesPower flowEngineering

The invention relates to an oil press. The oil press comprises a frying device, a pressing device, a feeding device and a controller, wherein the frying device is used for frying materials, the pressing device is used for pressing the fried materials, the feeding device is used for conveying the materials in the frying device to the pressing device for pressing and capable of controlling the material amount conveyed from the frying device to the pressing device in unit time, and the controller is used for controlling the frying device, the pressing device and the feeding device. The oil press further comprises a current detection device which is used for detecting a work current value of the pressing device and sending the signal of the work current value to the controller, and thereby the controller can control an opening of the feeding device. In addition, the invention relates to a control method of the oil press.

Owner:中山市唯美天丽塑胶颜料有限公司

Edible sunflower seed oil squeezing processing treatment system and squeezing processing process

InactiveCN111909779AReduce oil outputPrevent stacking into blocksFatty-oils/fats refiningFatty-oils/fats productionEngineeringSunflower oil

The present invention relates to an edible sunflower seed oil squeezing processing treatment system and a squeezing processing process. The system comprises a material loading frame, a squeezing assembly and an oil discharging assembly, wherein the squeezing assembly and the oil discharging assembly are arranged in order from top to bottom in the loading frame. The system and the process can solvethe following problems that in the existing sunflower seed squeezing treatment process: a) sunflower seeds are frequently impacted multiple times to be broken and seep oil, but due to long-time impact, the sunflower seeds are often pushed to the bottommost end to be stacked into blocks, and therefore the oil yield of the sunflower seeds is reduced and the oil discharge efficiency is influenced; b), when existing sunflower seeds are subjected to squeezing and oil discharging treatment, a large amount of oil residues are often generated, so that the oil residues often enter a collecting vesselalong with oil during oil discharging, impurities of the oil in the collecting vessel are excessive, and the quality of the oil is influenced.

Owner:苏静雯

Paraffin rosin water plugging agent for water plugging of thick oil huff-puff well and water plugging construction method

ActiveCN102504779BAvoid cold damageIncrease oil outputDrilling compositionSealing/packingFreezing Point TemperatureParaffin wax

The invention provides a paraffin rosin water plugging agent for water plugging of a thick oil huff-puff well and a water plugging construction method. The water plugging agent for the water plugging of the thick oil huff-puff well is mixed liquid prepared by paraffin, rosin and water. The water plugging construction method of the thick oil huff-puff well comprises the steps that the paraffin-rosin mixed liquid water plugging agent provided by the invention is filled into a stratum to be treated for selective water plugging, and in addition, the temperature of the water plugging agent in the filling process is ensured to be higher than the freezing point temperature of the paraffin and the softening point temperature of the rosin. The technology provided by the invention is utilized, because the construction temperature during the water plugging agent filling is higher than the freezing point temperature of the paraffin and the softening point temperature of the rosin, water and solidcontent objects such as the paraffin, the rosin and the like form liquid-liquid mixed phases, and the liquid-liquid mixed phases can easily enter the deep part of the stratum; after the mixed phases are squeezed into the stratum, the paraffin and the rosin are crystallized and separated out along with the heat exchange when the temperature is lower than 55 DEG C, and the paraffin and the rosin are dissolved after meeting oil and are unchanged after meeting water, so the selective water plugging is realized; and simultaneously, the cold damage problem can be effectively avoided.

Owner:PETROCHINA CO LTD

Production process for camellia seed oil

InactiveCN107653054ARetain nutrientsRetention of active substancesFatty-oils/fats productionEdible oils/fatsCamellia oleiferaCell separation

The invention relates to a production process for camellia seed oil. The production process comprises the following steps: 1) raw material cleaning and selecting; 2) hulling treatment; 3) seed-hull separation; 4) camellia seed baking; 5) material steaming and tempering; and 6) cooling, squeezing and oil discharging. The production process provided by the invention adopts physical squeezing, so nutritional components, active substances and camellia fragrance in oil are retained; meanwhile, specific processes like hull-seed separation, camellia seed baking and material steaming and tempering greatly improve the extraction rate of the oil compared with a conventional squeezing process; and the process provided by the invention can produce purely-natural, organic and green camellia seed edibleoil which is comparable to olive oil.

Owner:怀化盛源油脂有限公司

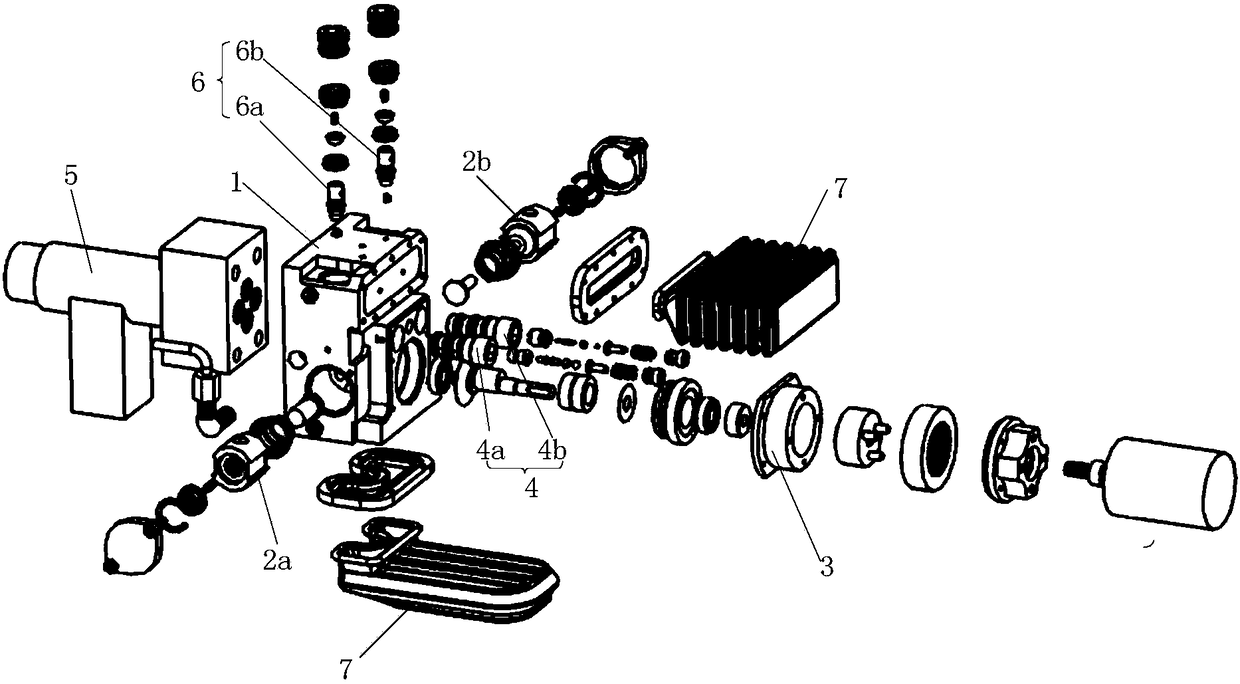

Variable-quantity and variable-pressure plunger pump

ActiveCN108533482ARelieve pressureProcessing efficiencyPositive displacement pump componentsPump controlEngineeringVariable pressure

The invention provides a variable-quantity and variable-pressure plunger pump. The variable-quantity and variable-pressure plunger pump comprises a pump body, a plunger assembly, a power assembly, anoil pressure adjusting assembly and an oil pressure output assembly. The plunger assembly is arranged on the pump body. The power assembly is arranged on the pump body and connected with the plunger assembly, and drives the plunger assembly to move to pump out oil fed in the pump body. The oil pressure adjusting assembly is arranged on the pump body; the oil pumped out by the plunger assembly is output after passing through the oil pressure adjusting assembly; and when the oil pressure exceeds a set value, the oil pressure adjusting assembly relieves the pressure to reduce the output oil pressure. The oil pressure output assembly is arranged on the pump body, respectively communicates with the oil pressure adjusting assembly, the pump body and an external execution mechanism, and controlsopening, stop and flowing direction of the oil.

