Plant oil-based drilling fluid and preparation method thereof

An oil-based drilling fluid and vegetable oil technology, applied in the field of petroleum exploration, can solve the problems of high cost of oily drilling cuttings, low toxicity of gas-to-oil drilling fluid, and direct discharge of drilling cuttings, etc., and achieve good water resistance and emulsion stability Good, high temperature and high pressure low filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

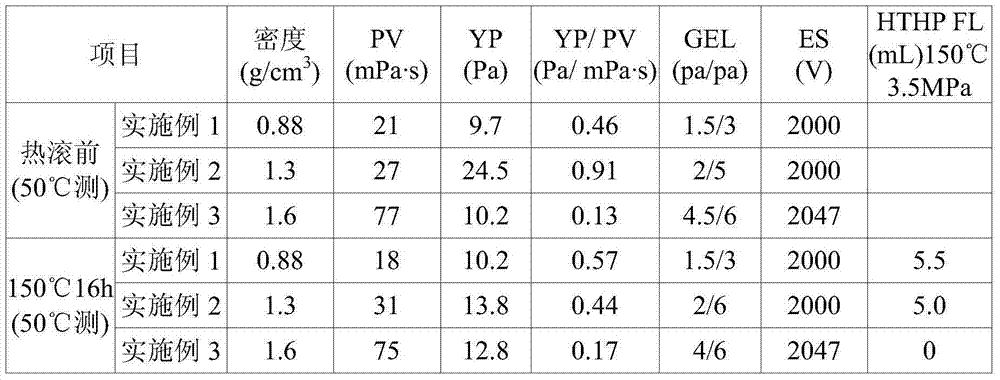

Embodiment 1

[0026] The present embodiment provides a kind of vegetable oil oil base drilling fluid, and this vegetable oil oil base drilling fluid comprises vegetable oil, salt solution, emulsifier, wetting agent, organic soil, fluid loss reducer; The volume ratio of vegetable oil and salt solution is 95: 5. Based on 100mL vegetable oil+salt solution: the content of emulsifier is 3.5g, the content of wetting agent is 0.5g, the content of organic soil is 2g, and the content of fluid loss control agent is 3g, of which:

[0027] Described vegetable oil is soybean oil, and salt solution is the calcium chloride solution of 20wt%;

[0028] The emulsifier is Span-80;

[0029] Described wetting agent is alkanol amide, and its general formula is RCON (CH 2 CH 2 Oh) 2 , where R=C 12 alkyl;

[0030] The organic soil is lipophilic clay, which is dispersed, purified and modified by montmorillonite, and the metal ions between the layers of montmorillonite are replaced with hexadecyltrimethylammoni...

Embodiment 2

[0036] This embodiment provides a vegetable oil-based drilling fluid, which comprises vegetable oil, salt solution, emulsifier, wetting agent, organic soil, fluid loss reducer, weighting agent; the volume ratio of vegetable oil to salt solution 95:5; based on 100mL vegetable oil+salt solution: the content of emulsifier is 3g, the content of wetting agent is 0.8g, the content of organic soil is 2g, and the content of fluid loss control agent is 3g, of which:

[0037] Described vegetable oil is rapeseed oil, and salt solution is the potassium formate solution of 20wt%;

[0038] Described emulsifier is calcium oleate;

[0039] The wetting agent is C 12 h 25 O(CH 2 CH 2 O) nH, n=8;

[0040]The organic soil is lipophilic clay, which is dispersed, purified and modified by montmorillonite, and the metal ions between the layers of montmorillonite are replaced with hexadecyltrimethylammonium chloride, so that the layer The spacing is expanded to 1.7-4.8nm to form a hydrophobic or...

Embodiment 3

[0047] This embodiment provides a vegetable oil-based drilling fluid, which comprises vegetable oil, salt solution, emulsifier, wetting agent, organic soil, fluid loss reducer, weighting agent; the volume ratio of vegetable oil to salt solution 80:20; based on 100mL vegetable oil+salt solution: the content of emulsifier is 3g, the content of wetting agent is 0.5g, the content of organic soil is 2g, and the content of fluid loss control agent is 3g, wherein:

[0048] Described vegetable oil is coconut oil, and salt solution is the sodium formate solution of 20wt%;

[0049] Described emulsifier is alkanol amide, and its general formula is RCON (CH 2 CH 2 Oh) 2 , where R=C 12 alkyl;

[0050] Described wetting agent is alkanol amide, and its general formula is RCON (CH 2 CH 2 Oh) 2 , where R=C 18 alkyl;

[0051] The organic soil is lipophilic clay, which is dispersed, purified and modified by montmorillonite, and the metal ions between the layers of montmorillonite are re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com