Cooling evaporating treatment method and cooling evaporating treatment apparatus of high boiling point liquid

A treatment method and boiling point technology, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of large biochemical treatment volume, high investment cost, large floor space, etc., and shorten the treatment time. process, reduce investment costs, reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of the content of the patent of the present invention, the implementation process of the patent of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

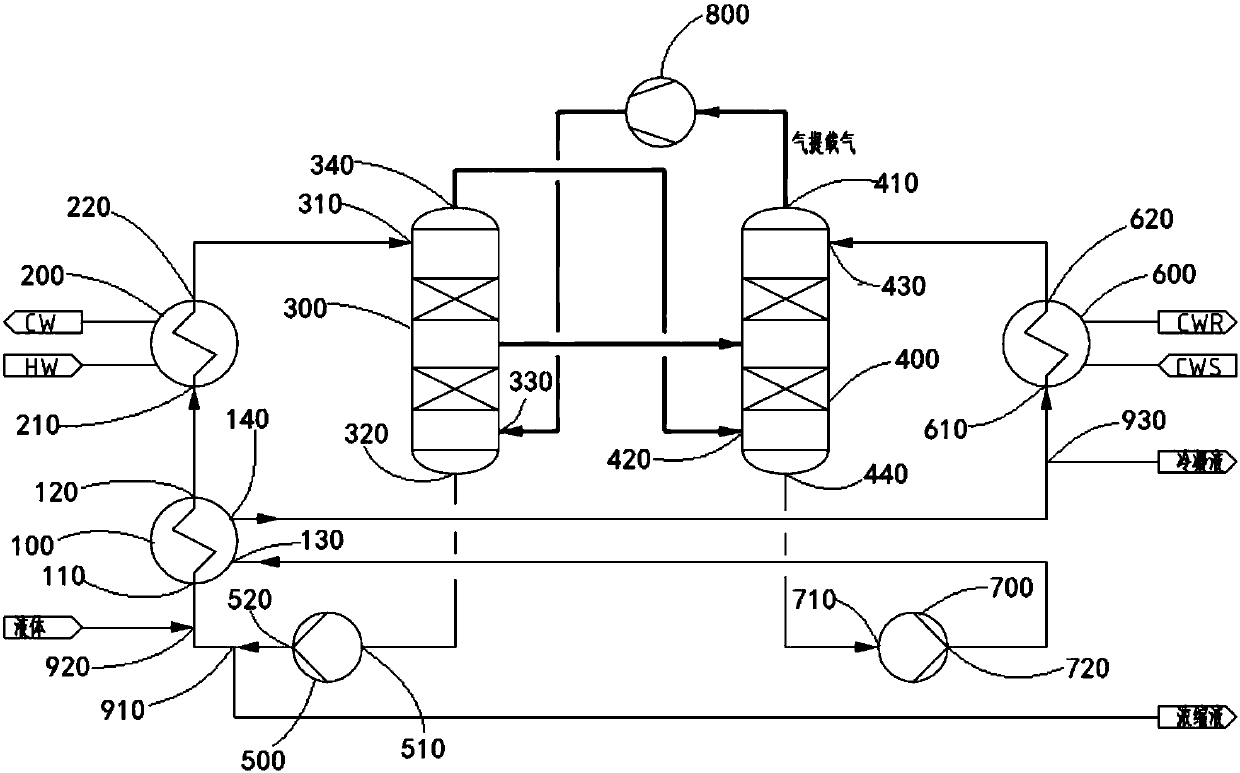

[0027] see figure 1 , the figure shows a device for treating industrial sewage containing salt and COD by a cooling and evaporating treatment method of a higher boiling point liquid of the present invention.

[0028] The device includes a higher boiling point liquid low temperature heat heating unit, an evaporation saturation unit, a cooling and dehumidification unit, a concentrated liquid circulation unit, a condensate liquid circulation unit and a stripping medium circulation unit, wherein the relatively high boiling point liquid low temperature heat heating unit includes a heat exchanger 100 And the heater 200, the evaporation saturation unit is a saturation tower 300, the cooling and dehumidification un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com