High-concentration continuous and stable polymerization method and system for poly-p-phenylene terephthamide

A technology for poly(p-phenylene terephthalamide) and terephthaloyl chloride, which is applied in the field of polymer synthesis, can solve problems such as polymer volume expansion, achieve stable dissolution time, reduce production cost, and eliminate storage time. different effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

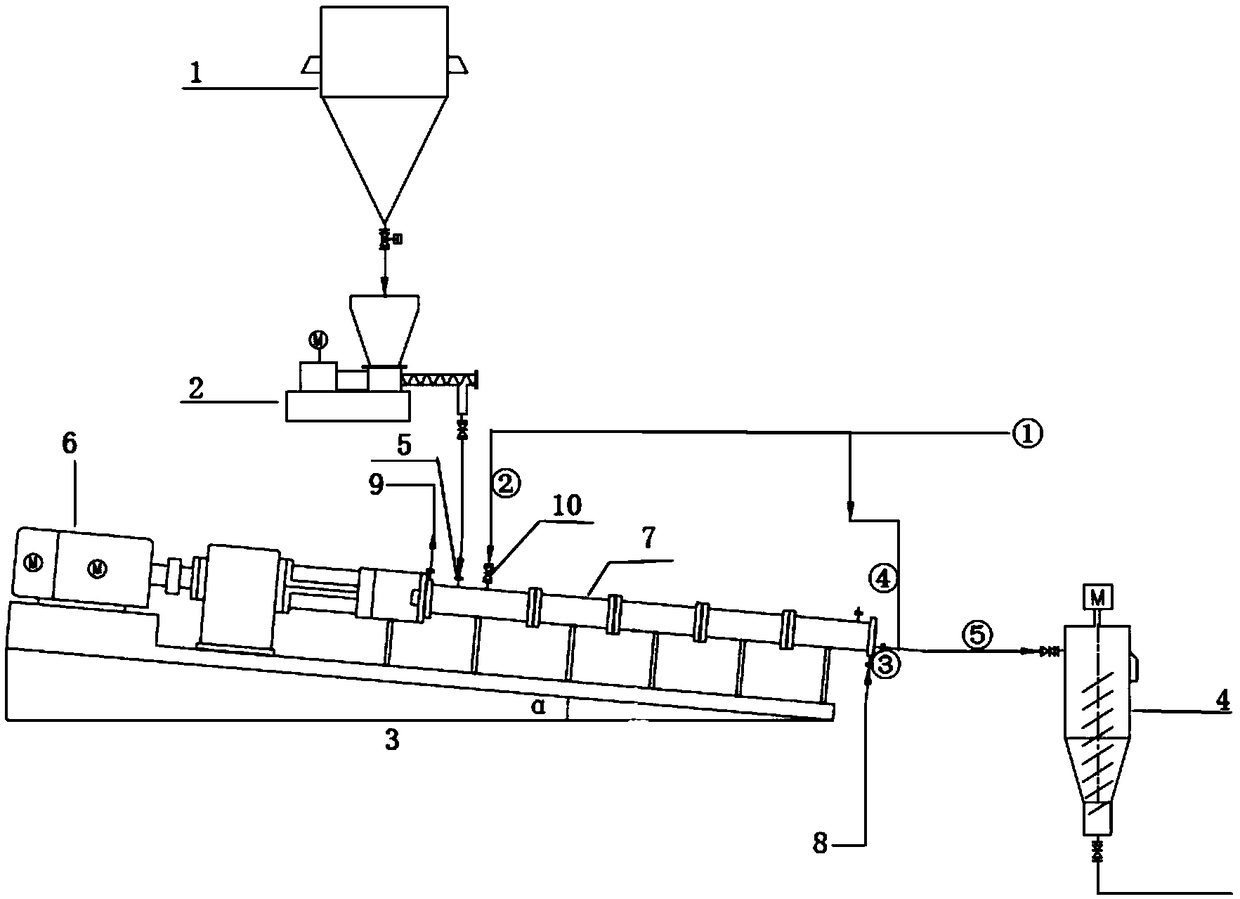

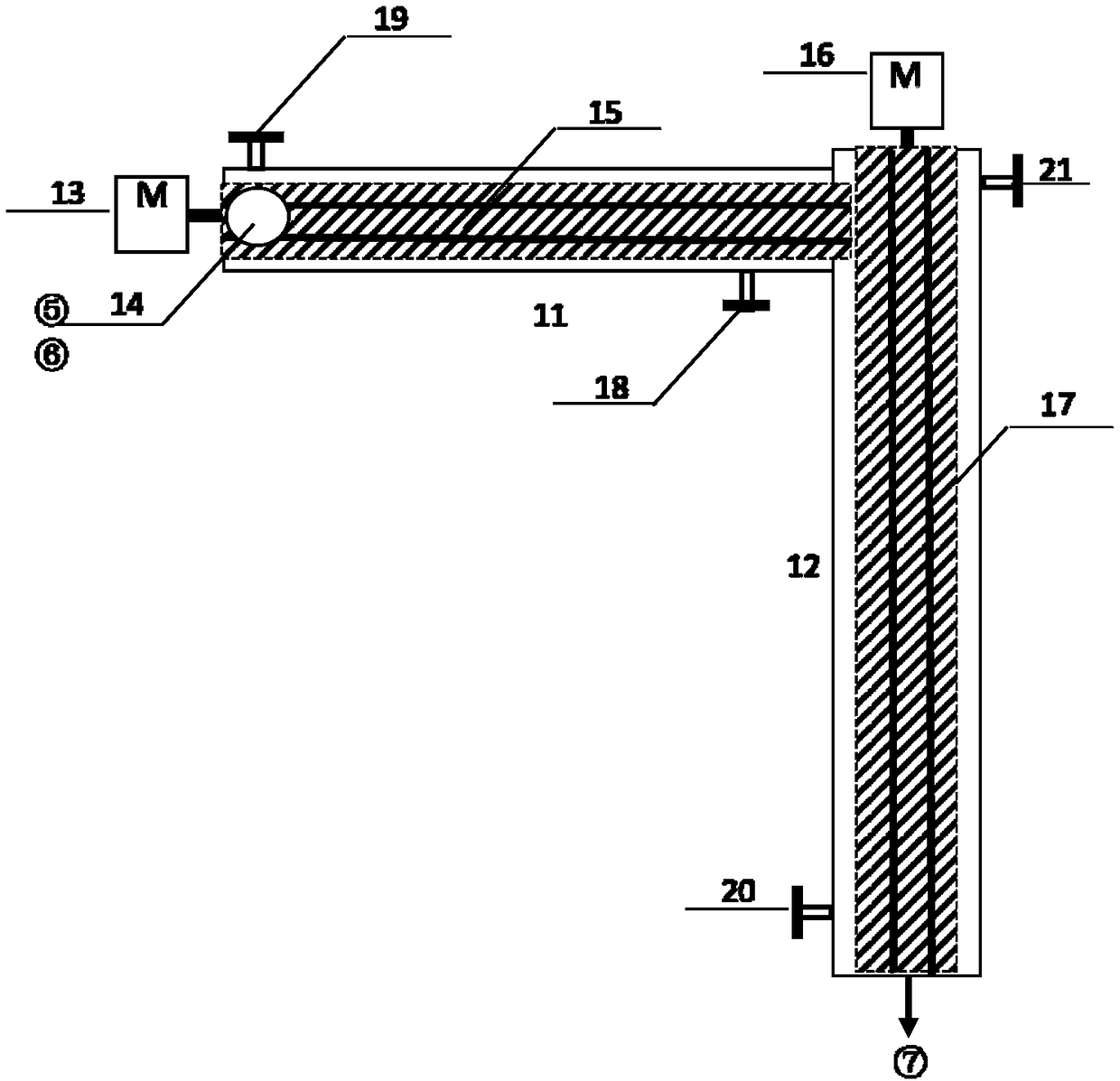

Embodiment 1

[0036] The NMP solution in which calcium chloride was dissolved was cooled to 15°C. Calcium chloride concentration is 8% (mass ratio). NMP / CaCl with a metering pump 2 The solution is continuously metered and transported to the twin-screw dissolver, keeping the flow at 800.00kg / h, of which the flow into the twin-screw dissolver is kept at 300.00kg / h; under the protection of nitrogen, the PPD solid particles are continuously metered and transported to the twin-screw with a weight loss scale In the dissolver, the feed rate of PPD is 50.00kg / h. The twin-screw continuous dissolver is a Ф73 co-rotating twin-screw extruder with an aspect ratio of 20. The screw installation is inclined at 5°. The p-phenylenediamine was continuously dissolved and gradually cooled to 13°C in a twin-screw continuous dissolver. Use a high-speed stirrer to mix the remaining 500.00kg / h of NMP / CaCl 2 Solution and PPD / NMP / CaCl at screw outlet 2 The solutions are mixed and then passed into storage tanks ...

Embodiment 2

