Chromium slag roasting oxidation comprehensive detoxification cleaning process

A chromium residue and roasting technology, applied in chromate/dichromate, climate sustainability, sustainable waste treatment, etc., can solve the problems of low total chromium content and high comprehensive utilization rate in detoxification residues, and improve safety. performance and utilization rate, high comprehensive utilization rate, and the effect of solving the speed and effect of disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

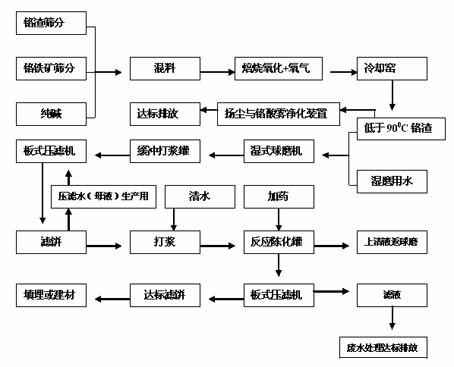

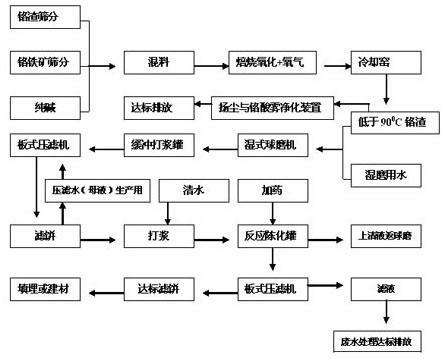

[0033] The chromium slag roasting oxidation comprehensive detoxification cleaning process of the present invention, the main process flow: roasting oxidation + ball mill leaching + plate and frame press filter dehydration + liquid production red alum sodium production + filter cake secondary beating to extract supernatant + acidification solidification + landfill or building materials.

[0034] 1. Chromium slag adopts roasting oxidation comprehensive detoxification cleaning process: main reaction mechanism raw material is chromium slag, chromite and soda ash are auxiliary materials, chromium slag is raw material, and replaces dolomite and limestone as auxiliary materials. 0 C, high temperature and residual trivalent chromium in soda ash and chromium slag are oxidized to hexavalent chromium by high temperature roasting, the conversion rate is more than 80%, and the discharge temperature is 800 0 C, cooled to 90 by cooling kiln 0 Enter the wet ball mill below C, the solid: liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com