Combined evaporator and condenser and control method thereof

A control method and evaporator technology, which are applied in indirect heat exchangers, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of low heat exchange efficiency, surface scaling, and unsatisfactory heat exchange efficiency. Improve the evaporation rate, increase the liquid impact force, and enhance the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

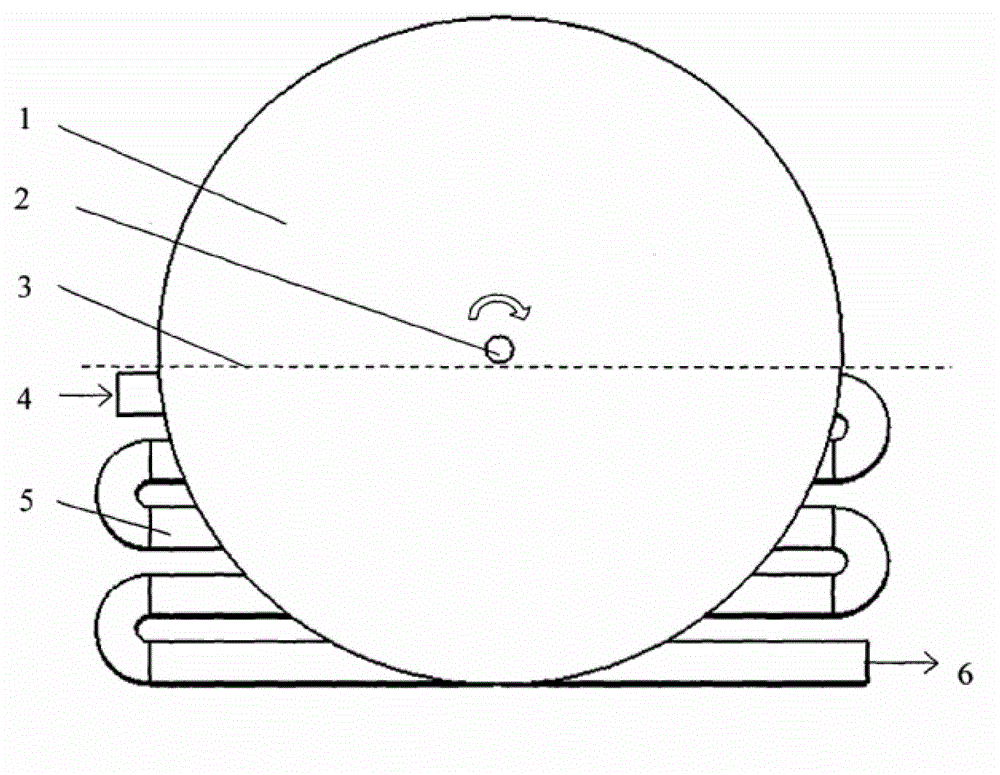

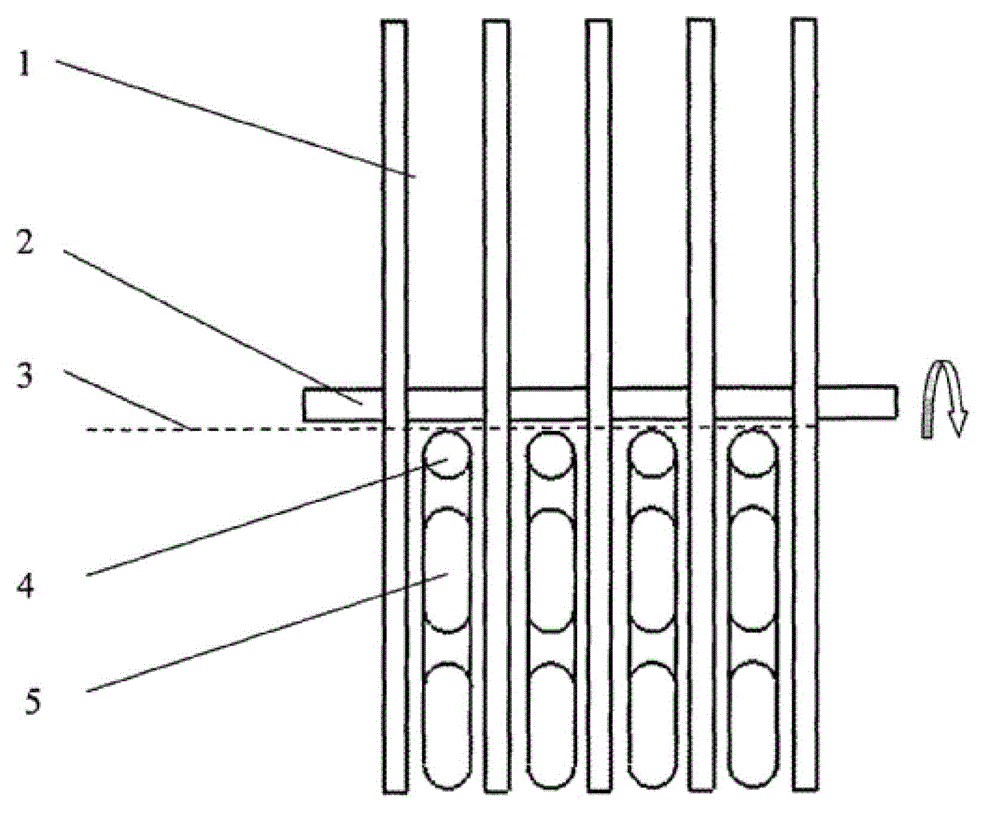

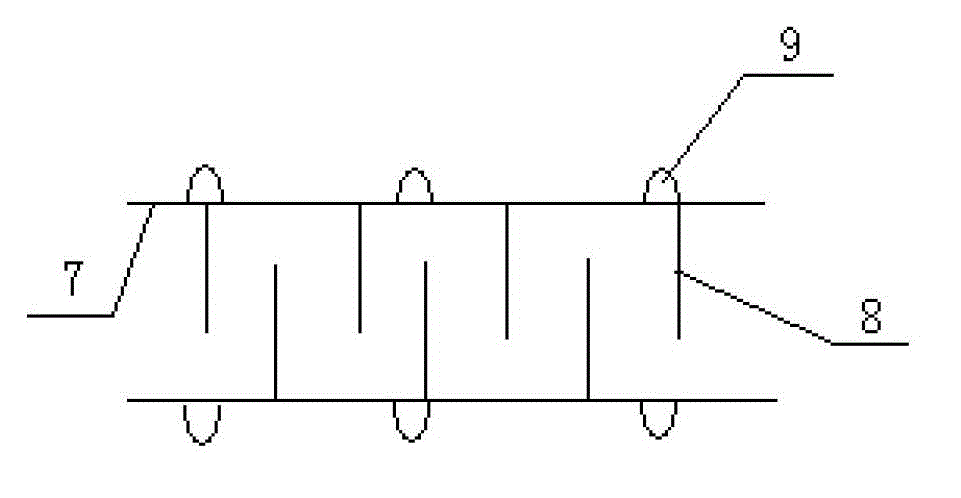

[0035] like Figure 1~Figure 3 Shown: A combined evaporator and condenser, including a rotating disk evaporator 1 and a tube bundle condenser 5, which are composed of a plurality of rotating disks arranged in parallel and spaced to play an evaporation role driven by a rotating shaft 2 . The tube bundle 7 of the tube bundle condenser 5 is arranged in a detour in the interval of the rotating disk, and along the outer surface of the tube bundle 7, a plurality of annular protrusions 9 are arranged side by side. The contact surface between the outer surface of the annular protrusion 9 and the tube bundle 7 transitions smoothly. The distance between the rotating disk and the annular projection 9 is between 1 mm and 10 mm, and in this embodiment, it is selected as 2 mm. The inner wall of the tube bundle 7 is provided with baffles 8 spaced up and down.

[0036] During installation and use, the liquid level 3 of the evaporating liquid is located at the lower half of the rotating disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com