Anti-scorching CR unvulcanized rubber capable of being stored for long time at room temperature, preparation method thereof and preparation method of anti-scorching agent

A long-term storage, unvulcanized technology, applied in the direction of organic chemistry, etc., can solve the problems of ozone resistance, oil resistance, poor fatigue resistance, no formulation and specific process methods, no mention of long-term storage of CR compound rubber, etc., to achieve strong Reduced elongation, excellent scorch safety, and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

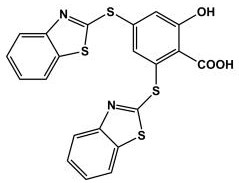

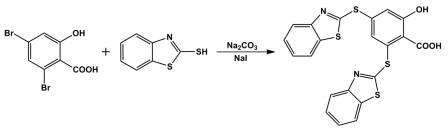

[0035] This example is the production method of the anti-scorch agent. In the reaction vessel, add 2-mercaptobenzothiazole (0.21mol, 35.0 g), 3,5-dibromosalicylic acid (0.10 mol, 29.6 g), carbonic acid Sodium (0.3 mol, 31.8 g), sodium iodide (0.02 mol, 3.0 g) and ethanol solvent (5.0 mol, 288 mol) were reacted at 50-80°C for 24-48 h in a nitrogen atmosphere. After the reaction is finished, the solvent is spin-dried and vacuum-dried to obtain figure 1The shown 3,5-dibenzothiazole salicylic acid is referred to as DPNTS for short, and the reaction formula is as follows figure 2 shown.

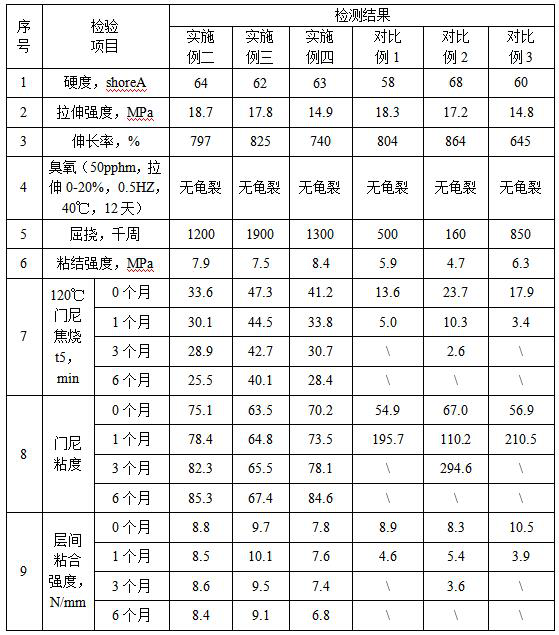

Embodiment 2

[0038] The components and mass parts of the rubber compound are: 100 parts of neoprene rubber, 4 parts of high-activity magnesium oxide, 0.5 parts of stearic acid, 20 parts of carbon black, 30 parts of white carbon black, 1 part of coupling agent, and 15 parts of alkane oil Parts, 2 parts of zinc oxide by indirect method, 3 parts of dimorpholine disulfide, 0.5 parts of insoluble sulfur, 0.5 parts of N-oxydiethylene-2-benzothiazole sulfenamide, 0.6 parts of ethylene thiourea, functional type Anti-scorch agent 3,5-dibenzothiazole salicylic acid 0.2 parts, anti-sticking agent 2 parts.

[0039] The preparation process of the rubber material is as follows: the neoprene rubber is thinly passed on the open mill and then removed, put into the internal mixer or the open mixer, and then put into carbon black, white carbon black, coupling agent, functional anti-scorch agent, anti-scorch agent, etc. Roller sticky agent, after mixing for 12 minutes, discharge the glue, the temperature of t...

Embodiment 3

[0041] The components and mass parts of the rubber are: 75 parts of neoprene rubber, 25 parts of chlorinated polyethylene CM, 5 parts of magnesium oxide, 0.7 parts of stearic acid, 20 parts of calcium carbonate, 30 parts of white carbon black, coupling agent 2.0 parts of Si-69, 15 parts of naphthenic oil, 4 parts of indirect zinc oxide, 0.5 parts of functional anti-scorch agent 3,5-dibenzothiazole salicylic acid, 1,3-trimethylene-2-thiourea 0.3 parts, 2.0 parts of N,N'-m-phenylene bismaleimide, 0.3 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 2 parts of antioxidant 1010.

[0042] The rubber preparation process is as follows: according to the ratio of 5-10 parts to 100 parts of chlorinated polyethylene, add naphthenic oil to chlorinated polyethylene powder and stir evenly, and pass it on the cold roll mill for more than 10 times until the film into uniform translucence, and the next sheet is ready for use; the neoprene raw rubber and the above-mentioned thin-passed film a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com