Method for recycling waste product and by-product in sulfuric acid method titanium dioxide production

A technology of titanium dioxide and sulfuric acid method, applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of long process flow of impurity removal and preparation, loss of product advantages, high operating costs, etc., to achieve high production and maintenance costs, reduce investment and The effect of reducing production operation cost and production maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

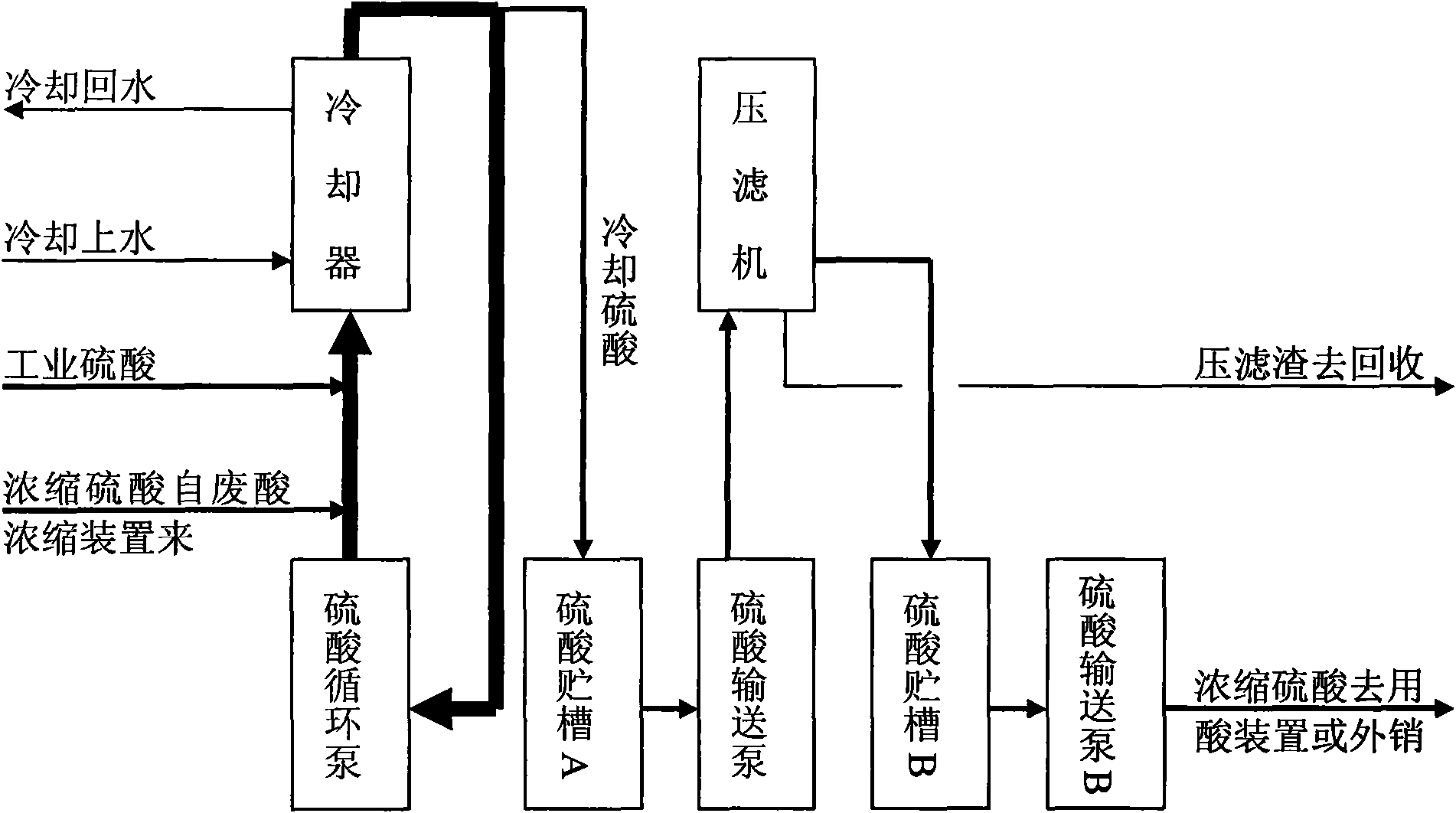

[0023] Firstly, the uncooled and impurity-removed 30% concentrated sulfuric acid and 98% industrial sulfuric acid from the waste acid concentrator are sent to the pipeline of the forced circulation system together, and the large flow and low temperature sulfuric acid in the circulation pipeline Mixing, the concentration of the mixed sulfuric acid is controlled at 55%, the mixed sulfuric acid is removed by the cooling water through the cooler, so that the temperature of the circulating acid is maintained at 60 ° C, and a part of the ferrous sulfate monohydrate is precipitated while mixing and cooling. The main solid crystals. The cooled sulfuric acid automatically discharges part of the sulfuric acid into the sulfuric acid storage tank A under the pressure of the circulation pipeline.

[0024] Next, the sulfuric acid delivery pump A outputs the cooled sulfuric acid containing solid crystals from the sulfuric acid storage tank A and sends it to the filter press for filtration, a...