Owner:HANGZHOU OUDUN ELECTROMECHANICAL

Processed cheese and processing method thereof

The invention provides processed cheese and a processing method thereof. The processed cheese comprises main materials and auxiliary materials, wherein the main materials include 10-25 parts by weight of chymosin casein, 10-30 parts by weight of plant fat, 1-15 parts by weight of milk fat, 15-40 parts by weight of composite natural cheese and 30-40 parts by weight of water; and the auxiliary materials include 0.5-3 parts by weight of emulsifying salt, 0.3-3 parts by weight of tablet salt, 0.1-1 part by weight of acidity regulator and 0.5-3 parts by weight of nutrient accessories. In a formula, the plant fat is added into the main materials to reduce the cost of raw materials of the processed cheese, a proper amount of milk fat is added to provide many complete fat globules, the chymosin casein as well as the emulsifying salt, acid and table salt at a proper proportion are adopted, and various kinds of natural cheese are added. In a process, a certain adding order is adopted, and the heating of the product and the mechanical effect are controlled. Through perfect match of the formula and process, the pizza cheese with good functionality and flavor is prepared while the cost is reduced.

Owner:孙玉强 +1

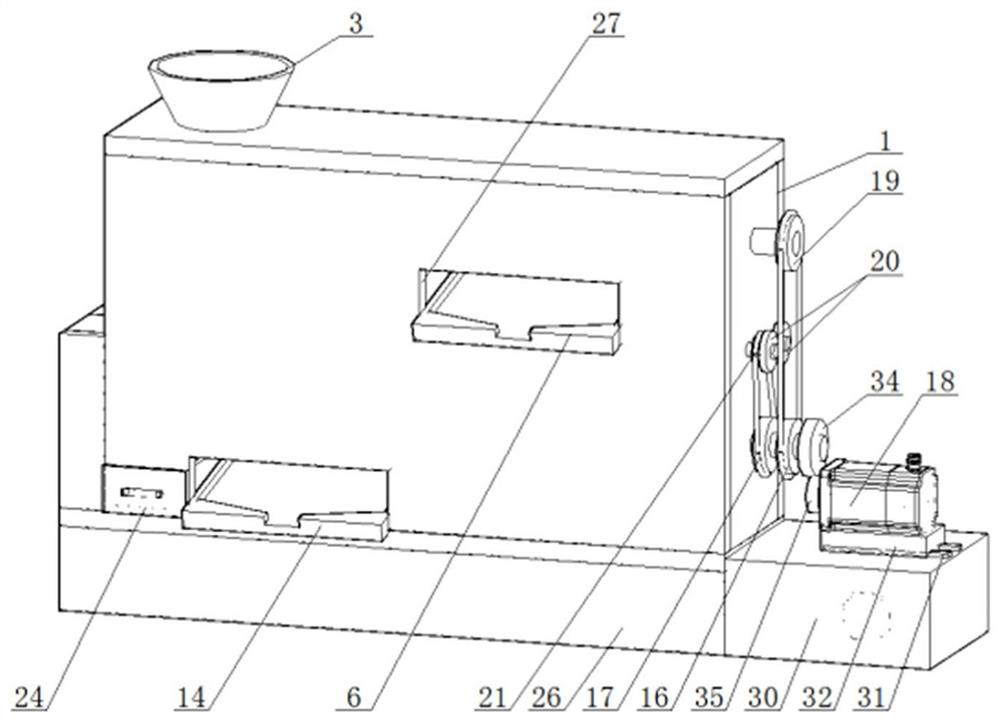

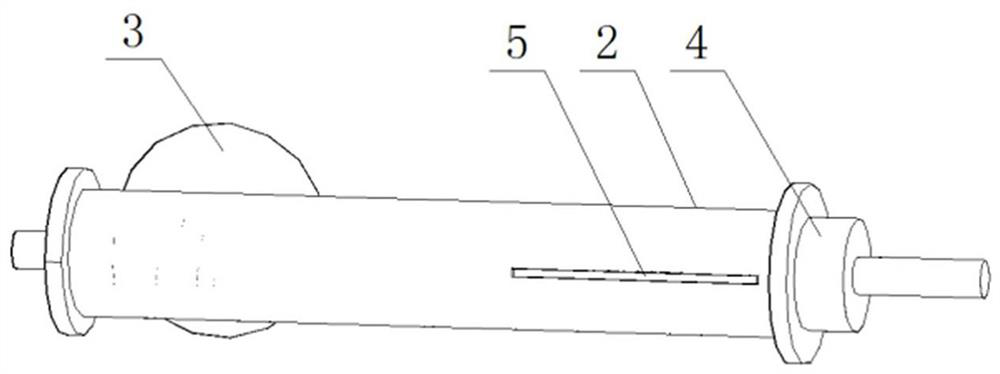

Hybrid oil squeezer for carrying out cold squeezing and hot squeezing

ActiveCN111716793AIncrease oil outputImprove oil extraction rateFatty-oils/fats productionGrain treatmentsThermodynamicsEngineering

The invention discloses a hybrid oil squeezer for carrying out cold squeezing and hot squeezing. The hybrid oil squeezer comprises a shell, wherein the upper part of an inner cavity of the shell is fixedly connected with a cold squeezing bore; the top of the left side of the cold squeezing bore is fixedly connected with a feeding hopper; the inside of the cold squeezing bore is rotatably connectedwith a cold squeezing rod; a crushing cavity is formed in the right side of the inner cavity of the shell; a discharging opening in the right end of the cold squeezing bore is communicated with the upper end of the crushing cavity; a plurality of groups of crushing blades are arranged in the crushing cavity; the bottom of the inner cavity of the shell is fixedly connected with a hot squeezing bore; a feeding opening in the right end of the hot squeezing bore is communicated with the lower end of the crushing cavity; the inside of the hot squeezing bore is rotatably connected with a hot squeezing rod; and a heating mechanism is fixedly mounted on the outer side wall of the hot squeezing bore. The hybrid oil squeezer has the advantages that the structure is simple, the oil squeezing amountcan be increased, and the oil discharging efficiency is improved; and the hybrid oil squeezer is mainly used for squeezing the oil.

Owner:当阳红缘丰食品有限公司

Sesame oil production process

InactiveCN106811287AAffect qualityPerfect protein denaturationFatty-oils/fats productionEdible oils/fatsProcess engineeringSesame Oils

The invention discloses a sesame oil production process which comprises the following specific steps: 1, selecting semen sesami nigrum as a raw material, and removing impurities and premature seeds in the raw material; 2, bleaching the selected raw material in a bleacher; 3, stir-frying the raw material of which the moisture content reaches the standard in a sesame frying machine, and matching with a power stirrer; 4, taking out the sesames out of the sesame frying machine, and performing heat dissipation treatment on the raw material by using a smoking machine; 5, screening the cooled sesames, and removing sesame skin, oil powder and the like dropping while frying; 6, grinding the sesames in a carborundum grinder pulping machine so as to obtain paste; and 7, mixing the pulp, taking the oil, adding the ground sesame paste into a pulp mixing pot, and filling water into the sesame paste so as to enable the sesame oil to suspend on the surface, wherein the water adding amount is 81-84% of the weight of the sesame paste. According to the process disclosed by the invention, the system is perfect, the oil contained in the sesames can be extracted to the greatest degree, and the processing efficiency is high.

