Device and process for producing low-salt calcium chloride through alkaline calcium

A technology of calcium chloride and alkaline calcium, which is applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problem of high salt content in calcium chloride products, and achieve continuous operation automation and processing The effect of large quantity and short discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

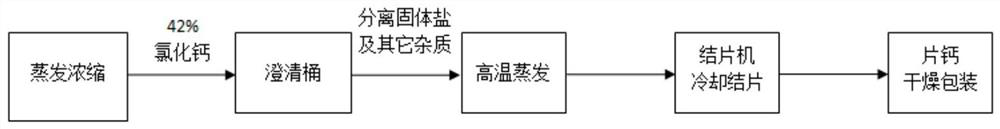

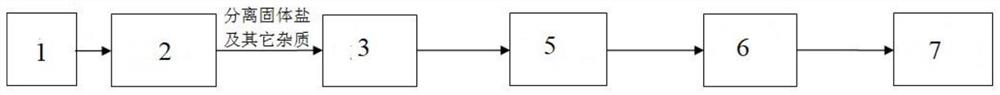

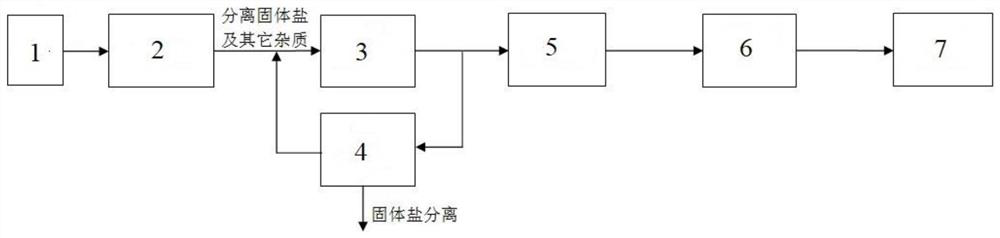

[0044] Such as image 3 As shown, the device for producing low-salt calcium chloride by alkaline method calcium in this embodiment includes: 42wt% calcium liquid evaporation tank 1, clarification tank 2, 56wt% calcium liquid evaporation tank 3, settling centrifuge 4, high temperature evaporation tank 5 , cooling flaking machine 6 and flake calcium dry packaging device 7, wherein, 42wt% calcium liquid evaporating tank 1 is connected to the inlet of clarification tank 2 and 56wt% calcium liquid evaporating tank 3 successively through pipeline, the outlet of 56wt% calcium liquid evaporating tank 3 The pipeline is divided into two routes, one is connected to the decanter centrifuge 4, and the other is connected to the high-temperature evaporator 5, the cooling flaking machine 6 and the flake calcium drying packaging device 7 in sequence, and the outlet pipeline of the decanter centrifuge 4 is connected to the 56wt% calcium liquid evaporator 3 entrance. Among them, the 42wt% calci...

Embodiment 2

[0050] Such as Figure 4 As shown, the present embodiment produces the device of low-salt calcium chloride by alkaline method calcium, comprises: 42wt% calcium liquid evaporating tank 1, clarification tank 2 and 56wt% calcium liquid evaporating tank 3, sedimentation centrifuge 4 connected successively through pipeline , high-temperature evaporating tank 5, cooling flaking machine 6 and flake calcium dry packaging device 7; wherein, 42wt% calcium liquid evaporating tank 1 is a low-temperature three-effect evaporation concentration system, and 56wt% calcium liquid evaporating tank 3 includes a high-temperature two-effect evaporating system The second effect in the calcium system includes adding alkali and neutralizing the steam scrubbing system, and its heating chamber uses the secondary steam of the high-temperature evaporation tank 5 as a heat source. A decanter centrifuge as described above was used.

[0051] The present embodiment produces the technique of low-salt calcium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com