Active nano calcium carbonate for food additives and preparation method thereof

A technology of nano-calcium carbonate and food additives, applied in the direction of calcium carbonate/strontium/barium, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of difficult recovery, organic solvent pollution, etc., and achieve good dispersion , good compatibility, and the effect of improving food performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

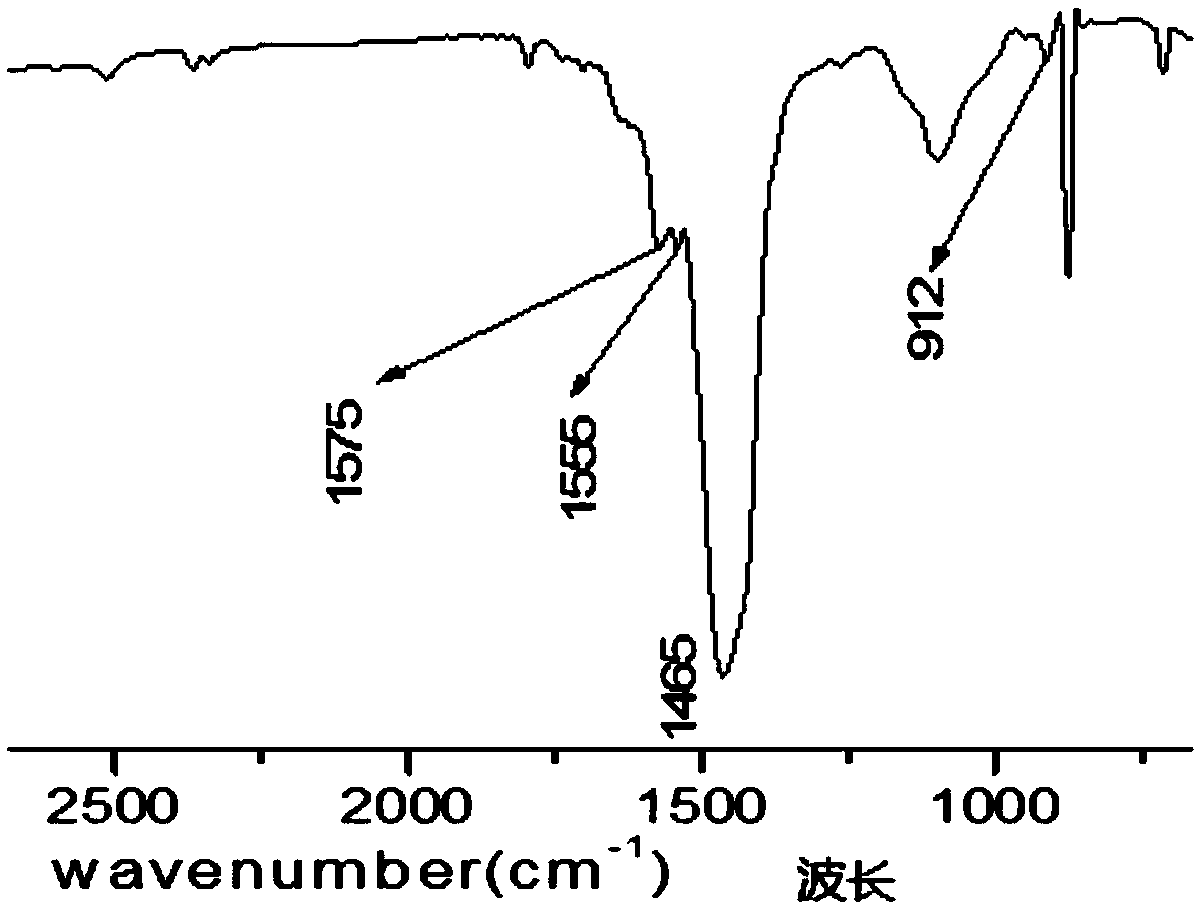

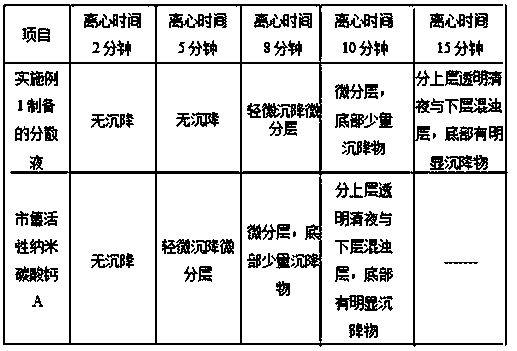

[0020] Accurately weigh 10 parts of undecylenic acid, 2 parts of natural Sophora japonica honey, 8 parts of sodium stearate, 20 parts of ethanol, 18 parts of calcium chloride, and use deionized water to make a calcium chloride aqueous solution with a concentration of 1M and add it with stirring In the reactor of the reflux device, stir at a constant temperature of 30°C to form a transparent solution. Make sodium carbonate into an aqueous solution with a concentration of 1M, in which the molar ratio of calcium ions to carbonate ions is 1:1, slowly add it into the reactor, and stir while adding. After the addition, the system is heated to 55-65°C and stirred Reflux reaction for 20 hours, add the remaining amount of deionized water, stir evenly, cool down and discharge to obtain active nano-calcium carbonate dispersion emulsion, which can be used directly or centrifugally separated, and vacuum-dried to constant weight to obtain active nano-calcium carbonate powder. Put in a desic...