Owner:安徽达园粮油有限公司

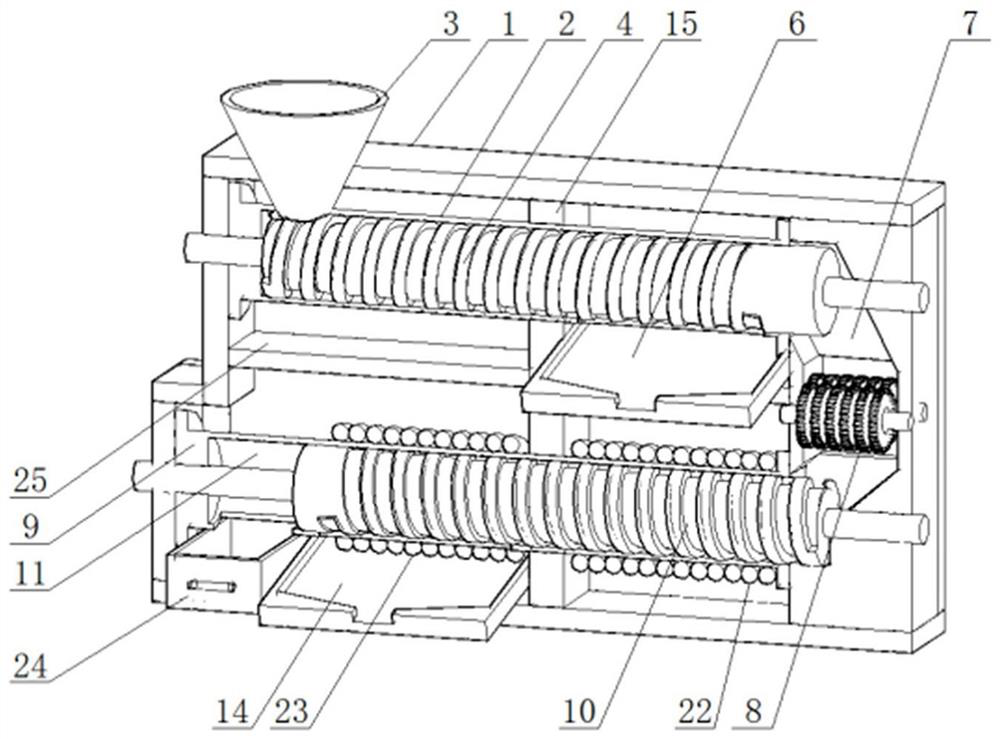

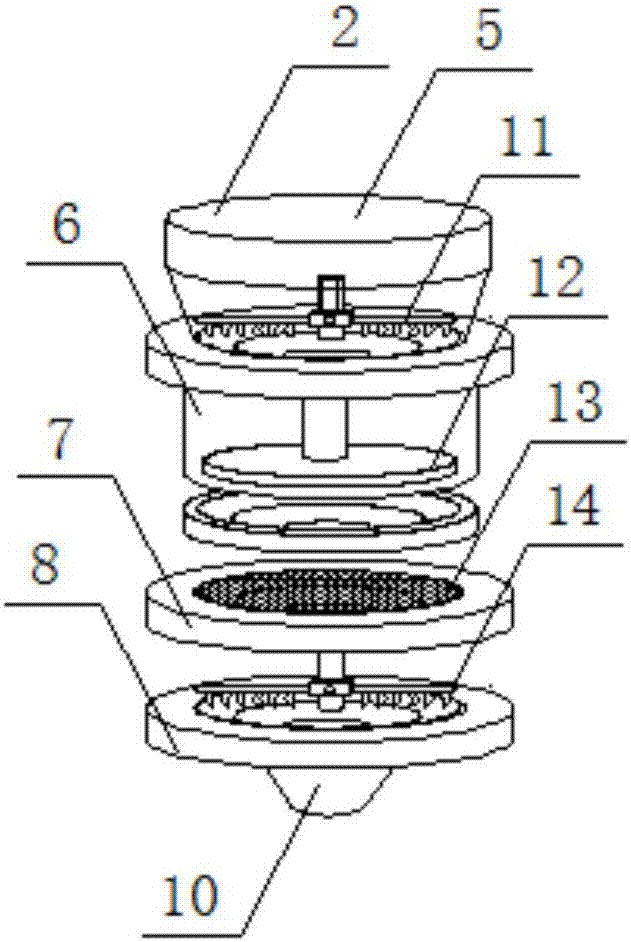

Sesame oil multistage press

InactiveCN110181848AIncrease oil outputImprove qualityFatty-oils/fats refiningFatty-oils/fats productionSlagDrive motor

The invention discloses a sesame oil multistage press in the technical field of sesame oil production. The sesame oil multistage press comprises a shell; a first-grade pressing channel and a second-grade pressing channel are arranged in the shell; a first pressing screw rod is arranged in the first-grade pressing channel; a second pressing screw rod is arranged in the second-grade pressing channel; driving motors are mounted at outer ends of the first-grade pressing channel and the second-grade pressing channel; the driving motors are connected with the first pressing screw rod and the secondpressing screw rod; the first-grade pressing channel is arranged above the second-grade pressing channel; and a feed hopper is mounted on the shell. The multistage pressing is performed on sesame seeds through the first-grade pressing channel, the second-grade pressing channel and an extrusion mechanism to realize more sufficient pressing of the sesame seeds; the sesame seeds are pressed out oil by multiple times to improve the oil yield; oil slag and the oil can be continuously twisted for quick separation, so that the oil slag is conveniently discharged in time; and the oil is filtered during collecting through an oil collecting box, so that the quality is improved.

