Variable-quantity and variable-pressure plunger pump

A technology of variable pressure column and plunger pump, which is applied in the field of hydraulic pumps, can solve the problems that the output pressure of the plunger pump cannot be adjusted, and achieve the effects of avoiding improper processing, realizing the conversion of oil circuits, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

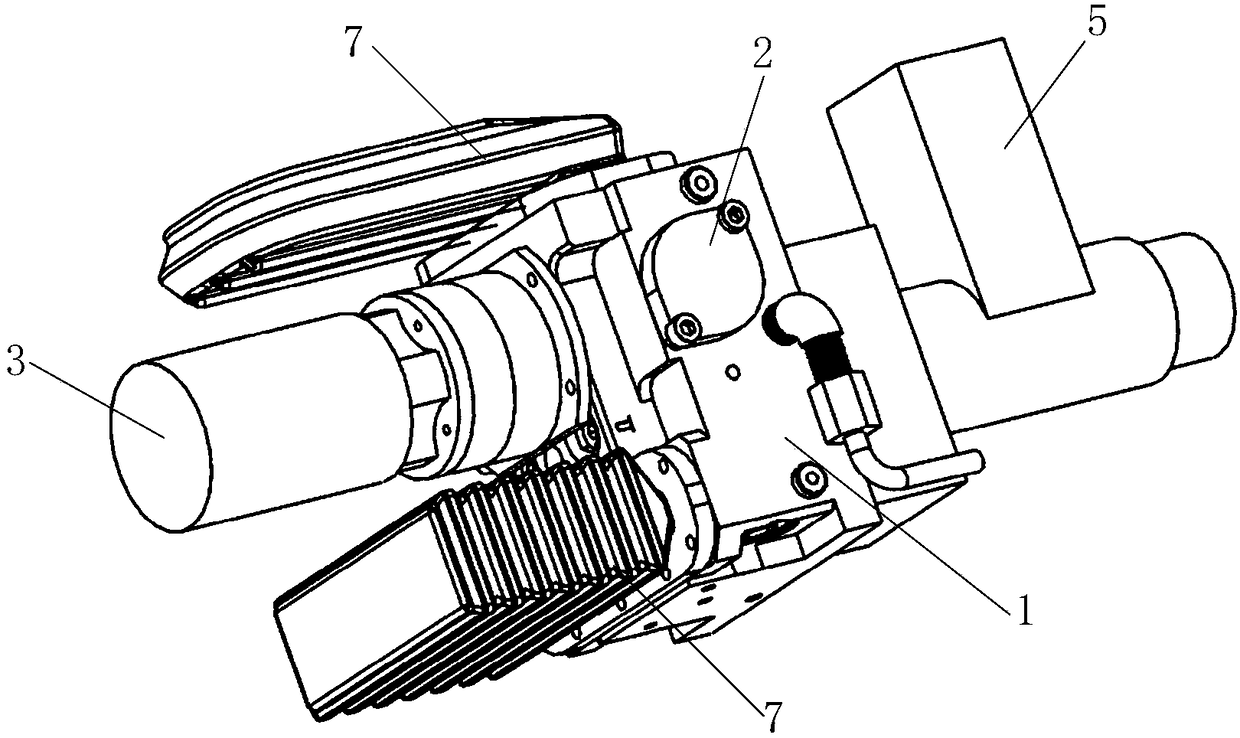

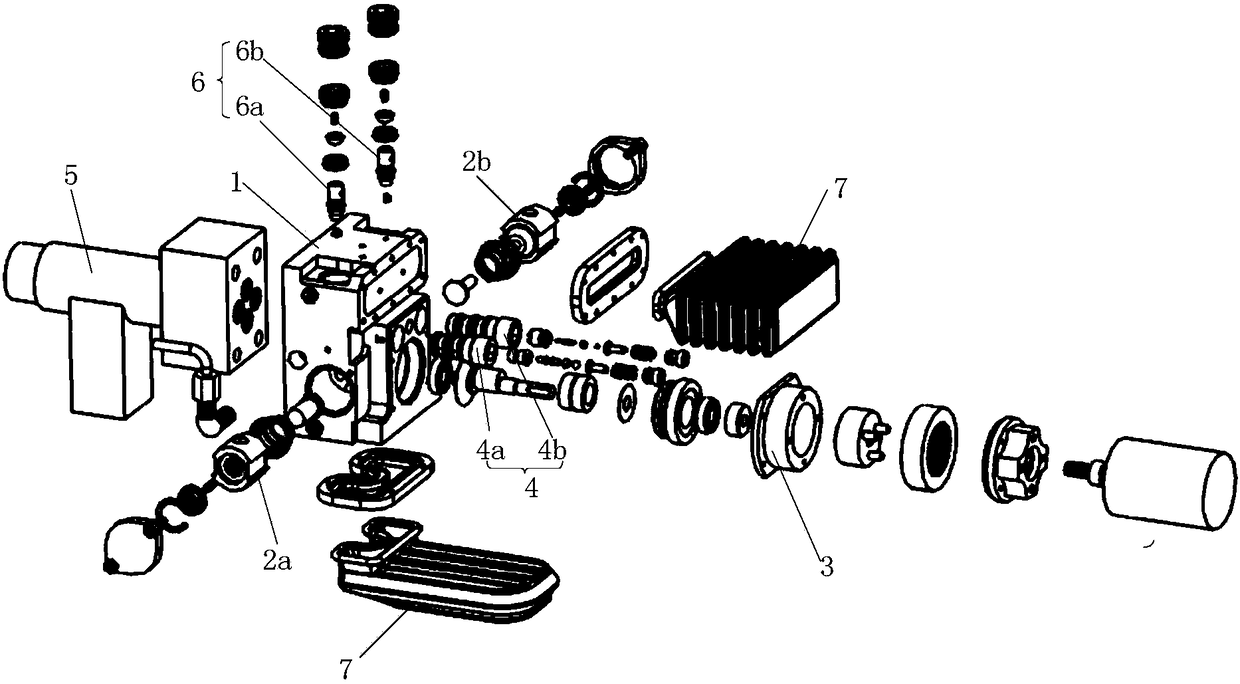

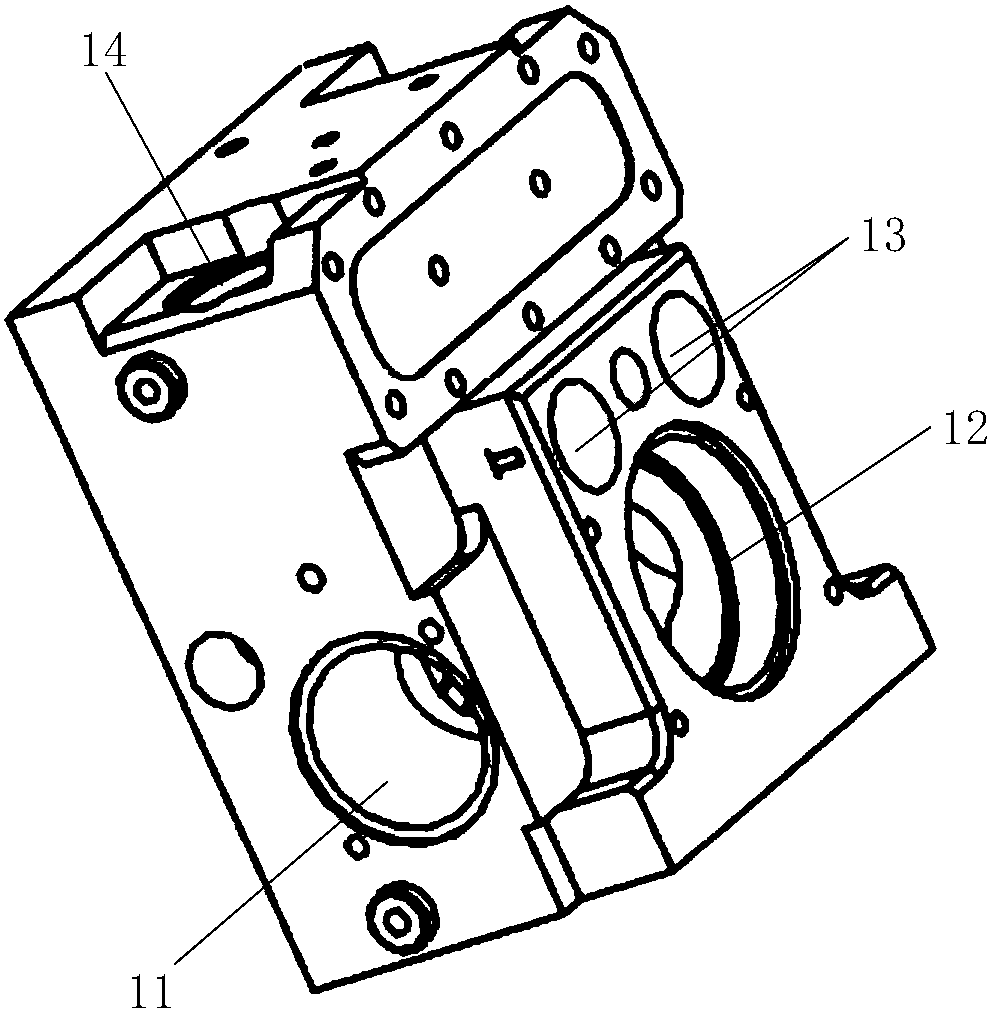

[0034] Such as Figure 1 to Figure 3C As shown, the variable pressure variable plunger pump provided in this embodiment includes a pump body 1 , a plunger assembly 2 , a power assembly 3 , an oil pressure adjustment assembly 4 and an oil pressure output assembly 5 . The plunger assembly 2 is arranged on the pump body 1 . The power assembly 3 is arranged on the pump body 1 and is connected to the plunger assembly 2 to drive the plunger assembly 2 to pump out the oil entering the pump body 1 . The oil pressure adjustment assembly 4 is installed in the pump body 1. The oil pumped by the plunger assembly 2 is output after passing through the oil pressure adjustment assembly 4. When the oil pressure exceeds the set value, the oil pressure adjustment assembly 4 releases the pressure , reduce the output oil pressure. The oil pressure output assembly 5 is arranged on the pump body 1 and communicates with the oil pressure adjustment assembly 4, the oil return passage on the pump body...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1 and its variations, the difference is that in this embodiment the oil pressure output assembly is a two-position four-way electromagnetic control directional valve, which is in the two-position three-way electromagnetic control directional valve of the first embodiment. An additional valve 58 is added on the basis, and there are two steel balls 56a, 56b in the main valve body 51 of the solenoid valve.

[0054] The additional valve 58 includes a piston 581, an additional valve spool 582 and an additional valve seat 583. The piston 581 is connected to the additional valve spool 582. The additional valve seat 583 is provided with a second oil inlet and outlet port B, and the pressure oil port P is connected to the additional valve seat 583. The oil inlets of the valve 48 are connected, the oil return port T is connected to the cavity in the valve seat of the additional valve, the first oil inlet and outlet A is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com