Sucker-rod pump oil extraction system for oil well

An oil production system and rod pump technology, which is used in the production of fluids, earth-moving drilling, wellbore/well components, etc., can solve the problems of small inner diameter of hollow rod, low tensile strength, and small internal flow, and prolong the service life. , The effect of improving oil production efficiency and increasing oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

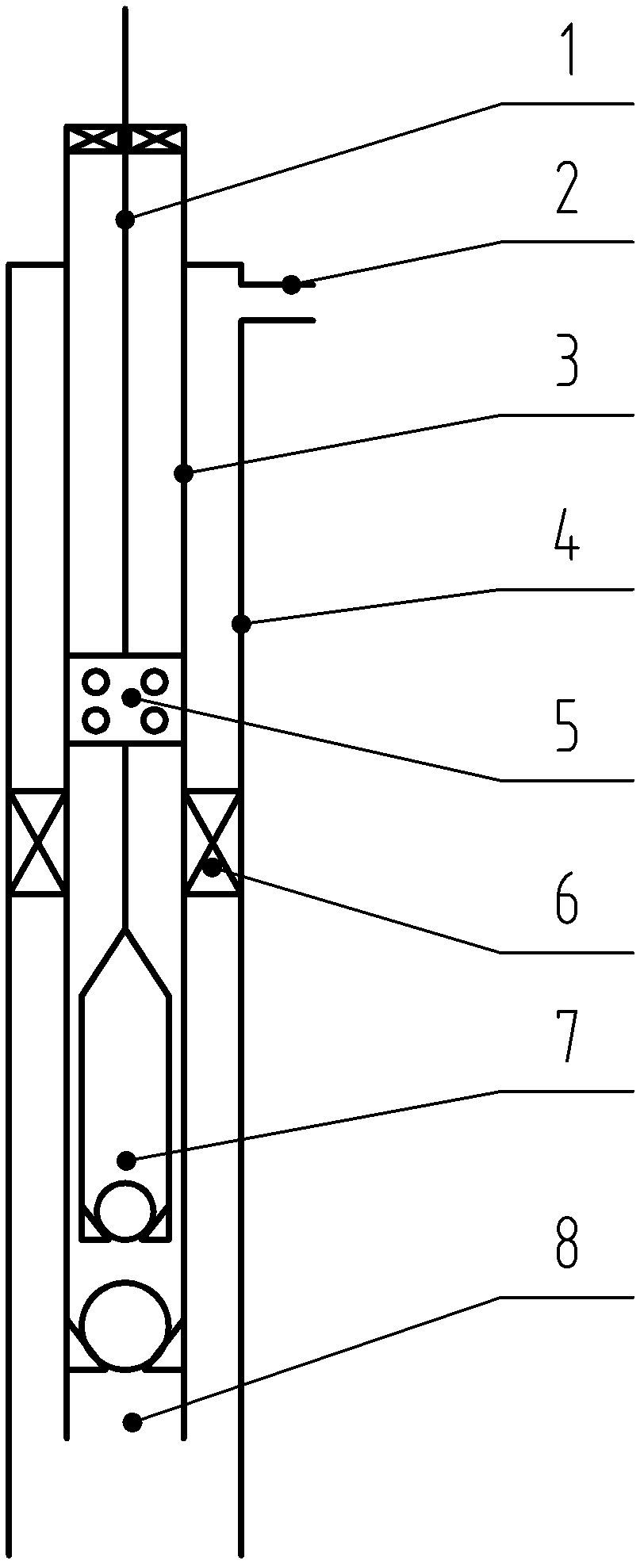

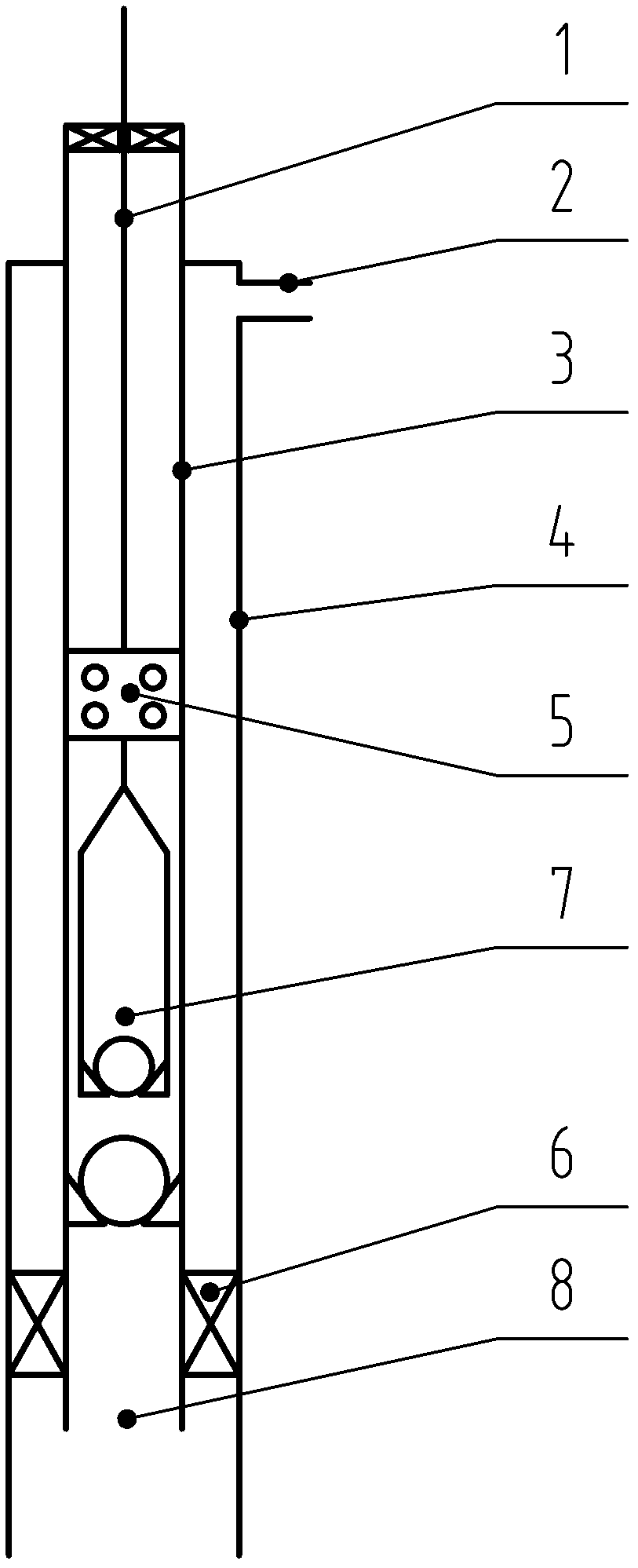

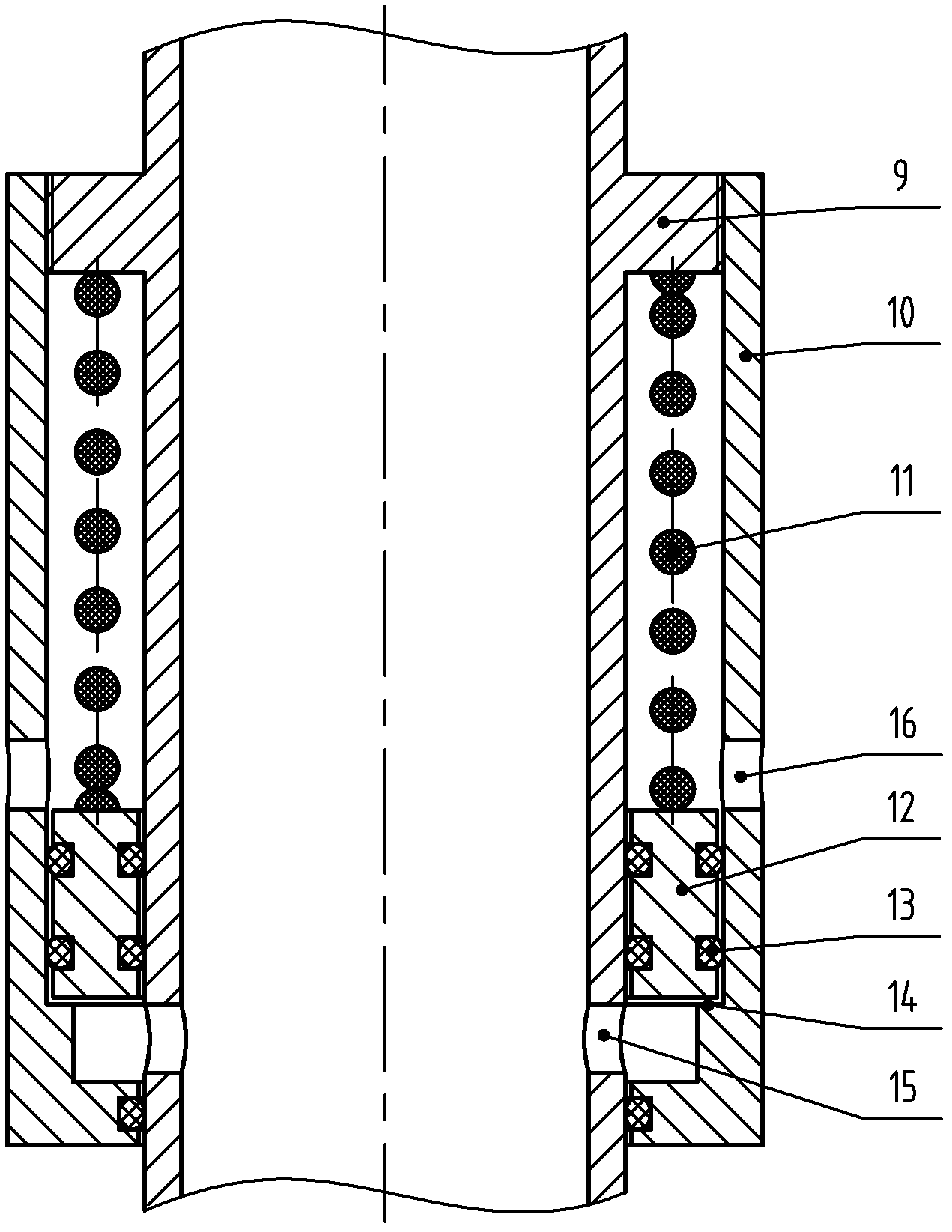

[0017] The first example is figure 1 , 3 As shown, it includes a casing 4 and an oil pipe 3 installed in the casing. A rod oil pump is installed in the oil pipe. The rod oil pump includes 7 oil well pumps and a sucker rod 1 connected to the oil well pump. A packer 6 is installed above the oil well pump in the oil jacket annulus between the casing and the oil jacket annulus to separate the upper and lower parts of the oil sheath annulus. A hydraulic communication valve 5 is connected to the oil pipe corresponding to the oil well pump and the packer. The hydraulic communication valve described above includes a central pipe seat 9, the inner hole diameter of the central pipe seat is the same as that of the oil pipe, the two ends of the central pipe seat are provided with threads, and the upper end is connected with the oil pipe through the threaded joint, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com