Owner:ANHUI HUAAN FOOD

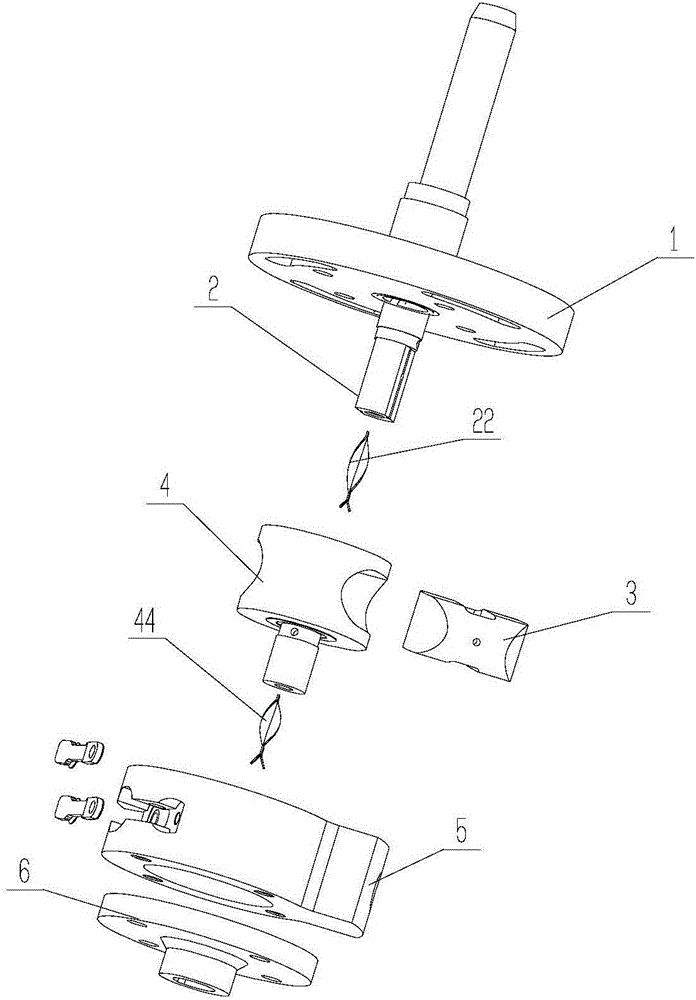

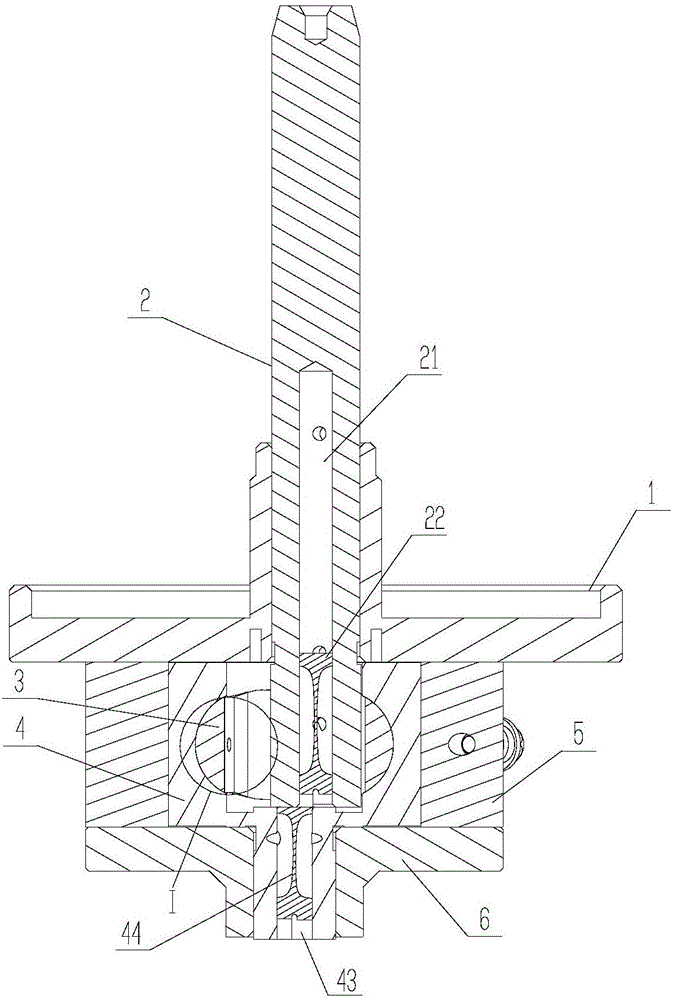

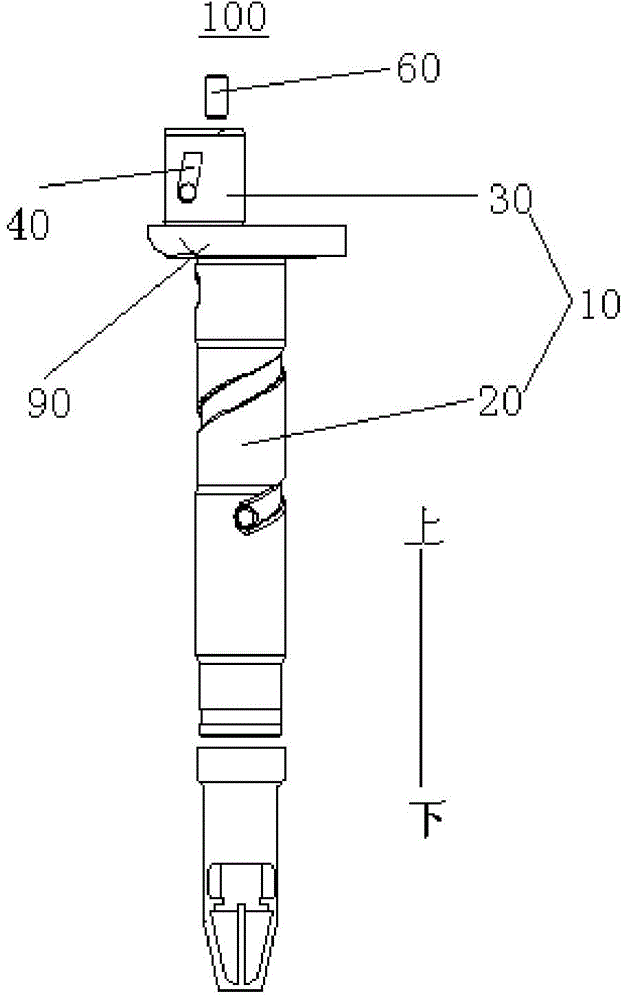

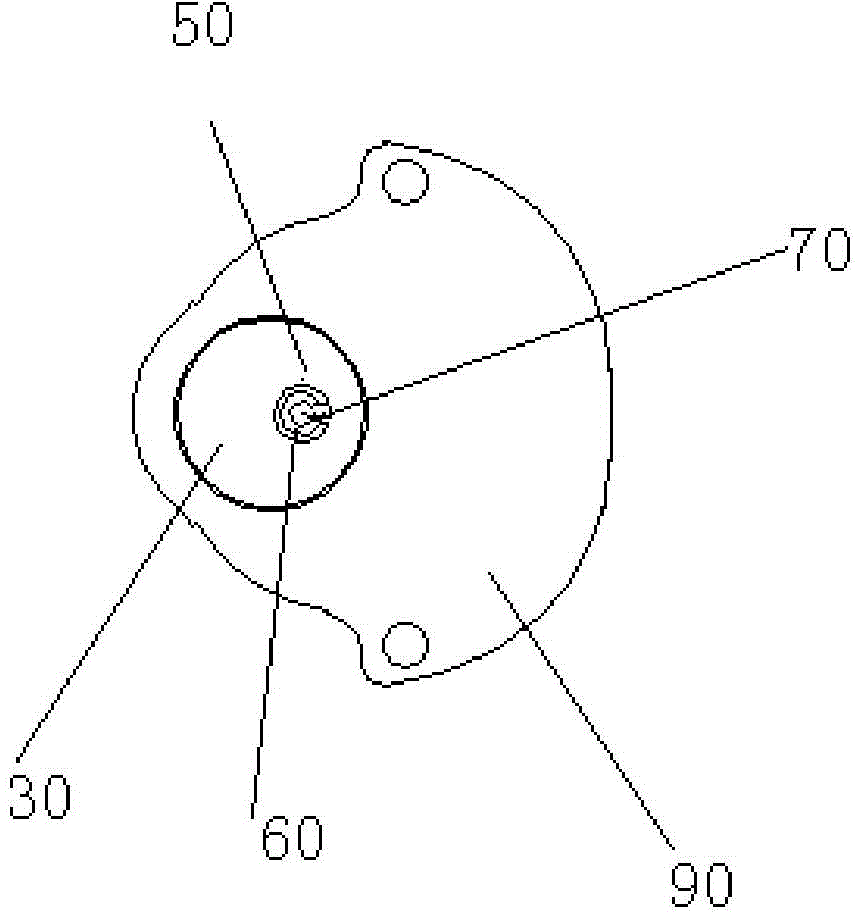

Crankshaft for piston compressor and piston compressor with the same

ActiveCN104819127AIncrease oil outputLow calorific valueCrankshaftsPositive displacement pump componentsEngineeringMechanical engineering

The invention discloses a crankshaft for a piston compressor and a piston compressor with the crank shaft. The piston compressor comprises a connecting rod and a piston connected at one end of the connecting rod, wherein the other end of the connecting rod is sleeved on the crankshaft. The crankshaft comprises a body, and the body comprises a long shaft segment and an eccentric shaft segment arranged at one end of the long shaft segment. An oil outlet groove is formed in the side wall of the eccentric shaft segment and does not penetrate through the end surface, far away from the long shaft segment, of the eccentric shaft segment. An oil outlet hole is formed in the eccentric shaft segment. One end of the oil outlet hole penetrates through the end surface of the eccentric shaft segment. The oil outlet groove is communicated with the oil outlet hole. The other end of the connecting rod is sleeved on the eccentric shaft segment and seals the oil outlet groove. The lubricating oil thrown from the oil outlet hole is thrown to a piston. The crank shaft for the piston compressor can improve the oil outlet volume of the piston compressor.

Owner:ANHUI MEIZHI COMPRESSOR +1

Processing method of rapeseed oil

InactiveCN108559618AIncrease oil outputOil thoroughlyFatty-oils/fats refiningFatty-oils/fats productionChemistryWater soluble

The invention discloses a processing method of rapeseed oil. The processing method comprises the steps of rapeseed treatment, parching of rapeseed, oil expression, addition of auxiliary materials, dephosphorization treatment, purification of rapeseed oil, decolorization, deodorization and the like. Sediments in the rapeseed are sifted out before parching and a proper amount of cavings is added into the rapeseed when oil is expressed; the sediments have certain oil absorption and the oil pump capacity can be improved by sifting out the sediments; meanwhile, the cavings can slow down the slidingof the rapeseed; the rapeseed oil is expressed more thorough, so that the oil pump capacity is effectively improved. During the dephosphorization treatment, a table salt solution is added into the crude oil; table salt has the advantages that harmful components such as erucic acid and jervine in the crude rapeseed oil to a human body can be weakened, and further the quality of the oil is increased; in addition, water-soluble silicate and active white earth are synergized together during decolorization; due to complementary characteristics of the two substances, as well as higher adsorption activity to phospholipids, trace metals and soaps, the oil color can be improved; besides, the method has the advantages that the use of white earth can be effectively saved and the investment cost is reduced.

Owner:淮北市振丰粮油有限公司

Preparation method of selenium-enriched Sichuan pepper oil

The invention mainly belongs to the technical field of grease processing, and discloses a preparation method of selenium-enriched Sichuan pepper oil. The preparation method comprises steps of raw material preparation, fermentation, drying, heating, deep frying, and packaging. The preparation method is simple; operation is convenient; the obtained Sichuan pepper oil is thick in flavor, fresh, golden yellow, and slightly pungent; no additive is added; the selenium-enriched Sichuan pepper oil is safe and good for health; the variety of commercial Sichuan pepper oil is increased; requirements of consumers on nutrients and mouthfeel are satisfied. According to the preparation method, a white granulated sugar solution is added into Sichuan pepper firstly, inoculation with Angel saccharomyces cerevisiae is carried out to promote bacteria proliferation, protein selenium is added for low temperature long term fermentation, so that full leaching of effective components in Sichuan pepper seeds and leaves is realized, fragrance and oil yield are improved, selenium content is increased, and Sichuan pepper oil health care functions are improved; plant oil is heated to remove raw oil smell, natural cooling is carried out, and then dried Sichuan pepper is added for deep frying, so that generation of scorched smell is avoided, the obtained product is safe and good for health, water in Sichuan pepper is removed completely, grease and flavor ingredients in Sichuan pepper are extracted, Sichuan pepper oil oxidative rancidity is avoided, and self life is prolonged.

