Pump body of rotary cylinder piston compressor and compressor adopting pump body

A compressor pump and piston technology, applied in the field of compressors, can solve the problems of large oil circulation resistance in the oil tank, and achieve the effects of increasing the oil output, solving the problem of abnormal wear and reducing the oil output resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

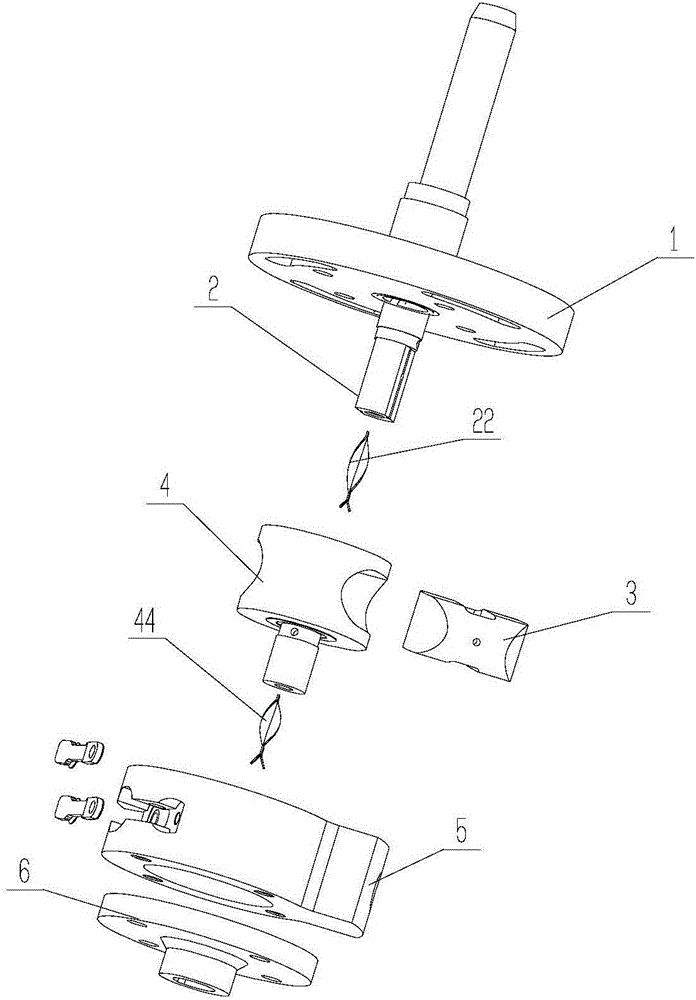

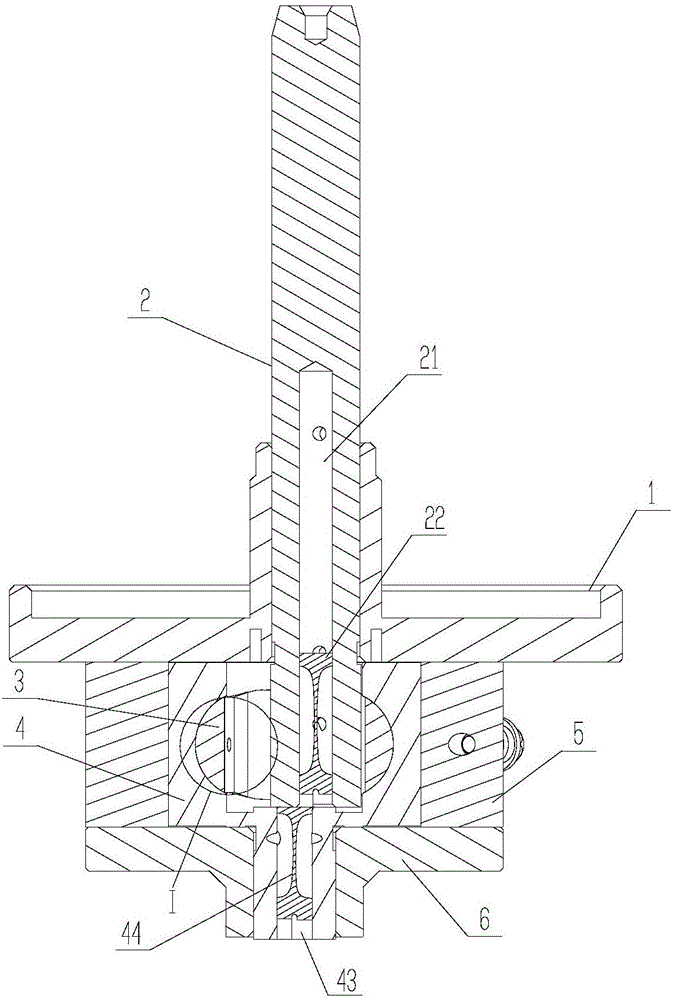

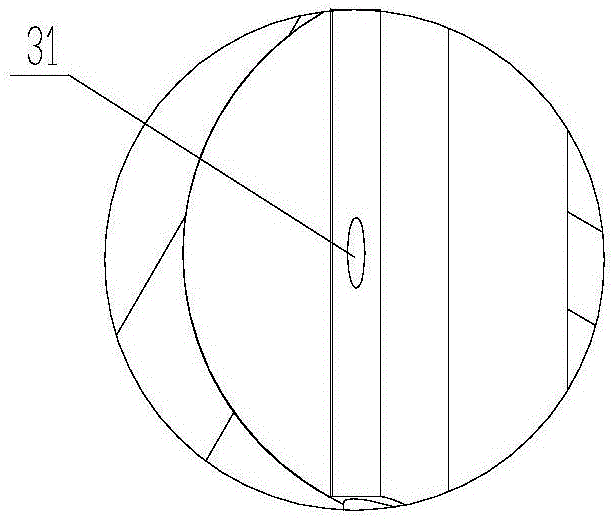

[0038] Such as Figure 1 to Figure 5 As shown, this embodiment provides a rotary cylinder piston compressor pump body, which includes an upper flange 1, a rotating shaft 2, a piston 3, a cylinder 4, a cylinder liner 5 and a lower flange 6, Wherein, the piston 3 is installed in the piston hole 41 of the cylinder 4, the cylinder short axis 42 of the cylinder 4 is installed on the lower flange 6, and the cylinder liner 5 is coaxially installed with the cylinder 4, and the lower flange 6 is fixed on the lower end of the cylinder liner 5, The piston supporting surface of the rotating shaft 2 is installed in cooperation with the piston plane, and the upper flange 1 fixes the upper half of the rotating shaft 2, and the upper flange 1 is fixed on the upper end of the cylinder liner 5 by screws.

[0039] Specifically, the rotating shaft 2 is provided with a rotating shaft hole 21 , and the cylinder 4 is provided with an oil guide passage communicating with the rotating shaft hole 21 . ...

Embodiment approach 2

[0055] Such as Figure 6 to Figure 9 As shown, in this embodiment, another structural form of the oil guide channel is provided, refer to Image 6 , Figure 7 , this oil guide passage is the oil guide pipe 7. Cylinder 4 comprises cylinder stub shaft 42, and this cylinder stub shaft 42 is provided with the through-hole structure 48 that is used for providing the movement space for the movement of oil guide pipe 7, and oil guide pipe 7 is arranged in the through-hole structure 48, and one end of oil guide pipe 7 is installed on On the rotating shaft 2 , the outlet end of the oil guiding pipe 7 is in contact with the rotating shaft hole 21 , and an oil guiding plate 8 is arranged in the oil guiding pipe 7 . The structure of the oil guide sheet is the same as that of the shaft hole oil guide sheet 22 mentioned in one embodiment.

[0056] In order to provide movement space for the oil guide pipe 7 , the inner diameter of the short shaft 42 of the cylinder is larger than that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com