Preparation method of drilling-fluid-use high-temperature-resistant saturated-salt-resistant filtrate loss reducer

A filtrate reducer and anti-high temperature technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of increasing resistance to high temperature shear damage, improving difficulty, and stabilizing the performance of resistance to salt and calcium intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

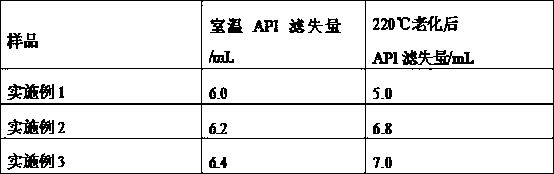

Examples

Embodiment 1

[0015] Embodiment 1: A high-temperature protective glue anti-slump fluid loss agent for drilling fluid, the preparation method of which is:

[0016] 1) Add 35 grams of water to the reaction kettle, add 30 grams of acrylamide, 10 grams of 2-acrylamido-2-methylpropanesulfonic acid, and 3 grams of polyvinylpyrrolidone into the reaction kettle and stir to dissolve to the total mass percentage concentration For a 55% mixed aqueous solution, raise the temperature to 40°C;

[0017] 2) Add 4 grams of dimethyl diallyl ammonium chloride and stir to dissolve;

[0018] 3) Add an aqueous solution of potassium hydroxide with a mass percentage concentration of 20%, and adjust the pH value to be between 8;

[0019] 4) Nitrogen protection for 20 minutes;

[0020] 5) Add 1 gram of an initiator with a mass percent concentration of 10%——azobisisobutyronitrile initiator;

[0021] 6) Heat the above solution to 40°C to initiate detonation, keep the temperature for 20 minutes, and obtain a whi...

Embodiment 2

[0023] Embodiment 2: A high-temperature protective glue anti-slump fluid loss agent for drilling fluid, the preparation method of which is:

[0024] 1) Add 40 grams of water to the reaction kettle, add 35 grams of acrylamide, 13 grams of 2-acrylamido-2-methylpropanesulfonic acid, and 4 grams of polyvinylpyrrolidone into the reaction kettle, stir and dissolve to the total mass percentage concentration For a 56% mixed aqueous solution, raise the temperature to 35°C;

[0025] 2) Add 5 grams of dimethyl diallyl ammonium chloride and fully stir to dissolve;

[0026] 3) Add potassium hydroxide aqueous solution with a mass percentage concentration of 20%, and adjust the pH value to 7.5;

[0027] 4) Nitrogen protection for 25 minutes;

[0028] 5) Add 1.5 grams of an initiator with a mass percent concentration of 10%——azobisisobutyronitrile initiator;

[0029] 6) Heat the above solution to 45°C to initiate detonation, keep the temperature for 15 minutes, and obtain a white elastic s...

Embodiment 3

[0031] Embodiment 3: A high-temperature protective glue anti-slump fluid loss agent for drilling fluid, the preparation method of which is:

[0032] 1) Add 45 grams of water to the reaction kettle, add 40 grams of acrylamide, 15 grams of 2-acrylamido-2-methylpropanesulfonic acid, and 5 grams of polyvinylpyrrolidone into the reaction kettle and stir to dissolve to the total mass percentage concentration For a 57% mixed aqueous solution, raise the temperature to 40°C;

[0033] 2) Add 6 grams of dimethyl diallyl ammonium chloride and fully stir to dissolve;

[0034] 3) Add an aqueous solution of potassium hydroxide with a mass percentage concentration of 20%, and adjust the pH value to between 7;

[0035] 4) Nitrogen protection for 30 minutes;

[0036] 5) Add 2 grams of an initiator with a mass percent concentration of 10%——azobisisobutyronitrile initiator;

[0037] 6) Heat the above solution to 40°C to initiate detonation, keep the temperature for 10 minutes, and obtain a whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com