Owner:CHUZHOU YINSHI GREASE CO LTD

Rapeseed oil full-automatic squeezing device

PendingCN111016252ARealize automatic feeding processQuality improvementPressesOil canElectric machinery

The invention discloses a rapeseed oil full-automatic squeezing device, comprising a device body, wherein a feeding hole is formed in the top part of the device body; first electric telescopic rods are fixed to the two sides of the top part of the feeding port correspondingly; a top plate is mounted at the top parts of the first electric telescopic rods; a second gearbox is mounted in the middle of the top part of the top plate; a second motor is mounted at the top part of the second gear box; and a first auger is mounted at the bottom part of the second gear box. According to the rapeseed oilfull-automatic squeezing device, automatic feeding of rapeseeds can be achieved; in the feeding process, the rapeseeds can be subjected to dust removal and drying treatment, thereby improving rapeseed quality, and preventing the phenomenon of blockage caused by excessive rapeseeds during feeding; the rapseeds can be heated to improve the oil yield while being squeezed, and the rapeseed waste residues generated during oil squeezing can be subjected to oil filtering treatment, so that oil in the waste residues can be treated more cleanly; and the rapeseed oil can be filtered multiple times, impurities are prevented from being contained in the oil, and the oil squeezing quality is improved.

Owner:兴化市荣宝油脂有限公司

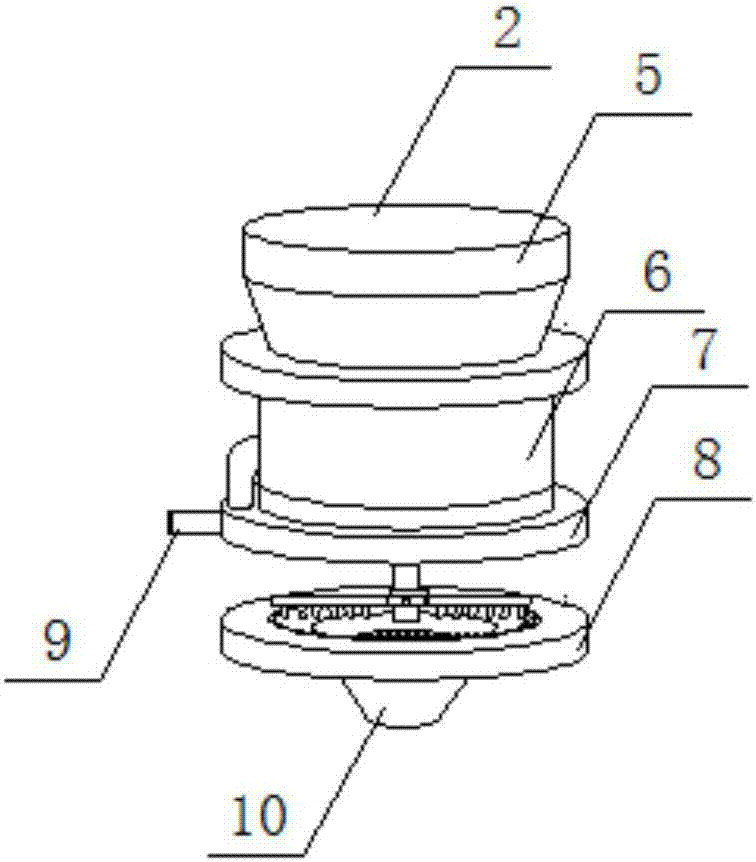

Oil press for Abelmoschus esculentus seed oil

InactiveCN106626481AReduce consumptionGuaranteed nutritionFatty-oils/fats productionPressesVegetable oilPetroleum engineering

The invention relates to the field of plant oil extraction devices, in particular to an oil press for Abelmoschus esculentus seed oil. The oil press includes a pretreatment mechanism and a pressing mechanism; the pretreatment mechanism is arranged above the pressing mechanism; the pretreatment mechanism includes a heating oven, a separation layer and a crushing bin; the heating oven is arranged right above the crushing bin; and the separation layer is arranged between the heating oven and the crushing bin. The oil press can reduce energy waste, is large in oil capacity, can reduce in pressing cost, can improve the purity of oil, and can ensure the nutriments of the Abelmoschus esculentus seed oil.

Owner:DANYANG HUADU GARDENING

Agricultural vegetable seed oil mill

InactiveCN107159408AIncrease oil outputAvoid insufficient heatingFatty-oils/fats productionGrain treatmentsFiltrationPulp and paper industry

The invention discloses an agricultural rapeseed oil press, which comprises a machine case, a pressing device, a control cabinet, a hot air blower, a pretreatment box, a pressing box, a filter disc, a uniform disc, an air duct, a collecting box, a pre-stirring device, a pressing plate, Strainer, stirring rod, rotor and cutter. The beneficial effects of the invention are: by installing a hot air blower on one side of the case, the hot air is blown into the inside of the pressing box by the hot air blower, so that the rapeseed oil can obtain sufficient heat during the pressing process, thereby increasing the oil yield of the rapeseed. By installing a pretreatment box above the press box, the rapeseed is pre-crushed by the pre-stirring device inside the pretreatment box, so that the rapeseed skin film is broken, thereby improving the oil extraction effect during the pressing process. By installing a filter disc under the press box, a layer of filter screen is installed on the filter disc to filter the residue and rapeseed oil, and by installing a uniform disc under the filter disc, the rapeseed oil is allowed to stand still with the stirring rod inside the uniform disc. Stir to process.

Owner:柳州市文宇科技服务有限公司

Coconut oil extraction process

InactiveCN108085123ADoes not destroy proteinIncrease freshnessFatty-oils/fats productionFresh coconutCoconut oil

The invention discloses a coconut oil extraction process which comprises the following steps: collecting fresh coconut meat and coconut cakes from germinant mature coconuts, performing sterilization,wall breakage, fermentation and enzyme deactivation, and implementing a centrifugal coconut oil extraction method, thereby obtaining coconut oil. The coconut oil extraction process disclosed by the invention is free of high-temperature treatment process, nutrient components such as proteins in coconuts are not damaged, relatively high coconut oil yield is achieved, the coconut oil is high in freshness degree and thick in coconut fragrance, and nutrient substances in the coconuts are relatively well maintained.

