Concrete product isolation mold releasing agent and preparation method thereof

A technology for concrete products and mold release agents, which is applied in the petroleum industry, nanotechnology, nanotechnology for materials and surface science, etc. The effect of overcoming environmental pollution problems, repairing micro-pits and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

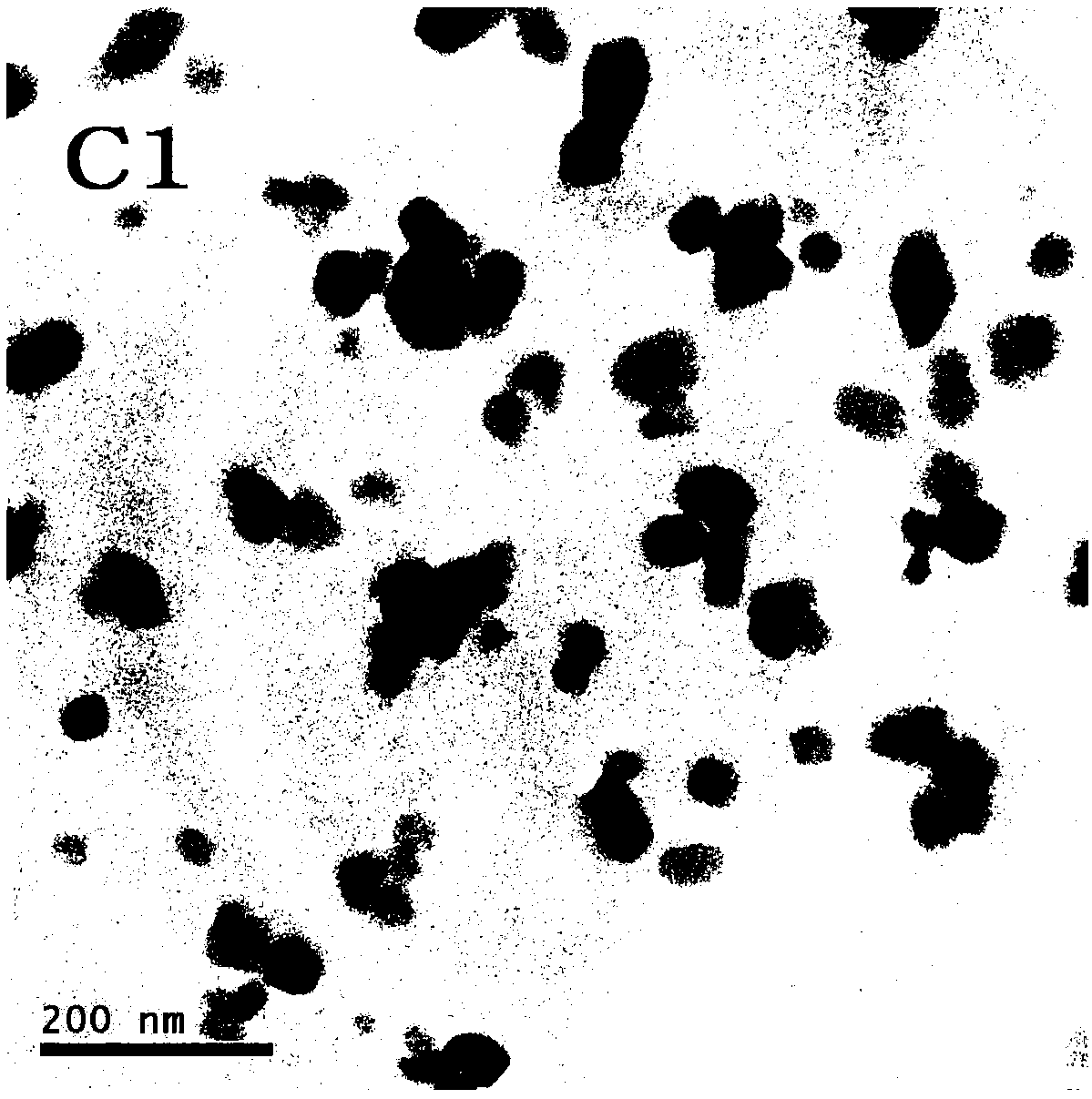

Image

Examples

Embodiment 1

[0023] Weigh 20 parts of silicone oil with an average viscosity of 1000cp, 20 parts of silicone oil with an average viscosity of 500cp, 8 parts of emulsifier Tween-60, 8 parts of Span-60, weigh 16 parts of deionized water, and weigh 2 parts of stearin Acid, 8 parts of ethanol, and 5 parts of anhydrous calcium chloride were prepared with deionized water to make a calcium chloride aqueous solution with a concentration of 0.5M, added to a reaction vessel with a stirring reflux device, and stirred at 45°C to form a transparent solution. According to the molar ratio of calcium ions to carbonate ions of 1:1, slowly add anhydrous sodium carbonate powder into the silicone oil-calcium chloride solution prepared above under stirring, and stir while adding. Foaming agent, heat up the system to 45-55°C, stir and reflux for 36 hours, add deionized water, stop heating, stir slowly, cool down and invert the phase, and obtain a silicone oil nano-calcium carbonate emulsion concrete with a solid...

Embodiment 2

[0025] Weigh 30 parts of silicone oil with an average viscosity of 1000cp, 1.5 parts of Tween-60, 1.5 parts of Span-60, 0.5 part of Tween-20, 0.5 part of Span-20 of emulsifier, and 8 parts of deionized water, weigh Take 0.8 parts of ethanol, 0.2 parts of polyvinyl alcohol, 0.3 parts of anhydrous calcium chloride and deionized water to make a calcium chloride aqueous solution with a concentration of 2.5M, add it into a reactor with a stirring reflux device, and stir at 50°C to form a transparent solution. Stir to form a clear solution. According to the molar ratio of calcium ions to carbonate ions of 1:1, slowly add anhydrous sodium carbonate powder or 0.5M aqueous sodium carbonate solution into the silicone oil-calcium chloride solution prepared above under stirring, and stir while adding, After the addition is complete, add 0.5 parts of defoamer, raise the temperature of the system to 55-65 ° C, stir and reflux for 24.0 hours, add deionized water, stop heating, stir slowly, c...

Embodiment 3

[0027] Weigh 35 parts of silicone oil with an average viscosity of 500cp, 7 parts of Tween 80, 7 parts of Span-80, 0.5 part of Tween-20, 0.5 part of Span-20, 15 parts of deionized water, and weigh 3 parts of ethanol, 2 parts of stearic acid, 0.5 part of sodium stearate, 3 parts of anhydrous calcium chloride are made into the calcium chloride aqueous solution that concentration is 2M with deionized water, add in the reactor with stirring reflux device, 50 °C to form a transparent solution. According to the molar ratio of calcium ions to carbonate ions of 1:1, slowly add anhydrous sodium carbonate powder or 2.5M aqueous sodium carbonate solution into the silicone oil-calcium chloride solution prepared above under stirring, and stir while adding, After the addition is complete, add 0.8 parts of defoamer, raise the temperature of the system to 65-75°C, stir and reflux for 20.0 hours, add deionized water, stop heating, stir slowly, cool down and invert the phase, and obtain a solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com