Embodiment 2

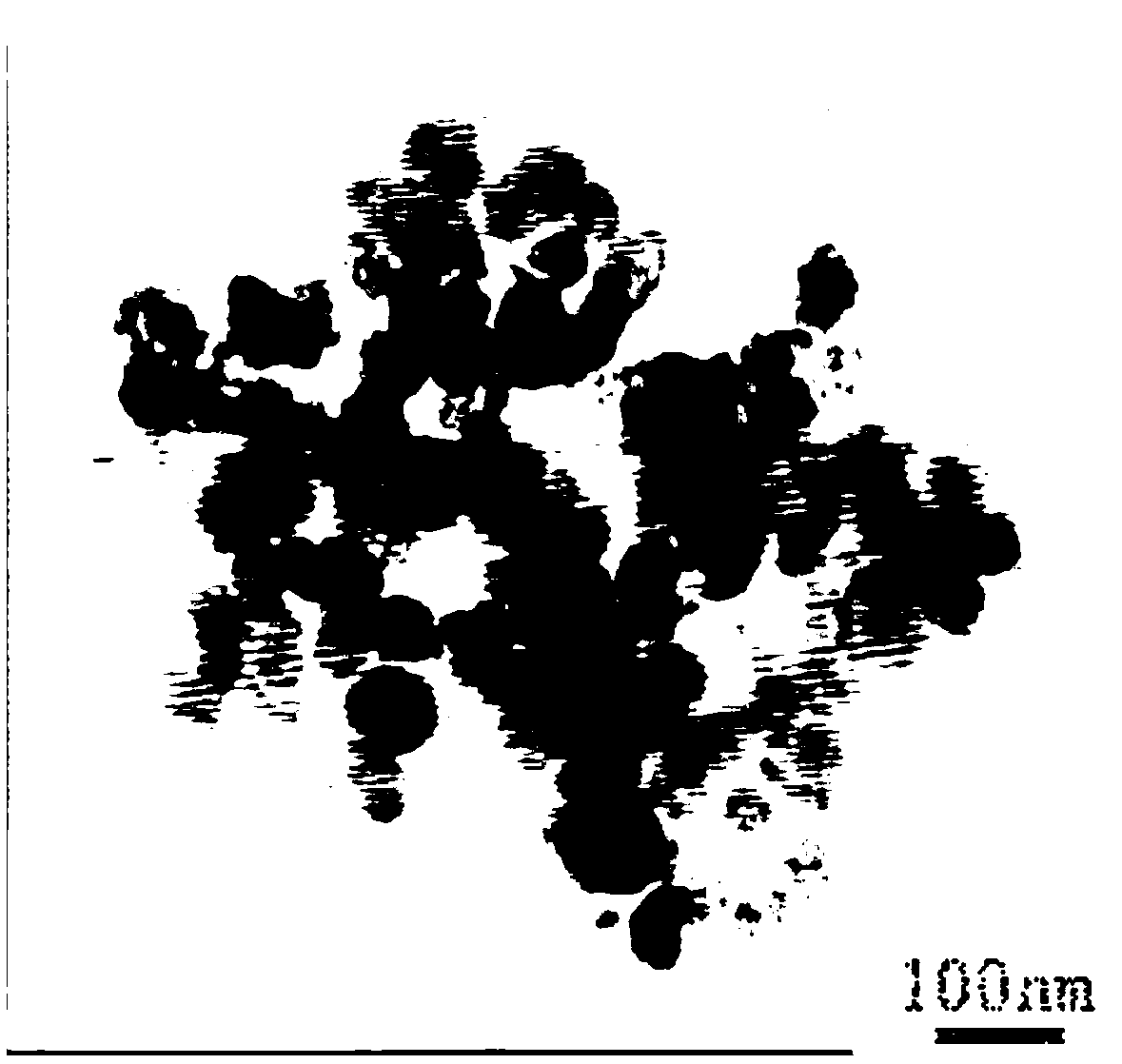

[0022] Accurately weigh 0.15 parts of oleic acid, 0.15 parts of ethanol, and 0.1 parts of calcium chloride to make a calcium chloride aqueous solution with a concentration of 0.5M with deionized water, add it to the reactor with a stirring reflux device, and stir at a constant temperature of 30 ° C to form a transparent solution . Make sodium carbonate into an aqueous solution with a concentration of 0.5M, in which the molar ratio of calcium ions to carbonate ions is 1:1, slowly add it into the reactor, stir while adding, after the addition is complete, the temperature of the system is raised to 25-35°C, Stir and reflux for 35 hours, add the remaining amount of deionized water, and stir evenly to obtain an active nano-calcium carbonate dispersion emulsion, which can be used directly or centrifugally separated, and vacuum-dried to constant weight to obtain an active nano-calcium carbonate powder. spare in the device. Observation by transmission electron microscope shows that t...

Embodiment 3

[0024] Accurately weigh 10 parts of stearic acid, 10 parts of sodium stearate, 2 parts of natural jujube flower honey, 18 parts of ethanol, and 18 parts of calcium chloride. Use deionized water to make a calcium chloride aqueous solution with a concentration of 2M and add it to reflux with stirring. In the device reactor, stir at a constant temperature of 30°C to form a transparent solution. According to the molar ratio of calcium ions to carbonate ions is 1:1, slowly add anhydrous sodium carbonate powder into the reactor, and stir while adding. After the addition is completed, the system is heated to 35-45°C, stirred and refluxed for 45 hours, Add the remaining amount of deionized water and stir evenly to obtain an active nano-calcium carbonate dispersion emulsion, which can be used directly or centrifugally separated, and vacuum-dried to constant weight to obtain an active nano-calcium carbonate powder, which is put into a desiccator for subsequent use. Observation by transm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com