Owner:海南尧香堂文化创意有限公司

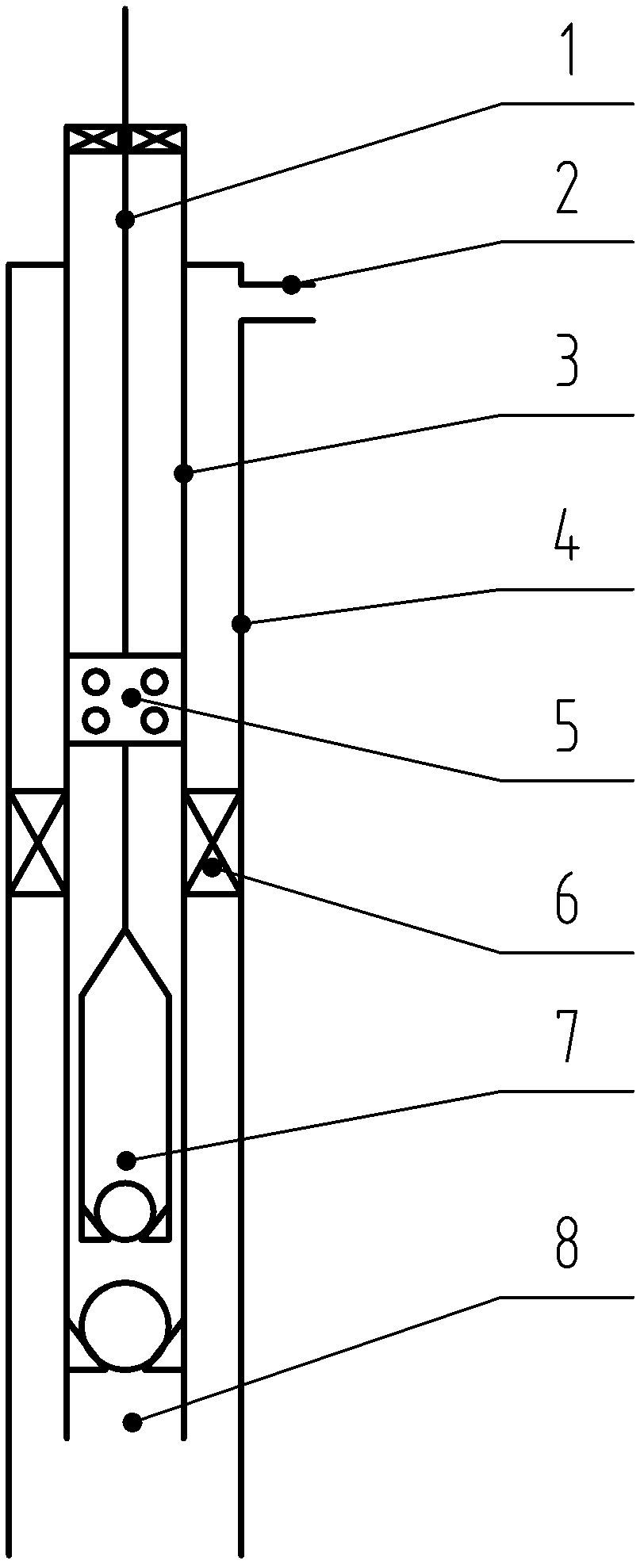

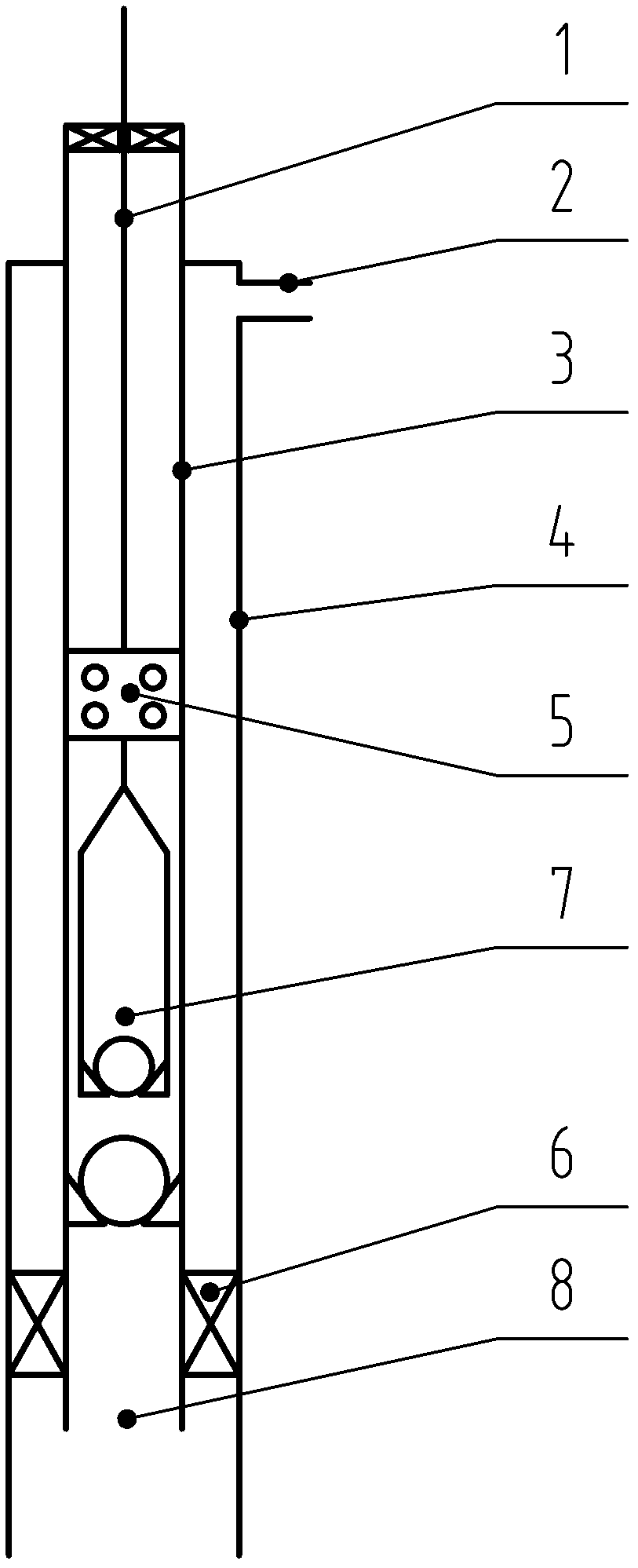

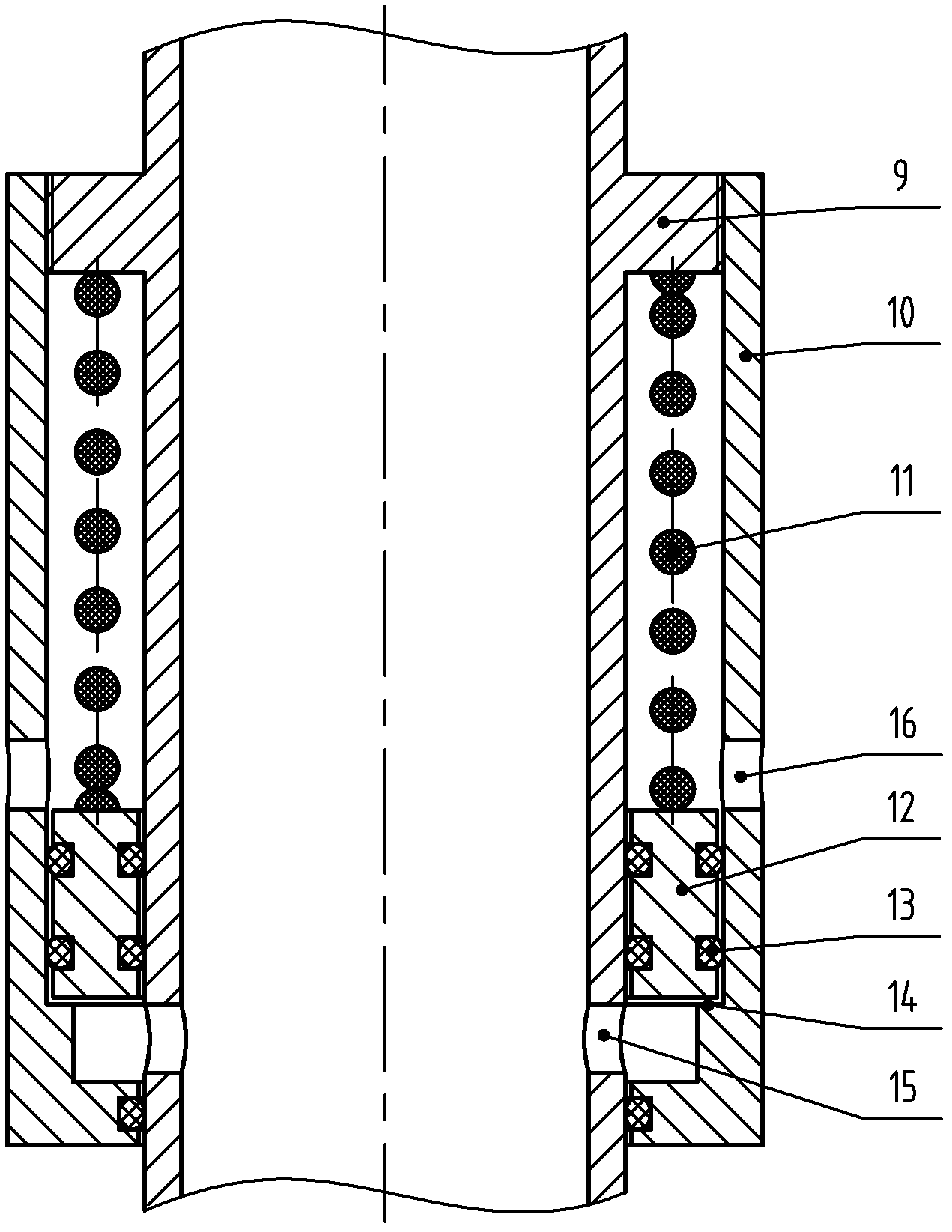

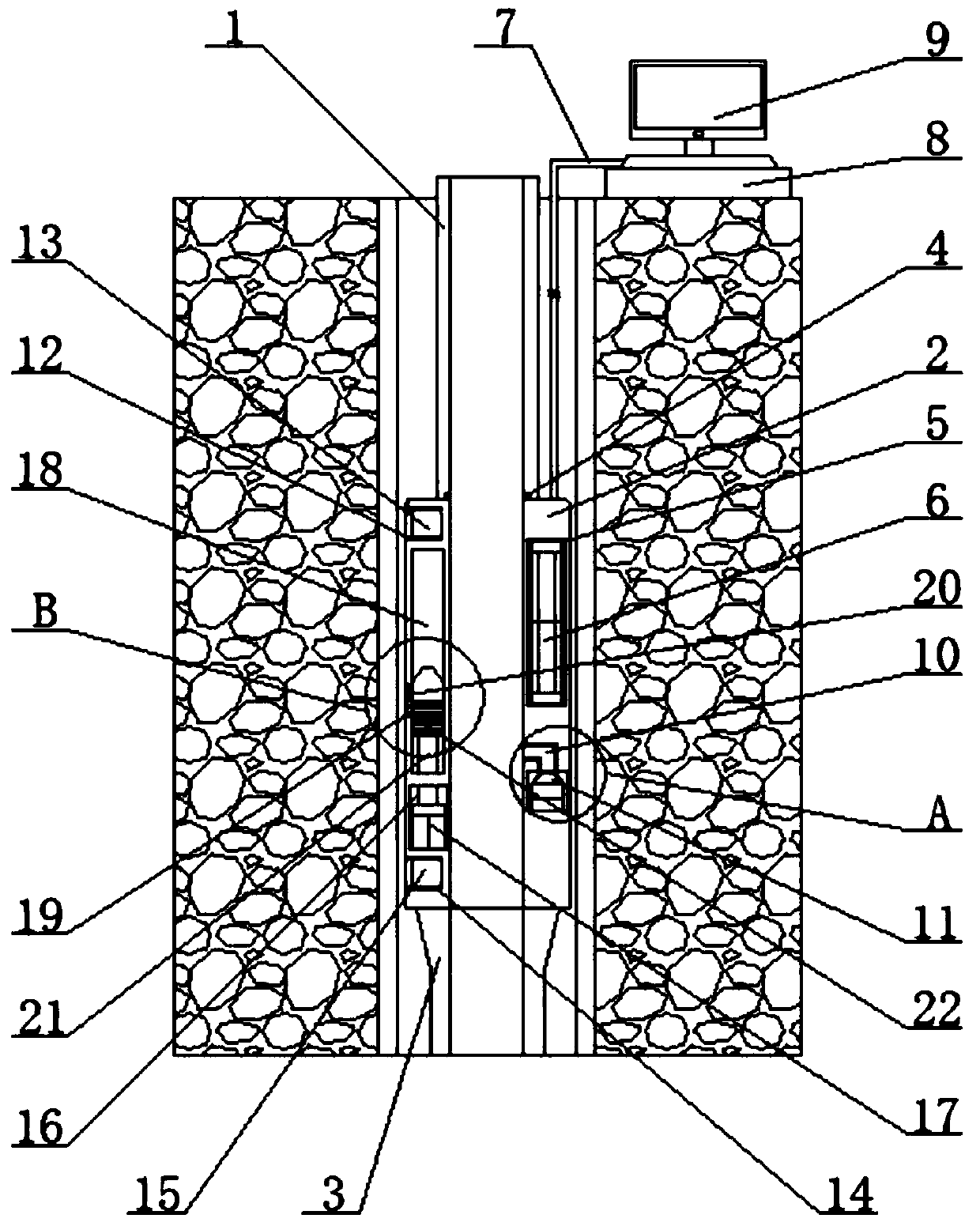

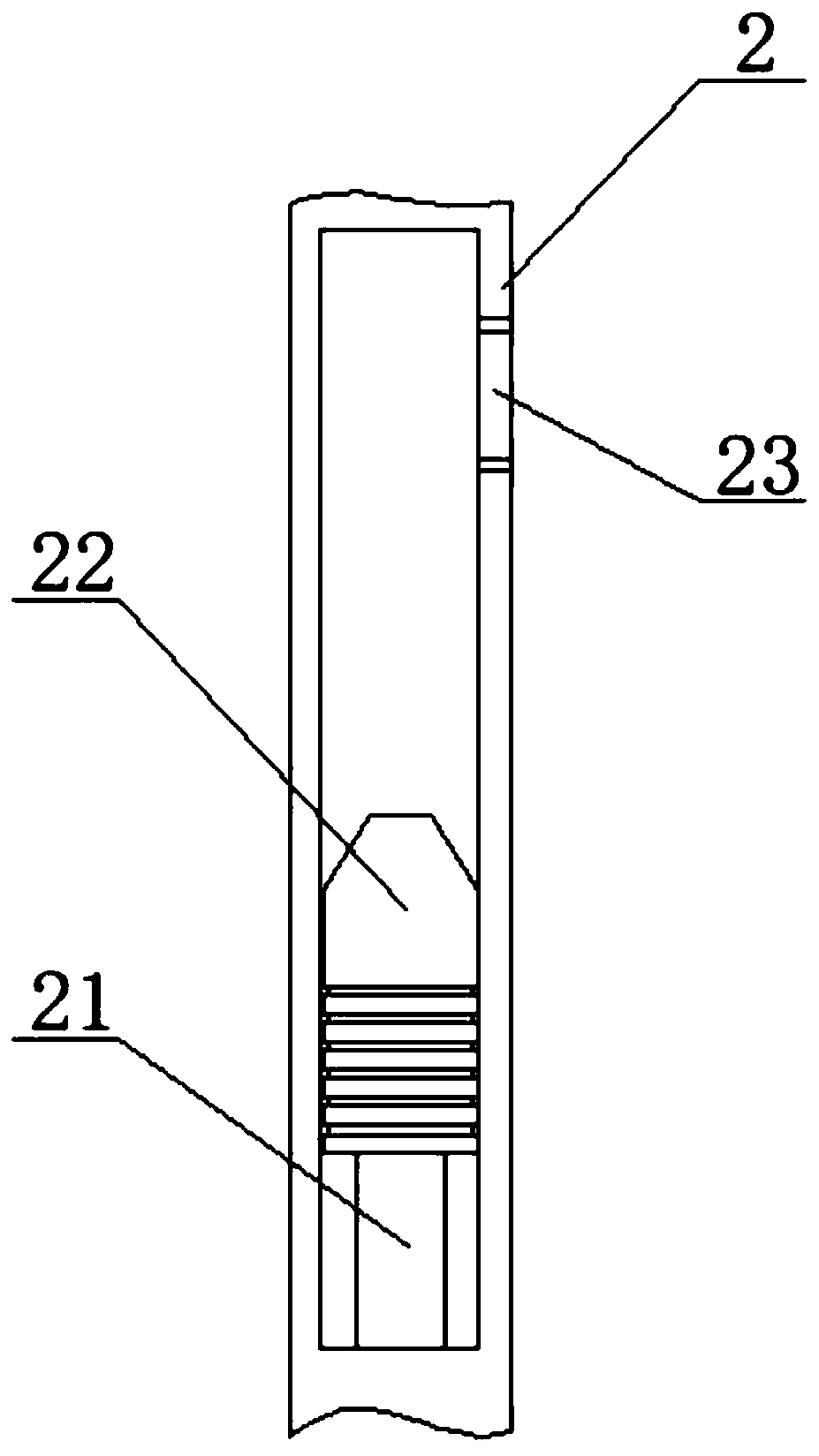

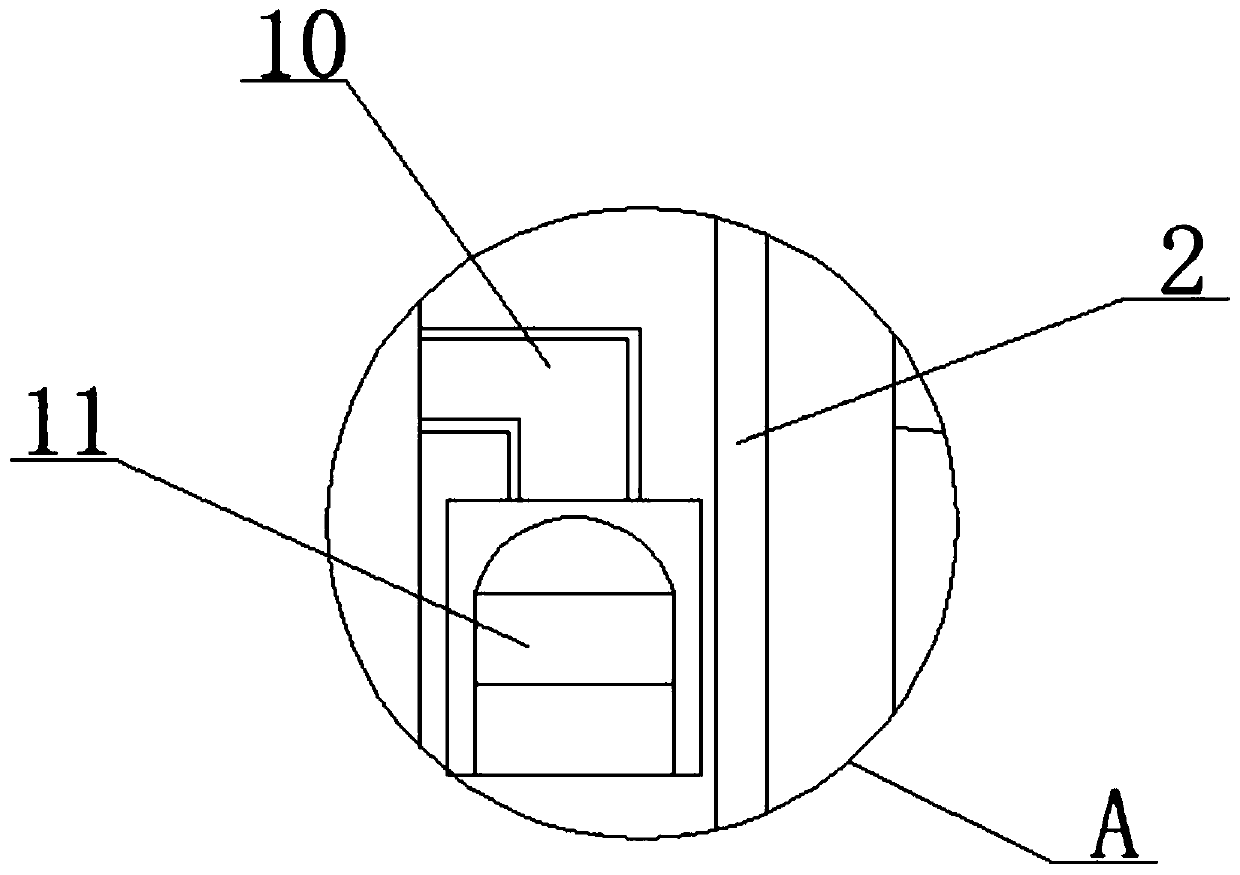

A bridge concentric constant pressure intelligent water distributor for water injection wells

ActiveCN110159236BSolve the problem of small oil productionSolve the problem of small oil outputFluid removalHydraulic pumpOil field

The invention relates to the technical field of water distributors, and discloses a bridge type concentric constant-pressure intelligent water distributor used for a water injection well. The distributor comprises an upper joint pipe, a water distributor body is fixedly mounted on the bottom of the upper joint pipe, a lower joint pipe is fixedly mounted on the bottom of the water distributor body,the bottom of an inner cavity of the upper joint pipe is fixedly sleeved with a seal ring, a hollow groove is formed in one side of the water distributor body, a sensor is fixedly mounted in an innercavity of the hollow groove, the top of the sensor is fixedly connected with a cable, one end of the cable penetrates to the top of the water distributor body and extends to the ground, and one end of the cable is fixedly connected with a fixed plate. According to the bridge type concentric constant-pressure intelligent water distributor used for the water injection well, through cooperation of awater injection pressure device, a micro hydraulic pump and a seal plug, water can be better injected into different layers conveniently, the problem that in the water injection process, the injectedwater amount cannot be accurately mastered, and the oilfield exploitation oil pump capacity is small is solved, and the oilfield exploitation oil pump capacity is improved.

Owner:大庆慧博祥石油科技有限公司

Walnut oil press

InactiveCN108215277AReduce consumptionGuaranteed nutritionFatty-oils/fats productionPressesVegetable oilEnergy consumption