Embodiment 2

[0028] First, the uncooled and impurity-removed 55% concentrated sulfuric acid and 98% industrial sulfuric acid from the waste acid concentrator are sent into the pipeline of the forced circulation loop together, and the large flow, low temperature sulfuric acid in the circulation pipeline Mixing, the concentration of sulfuric acid after mixing is controlled at 91%. The sulfuric acid after mixing is removed by cooling water through the cooler, so that the temperature of the circulating acid is maintained at 55 ° C. While mixing and cooling, a part of ferrous sulfate monohydrate is precipitated. The main solid crystals. The cooled sulfuric acid automatically discharges part of the sulfuric acid into the sulfuric acid storage tank A under the pressure of the circulation pipeline.

[0029] Next, the sulfuric acid delivery pump A outputs the cooled sulfuric acid containing solid crystals from the sulfuric acid storage tank A and sends it to the filter press for filtration, and the...

Embodiment 3

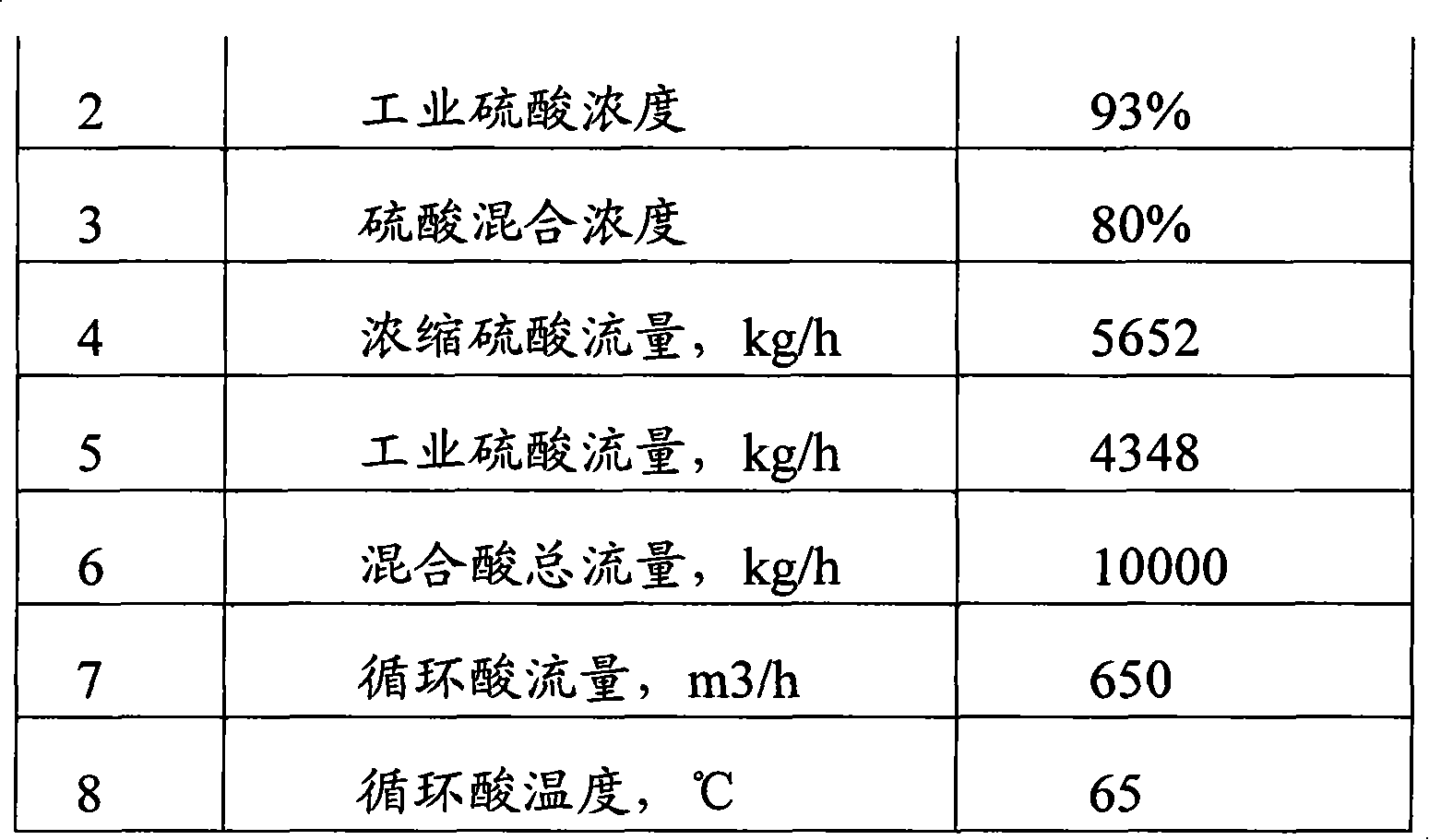

[0033] Firstly, the uncooled and impurity-removed 70% concentrated sulfuric acid and 93% industrial sulfuric acid from the waste acid concentrator are sent into the pipeline of the forced circulation system together, and the large-flow, low-temperature sulfuric acid in the circulation pipeline Mixing, the concentration of the mixed sulfuric acid is controlled at 80%, the mixed sulfuric acid is removed by the cooling water through the cooler, so that the temperature of the circulating acid is maintained at 65 ° C, and a part of the ferrous sulfate monohydrate is precipitated while mixing and cooling. The main solid crystals. The cooled sulfuric acid automatically discharges part of the sulfuric acid into the sulfuric acid storage tank A under the pressure of the circulation pipeline.

[0034] Next, the sulfuric acid delivery pump A outputs the cooled sulfuric acid containing solid crystals from the sulfuric acid storage tank A and sends it to the filter press for filtration, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com