Chemical composite driving antiscaling soft plunger oil pump

A compound flooding and oil pumping technology, applied in the direction of pumps, pump components, variable displacement pump components, etc., can solve the problems affecting the development effect of chemical compound flooding, etc., to prolong the pump inspection period, improve the adaptability, and slow down the scaling speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

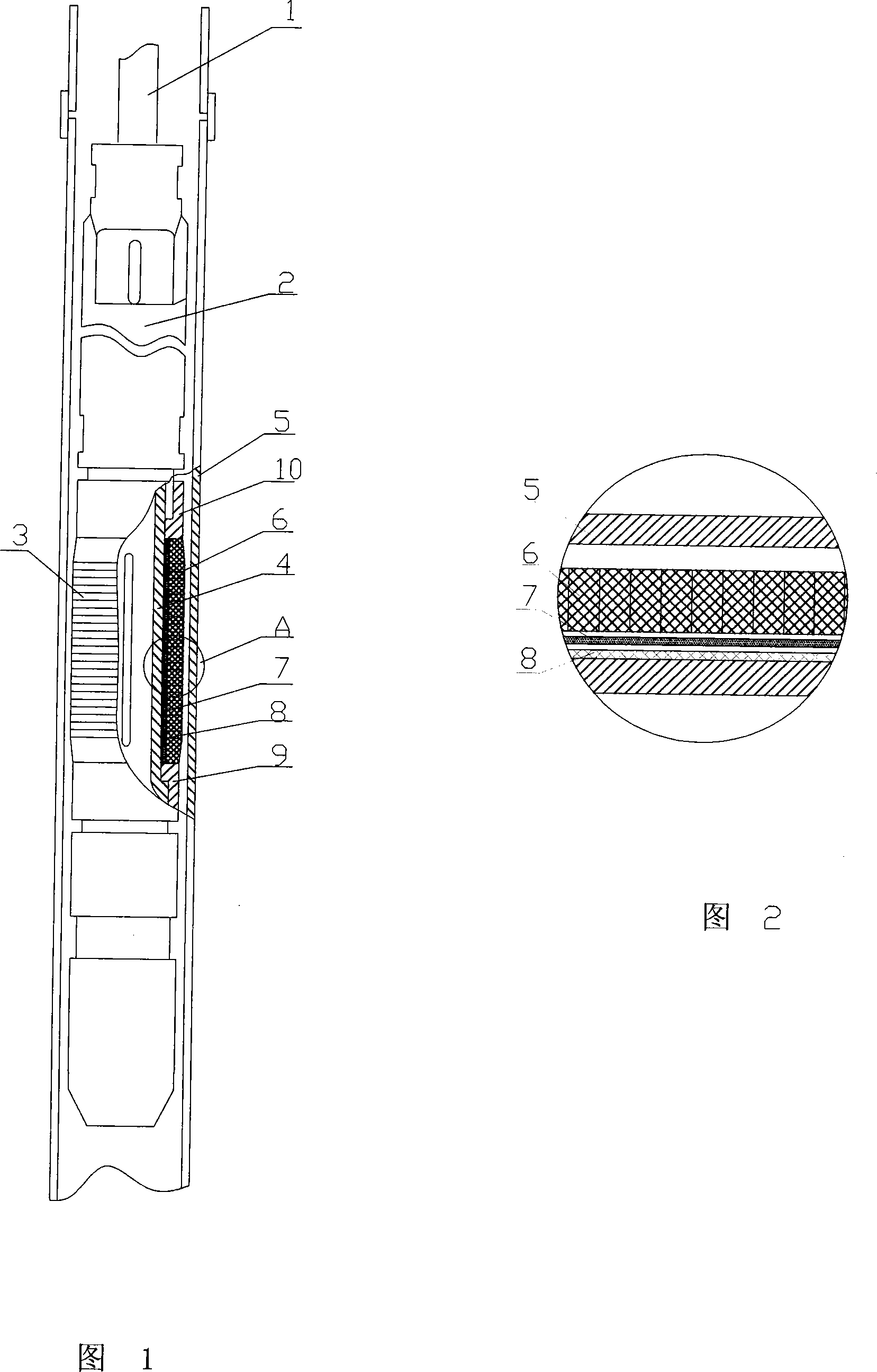

[0010] The present invention will be further described below in conjunction with the embodiments: the chemical compound flooding and anti-scaling soft plunger oil well pump includes a pump barrel 5 and a plunger body 3, the plunger body 3 has a built-in center bracket 4, and the center bracket 4 with a long hole The inner layer 8 of the plunger body bushing, the outer layer 7 of the plunger body bushing and the sealing ring 6 are sequentially set on the outside. The sealing ring 6 is made of high hardness and wear-resistant carbon fiber nylon material, and the inner layer 7 of the plunger body bushing and the plunger The outer layer 8 of the body bushing is made of rubber material, and the plunger body 3 adopts the above-mentioned soft plunger design. Its function is to lift the liquid by relying on the pressure of the liquid column to expand and seal the pump barrel during the upstroke of the plunger body 3, and to lift the liquid during the downstroke. The shrinkage of the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com