The invention relates to the field of vegetable oil extraction equipment, in particular to a walnut oil press. The walnut oil press is mainly composed of a pretreatment mechanism and a pressing mechanism. The pretreatment mechanism is arranged above the pressing mechanism. The pretreatment mechanism is mainly composed of a heating drying oven, a partition layer and a crushing bin. The heating drying oven is arranged over the crushing bin. The partition layer is arranged between the heating drying oven and the crushing bin. Through the walnut oil press, energy consumption can be reduced, the oil yield is large, the oil pressing cost is reduced, the oil pressing purity is improved, and nutrition of walnut oil is guaranteed.

Owner:丹阳市香逸林果专业合作社

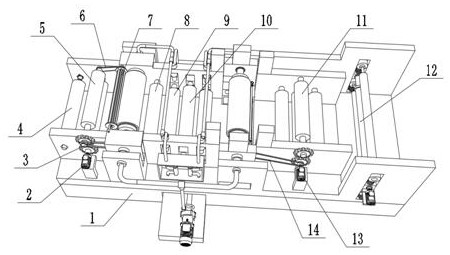

Oil-permeable water-blocking type propping agent and preparation method thereof

InactiveCN106190091AIncrease oil outputImprove diversion capacityFluid removalDrilling compositionPlasticizerThermal insulation

The invention discloses an oil-permeable water-blocking type propping agent and a preparation method thereof. Firstly, a polyurethane curing agent and nano-particles are added into the polyurethane solution, the mixture is subjected to ultrasonic dispersion for 20-40 minutes to obtain a suspension solution with dispersed nano-particles; a silane coupling agent, a thermoplastic resin, a plasticizer, a coloring agent and an amine curing agent are added into the aggregate in turn under the conditions of 110-200 DEG C thermal insulation and stirring, the mixture is stirred for 5-10 min and then a dispersing agent is added, the mixture is continuously stirred until the dispersing agent is uniformly dispersed, discharging, cooling and sieving are performed to obtain a coated propping agent; the coated propping agent is arranged in the suspension solution with dispersed nano-particles, soaked for 30 min, then filtered and dried to obtain the