Preparation method of all-solid-state composite polymer electrolyte membrane

A technology of composite polymer and electrolyte membrane, applied in the direction of circuits, electrical components, battery components, etc., can solve the problem of low conductivity, achieve high conductivity, high production efficiency, and improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

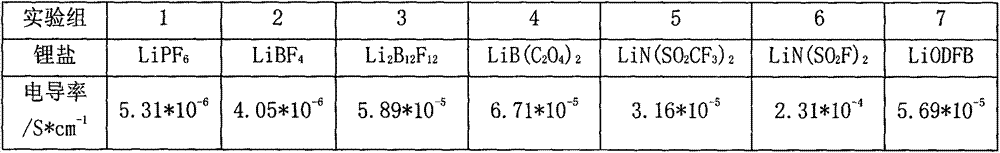

[0019] Embodiment 1: Measure the conductivity at room temperature of electrolyte membranes made of different lithium salts

[0020] Experimental group 1: Mix 2.5g PEO and 2.5g PPC powder, add the PEO / PPC mixture into 50ml acetone solution, stir for 12 hours to obtain a uniform PEO / PPC-acetone solution. 0.5g LiPF 6 1.0 g of calcium fluoride was added to 50 ml of acetone solution, and stirred for 12 hours to obtain a lithium salt-calcium fluoride-acetone solution. Mix the above PEO / PPC-acetone solution with the lithium salt-calcium fluoride-acetone solution and stir for 12 hours, then pour the obtained mixed solution into a polytetrafluoroethylene mold, place it at room temperature, and form a film naturally; vacuum dry at 60°C After 24 hours, the all-solid composite polymer electrolyte membrane was obtained.

[0021] The method for measuring the conductivity of the electrolyte membrane at room temperature is as follows:

[0022] Measured by Chenhua CHI760B electrochemical wo...

Embodiment 2

[0028] Embodiment 2: Take 8.0g PEO, 2.0g PPC powder and mix, add PEO / PPC mixture in 50ml acetone solution, stir 12h to obtain uniform PEO / PPC-acetone solution. 0.5g LiBF 4 , 1.0g of calcium fluoride was added to 50ml of acetone solution, stirred for 12h to obtain LiBF 4 - Calcium fluoride-acetone solution. The above PEO / PPC-acetone solution and LiBF 4 - Calcium fluoride-acetone solution is mixed and stirred for 12 hours, then pour the obtained mixed solution into a polytetrafluoroethylene mold, place it at room temperature, and form a film naturally; vacuum dry at 60°C for 24 hours to obtain an all-solid composite polymer electrolyte membrane .

[0029] Experimental group 3: Mix 5.0g PEO and 5.0g PPC powder, add the PEO / PPC mixture into 50ml acetone solution, stir for 12 hours to obtain a uniform PEO / PPC-acetone solution. 0.5g Li 2 B 12 f 12 1.0 g of calcium fluoride was added to 50 ml of acetone solution, and stirred for 12 hours to obtain a lithium salt-calcium fluori...

Embodiment 8

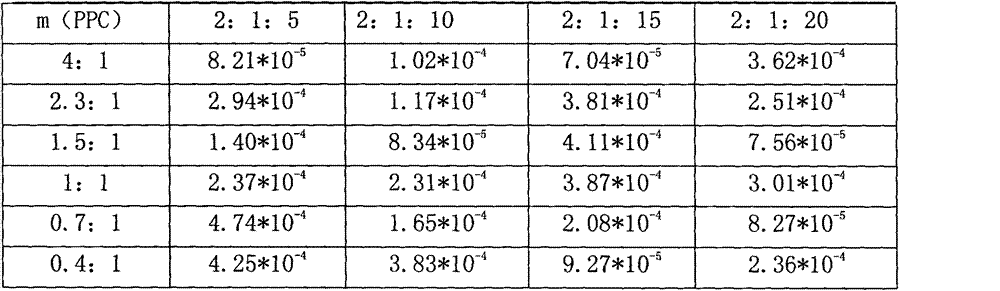

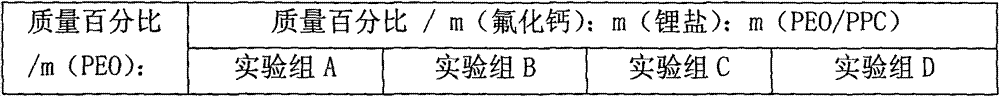

[0034] Example 8: The following experimental groups A-D are all-solid-state composite polymer electrolyte membranes made of lithium salts, calcium fluoride, PEO and PPC with different mass ratios, and the electrical conductivity of the prepared electrolyte membranes is measured respectively, as shown below :

[0035] Experimental group A : Weigh 0.5g of LiN(SO 2 F) 2 6 parts, 6 parts of 1g of calcium fluoride, and then according to the mass ratio of lithium salt, calcium fluoride and PEO / PPC mixture as 1:2:5, weigh 6 groups of PEO / PPC mixtures, that is, the mass ratio of PEO and PPC respectively 4:1 (PEO2.0g, PPC0.5g), 2.3:1 (PEO1.74g, PPC0.76g), 1.5:1 (PEO1.5g, PPC1g), 1:1 (PEO1.25g, PPC1.25g) , 0.7:1 (PEO1.03g, PPC1.47g), 0.4:1 (PEO0.71g, PPC1.79g).

[0036] Add the above-mentioned 6 groups of PEO / PPC mixtures weighed into 50ml of acetone solution respectively, and stir for 12 hours to obtain 6 groups of uniform PEO / PPC-acetone solutions.

[0037] 6 parts weighed LiN(SO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com