[0038] The NMP solution in which calcium chloride was dissolved was cooled to 10 °C. Calcium chloride concentration is 12% (mass ratio). NMP / CaCl with a metering pump 2 The solution is continuously metered and delivered to the twin-screw dissolver, keeping the flow at 1600.00kg / h, of which the flow into the twin-screw dissolver is kept at 800.00kg / h; under the protection of nitrogen, the PPD solid particles are continuously metered and delivered to the twin-screw with a weight loss scale In the dissolver, the feed rate of PPD is 120.00kg / h. The twin-screw continuous dissolver is a Ф100 type co-rotating twin-screw extruder with an aspect ratio of 10. The screw is installed with an inclination of 3°. The p-phenylenediamine was continuously dissolved in a twin-screw continuous dissolver and its temperature was stabilized at 10 °C. Use a static pipeline mixer to mix the remaining 800.00kg / h of NMP / CaCl 2 Solution and PPD / NMP / CaCl at screw outlet 2 The solutions are mixed and...

Embodiment 3

[0040] The NMP solution in which calcium chloride was dissolved was cooled to 15°C. Calcium chloride concentration is 10% (mass ratio). NMP / CaCl with a metering pump 2 The solution is continuously metered and transported to the twin-screw dissolver, and the flow rate is kept at 1200.00kg / h, of which the flow rate entering the twin-screw dissolver is kept at 500.00kg / h; under the protection of nitrogen, the PPD solid particles are continuously metered and transported to the twin-screw with a weight loss scale In the dissolver, the feed rate of PPD is 80.00kg / h. The twin-screw continuous dissolver is a Ф100 type co-rotating twin-screw extruder with an aspect ratio of 10. The screw installation is inclined at 2°. The p-phenylenediamine was continuously dissolved in a twin-screw continuous dissolver and the temperature was maintained at 15°C. Using a high-speed stirrer to mix the remaining 700.00kg / h of NMP / CaCl 2 Solution and PPD / NMP / CaCl at screw outlet 2The solutions are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com