oil-permeable water-blocking type propping agent. The propping agent has good lipophilicity and hydrophobicity, the oil yield of crude oil is increased, the flow guiding capacity of the crude oil is greatly improved, the oil exploitation is facilitated, and the propping agent is very important for improving the yield and grade of crude oil in China.

Owner:XINMI WANLI IND DEV

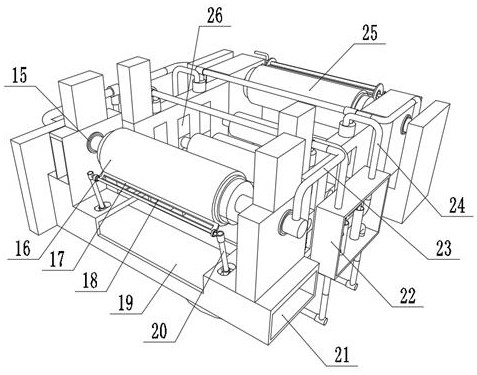

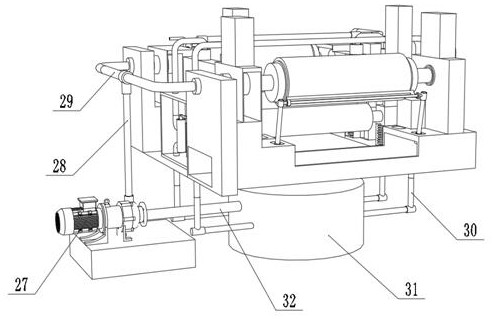

Natural luster finishing device with self-purification function

The invention discloses a natural luster finishing device with a self-purification function, relates to the technical field of natural luster finishing equipment, and aims to solve the problem that the tension degree is not easy to control. The device specifically comprises a shell; a tensioning assembly and a control mechanism are arranged on the inner wall of the shell; the tensioning assembly is composed of two tensioning rollers and an adjusting roller; the control mechanism comprises an oil inlet assembly and an oil outlet assembly; and the oil inlet assembly is composed of two connectingpipes I, four sliding cylinders and four piston rods. By arranging the tensioning assembly composed of the two tensioning rollers and the adjusting roller, high-temperature oil is controlled to entera natural luster finishing roller I and a second natural luster finishing roller II to conduct natural luster finishing on materials, at the moment, the oil can enter the sliding cylinders, and the piston rods are extruded to enable the two tensioning rollers to move downwards, so that the materials are tensioned; and when the materials are excessively tensioned, the materials extrude the adjusting roller downwards, and the oil outlet amount of the oil outlet assembly is increased, so that the piston rods move upwards until balance is achieved, and the tension degree of the materials is adjusted.

Owner:舒城娃娃乐儿童用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com